ignition MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 880 of 909

CONTROL SYSTEM

U–17

U

1B +5 V•Air mix actuator

•Airflow mode

actuator

•Solar radiation

sensorIgnition switch at ON

position

5.0•Inspect for short circuit

(Climate control unit— air

mix actuator, airflow mode

actuator, solar radiation

sensor: 1B—B, B, A)

•Inspect air mix actuator

•Inspect airflow mode

actuator

•Inspect solar radiation

sensor

•Inspect terminal voltage of

climate control unit

connector (2H, 2L)

Ignition switch at LOCK

positionBelow 1.0•Replace climate control unit

1C Blower motor

control signalPower MOS FET Fan switch is OFF Below 1.0•Inspect terminal voltage of

climate control unit (1A)

Fan switch is at manual

LO4.1

Fan switch is at manual

HI7.9

1D—— —— —

1E Rear window

defroster SW

signalRear window

defroster relayRear window defroster

switch is off

12•Inspect for continuity or

short circuit (Climate control

unit—rear window defroster

relay: 1E—E)

•Inspect rear window

defroster relay

Rear window defroster

switch is on Below 1.0•Inspect terminal voltage of

climate control unit (2H, 2L)

•Inspect center panel

1F On-board

diagnostic signalA/C check

connectorTerminal A of A/C check

connector is shorted. Below 1.0•Inspect for continuity

(Climate control unit—A/C

check connector: 1F—A)

Other

5.4•Inspect short circuit (Climate

control unit—A/C check

connector: 1F—A)

•Inspect terminal voltage of

climate control unit (2H, 2L)

1G—— —— —

1H—— —— —

1I GND•Cabin

temperature

sensor

•Evaporator

temperature

sensor

•Ambient

temperature

sensor

•Water

temperature

sensor

•Air mix actuator

•Airflow mode

actuatorUnder any condition

Below 1.0•Inspect terminal voltage of

climate control unit (2L)

1J Water heater

selectGround Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 1J—GND)

•Inspect center panel Terminal Signal Connected to Test condition Voltage (V) Action

Page 883 of 909

U–20

CONTROL SYSTEM

2B TNS signal TNS relay Headlight switch OFF

Below 1.0•Inspect for short circuit

(Climate control unit—TNS

relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

Headlight switch ON

12•Inspect for continuity or

short circuit (Climate control

unit—TNS relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

2C Motor drive signal Air mix actuator Moving to COLD 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2D—

D, 2C—F)

•Inspect air mix actuator Moving to HOT

Below 1.0

2D Motor drive signal Air mix actuator Moving to HOT 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2C—

F, 2D—D)

•Inspect air mix actuator Moving to COLD

Below 1.0

2E Motor drive signal Airflow mode

actuatorMoving to DEFROSTER 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2E—F, 2G—D)

•Inspect airflow mode

actuator Moving to VENT

Below 1.0

2F Backup power

supply ROOM 15 A fuse Under any condition

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2F— ROOM 15

A fuse)

•Inspect ROOM 15 A fuse

2G Motor drive signal Airflow mode

actuatorMoving to VENT 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2G—D, 2E—F)

•Inspect airflow mode

actuator Moving to DEFROSTER

Below 1.0

2H IG2 A/C 15 A fuse Ignition switch at ON

position

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2H—A/C 15 A

fuse)

•Inspect A/C 15 A fuse

Ignition switch at LOCK

position Below 1.0•Inspect for short circuit

(Climate control unit—fuse:

2H—A/C 15 A fuse)

2I Motor drive signal Air intake actuator Moving to

RECIRCULATE12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2I—F, 2K—D)

•Inspect air intake actuator Moving to FRESH

Below 1.0

2J—— —— —

2K Motor drive signal Air intake actuator Moving to FRESH 12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2K—D, 2I—F)

•Inspect air intake actuator Moving to

RECIRCULATE

Below 1.0

2L GND Ground Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 2L—GND) Terminal Signal Connected to Test condition Voltage (V) Action

Page 886 of 909

ON-BOARD DIAGNOSTIC

U–22–1

U

U–22H EA TER AND A I R C O NDI T ION ER SYST EMS

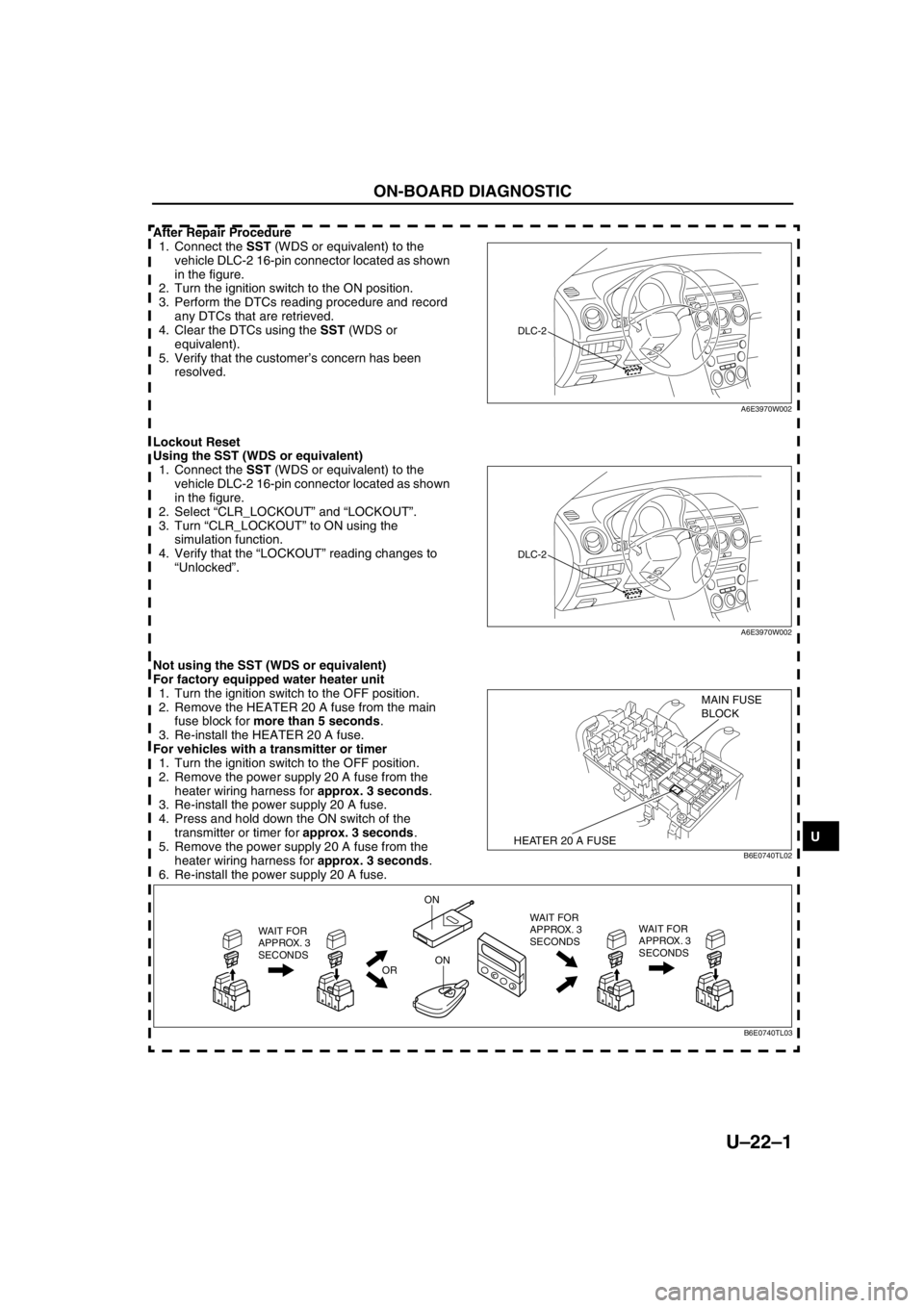

After Repair Procedure

1. Connect the SST (WDS or equivalent) to the

vehicle DLC-2 16-pin connector located as shown

in the figure.

2. Turn the ignition switch to the ON position.

3. Perform the DTCs reading procedure and record

any DTCs that are retrieved.

4. Clear the DTCs using the SST (WDS or

equivalent).

5. Verify that the customer’s concern has been

resolved.

Lockout Reset

Using the SST (WDS or equivalent)

1. Connect the SST (WDS or equivalent) to the

vehicle DLC-2 16-pin connector located as shown

in the figure.

2. Select “CLR_LOCKOUT” and “LOCKOUT”.

3. Turn “CLR_LOCKOUT” to ON using the

simulation function.

4. Verify that the “LOCKOUT” reading changes to

“Unlocked”.

Not using the SST (WDS or equivalent)

For factory equipped water heater unit

1. Turn the ignition switch to the OFF position.

2. Remove the HEATER 20 A fuse from the main

fuse block for more than 5 seconds.

3. Re-install the HEATER 20 A fuse.

For vehicles with a transmitter or timer

1. Turn the ignition switch to the OFF position.

2. Remove the power supply 20 A fuse from the

heater wiring harness for approx. 3 seconds.

3. Re-install the power supply 20 A fuse.

4. Press and hold down the ON switch of the

transmitter or timer for approx. 3 seconds.

5. Remove the power supply 20 A fuse from the

heater wiring harness for approx. 3 seconds.

6. Re-install the power supply 20 A fuse.

ON-BOARD DIAGNOSTIC

DLC-2

A6E3970W002

DLC-2

A6E3970W002

HEATER 20 A FUSE

MAIN FUSE

BLOCK

B6E0740TL02

WAIT FOR

APPROX. 3

SECONDS

OR

ON

ONWAIT FOR

APPROX. 3

SECONDS WAIT FOR

APPROX. 3

SECONDS

B6E0740TL03

Page 887 of 909

U–22–2

ON-BOARD DIAGNOSTIC

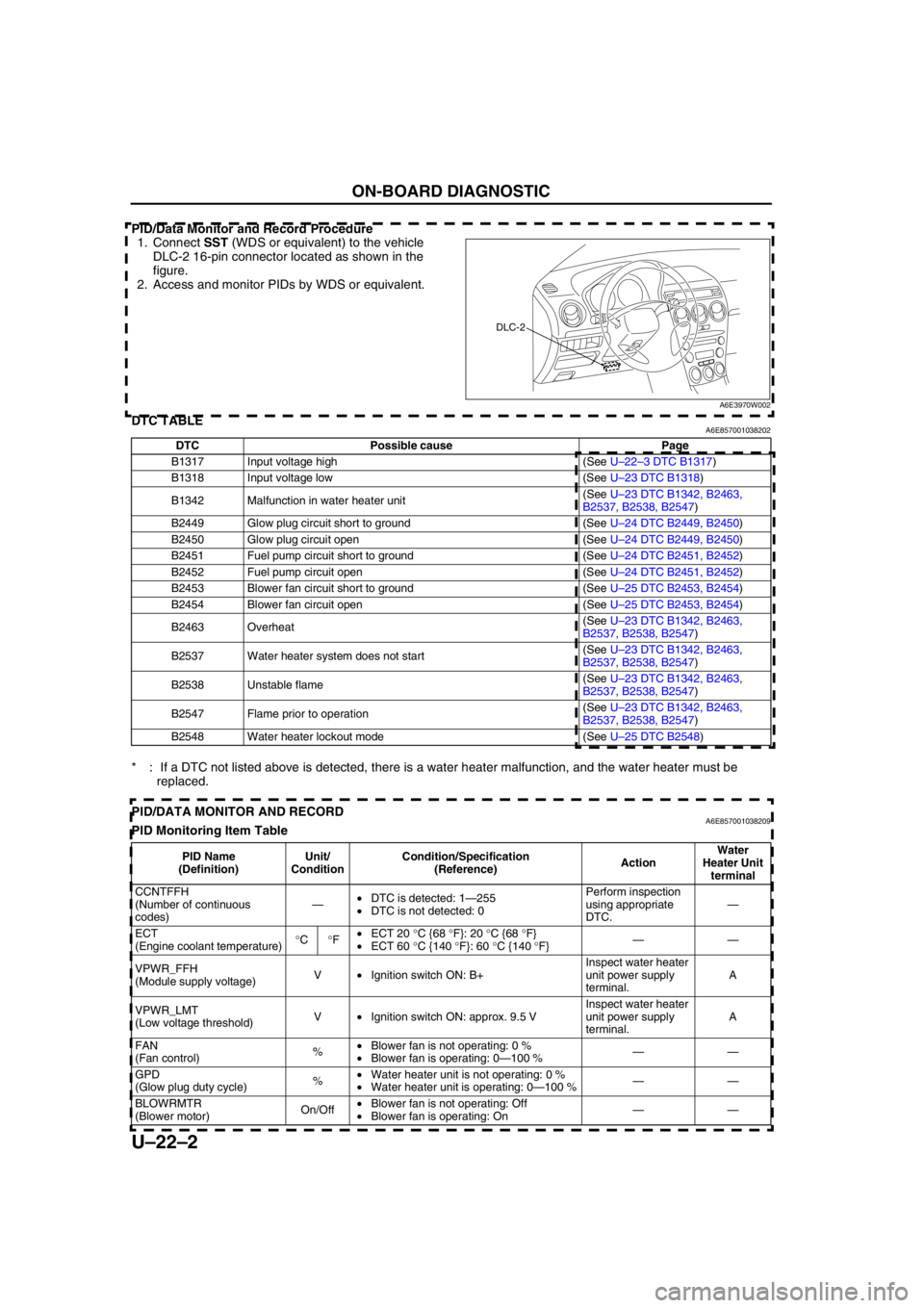

PID/Data Monitor and Record Procedure

1. Connect SST (WDS or equivalent) to the vehicle

DLC-2 16-pin connector located as shown in the

figure.

2. Access and monitor PIDs by WDS or equivalent.

End Of SieDTC TABLEA6E857001038202

* : If a DTC not listed above is detected, there is a water heater malfunction, and the water heater must be

replaced.

End Of SiePID/DATA MONITOR AND RECORDA6E857001038209PID Monitoring Item Table

DLC-2

A6E3970W002

DTC Possible cause Page

B1317 Input voltage high (See U–22–3 DTC B1317)

B1318 Input voltage low (See U–23 DTC B1318)

B1342 Malfunction in water heater unit(See U–23 DTC B1342, B2463,

B2537, B2538, B2547)

B2449 Glow plug circuit short to ground (See U–24 DTC B2449, B2450)

B2450 Glow plug circuit open (See U–24 DTC B2449, B2450)

B2451 Fuel pump circuit short to ground (See U–24 DTC B2451, B2452)

B2452 Fuel pump circuit open (See U–24 DTC B2451, B2452)

B2453 Blower fan circuit short to ground (See U–25 DTC B2453, B2454)

B2454 Blower fan circuit open (See U–25 DTC B2453, B2454)

B2463 Overheat(See U–23 DTC B1342, B2463,

B2537, B2538, B2547)

B2537 Water heater system does not start(See U–23 DTC B1342, B2463,

B2537, B2538, B2547)

B2538 Unstable flame(See U–23 DTC B1342, B2463,

B2537, B2538, B2547)

B2547 Flame prior to operation(See U–23 DTC B1342, B2463,

B2537, B2538, B2547)

B2548 Water heater lockout mode (See U–25 DTC B2548)

PID Name

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionWater

Heater Unit

terminal

CCNTFFH

(Number of continuous

codes)—•DTC is detected: 1—255

•DTC is not detected: 0Perform inspection

using appropriate

DTC.—

ECT

(Engine coolant temperature)°C°F•ECT 20 °C {68 °F}: 20 °C {68 °F}

•ECT 60 °C {140 °F}: 60 °C {140 °F}——

VPWR_FFH

(Module supply voltage)V•Ignition switch ON: B+Inspect water heater

unit power supply

terminal.A

VPWR_LMT

(Low voltage threshold)V•Ignition switch ON: approx. 9.5 VInspect water heater

unit power supply

terminal.A

FAN

(Fan control)%•Blower fan is not operating: 0 %

•Blower fan is operating: 0—100 %——

GPD

(Glow plug duty cycle)%•Water heater unit is not operating: 0 %

•Water heater unit is operating: 0—100 %——

BLOWRMTR

(Blower motor)On/Off•Blower fan is not operating: Off

•Blower fan is operating: On——

Page 889 of 909

ON-BOARD DIAGNOSTIC

U–23

U

UHEATER AND AIR CONDITIONER SYSTEMSDTC B1318A6E857001038204

Diagnostic procedure

End Of Sie

DTC B1342, B2463, B2537, B2538, B2547A6E857001038205

Diagnostic procedure

End Of Sie

ON-BOARD DIAGNOSTIC

DTC B1318 Input voltage low

DETECTION

CONDITION•Voltage detected at water heater unit terminals A is less than 9 V.

POSSIBLE

CAUSE•Generator malfunction

•Battery malfunction

STEP INSPECTION ACTION

1INSPECT BATTERY VOLTAGE

•Measure the battery voltage.

•Is the voltage more than 9 V?Yes Go to the next step.

No The battery is weak.

•Inspect the charging system.

2INSPECT WIRING HARNESS BETWEEN W.HEAT

40 A FUSE AND WATER HEATER UNIT

•Turn the ignition switch to the ON position.

•Measure the voltage at water heater unit

connector terminal A.

•Is the voltage more than 9 V?Yes Go to the next step.

No Repair the wiring harness.

3INSPECT WATER HEATER UNIT

•Clear the DTC.

•Perform the KOEO Self Test. (See U–22 KOEO

Self Test/Combustion Test.)

•Is the same DTC present?Yes Replace the water heater unit.

(See U–15 WATER HEATER UNIT REMOVAL/

INSTALLATION)

No Go to the next step.

4VERIFY AFTER REPAIR PROCEDURE

•Perform the after repair procedure. (See U–22–1

After Repair Procedure.)

•Are any DTCs present?Yes Go to the applicable DTC troubleshooting.

No Troubleshooting completed.

A C E

B

D F WATER HEATER UNIT CONNECTOR

DTCB1342 Malfunction in water heater unit

B2463 Overheat

B2537 Water heater system does not start

B2538 Unstable flame

B2547 Flame prior to operation

DETECTION

CONDITION•CPU detects malfunction in water heater unit

POSSIBLE

CAUSE•Water heater unit malfunction

—CPU malfunction

—Glow plug malfunction

—Flame detection sensor malfunction

STEP INSPECTION ACTION

1INSPECT WATER HEATER UNIT

•Replace the water heater unit. (See U–15

WATER HEATER UNIT REMOVAL/

INSTALLATION)

•Perform the Combustion Test. (See U–22 KOEO

Self Test/Combustion Test.)

•Are any DTCs present?Yes Go to the applicable DTC troubleshooting.

No Troubleshooting completed.

Page 896 of 909

TD–4

TECHNICAL DATA

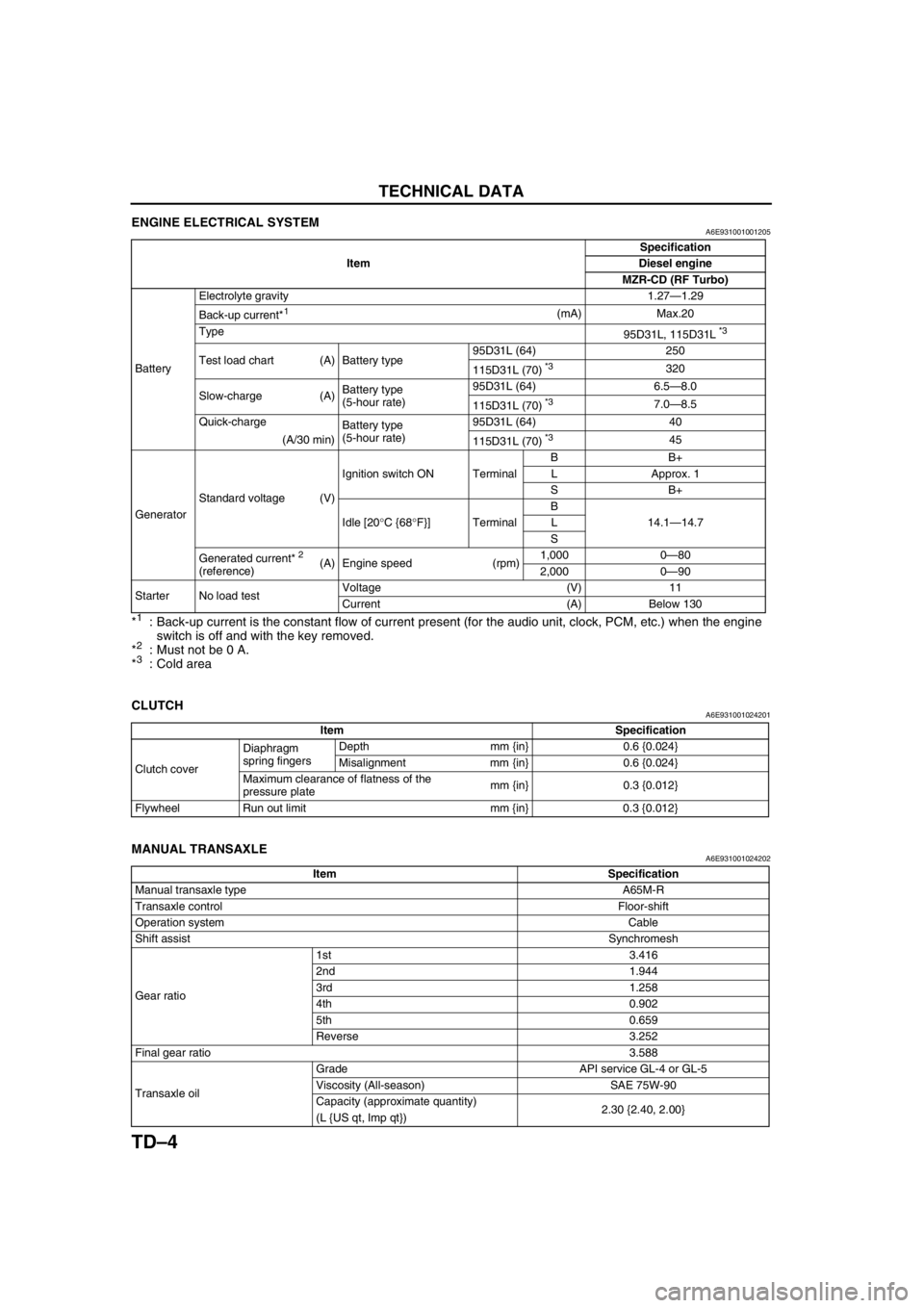

ENGINE ELECTRICAL SYSTEMA6E931001001205

*1: Back-up current is the constant flow of current present (for the audio unit, clock, PCM, etc.) when the engine

switch is off and with the key removed.

*

2: Must not be 0 A.

*3: Cold area

End Of Sie

CLUTCHA6E931001024201

End Of Sie

MANUAL TRANSAXLEA6E931001024202

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

BatteryElectrolyte gravity 1.27—1.29

Back-up current*

1(mA) Max.20

Type

95D31L, 115D31L

*3

Test load chart (A) Battery type95D31L (64) 250

115D31L (70) *3320

Slow-charge (A)Battery type

(5-hour rate)95D31L (64) 6.5—8.0

115D31L (70)

*37.0—8.5

Quick-charge

Battery type

(5-hour rate)95D31L (64) 40

(A/30 min)

115D31L (70)

*345

GeneratorStandard voltage (V)Ignition switch ON TerminalBB+

L Approx. 1

SB+

Idle [20°C {68°F}] TerminalB

14.1—14.7 L

S

Generated current*

2

(reference) (A) Engine speed (rpm)1,000 0—80

2,000 0—90

Starter No load testVoltage (V) 11

Current (A) Below 130

Item Specification

Clutch coverDiaphragm

spring fingersDepth mm {in} 0.6 {0.024}

Misalignment mm {in} 0.6 {0.024}

Maximum clearance of flatness of the

pressure platemm {in} 0.3 {0.012}

Flywheel Run out limit mm {in} 0.3 {0.012}

Item Specification

Manual transaxle typeA65M-R

Transaxle controlFloor-shift

Operation systemCable

Shift assistSynchromesh

Gear ratio1st 3.416

2nd 1.944

3rd 1.258

4th 0.902

5th 0.659

Reverse 3.252

Final gear ratio3.588

Transaxle oilGrade API service GL-4 or GL-5

Viscosity (All-season) SAE 75W-90

Capacity (approximate quantity)

2.30 {2.40, 2.00}

(L {US qt, Imp qt})