4WD MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 770 of 909

R–8

WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT (WGN)A6E741201015201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is 405 mm {15.94 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.

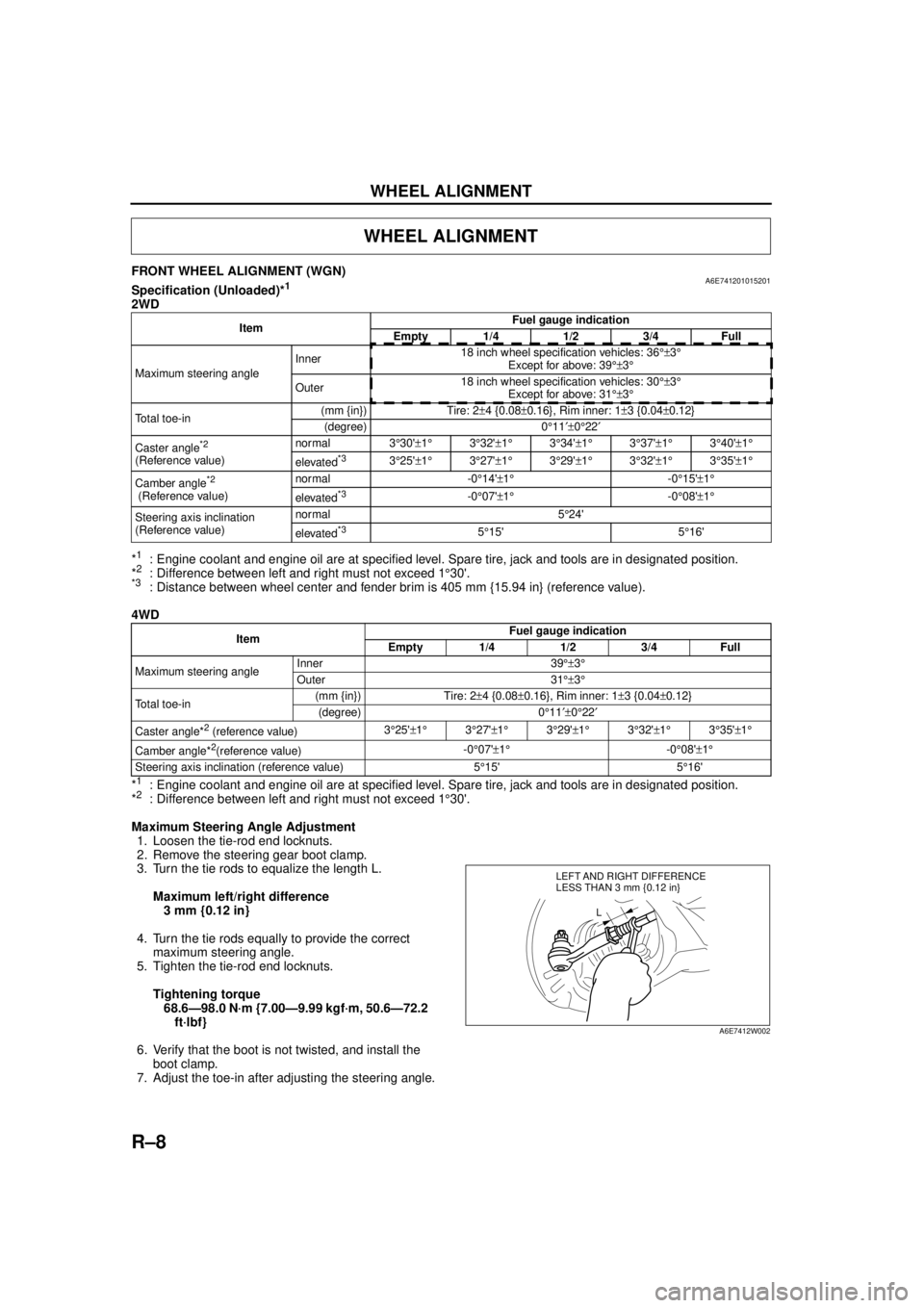

Maximum Steering Angle Adjustment 1. Loosen the tie-rod end locknuts.

2. Remove the steering gear boot clamp.

3. Turn the tie rods to equalize the length L.

Maximum left/right difference3 mm {0.12 in}

4. Turn the tie rods equally to provide the correct maximum steering angle.

5. Tighten the tie-rod end locknuts.

Tightening torque68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

6. Verify that the boot is not twisted, and install the boot clamp.

7. Adjust the toe-in after adjusting the steering angle.

WHEEL ALIGNMENT

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1° 3°37' ±1° 3°40' ±1 °

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1° 3°32' ±1° 3°35' ±1 °

Camber angle

*2

(Reference value) normal -0

°14' ±1 ° -0°15' ±1°

elevated*3-0 °07' ±1 ° -0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle*

2 (reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1 °

Camber angle*

2(reference value) -0

°07' ±1 ° -0°08' ±1°

Steering axis inclination (reference value) 5 °15' 5 °16'

LEFT AND RIGHT DIFFERENCE

L

LESS THAN 3 mm {0.12 in}

A6E7412W002

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

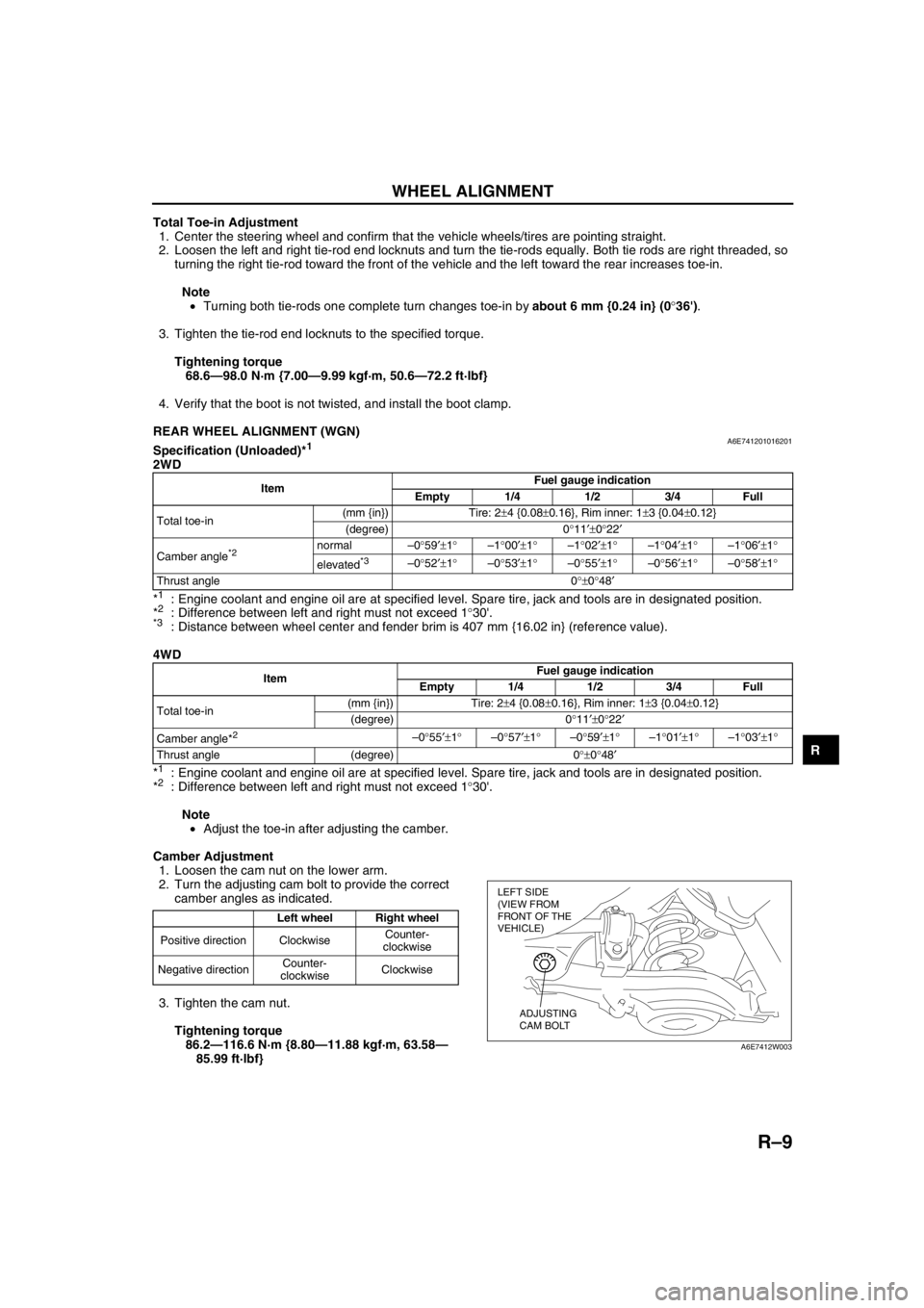

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 775 of 909

REAR SUSPENSION

R–13

R

REAR STABILIZER REMOVAL/INSTALLATION (4WD)A6E7416281002011. Remove the rear auto leveling sensor.

(See T–20 REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATION.)

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

4. Adjust the headlight zeroset.

.

Bolt (Differential Front Side) Removal Note

1. Disconnect differential oil temperature sensor connector and 4WD solenoid connector.

2. Support the differential with a jack as shown in

the figure.

3. Remove the bolt.

5

4

3

1

AA

2

6

GREASEGREASE

43.1—60.8

{4.40—6.19,

31.8—44.8}

74.5—104.9

{7.60—10.69, 54.95—77.37}

43.1—60.8

{4.40—6.19,

31.8—44.8}

RUBBER

GREASE

43.1—60.8

{4.40—6.19,

31.8—44.8}

N·m {kgf·m, ft·lbf} 75.5—94.5

{7.70—9.63, 55.7—69.6}

A6E74162007

1 Stabilizer control link

2 Coil spring component (One side only)

3 Stabilizer bracket

4 Bushing5 Bolt (Differential front side)

(See R–13 Bolt (Differential Front Side) Removal

Note)

(See R–14 Bolt (Differential Front Side) Installation

Note)

6 Rear stabilizer

JACK

A6E74162011

Page 776 of 909

R–14

REAR SUSPENSION

Bolt (Differential Front Side) Installation Note

1. Support the differential with a jack, and then

install the bolt.

2. Connect differential oil temperature sensor

connector and 4WD solenoid connector.

End Of SieTRAILING LINK REMOVAL/INSTALLATION (4WD)A6E741628200201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

3. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162011

Page 778 of 909

R–16

REAR SUSPENSION

Bolt (Trailing Link Front Side) Removal Note

1. Support the trailing link with a jack.

Caution

•Removing the trailing link is dangerous.

The trailing link could fall and cause

serious injury or death. Verify that the

jack securely supports the trailing link.

2. Remove the bolts (trailing link front side).

Bolt (Lateral Link Outer Side) Removal Note

1. Loosen the bolt (lateral link inner side).

2. Remove the bolt (lateral link outer side).

Bolt (Lateral Link Outer Side) Installation Note

1. Tighten the bolt (lateral link outer side).

2. Tighten the bolt (lateral link inner side).

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—85.99 ft·lbf}

Bolt (Trailing Link Front Side) Installation Note

1. Support the trailing link with a jack.

2. Tighten the bolts (trailing link front side).

End Of SieREAR CROSSMEMBER REMOVAL/INSTALLATION (4WD)A6E741628400201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove the rear auto leveling sensor and harness.

(See T–20 REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATION.)

2. Remove the middle pipe.

(See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Adjust the headlight zeroset.

6. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162010

JACK

A6E74162010

Page 783 of 909

S–2

OUTLINE, EXTERIOR ATTACHMENT

OUTLINE OF CONSTRUCTIONA6E770201086201•The construction and operation of the body system is essentially carried over from that of the current Mazda6

(GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C)

End Of Sie

FEATURESA6E770201086202Improved Marketability

•A rear spoiler with a built in high-mount brake light has been adopted. (WGN)

•A roof rail has been adopted. (WGN)

•A tonneau cover with an attached net has been adopted. (WGN)

•A fixed rear seat cushion has been adopted. (4WD WGN)

End Of Sie

OUTLINEA6E772801092201•A rear spoiler with a built in high-mount brake light has been adopted.

•A roof rail has been adopted.

End Of Sie

STRUCTURAL VIEWA6E772801092202

.

End Of Sie

OUTLINE

EXTERIOR ATTACHMENT

1

2

A6E7728T101

1 Roof rail2 Rear spoiler

Page 785 of 909

S–4

SEAT

End Of Sie

OUTLINEA6E775257100201•A fixed rear seat cushion has been adopted. (4WD WGN)

End Of Sie

STRUCTURAL VIEWA6E775257100202

.

End Of Sie

SEAT

12

44

33

A6E77521101

1 Full flat fold down function (except 4WD WGN)

2 Fold down function (4WD WGN)3 Rear seat back

4 Rear seat cushion

Page 809 of 909

S–28

SEAT BELT

REAR SIDE SEAT BELT REMOVAL/INSTALLATIONA6E775057730201

Caution

•The rear side seat belt for 4WD models is equipped with a silencer to reduce abnormal noise while

driving. If the silencer is not installed in the proper position, the push knob may not function

properly. When attaching the silencer, be sure to attach it in the correct area as shown below.

Note

•Rear side seat belts are built into the rear seat back. See rear seat disassembly/assembly, to remove/

install the rear side seat belt.

1. Peel off the backing of the double-sided adhesive tape.

2. Attach double-sided adhesive tape to the silencer as shown.

End Of Sie

REAR CENTER SEAT BELT REMOVAL/INSTALLATIONA6E775057730202WGN

Caution

•The ELR has a spring that will unwind if the retractor's cover is removed. The spring cannot be

rewound by hand. If this occurs, the ELR will not work properly. Therefore, do not disassemble the

retractor.

1. Remove the headliner.

2. Remove the bolts.

3. Remove the rear center seat belt.

4. Install in the reverse order of removal.

End Of Sie

SEAT BELT

SILENCERRETRACTOR

mm {in} 29—35

{1.2—1.3}

-3—3

{-0.1—0.1} 60

{2.3} 60

{2.3}

60

{2.3}

60

{2.3}40

{1.5}

29—35

{1.2—1.3}

-3—3

{-0.1—0.1}

SILENCER RETRACTOR

60{2.3}

A6E77502101

39—78 N·m

{3.9—8.0 kgf·m, 29—57 ft·lbf}

REAR CENTER

SEAT BELT

BOLT

A6A7750W101

Page 810 of 909

SEAT

S–29

S

REAR SEAT REMOVAL/INSTALLATIONA6E7752572002014WD (WGN)

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

.

Remote wire removal note

1. Turn over the trunk floor mat.

2. Remove the case.

3. Remove the remote wire.

End Of Sie

SEAT

3

2

1

1

A: 36.3—53.9 N·m

{3.71—5.49 kgf·m, 26.8—39.7 ft·lbf}

B: 38.3—78.4 N·m

{3.91—7.99 kgf·m, 28.3—57.8 ft·lbf}

A

A

B

B

A6E77521102

1 Remote wire

(See S–29 Remote wire removal note)2 Rear seat cushion

3 Rear seat back

CASE

REMOTE WIRE

A6E7752W014

Page 811 of 909

S–30

SEAT

REAR SEAT DISASSEMBLY/ASSEMBLYA6E775257200202WGN

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly..

End Of Sie

9

1

6

9

8

7

25

4

2

5

4

3

1

6

87

19

18

18

1315

16

171110

11

22

21

20

14

21

2224

24

20

23

3

A

A

12

10

19

23

12

25

25

4WD

4

3

A6E77521015

1 Headrest

2 Hinge cover (2WD)

3 Seat cushion trim

4 Seat cushion pad

5 Seat cushion frame (2WD)

6 Remote button cover

7 Seat back catch cover

8 Child seat anchor cover

9 Retainer bar anchor

10 Seat back board

11 Pole guide

12 Remote button

13 Armrest assembly14 Cup holder

15 Armrest hinge

16 Armrest trim

17 Armrest pad

18 Seat back trim

19 Seat back pad

20 Seat belt guide

21 Retractor cover

22 Rear seat belt

23 Seat back catch

24 Remote wire

25 Seat back frame