4WD MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 860 of 909

![MAZDA 6 2002 Workshop Manual Suplement T–48

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

14•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 16.

15INSPECT WIRING HARNESS BETWEEN PCM

AND DSC HU/CM

•Disconnect MAZDA 6 2002 Workshop Manual Suplement T–48

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

14•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 16.

15INSPECT WIRING HARNESS BETWEEN PCM

AND DSC HU/CM

•Disconnect](/img/28/57057/w960_57057-859.png)

T–48

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

14•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 16.

15INSPECT WIRING HARNESS BETWEEN PCM

AND DSC HU/CM

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

PCM and DSC HU/CM terminals for short to

ground, short power supply, and open circuit:

Except MZR-CD (RF Turbo)

—2R—AF (CAN_L)

—2U—AG (CAN_H)

MZR-CD (RF Turbo)

—39—AF (CAN_L)

—13—AG (CAN_H)

•Is wiring harness okay?Yes Replace PCM, then go to Step 17.

No Replace wiring harness.

16INSPECT WIRING HARNESS BETWEEN PCM

AND ABS (ABS/TCS) HU/CM

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

PCM and ABS (ABS/TCS) HU/CM terminals

for short to ground, short power supply, and

open circuit:

Except MZR-CD (RF Turbo)

—2R—R (CAN_L)

—2U—O (CAN_H)

MZR-CD (RF Turbo)

—39—R (CAN_L)

—13—O (CAN_H)

•Is wiring harness okay?Yes Replace PCM, then go to Step 28.

No Replace wiring harness.

17CHECK DTC INDICATE

•Connect PCM connector.

•Connect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Connect instrument cluster connector.

•Clear DTC from module memory using SST

(WDS or equivalent).

•Perform KOEO/KOER self-test.

•Are DTCs U0073, U1900 and/or U2516

indicated?Yes Repeat from Step 2.

No Troubleshooting completed.

18DETERMINING THE LOCATION OF A

MALFUNCTION

•Determine the malfunctioning part of the

CAN system.

(See T–42 PROCEDURES FOR

DETERMINING THE LOCATION OF A

MALFUNCTION)

•Is the malfunctioning part the wiring harness

G or the instrument cluster?Yes Go to Step 25.

No Go to next step.

19DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

F or the 4WD control module?Yes Go to Step 27.

No Go to next step.

20DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

E?Yes Go to Step 29.

No Go to next step.

21DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

D or the ABS (ABS/TCS) HU/CM? (with ABS

(ABS/TCS))

•Is the malfunctioning part the wiring harness

D or the DSC HU/CM? (with DSC)Yes Go to Step 32.

No Go to next step. STEP INSPECTION ACTION

Page 861 of 909

![MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

2 MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

2](/img/28/57057/w960_57057-860.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

23DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

B or the TCM?Yes Go to Step 39.

No Go to next step.

24DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

A or the PCM?Yes Go to Step 43.

No Go to next step.

25INSPECT INSTRUMENT CLUSTER

CONNECTOR

•Disconnect negative battery cable.

•Disconnect instrument cluster connector.

•Are poor connection detection bars of

instrument cluster connector okay?Yes Go to next step.

No Replace wiring harness.

26INSPECT WIRING HARNESS BETWEEN

INSTRUMENT CLUSTER AND 4WD

CONTROL MODULE

•Disconnect 4WD control module connector.

•Inspect the following wiring harness between

4WD control module and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—H—2W (CAN_L)

—G—2X (CAN_H)

•Is wiring harness okay?Yes Replace instrument cluster, then go to Step 45.

No Replace wiring harness.

27INSPECT 4WD CONTROL MODULE

CONNECTOR

•Disconnect negative battery cable.

•Disconnect 4WD control module connector.

•Is the connector for the 4WD control module

connected correctly?Yes Go to next step.

No Replace wiring harness.

28INSPECT WIRING HARNESS BETWEEN 4WD

CONTROL MODULE AND INSTRUMENT

CLUSTER

•Disconnect instrument cluster connector.

•Inspect the following wiring harness between

4WD control module and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—H—2W (CAN_L)

—G—2X (CAN_H)

•Is wiring harness okay?Yes Replace 4WD control module, then go to Step 45.

No Replace wiring harness.

29•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 31.

30INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND 4WD CONTROL MODULE

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and 4WD control module

terminals for short to ground, short power

supply, and open circuit:

—AF—H (CAN_L)

—AG—G (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness. STEP INSPECTION ACTION

Page 862 of 909

![MAZDA 6 2002 Workshop Manual Suplement T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the MAZDA 6 2002 Workshop Manual Suplement T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the](/img/28/57057/w960_57057-861.png)

T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and 4WD control

module terminals for short to ground, short

power supply, and open circuit:

—R—H (CAN_L)

—O—G (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness.

32INSPECT ABS (ABS/TCS) HU/CM OR DSC

HU/CM CONNECTOR

•Disconnect negative battery cable.

•Disconnect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Is the connector for the ABS (ABS/TCS) HU/

CM or DSC HU/CM connected correctly?Yes Go to next step.

No Replace wiring harness.

33•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 35.

34INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND 4WD CONTROL MODULE

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and 4WD control module

terminals for short to ground, short power

supply, and open circuit:

—AF—H (CAN_L)

—AG—G (CAN_H)

•Is wiring harness okay?Yes Replace DSC HU/CM, then go to Step 45.

No Replace wiring harness.

35INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and 4WD control

module terminals for short to ground, short

power supply, and open circuit:

—R—H (CAN_L)

—O—G (CAN_H)

•Is wiring harness okay?Yes Replace ABS (ABS/TCS) HU/CM, then go to Step 45.

No Replace wiring harness.

36•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 38.

37INSPECT WIRING HARNESS BETWEEN TCM

AND DSC HU/CM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and DSC HU/CM terminals for short to

ground, short power supply, and open circuit:

—2J—AF (CAN_L)

—2M—AG (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness.

38INSPECT WIRING HARNESS BETWEEN TCM

AND ABS (ABS/TCS) HU/CM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and ABS (ABS/TCS) HU/CM terminals

for short to ground, short power supply, and

open circuit:

—2J—R (CAN_L)

—2M—O (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness. STEP INSPECTION ACTION

Page 863 of 909

![MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM con MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM con](/img/28/57057/w960_57057-862.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM connected

correctly?Yes Go to next step.

No Replace wiring harness.

40•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 42.

41INSPECT WIRING HARNESS BETWEEN TCM

AND DSC HU/CM

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

TCM and DSC HU/CM terminals for short to

ground, short power supply, and open circuit:

—2J—AF (CAN_L)

—2M—AG (CAN_H)

•Is wiring harness okay?Yes Replace TCM, then go to Step 45.

No Replace wiring harness.

42INSPECT WIRING HARNESS BETWEEN TCM

AND ABS (ABS/TCS) HU/CM

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

TCM and ABS (ABS/TCS) HU/CM terminals

for short to ground, short power supply, and

open circuit:

—2J—R (CAN_L)

—2M—O (CAN_H)

•Is wiring harness okay?Yes Replace TCM, then go to Step 45.

No Replace wiring harness.

43INSPECT PCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect PCM connector.

•Is the connector for the PCM connected

correctly?Yes Go to next step.

No Replace wiring harness.

44INSPECT WIRING HARNESS BETWEEN TCM

AND PCM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and PCM terminals for short to ground,

short power supply, and open circuit:

—2J—2R (CAN_L)

—2M—2U (CAN_H)

•Is wiring harness okay?Yes Replace PCM, then go to next step.

No Replace wiring harness.

45CHECK DTC INDICATE

•Connect PCM connector.

•Connect TCM connector.

•Connect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Connect 4WD control module connector.

•Connect instrument cluster connector.

•Clear DTC from module memory using SST

(WDS or equivalent).

•Perform KOEO/KOER self-test.

•Are DTC’s U0073, U1900 and/or U2516

indicated?Yes Repeat from Step 18.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 881 of 909

U–18

CONTROL SYSTEM

1K Ambient

temperature

sensor inputAmbient

temperature sensorDepends on temperature

surrounding sensor

See Figure

2•Inspect for continuity

(Climate control unit—

ambient temperature

sensor: 1K—B, 1I—A)

•Inspect for short circuit

(Climate control unit—

ambient temperature

sensor: 1K—B)

•Inspect ambient

temperature sensor

•Inspect terminal voltage of

climate control unit (2H, 2L)

1L MZR-CD (RF

Turbo) selectGround Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 1L—GND)

•Inspect center panel

1M Cabin

temperature

sensor inputCabin temperature

sensorDepends on temperature

surrounding sensor

See Figure

3•Inspect for continuity

(Climate control unit— cabin

temperature sensor: 1M—B,

1I—A)

•Inspect for short circuit

(Climate control unit— cabin

temperature sensor: 1M—B)

•Inspect cabin temperature

sensor

•Inspect terminal voltage of

climate control unit (2H, 2L)

1N—— —— —

1O Water

temperature

sensor inputWater temperature

sensorDepends on temperature

surrounding sensor

See Figure

4•Inspect for continuity

(Climate control unit—water

temperature sensor: 1O—A,

1I—B)

•Inspect for short circuit

(Climate control unit—water

temperature sensor: 1O—A)

•Inspect water temperature

sensor

•Inspect terminal voltage of

climate control unit (2H, 2L)

1P A/C Refrigerant

pressure switchFan switch at OFF

12•Inspect for continuity or

short circuit (Climate control

unit—refrigerant pressure

switch: 1P—A) (Refrigerant

pressure switch—PCM: B—

1AC (except MZR-CD (RF

Turbo)), 84 (MZR-CD (RF

Turbo)))

•Inspect refrigerant pressure

switch

•Inspect PCM terminal

voltage (1AC (except MZR-

CD (RF Turbo)), 84 (MZR-

CD (RF Turbo)))

(See F1–33 PCM

INSPECTION (4WD) )

(See F2–65 PCM

INSPECTION )

Fan switch at 1st

position, A/C switch ONBelow 1.0•Inspect terminal voltage of

climate control unit (2H, 2L) Terminal Signal Connected to Test condition Voltage (V) Action

Page 895 of 909

TECHNICAL DATA

TD–3

TD

Recommended engine oil

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

End Of Sie

COOLING SYSTEMA6E931001001203

End Of Sie

FUEL AND EMISSION CONTROL SYSTEMA6E931001001204

*1: Excludes temporary idle speed drop just after the electrical loads are turned on.

End Of Sie

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3

B3B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Coolant capacity (L {US qt, Imp qt}) 9.0 {9.5, 7.9}

Radiator capCap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

ThermostatType Wax, bottom-bypass

Initial-opening temperature (°C {°F})80—84

{176—183}

Full-opening temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

Cooling fan Motor Current (A)4.4—7.4 (Cooling fan motor No.1)

6.3—9.3 (Cooling fan motor No.2)

ItemEngine

L3 (4WD)

Idle speed

*1(rpm) 650—750 (700±50)

ItemEngine

MZR-CD (RF Turbo)

Idle speed (rpm) 725—825 (775±50)

Idle-up speed (rpm) When A/C is operated 725—825 (775±50)

Boost relief pressure (kPa {mmHg, inHg}) Approx. –14.5 {–108, –4.27}

Page 898 of 909

TD–6

TECHNICAL DATA

FRONT AND REAR AXLEA6E931001018201

End Of Sie

STEERING SYSTEMA6E931001034201

End Of Sie

Item Specification

FRONT DRIVE SHAFT

Shaft length

(Air in boot at atmospheric

pressure)(mm {in})Left sideMZR-CD (RF Turbo): 666.1—676.1 {26.23—26.61}

4WD: 667—677 {26.26—26.65}

Right sideMZR-CD (RF Turbo): 615.9—625.9 {24.25—24.64}

4WD: 631—641 {24.85—25.23}

REAR DRIVE SHAFT (4WD)

Shaft length

(Air in boot at atmospheric

pressure)(mm {in})Left side 805.4—815.4 {31.71—32.10}

Right side 852.4—862.4 {33.56—33.95}

REAR DIFFERENTIAL (4WD)

Pinion height (mm {in})–0.025—0.025 {–0.001—0.001}

Backlash of side gear and differential pinion (mm {in}) 0.1 {0.004} or less

Drive pinion preload (N·m kgf·cm, in·lbf) 1.3—1.8 {13.3—18.3, 11.5—15.9}

Backlash of drive pinion and

ring gear(mm {in})Standard 0.09—0.11 {0.0036—0.0043}

Minimum 0.05 {0.002}

Differential oilGrade API service GL-5

ViscosityAbove –18°C {0°F}: SAE 90

Below –18°C {0°F}: SAE 80

Capacity

(Approximate quantity)(L {US qt, lmp qt}) 1.00 {1.06, 0.88}

ELECTRONIC 4WD CONTROL SYSTEM

Differential oil temperature

sensor(kilohm)0°C {32°F} 91—100

10°C {50°F} 56—61

20°C {68°F} 35—39

30°C {86°F} 23—25

40°C {104°F} 14—17

50°C {122°F} 10—11

60°C {140°F} 7.1—7.9

70°C {158°F} 5.0—5.6

80°C {176°F} 3.6—4.0

4WD solenoid

(Rear differential oil temperature

at 20°C {68°F})(ohm) 1.5—2.0

Item Specification

ENGINE SPEED SENSING POWER STEERING

Power

steering oil

pumpOil pump fluid pressure 2WD (Except MZR-CD (RF Turbo)):

10.80—11.29 {110.2—115.1, 1,567—1,637}

MZR-CD (RF Turbo):

11.31—11.80 {115.4—120.3, 1,641—1,711}

4WD: 10.30—10.79 {105.1—110.0, 1,490—1,564} (MPa {kgf·cm

2, psi})

Gear housing fluid pressure 2WD (Except MZR-CD (RF Turbo)):

10.80—11.29 {110.2—115.1, 1,567—1,637}

MZR-CD (RF Turbo):

11.31—11.80 {115.4—120.3, 1,641—1,711}

4WD: 10.30—10.79 {105.1—110.0, 1,490—1,564} (MPa {kgf·cm

2, psi})

Power

steering

systemFluid type

ATF M-

III or equivalent (e.g. Dexron®II)

Capacity (Approximate quantity) MTX (Except MZR-CD (RF Turbo)): 0.80 {0.85, 0.70}

ATX (Except 4WD): 0.87 {0.92, 0.77}

MZR-CD (RF Turbo): 0.86 {0.91, 0.76}

4WD: 0.89 {0.94, 0.78} (L {US qt, Imp qt})

Page 899 of 909

TECHNICAL DATA

TD–7

TD

BRAKING SYSTEMA6E931001020201

End Of Sie

SUSPENSIONA6E931001013201Suspension

WGN (2WD)

*1: Engine coolant and engine oil are at specified level. Spare tire, jack, and tools are in designated position. Adjust to the median when carrying out wheel alignment.

*2: Difference between left and right must not exceed 1 ° 30 ′.*3: Distance between wheel center and fender brim is following. Front: 405 mm {15.94 in} (reference value) Rear:

407 mm {16.02 in} (reference value)

WGN (4WD)

*1: Engine coolant and engine oil are at specified level. Spare tire, jack, and tools are in designated position. Adjust to the median when carrying out wheel alignment.

*2: Difference between left and right must not exceed 1 ° 30 ′.

Item Specification

CONVENTIONAL BRAKE SYSTEM

Front disc

brake Minimum disc pad

thickness

(mm {in})L8, LF (GCC specs.): 22 mm {0.87 in}

LF (European (L.H.D. U.K.) specs.), L3, MZR-CD (RF Turbo):

23 mm {0.91 in}

Minimum disc plate

thickness (mm {in})L8, LF (GCC specs.): 22.8 mm {0.90 in}

LF (European (L.H.D. U.K.) specs.), L3, MZR-CD (RF Turbo): 23.8 mm {0.94 in}

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Fr o nt wh ee l

alignment

(Unloaded)

*1

Maximum steering

angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1 ° 3°37' ±1 ° 3°40' ±1°

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1°

Camber angle

*2

(Reference value) normal –0

°14' ±1 ° –0°15' ±1°

elevated*3–0 °07' ±1 ° –0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Rear wheel

alignment

(Unloaded)

*1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Camber angle

*2 normal –0 °59 ′±1° –1°00 ′±1° –1°02 ′±1° –1°04 ′±1° –1°06 ′±1°

elevated

*3–0 °52 ′±1° –0°53 ′±1° –0°55 ′±1° –0°56 ′±1° –0°58 ′±1°

Thrust angle 0 °±0°48 ′

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Fr o nt wh ee l

alignment

(Unloaded)

*1

Maximum steering

angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2 (Reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1°

Camber angle

*2 (Reference value) –0

°07' ±1 ° –0°08' ±1°

Steering axis inclination

(Reference value) 5

°15' 5 °16'

Rear wheel

alignment

(Unloaded)

*1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Camber angle

*2 –0 °55 ′±1° –0°57 ′±1° –0°59 ′±1° –1°01 ′±1° –1°03 ′±1°

Thrust angle 0 °±0°48 ′

Page 900 of 909

TD–8

TECHNICAL DATA

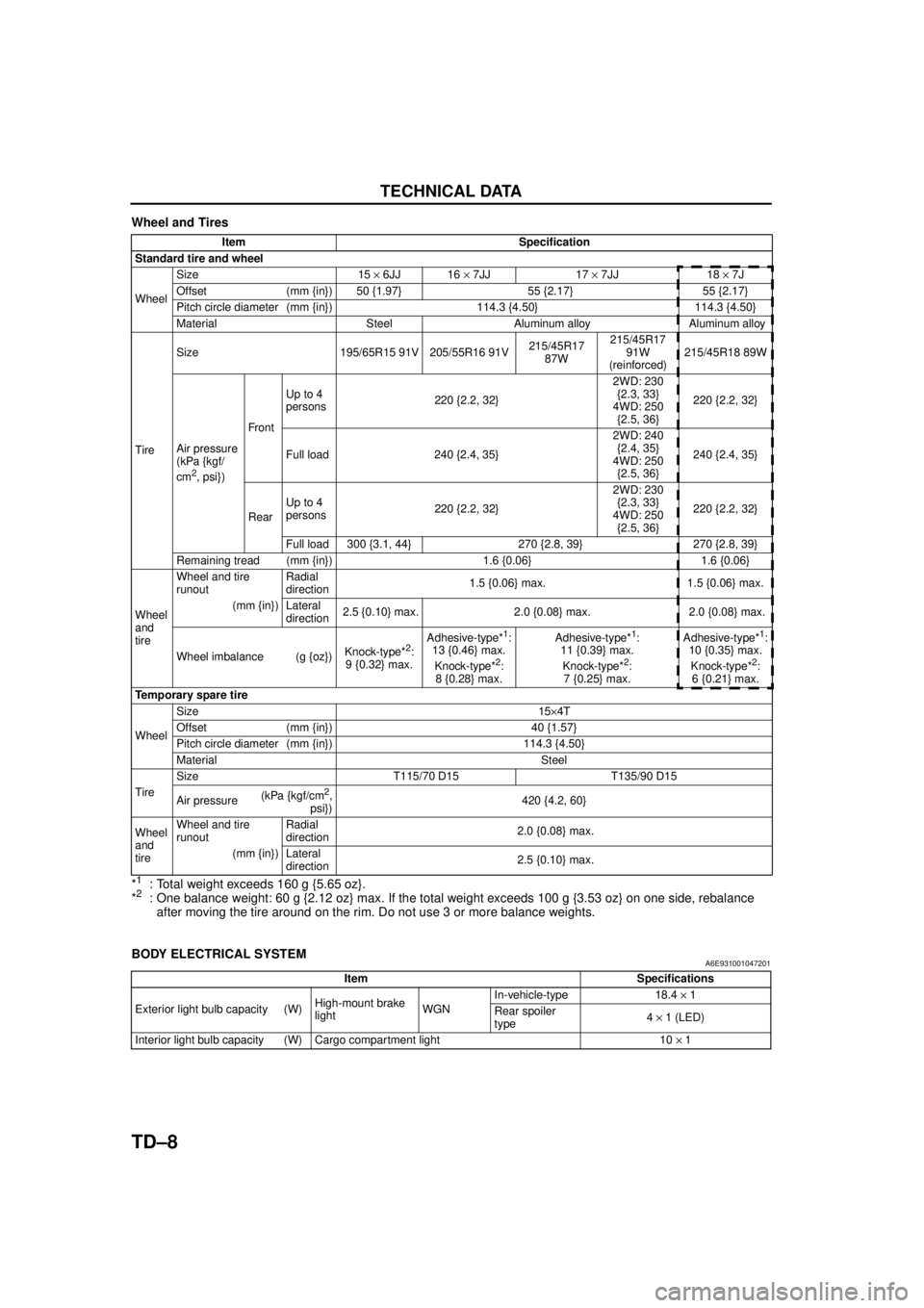

Wheel and Tires

*

1: Total weight exceeds 160 g {5.65 oz}.

*2: One balance weight: 60 g {2.12 oz} max. If the total weight exceeds 100 g {3.53 oz} on one side, rebalance after moving the tire around on the rim. Do not use 3 or more balance weights.

End Of Sie

BODY ELECTRICAL SYSTEMA6E931001047201

End Of Sie

Item Specification

Standard tire and wheel

Wheel Size 15

× 6JJ 16 × 7JJ 17 × 7JJ 18 × 7J

Offset (mm {in}) 50 {1.97} 55 {2.17} 55 {2.17}

Pitch circle diameter (mm {in}) 114.3 {4.50} 114.3 {4.50}

Material Steel Aluminum alloy Aluminum alloy

Tire Size 195/65R15 91V 205/55R16 91V

215/45R17

87W 215/45R17

91W

(reinforced) 215/45R18 89W

Air pressure

(kPa {kgf/

cm

2, psi}) Front

Up to 4

persons

220 {2.2, 32} 2WD: 230

{2.3, 33}

4WD: 250 {2.5, 36} 220 {2.2, 32}

Full load 240 {2.4, 35} 2WD: 240

{2.4, 35}

4WD: 250 {2.5, 36} 240 {2.4, 35}

Rear Up to 4

persons

220 {2.2, 32} 2WD: 230

{2.3, 33}

4WD: 250 {2.5, 36} 220 {2.2, 32}

Full load 300 {3.1, 44} 270 {2.8, 39} 270 {2.8, 39}

Remaining tread (mm {in}) 1.6 {0.06} 1.6 {0.06}

Wheel

and

tire Wheel and tire

runout

Radial

direction

1.5 {0.06} max. 1.5 {0.06} max.

(mm {in}) Lateral direction 2.5 {0.10} max. 2.0 {0.08} max. 2.0 {0.08} max.

Wheel imbalance (g {oz}) Knock-type*

2:

9 {0.32} max. Adhesive-type*

1:

13 {0.46} max.

Knock-type*

2:

8 {0.28} max. Adhesive-type*

1:

11 {0.39} max.

Knock-type*

2:

7 {0.25} max. Adhesive-type*

1:

10 {0.35} max.

Knock-type*

2:

6 {0.21} max.

Temporary spare tire

Wheel Size 15

×4T

Offset (mm {in}) 40 {1.57}

Pitch circle diameter (mm {in}) 114.3 {4.50}

Material Steel

Tire Size T115/70 D15 T135/90 D15

Air pressure

(kPa {kgf/cm

2,

psi}) 420 {4.2, 60}

Wheel

and

tire Wheel and tire

runout

Radial

direction

2.0 {0.08} max.

(mm {in}) Lateral direction 2.5 {0.10} max.

Item Specifications

Exterior light bulb capacity (W) High-mount brake

lightWGNIn-vehicle-type 18.4

× 1

Rear spoiler

type 4

× 1 (LED)

Interior light bulb capacity (W) Cargo compartment light 10 × 1