diagram MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 157 of 909

OUTLINE

F2–5

F2

CONTROL SYSTEM WIRING DIAGRAMA6E400218881205

BA

ABA

ABA

ABA

A1A

1B 1C 1D 1E 1F1G

1H2A

2B 2C2D

2E

2F2G 2H

a

b

c

d

e

f

g

30 42

44 4543 1A

1B 1C 1D 1E 1F

13 39

80

28 78

A 57

E5633 1

427 73464

1041038565 9169

E53

79 9

1460

CBD AE C

A

Dh

i

j

k

l

m

n

o C

D

LOCKACCONSTB

ACCIG2IG1ST

AA

M

BA

A

AAB

9

8

7

5

4

3

10

19

18

17

1516

14

131112

20

6

1

2

23

21

22

A6E40022002

Page 172 of 909

F2–20

CONTROL SYSTEM

BLOCK DIAGRAMA6E404018881203

.

CRUISE

MAIN

CRUISE

9

8

7

5

4

3

10

6

1

2

14

13

11

12

19

18

17

15

16

20

29

28

27

25

26

24

23

21

22

30

37

35

36

33

31

32

34

39

38

40

49

48

47

45

46

44

43

41

42

50

51

52

53

A6E40402017

Page 187 of 909

ENGINE TUNE-UP, INTAKE-AIR SYSTEM

F2–35

F2

Injection Amount Correction

Note

•Perform this procedure at the recommended interval as described under “Fuel injection system” in

“SCHEDULED MAINTENANCE.”

1. Perform “Engine Tune-up Preparation”. (See F2–34 ENGINE TUNE-UP PREPARATION.)

2. Perform “Injection Amount Correction” using the WDS or equivalent.

MAF Correction

Note

•Perform this procedure after replacing the MAF/IAT sensor or at the recommended interval as described

under “E.G.R. system” in “SCHEDULED MAINTENANCE.”

1. Perform “Engine Tune-up Preparation”. (See F2–34 ENGINE TUNE-UP PREPARATION.)

2. Perform “MAF Correction” using the WDS or equivalent.

End Of Sie

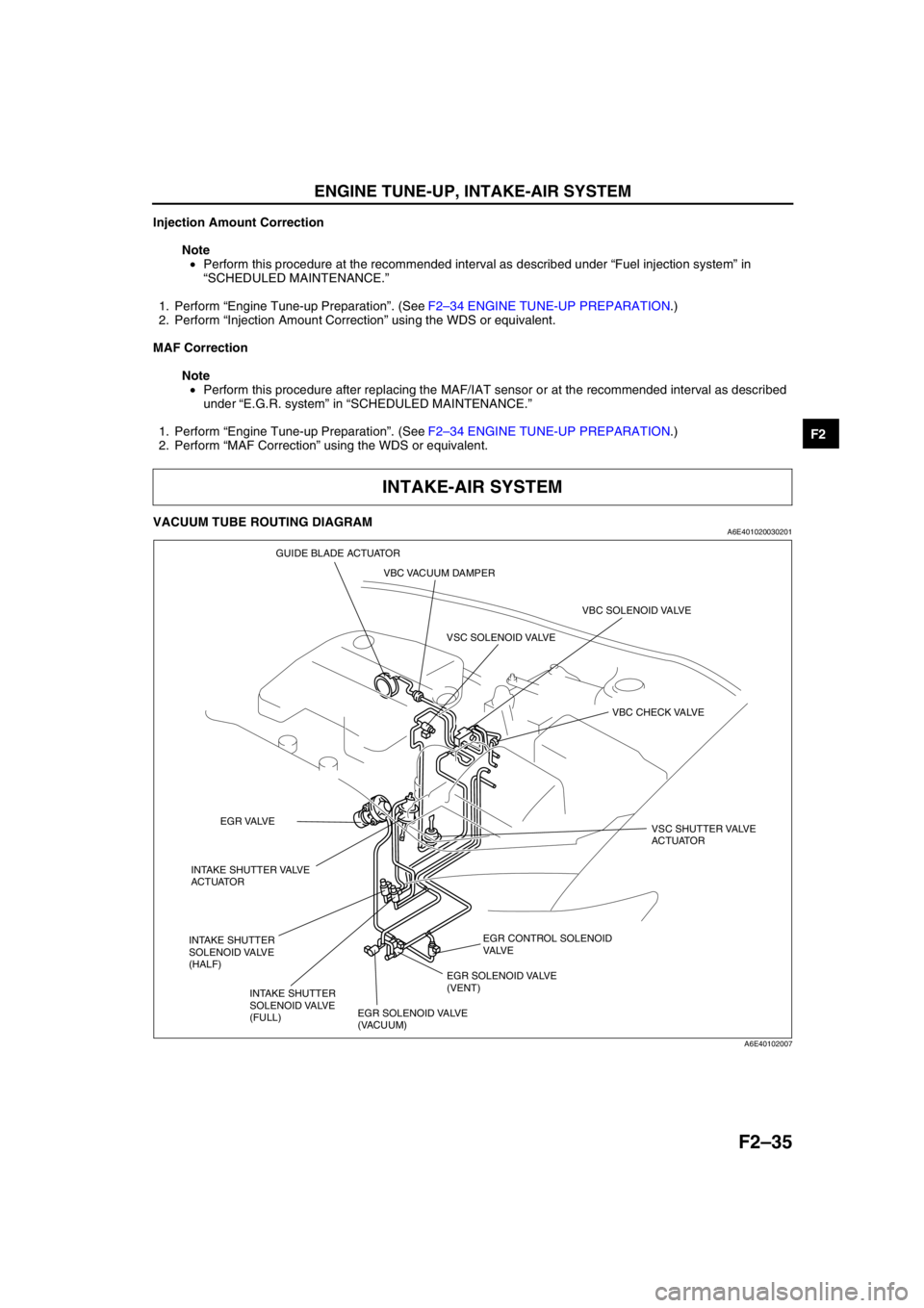

VACUUM TUBE ROUTING DIAGRAMA6E401020030201

End Of Sie

INTAKE-AIR SYSTEM

EGR CONTROL SOLENOID

VA LV E

VBC SOLENOID VALVE

VBC CHECK VALVE

EGR SOLENOID VALVE

(VACUUM)EGR SOLENOID VALVE

(VENT) VSC SOLENOID VALVE

VSC SHUTTER VALVE

ACTUATOR

INTAKE SHUTTER VALVE

ACTUATOREGR VALVE

INTAKE SHUTTER

SOLENOID VALVE

(HALF)

INTAKE SHUTTER

SOLENOID VALVE

(FULL)VBC VACUUM DAMPER GUIDE BLADE ACTUATOR

A6E40102007

Page 193 of 909

INTAKE-AIR SYSTEM

F2–41

F2

Open circuit

•If there is no continuity, the circuit is open. Repair or replace the harness.

—VBC solenoid valve terminal A (harness-side) and PCM control relay terminal C

—VBC solenoid valve terminal B (harness-side) and PCM connector terminal 67

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—VBC solenoid valve terminal A (harness-side) and GND

—VBC solenoid valve terminal B (harness-side) and power supply

End Of Sie

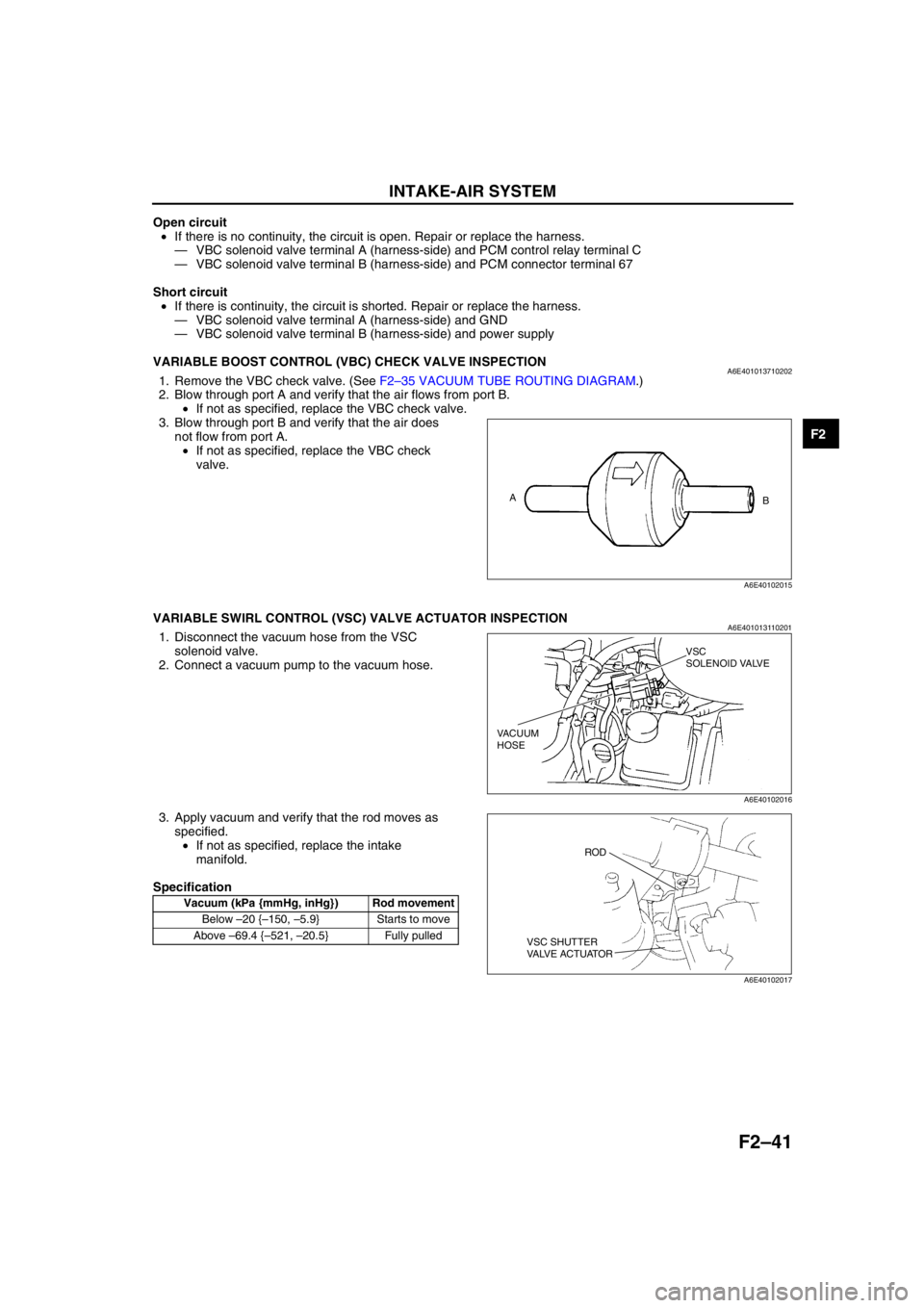

VARIABLE BOOST CONTROL (VBC) CHECK VALVE INSPECTIONA6E4010137102021. Remove the VBC check valve. (See F2–35 VACUUM TUBE ROUTING DIAGRAM.)

2. Blow through port A and verify that the air flows from port B.

•If not as specified, replace the VBC check valve.

3. Blow through port B and verify that the air does

not flow from port A.

•If not as specified, replace the VBC check

valve.

End Of Sie

VARIABLE SWIRL CONTROL (VSC) VALVE ACTUATOR INSPECTIONA6E4010131102011. Disconnect the vacuum hose from the VSC

solenoid valve.

2. Connect a vacuum pump to the vacuum hose.

3. Apply vacuum and verify that the rod moves as

specified.

•If not as specified, replace the intake

manifold.

Specification

End Of Sie

A

B

A6E40102015

Vacuum (kPa {mmHg, inHg}) Rod movement

Below –20 {–150, –5.9} Starts to move

Above –69.4 {–521, –20.5} Fully pulled

VSC

SOLENOID VALVE

VACUUM

HOSE

A6E40102016

ROD

VSC SHUTTER

VALVE ACTUATOR

A6E40102017

Page 416 of 909

![MAZDA 6 2002 Suplement User Guide K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI MAZDA 6 2002 Suplement User Guide K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI](/img/28/57057/w960_57057-415.png)

K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATIONS ............................................. K2-3

AUTOMATIC TRANSAXLE.................................. K2-4

OUTLINE ........................................................... K2-4

CROSS-SECTIONAL VIEW .............................. K2-6

ELECTRONIC CONTROL SYSTEM

STRUCTURAL VIEW...................................... K2-8

AUTOMATIC TRANSAXLE CONTROL SYSTEM

WIRING DIAGRAM ....................................... K2-10

AUTOMATIC TRANSAXLE BLOCK

DIAGRAM ..................................................... K2-11

AUTOMATIC TRANSAXLE DEVICE

RELATIONSHIP CHART .............................. K2-13

POWERTRAIN DESCRIPTION ....................... K2-15

TORQUE CONVERTER DESCRIPTION......... K2-40

OIL PUMP DESCRIPTION .............................. K2-41

CENTRIFUGAL BALANCE CLUTCH

DESCRIPTION ............................................. K2-42

CONTROL VALVE BODY DESCRIPTION ...... K2-43

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR DESCRIPTION ................... K2-45

INPUT/TURBINE SPEED SENSOR

DESCRIPTION ............................................. K2-45

INTERMEDIATE SENSOR DESCRIPTION..... K2-46

VEHICLE SPEEDOMETER SENSOR

DESCRIPTION ............................................. K2-46

SOLENOID VALVE DESCRIPTION ................ K2-47

CONTROLLER AREA NETWORK (CAN)

DESCRIPTION ............................................. K2-50

TRANSAXLE CONTROL MODULE

(TCM) DESCRIPTION .................................. K2-51

SHIFT CONTROL DESCRIPTION .................. K2-51

MANUAL MODE SHIFT CONTROL

DESCRIPTION ............................................. K2-52

LINE PRESSURE CONTROL DESCRIPTION K2-54

FEEDBACK CONTROL DESCRIPTION ......... K2-57

N-D SELECT CONTROL DESCRIPTION........ K2-59

TORQUE CONVERTER CLUTCH

(TCC) CONTROL DESCRIPTION ................ K2-59

SLOPE MODE CONTROL DESCRIPTION ..... K2-63

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM DESCRIPTION.............................. K2-64

COOLING SYSTEM DESCRIPTION ............... K2-69

LOCATION INDEX............................................. K2-70

AUTOMATIC TRANSAXLE LOCATION

INDEX ........................................................... K2-70

AUTOMATIC TRANSAXLE................................ K2-72

MECHANICAL SYSTEM TEST ....................... K2-72

ROAD TEST .................................................... K2-75AUTOMATIC TRANSAXLE FLUID

(ATF) INSPECTION ...................................... K2-78

AUTOMATIC TRANSAXLE FLUID

(ATF) REPLACEMENT ................................. K2-80

TRANSAXLE RANGE (TR) SWITCH

INSPECTION ................................................ K2-80

TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION .......................... K2-81

TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT .............................................. K2-83

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR INSPECTION ...................... K2-84

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR REMOVAL/INSTALLATION K2-85

INPUT/TURBINE SPEED SENSOR

INSPECTION ................................................ K2-85

INPUT/TURBINE SPEED SENSOR

REMOVAL/INSTALLATION .......................... K2-86

INTERMEDIATE SENSOR INSPECTION ....... K2-86

INTERMEDIATE SENSOR

REMOVAL/INSTALLATION .......................... K2-86

VEHICLE SPEEDOMETER SENSOR

(VSS) INSPECTION...................................... K2-87

VEHICLE SPEEDOMETER SENSOR

(VSS) REMOVAL/INSTALLATION ............... K2-87

SOLENOID VALVE INSPECTION ................... K2-88

SOLENOID VALVE

REMOVAL/INSTALLATION .......................... K2-90

TCM INSPECTION .......................................... K2-90

TCM REMOVAL/INSTALLATION .................... K2-96

AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION...... K2-99

OIL SEAL REMOVAL/INSTALLATION .......... K2-104

CONTROL VALVE BODY

REMOVAL/INSTALLATION ........................ K2-105

OIL COOLER FLUSHING .............................. K2-106

OIL COOLER REMOVAL/INSTALLATION .... K2-108

OIL COOLER DISASSEMBLY/ASSEMBLY .. K2-110

DRIVE PLATE REMOVAL/INSTALLATION... K2-112

TRANSFER....................................................... K2-114

TRANSFER OIL INSPECTION ...................... K2-114

TRANSFER OIL REPLACEMENT ................. K2-114

TRANSFER REMOVAL/INSTALLATION....... K2-115

BREATHER PLUG

REMOVAL/INSTALLATION ........................ K2-116

AUTOMATIC TRANSAXLE SHIFT

MECHANISM................................................. K2-117

SELECTOR LEVER INSPECTION ................ K2-117

SELECTOR LEVER COMPONENT

INSPECTION .............................................. K2-117

SELECTOR CABLE ADJUSTMENT .............. K2-118

SELECTOR LEVER

REMOVAL/INSTALLATION ........................ K2-119

SELECTOR LEVER

DISASSEMBLY/ASSEMBLY ...................... K2-122

ON-BOARD DIAGNOSTIC............................... K2-123

FOREWORD .................................................. K2-123 FEATURES

SERVICE

Page 425 of 909

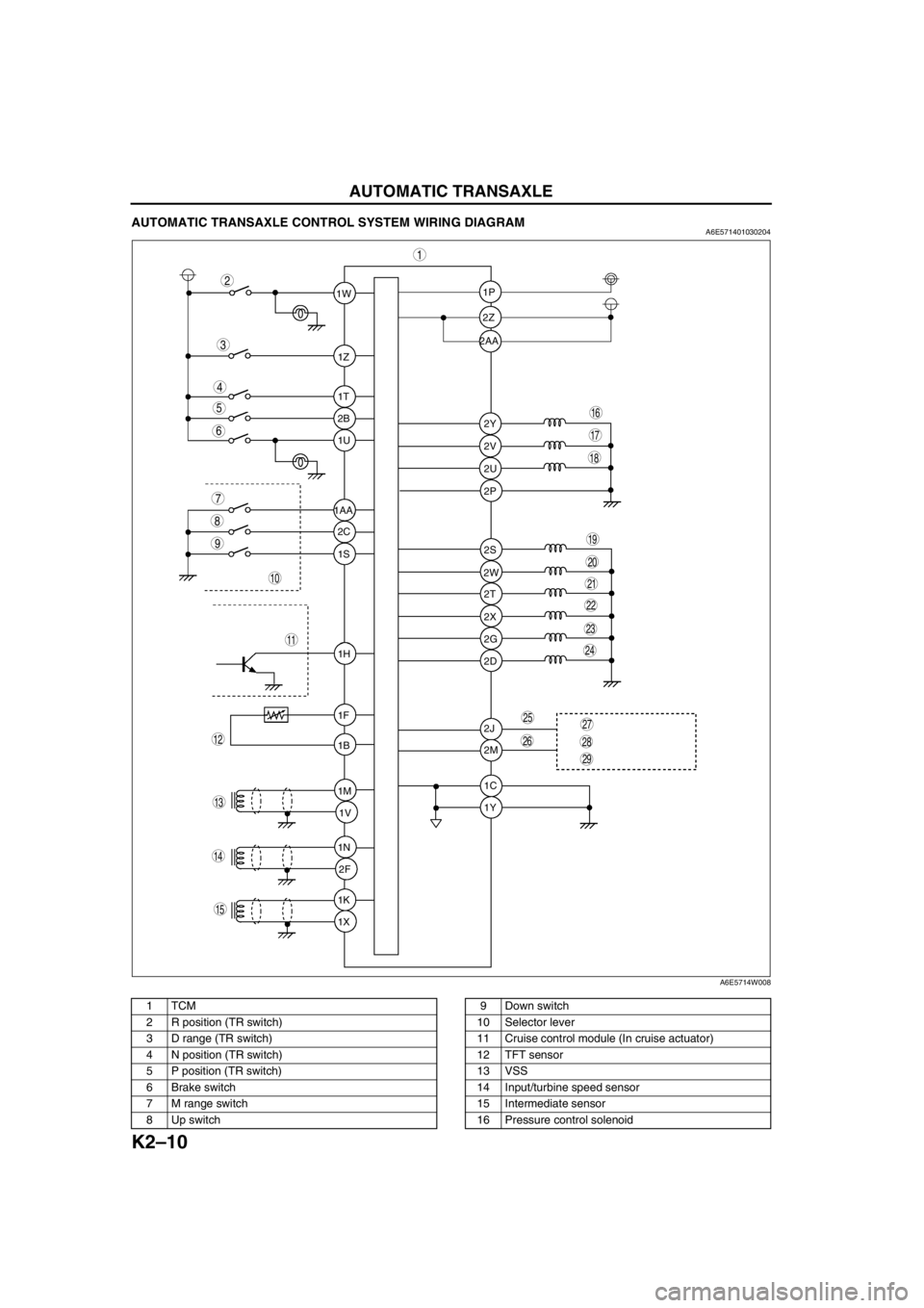

K2–10

AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLE CONTROL SYSTEM WIRING DIAGRAMA6E571401030204

.

1W1P

2P

2S

2T

2X

2G

2D

2J

2M

1C

1Y 2W 2Z

2Y

2V

2U 1Z

1T

2B

1U

2C

1S

1H

1F

1B

1M

1V

1N

2F

1K

1X 1AA2AA

9

8

7

5

4

3

1

2

10

19

18

17

15

16

14

13

11

12

20

6

29

28

2725

26

24

23

21

22

A6E5714W008

1TCM

2 R position (TR switch)

3 D range (TR switch)

4 N position (TR switch)

5 P position (TR switch)

6 Brake switch

7 M range switch

8 Up switch9 Down switch

10 Selector lever

11 Cruise control module (In cruise actuator)

12 TFT sensor

13 VSS

14 Input/turbine speed sensor

15 Intermediate sensor

16 Pressure control solenoid

Page 426 of 909

AUTOMATIC TRANSAXLE

K2–11

K2

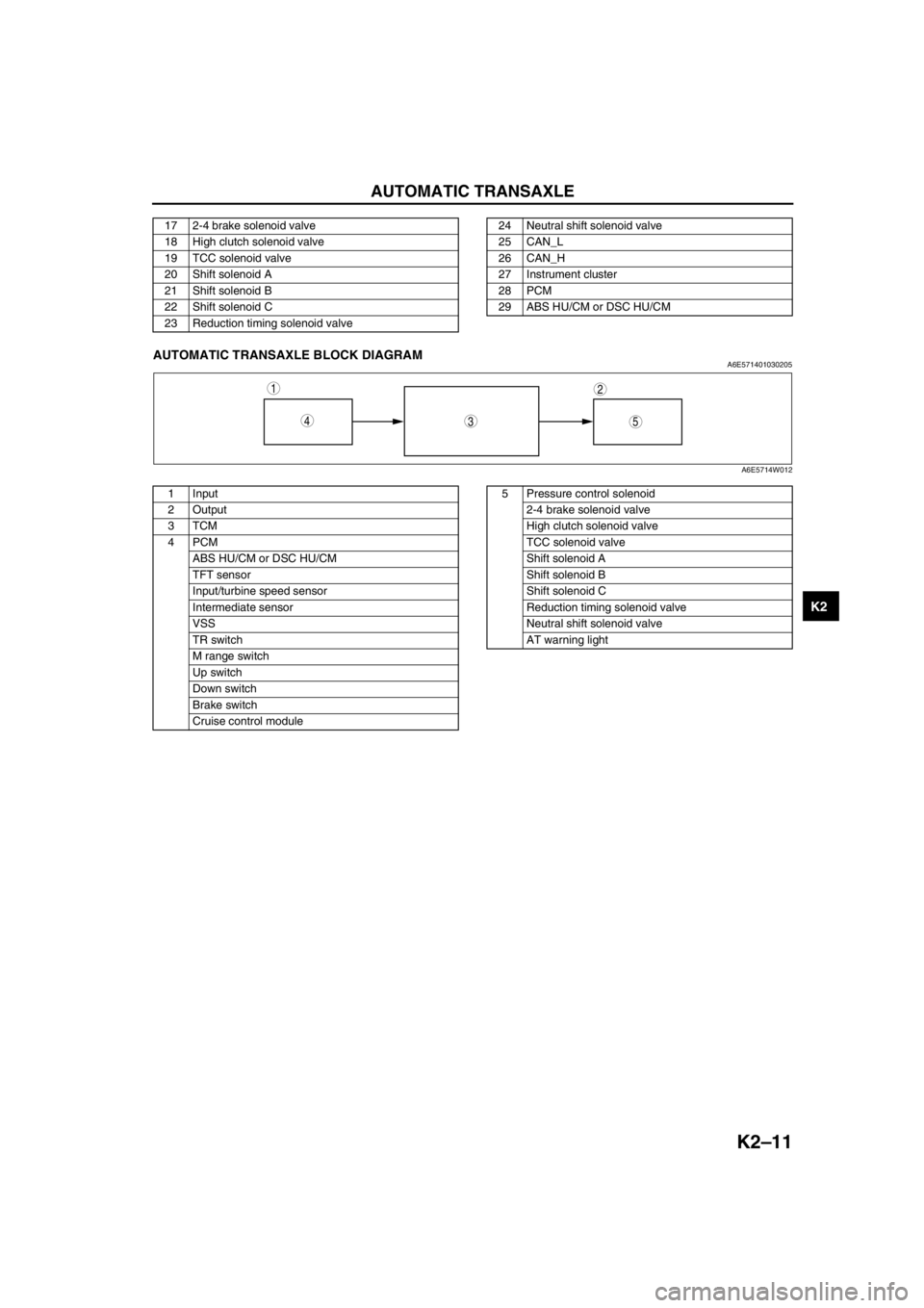

End Of SieAUTOMATIC TRANSAXLE BLOCK DIAGRAMA6E571401030205

.

17 2-4 brake solenoid valve

18 High clutch solenoid valve

19 TCC solenoid valve

20 Shift solenoid A

21 Shift solenoid B

22 Shift solenoid C

23 Reduction timing solenoid valve24 Neutral shift solenoid valve

25 CAN_L

26 CAN_H

27 Instrument cluster

28 PCM

29 ABS HU/CM or DSC HU/CM

543

12

A6E5714W012

1 Input

2Output

3TCM

4PCM

ABS HU/CM or DSC HU/CM

TFT sensor

Input/turbine speed sensor

Intermediate sensor

VSS

TR switch

M range switch

Up switch

Down switch

Brake switch

Cruise control module5 Pressure control solenoid

2-4 brake solenoid valve

High clutch solenoid valve

TCC solenoid valve

Shift solenoid A

Shift solenoid B

Shift solenoid C

Reduction timing solenoid valve

Neutral shift solenoid valve

AT warning light

Page 427 of 909

K2–12

AUTOMATIC TRANSAXLE

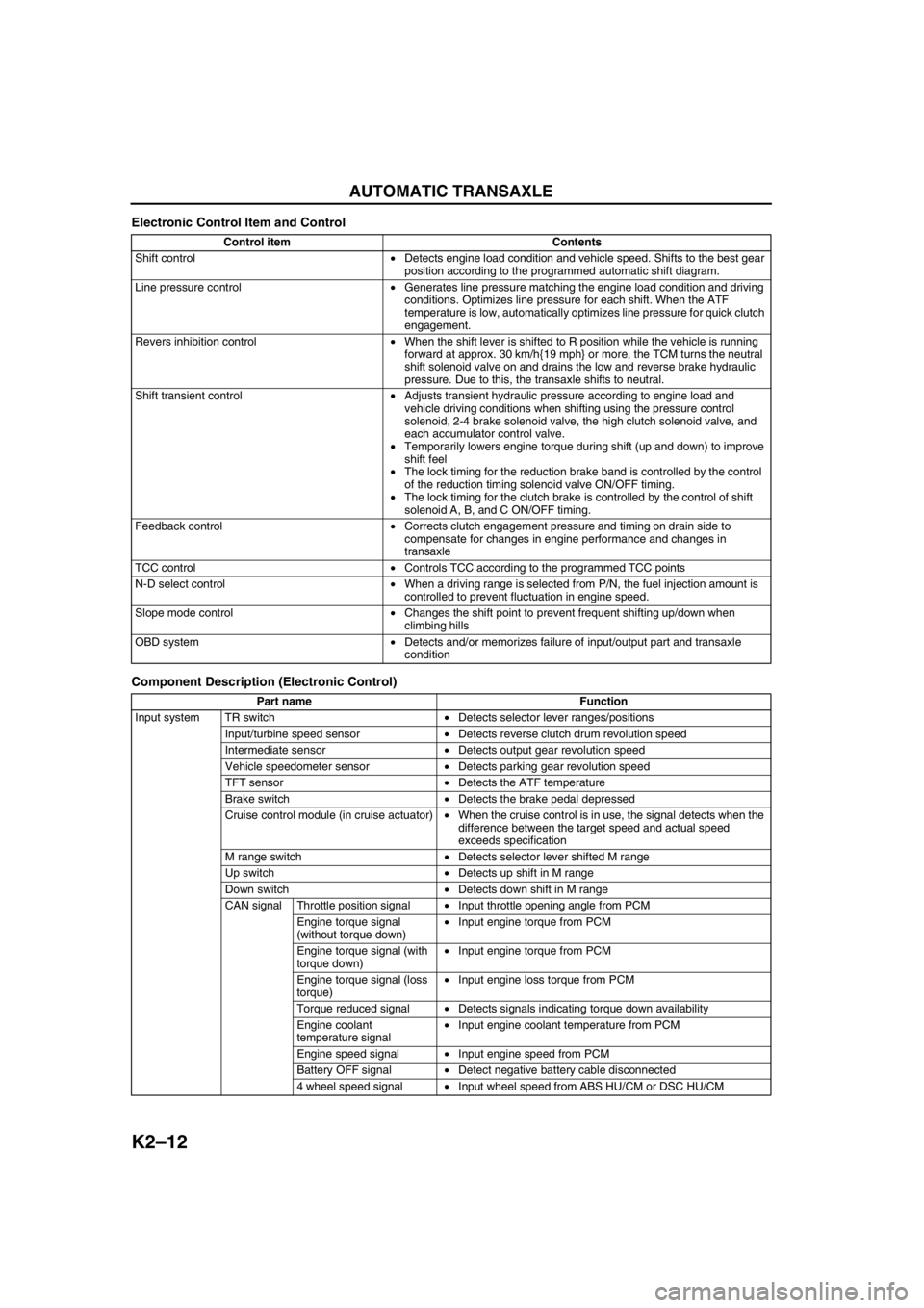

Electronic Control Item and Control

Component Description (Electronic Control)

Control item Contents

Shift control•Detects engine load condition and vehicle speed. Shifts to the best gear

position according to the programmed automatic shift diagram.

Line pressure control•Generates line pressure matching the engine load condition and driving

conditions. Optimizes line pressure for each shift. When the ATF

temperature is low, automatically optimizes line pressure for quick clutch

engagement.

Revers inhibition control•When the shift lever is shifted to R position while the vehicle is running

forward at approx. 30 km/h{19 mph} or more, the TCM turns the neutral

shift solenoid valve on and drains the low and reverse brake hydraulic

pressure. Due to this, the transaxle shifts to neutral.

Shift transient control•Adjusts transient hydraulic pressure according to engine load and

vehicle driving conditions when shifting using the pressure control

solenoid, 2-4 brake solenoid valve, the high clutch solenoid valve, and

each accumulator control valve.

•Temporarily lowers engine torque during shift (up and down) to improve

shift feel

•The lock timing for the reduction brake band is controlled by the control

of the reduction timing solenoid valve ON/OFF timing.

•The lock timing for the clutch brake is controlled by the control of shift

solenoid A, B, and C ON/OFF timing.

Feedback control•Corrects clutch engagement pressure and timing on drain side to

compensate for changes in engine performance and changes in

transaxle

TCC control•Controls TCC according to the programmed TCC points

N-D select control•When a driving range is selected from P/N, the fuel injection amount is

controlled to prevent fluctuation in engine speed.

Slope mode control•Changes the shift point to prevent frequent shifting up/down when

climbing hills

OBD system•Detects and/or memorizes failure of input/output part and transaxle

condition

Part name Function

Input system TR switch•Detects selector lever ranges/positions

Input/turbine speed sensor•Detects reverse clutch drum revolution speed

Intermediate sensor•Detects output gear revolution speed

Vehicle speedometer sensor•Detects parking gear revolution speed

TFT sensor•Detects the ATF temperature

Brake switch•Detects the brake pedal depressed

Cruise control module (in cruise actuator)•When the cruise control is in use, the signal detects when the

difference between the target speed and actual speed

exceeds specification

M range switch•Detects selector lever shifted M range

Up switch•Detects up shift in M range

Down switch•Detects down shift in M range

CAN signal Throttle position signal•Input throttle opening angle from PCM

Engine torque signal

(without torque down)•Input engine torque from PCM

Engine torque signal (with

torque down)•Input engine torque from PCM

Engine torque signal (loss

torque)•Input engine loss torque from PCM

Torque reduced signal•Detects signals indicating torque down availability

Engine coolant

temperature signal•Input engine coolant temperature from PCM

Engine speed signal•Input engine speed from PCM

Battery OFF signal•Detect negative battery cable disconnected

4 wheel speed signal•Input wheel speed from ABS HU/CM or DSC HU/CM

Page 466 of 909

AUTOMATIC TRANSAXLE

K2–51

K2

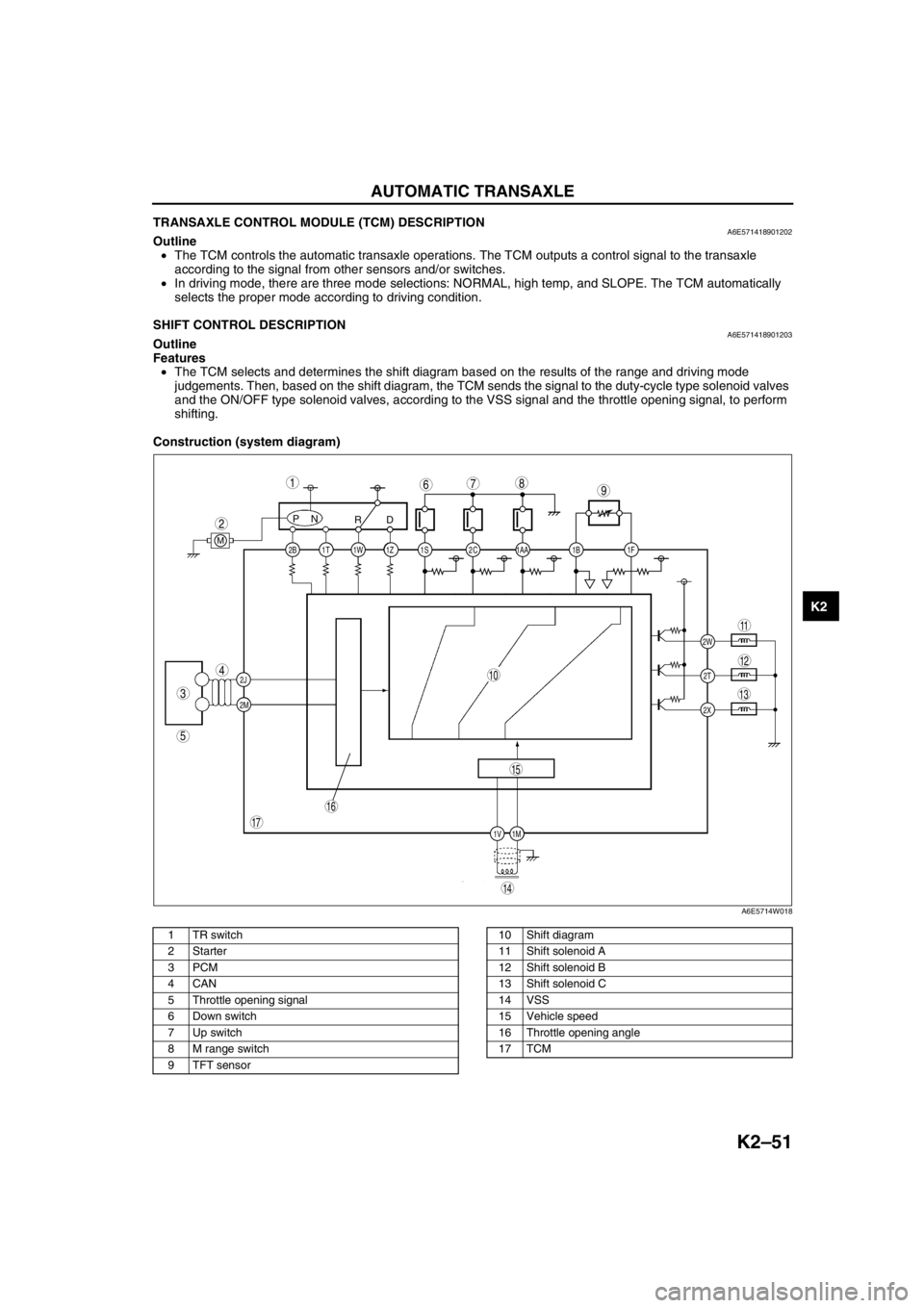

TRANSAXLE CONTROL MODULE (TCM) DESCRIPTIONA6E571418901202Outline

•The TCM controls the automatic transaxle operations. The TCM outputs a control signal to the transaxle

according to the signal from other sensors and/or switches.

•In driving mode, there are three mode selections: NORMAL, high temp, and SLOPE. The TCM automatically

selects the proper mode according to driving condition.

End Of Sie

SHIFT CONTROL DESCRIPTIONA6E571418901203Outline

Features

•The TCM selects and determines the shift diagram based on the results of the range and driving mode

judgements. Then, based on the shift diagram, the TCM sends the signal to the duty-cycle type solenoid valves

and the ON/OFF type solenoid valves, according to the VSS signal and the throttle opening signal, to perform

shifting.

Construction (system diagram)

.

2C 2B

2J

2M1AA 1S 1T 1Z1W 1B 1F

2W

1M 1V2T

2X

PN

RD

M

987

5

4

3

1

2

10

17

15

16

14

13

11

12

6

A6E5714W018

1 TR switch

2Starter

3PCM

4CAN

5 Throttle opening signal

6 Down switch

7 Up switch

8 M range switch

9 TFT sensor10 Shift diagram

11 Shift solenoid A

12 Shift solenoid B

13 Shift solenoid C

14 VSS

15 Vehicle speed

16 Throttle opening angle

17 TCM

Page 467 of 909

K2–52

AUTOMATIC TRANSAXLE

Operation

Range determination

•Each range is determined by operating the selector lever, and switching ON/OFF the switch in the TR switch

internal circuit. The present range is detected according to the ON/OFF signal of the switch.

•The following switches are built into the TR switch, and determine each range when the switch is on.

P position switch

R position switch

N position switch

D range switch

End Of Sie

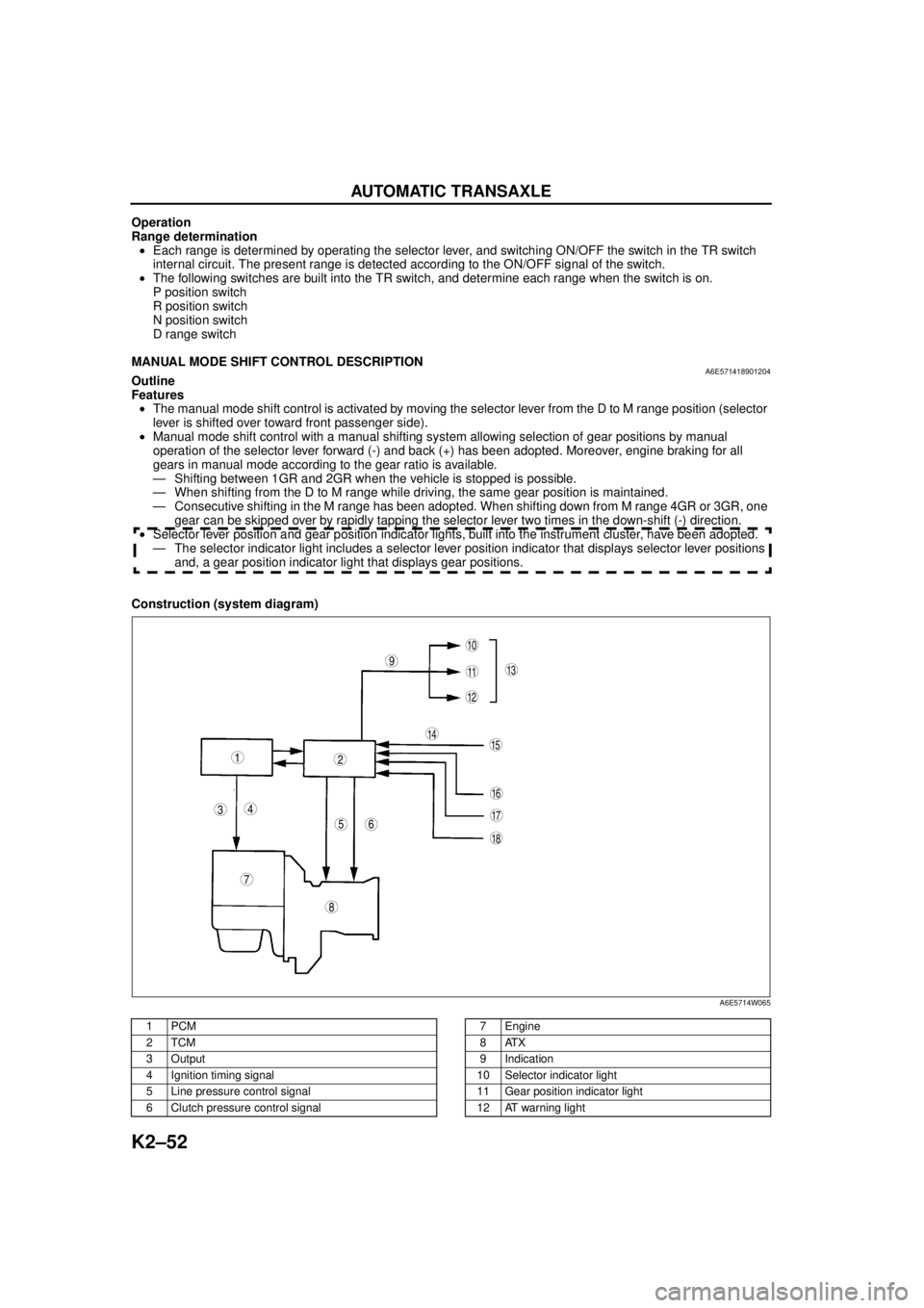

MANUAL MODE SHIFT CONTROL DESCRIPTIONA6E571418901204Outline

Features

•The manual mode shift control is activated by moving the selector lever from the D to M range position (selector

lever is shifted over toward front passenger side).

•Manual mode shift control with a manual shifting system allowing selection of gear positions by manual

operation of the selector lever forward (-) and back (+) has been adopted. Moreover, engine braking for all

gears in manual mode according to the gear ratio is available.

— Shifting between 1GR and 2GR when the vehicle is stopped is possible.

— When shifting from the D to M range while driving, the same gear position is maintained.

— Consecutive shifting in the M range has been adopted. When shifting down from M range 4GR or 3GR, one

gear can be skipped over by rapidly tapping the selector lever two times in the down-shift (-) direction.

•Selector lever position and gear position indicator lights, built into the instrument cluster, have been adopted.

— The selector indicator light includes a selector lever position indicator that displays selector lever positions

and, a gear position indicator light that displays gear positions.

Construction (system diagram)

.

9

8

7

5

43

12

10

18

17

15

16

14

1311

12

6

A6E5714W065

1PCM

2TCM

3Output

4 Ignition timing signal

5 Line pressure control signal

6 Clutch pressure control signal7Engine

8ATX

9 Indication

10 Selector indicator light

11 Gear position indicator light

12 AT warning light