differential MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 403 of 909

![MAZDA 6 2002 Suplement User Guide J2–1

J2

J2MANUAL TRANSAXLE [A65M-R]

OUTLINE.............................................................. J2-2

OUTLINE OF CONSTRUCTION........................ J2-2

FEATURES ......................... MAZDA 6 2002 Suplement User Guide J2–1

J2

J2MANUAL TRANSAXLE [A65M-R]

OUTLINE.............................................................. J2-2

OUTLINE OF CONSTRUCTION........................ J2-2

FEATURES .........................](/img/28/57057/w960_57057-402.png)

J2–1

J2

J2MANUAL TRANSAXLE [A65M-R]

OUTLINE.............................................................. J2-2

OUTLINE OF CONSTRUCTION........................ J2-2

FEATURES ........................................................ J2-2

SPECIFICATIONS ............................................. J2-2

LOCATION INDEX............................................... J2-3

MANUAL TRANSAXLE LOCATION INDEX ...... J2-3

MANUAL TRANSAXLE........................................ J2-4

TRANSAXLE OIL INSPECTION ........................ J2-4

TRANSAXLE OIL REPLACEMENT ................... J2-4

OIL SEAL (DIFFERENTIAL) REPLACEMENT .. J2-5

REVERSE SWITCH INSPECTION .................... J2-5

REVERSE SWITCH

REMOVAL/INSTALLATION ............................ J2-6

NEUTRAL SWITCH INSPECTION .................... J2-6

NEUTRAL SWITCH

REMOVAL/INSTALLATION ............................ J2-7

MANUAL TRANSAXLE

REMOVAL/INSTALLATION ............................ J2-7

SHIFT MECHANISM........................................... J2-12

SHIFT MECHANISM

REMOVAL/INSTALLATION .......................... J2-12 FEATURES

SERVICE

Page 405 of 909

LOCATION INDEX

J2–3

J2

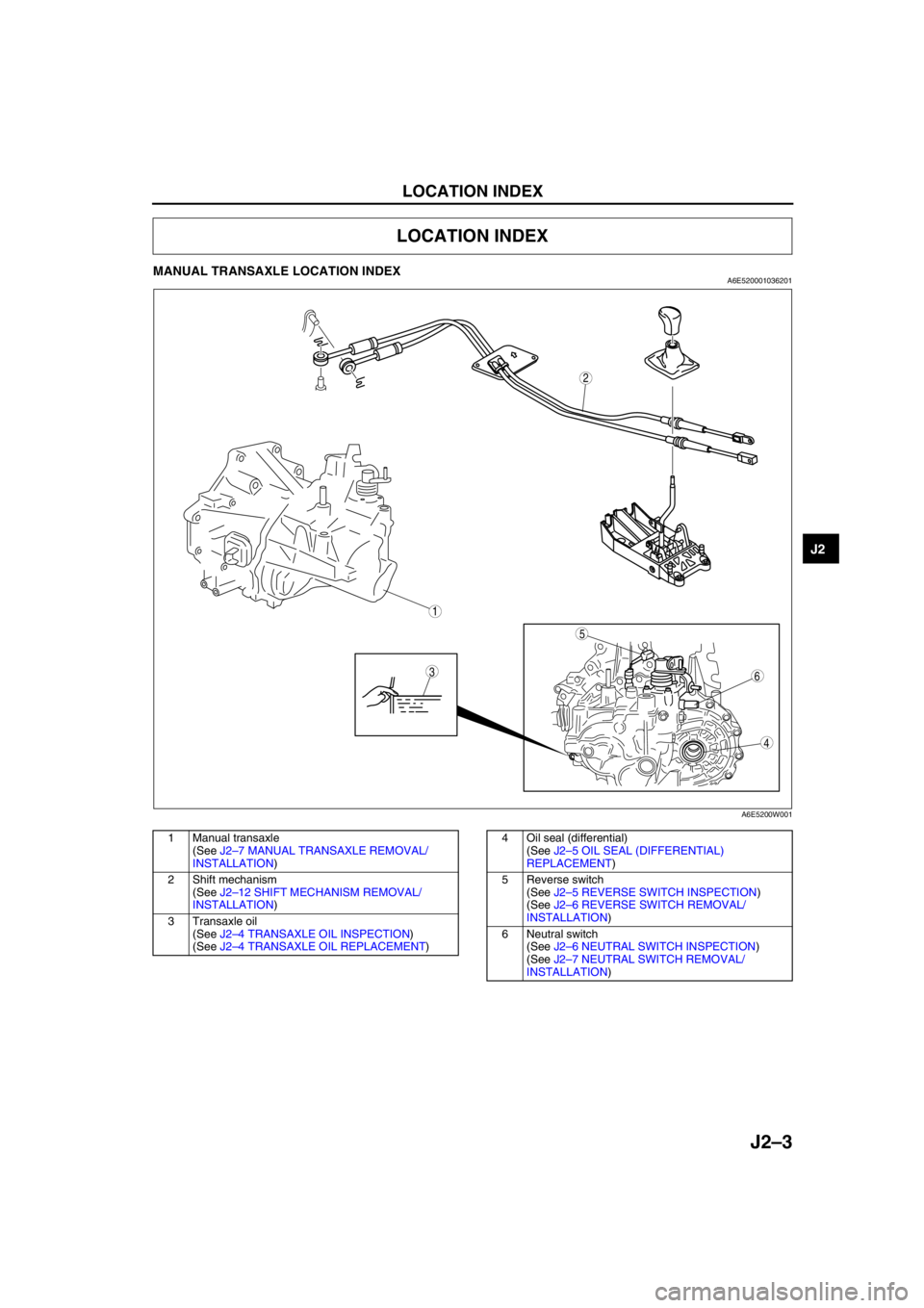

MANUAL TRANSAXLE LOCATION INDEXA6E520001036201

.

End Of Sie

LOCATION INDEX

2

5

36

4

1

A6E5200W001

1 Manual transaxle

(See J2–7 MANUAL TRANSAXLE REMOVAL/

INSTALLATION)

2 Shift mechanism

(See J2–12 SHIFT MECHANISM REMOVAL/

INSTALLATION)

3 Transaxle oil

(See J2–4 TRANSAXLE OIL INSPECTION)

(See J2–4 TRANSAXLE OIL REPLACEMENT)4 Oil seal (differential)

(See J2–5 OIL SEAL (DIFFERENTIAL)

REPLACEMENT)

5 Reverse switch

(See J2–5 REVERSE SWITCH INSPECTION)

(See J2–6 REVERSE SWITCH REMOVAL/

INSTALLATION)

6 Neutral switch

(See J2–6 NEUTRAL SWITCH INSPECTION)

(See J2–7 NEUTRAL SWITCH REMOVAL/

INSTALLATION)

Page 407 of 909

MANUAL TRANSAXLE

J2–5

J2

OIL SEAL (DIFFERENTIAL) REPLACEMENTA6E5212192402011. On level ground, jack up the vehicle and support it evenly on safety stands.

2. Drain the oil from the transaxle.

3. Remove the front wheels and splash shields.

4. Separate the drive shaft and joint shaft from the transaxle. (See Section M.)

5. Remove the oil seals using a screwdriver.

6. Using the SSTs and a hammer, tap each new oil

seal in evenly until the SSTs contact the transaxle

case.

7. Coat the lip of each oil seal with transaxle oil.

8. Insert the drive shaft and joint shaft into the

transaxle. (See Section M.)

9. Install the wheels and splash shields.

10. Add the specified amount and type of oil. (See

J2–4 TRANSAXLE OIL REPLACEMENT.)

End Of SieREVERSE SWITCH INSPECTIONA6E5212190102011. Disconnect the reverse switch connector.

2. Shift the shift lever to each position, and inspect

for continuity between terminals A and B.

•If not as specified, replace the reverse switch.

(See J2–6 REVERSE SWITCH REMOVAL/

INSTALLATION.)

3. Connect the reverse switch connector.

End Of Sie

AME5212W005

49 G030 797

49 U027 003

A6E5212W011

REVERSE SWITCH

A6E5212W012

BA REVERSE SWITCH

PART SIDE CONNENTOR

A6E5212W013

Shift positionConnector terminal

AB:

Continuity

Reverse

Others

A6E5212W014

Page 419 of 909

K2–4

AUTOMATIC TRANSAXLE

Bold frames:New specifications

End Of Sie

OUTLINEA6E571401030201•Adopted new JA5AX-EL automatic transaxle.

•Newly designed FF type five-speed automatic transaxle.

—Use of 3 sets of planetary gears, and a wider gear ratio setting realizes improvement of acceleration-from-

standing-start performance, fuel economy, and quietness. Also, by placement of two sets of planetary gears

in parallel with one set, the automatic transaxle is more compact.

•Adopted 2-4 brake clutch.

—Adopted a wet-type, multi-plate 2-4 brake clutch instead of the 2-4 brake band used in the past, for

smoother gear switching performance.

•Adopted centrifugal balance clutch

—The newly adopted centrifugal balance clutch pushes the clutch piston forcefully to low and high clutch by

centrifugal hydraulic pressure for smoother gear switching with batter response.

•Adopted controller area network (CAN)

—By adopting CAN, The TCM is always in contact with other computers in the car and controls the automatic

transaxle properly. This has also made troubleshooting diagnosis easier for the entire vehicle.

•Solenoid, sensor

—Adoption of four duty-type solenoids, five ON-OFF type solenoids, and three revolving sensors realizes

finer, more expedient control of gear shifting performance.

•Adoption of revers inhibit control

—If the reverse position is selected by mistake while driving in forward motion, the reverse inhibit control

system will cancel the operation electronically and set the position to neutral as a safety enhancement.

Outline of Operation

•The operation of the electronic automatic transaxle is classified into three systems: the electronic control

system, the hydraulic pressure control system, and the powertrain system (includes the torque converter

system.)

Electronic control system

•According to the signals from the switches and sensors in the input system, the TCM outputs the signal

which matches the present driving condition to the ON/OFF type solenoids and the duty-cycle type

solenoids in the hydraulic pressure control system.

Hydraulic pressure control system

•According to the signals from the TCM, each solenoid operates to switch the hydraulic passages in the

control valve body and controls the clutch engagement pressure.

•The line pressure is adjusted by the duty-cycle type pressure control solenoid. The hydraulic passages

are switched by the ON/OFF type solenoids and the clutch engagement pressure is controlled by the

duty-cycle type solenoids.

Powertrain system

•The driving force from the engine is transmitted through the torque converter to the transaxle.

•The transmitted driving force operates each clutch and brake according to the clutch engagement

pressure from the duty-cycle type solenoid, and the planetary gears change the gear ratio to the

optimal driving force. The changed driving force is transmitted through the differential to the axle shaft

and then the tires.

AUTOMATIC TRANSAXLE

Page 492 of 909

AUTOMATIC TRANSAXLE

K2–77

K2

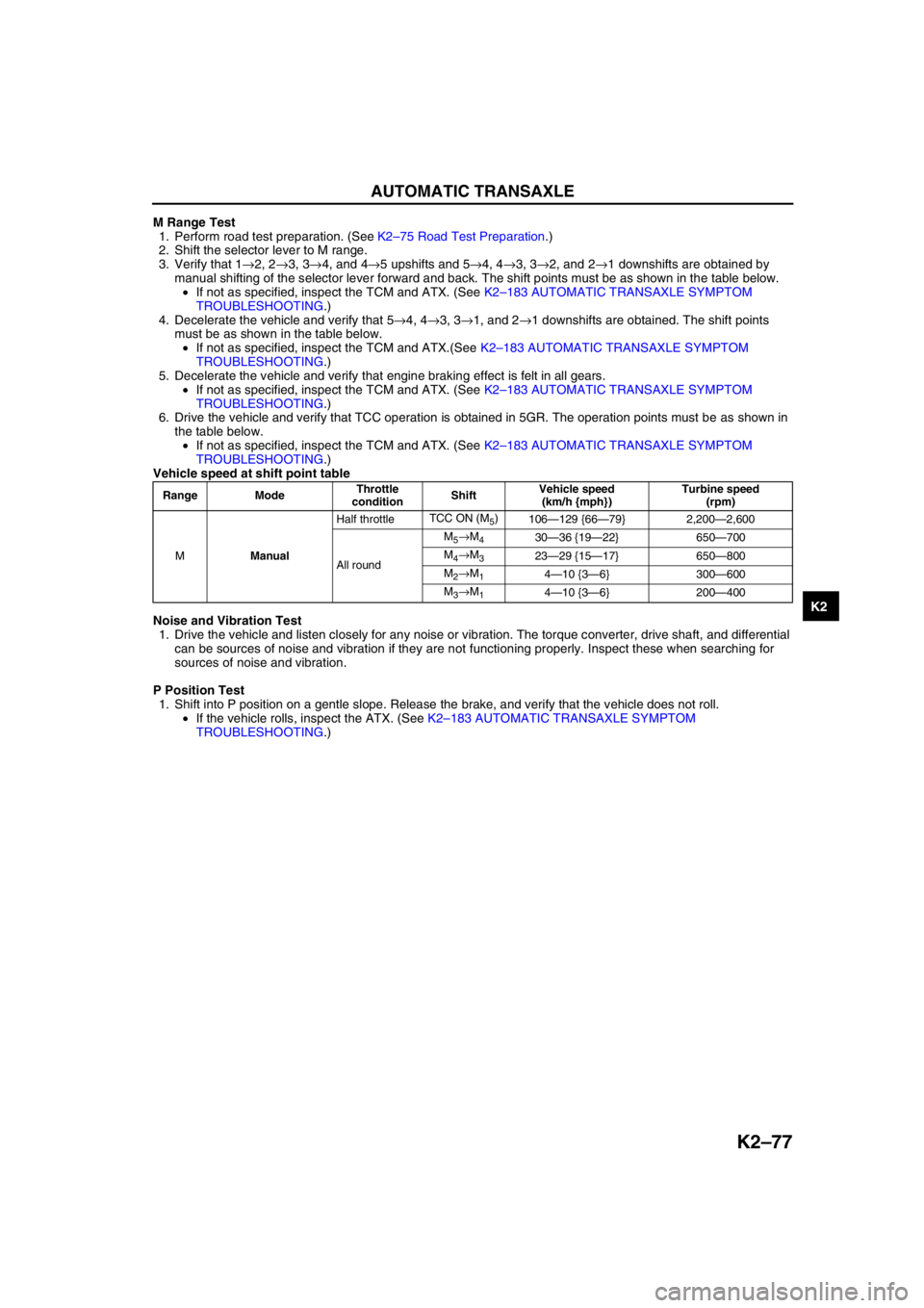

M Range Test

1. Perform road test preparation. (See K2–75 Road Test Preparation.)

2. Shift the selector lever to M range.

3. Verify that 1→2, 2→3, 3→4, and 4→5 upshifts and 5→4, 4→3, 3→2, and 2→1 downshifts are obtained by

manual shifting of the selector lever forward and back. The shift points must be as shown in the table below.

•If not as specified, inspect the TCM and ATX. (See K2–183 AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING.)

4. Decelerate the vehicle and verify that 5→4, 4→3, 3→1, and 2→1 downshifts are obtained. The shift points

must be as shown in the table below.

•If not as specified, inspect the TCM and ATX.(See K2–183 AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING.)

5. Decelerate the vehicle and verify that engine braking effect is felt in all gears.

•If not as specified, inspect the TCM and ATX. (See K2–183 AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING.)

6. Drive the vehicle and verify that TCC operation is obtained in 5GR. The operation points must be as shown in

the table below.

•If not as specified, inspect the TCM and ATX. (See K2–183 AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING.)

Vehicle speed at shift point table

Noise and Vibration Test

1. Drive the vehicle and listen closely for any noise or vibration. The torque converter, drive shaft, and differential

can be sources of noise and vibration if they are not functioning properly. Inspect these when searching for

sources of noise and vibration.

P Position Test

1. Shift into P position on a gentle slope. Release the brake, and verify that the vehicle does not roll.

•If the vehicle rolls, inspect the ATX. (See K2–183 AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING.)

Range ModeThrottle

conditionShiftVehicle speed

(km/h {mph})Turbine speed

(rpm)

MManualHalf throttleTCC ON (M

5)

106—129 {66—79} 2,200—2,600

All roundM

5→M430—36 {19—22} 650—700

M

4→M323—29 {15—17} 650—800

M

2→M14—10 {3—6} 300—600

M

3→M14—10 {3—6} 200—400

Page 519 of 909

K2–104

AUTOMATIC TRANSAXLE

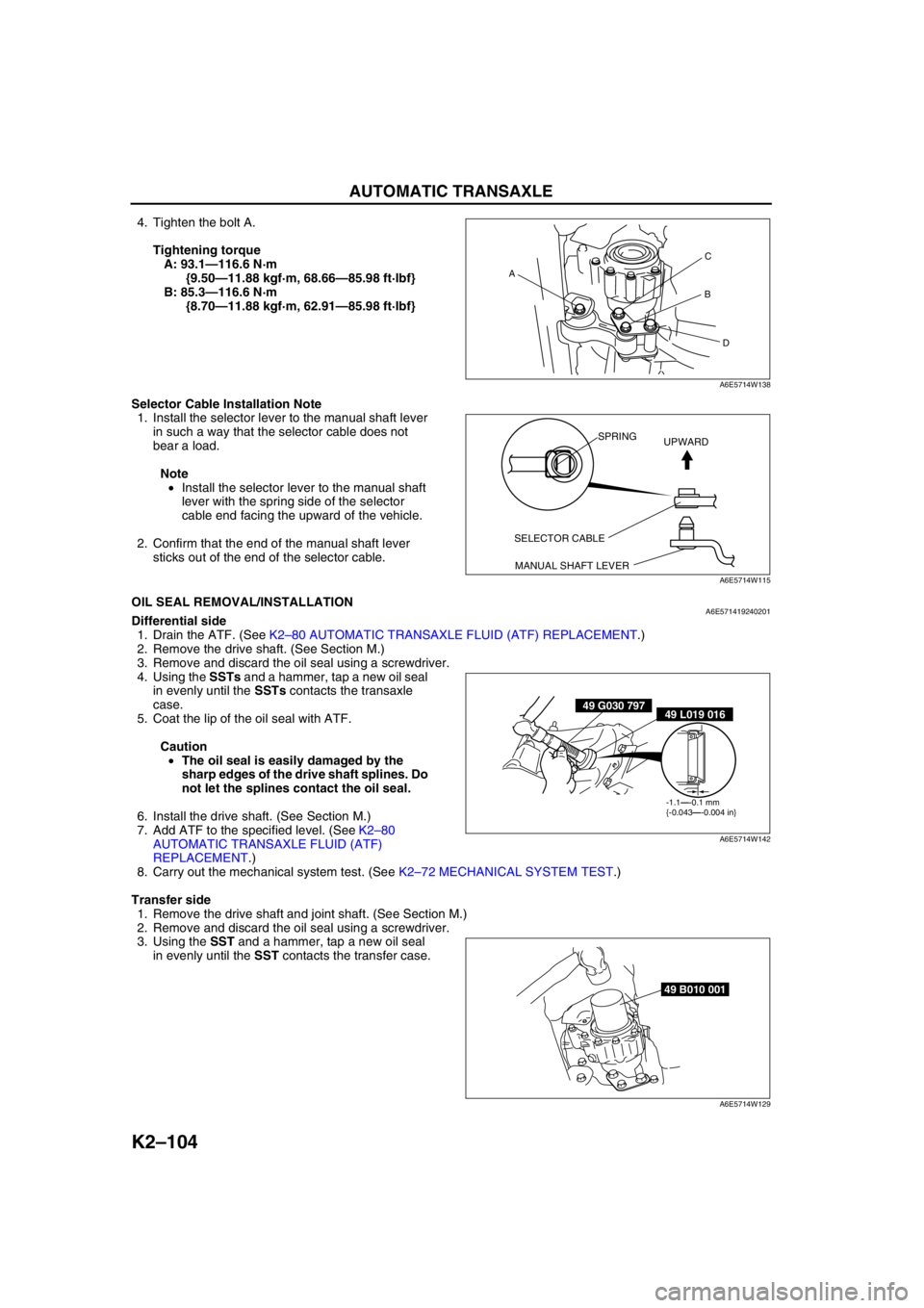

4. Tighten the bolt A.

Tightening torque

A: 93.1—116.6 N·m

{9.50—11.88 kgf·m, 68.66—85.98 ft·lbf}

B: 85.3—116.6 N·m

{8.70—11.88 kgf·m, 62.91—85.98 ft·lbf}

Selector Cable Installation Note

1. Install the selector lever to the manual shaft lever

in such a way that the selector cable does not

bear a load.

Note

•Install the selector lever to the manual shaft

lever with the spring side of the selector

cable end facing the upward of the vehicle.

2. Confirm that the end of the manual shaft lever

sticks out of the end of the selector cable.

End Of SieOIL SEAL REMOVAL/INSTALLATIONA6E571419240201Differential side

1. Drain the ATF. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

2. Remove the drive shaft. (See Section M.)

3. Remove and discard the oil seal using a screwdriver.

4. Using the SSTs and a hammer, tap a new oil seal

in evenly until the SSTs contacts the transaxle

case.

5. Coat the lip of the oil seal with ATF.

Caution

•The oil seal is easily damaged by the

sharp edges of the drive shaft splines. Do

not let the splines contact the oil seal.

6. Install the drive shaft. (See Section M.)

7. Add ATF to the specified level. (See K2–80

AUTOMATIC TRANSAXLE FLUID (ATF)

REPLACEMENT.)

8. Carry out the mechanical system test. (See K2–72 MECHANICAL SYSTEM TEST.)

Transfer side

1. Remove the drive shaft and joint shaft. (See Section M.)

2. Remove and discard the oil seal using a screwdriver.

3. Using the SST and a hammer, tap a new oil seal

in evenly until the SST contacts the transfer case.

AC

B

D

A6E5714W138

SELECTOR CABLE

MANUAL SHAFT LEVERSPRING

UPWARD

A6E5714W115

49 G030 79749 L019 016

-1.1—-0.1 mm

{-0.043—-0.004 in}

A6E5714W142

49 B010 001

A6E5714W129

Page 623 of 909

PROPELLER SHAFT

L–7

L

Propeller Shaft Installation Note

1. Align the mark made during removal, and install the propeller shaft.

Front side

2. Installing a new propeller shaft, align the

differential companion flange precast marking

with the tag on the propeller shaft.

End Of Sie

PROPELLER SHAFT DISASSEMBLY/ASSEMBLYA6E611025002202

Caution

•To prevent damage to parts when using a clamp, be sure to place an aluminum plate between

parts and the clamp.

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

A6J6110W006

MARK TA G

A6E6110W002

Page 631 of 909

M–1

M

MFRONT AND REAR AXLES

OUTLINE............................................................... M-2

OUTLINE OF CONSTRUCTION ........................ M-2

FEATURES ......................................................... M-2

SPECIFICATIONS .............................................. M-2

REAR AXLE.......................................................... M-4

REAR AXLE OUTLINE ....................................... M-4

CROSS-SECTIONAL VIEW ............................... M-4

DRIVE SHAFT....................................................... M-5

DRIVE SHAFT OUTLINE.................................... M-5

STRUCTURAL VIEW.......................................... M-5

REAR DRIVE SHAFT ......................................... M-5

REAR DIFFERENTIAL.......................................... M-6

REAR DIFFERENTIAL OUTLINE ....................... M-6

CROSS-SECTIONAL VIEW ............................... M-6

ELECTRONIC 4WD CONTROL SYSTEM............ M-7

OUTLINE ............................................................ M-7

ELECTRONIC CONTROL COUPLING .............. M-9

DIFFERENTIAL OIL TEMPERATURE

SENSOR ........................................................ M-12

4WD WARNING LIGHT .................................... M-12

4WD CONTROL MODURE .............................. M-13

4WD SYSTEM CONTROL................................ M-14

CONTROLLER AREA NETWORK (CAN) ........ M-15

ON-BOARD DIAGNOSTIC ............................... M-16

OUTLINE............................................................. M-18

SUPPLEMENTAL SERVICE

INFORMATION .............................................. M-18

LOCATION INDEX.............................................. M-19

AXLE/DRIVE SHAFT LOCATION INDEX ......... M-19

REAR DIFFERENTIAL/ELECTRONIC

4WD CONTROL SYSTEM LOCATION

INDEX ............................................................ M-20

GENERAL PROCEDURES................................. M-21

PRECAUTION (FRONT AND REAR AXLE) ..... M-21

REAR AXLE........................................................ M-22

WHEEL HUB BOLT REPL

ACEMENT ..................................................... M-22

WHEEL HUB, KNUCKLE

REMOVAL/INSTALLATION ........................... M-22

FRONT DRIVE SHAFT........................................ M-29

JOINT SHAFT (MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-29

JOINT SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-31

FRONT DRIVE SHAFT

(MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-34

FRONT DRIVE SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-39REAR DRIVE SHAFT.......................................... M-42

REAR DRIVE SHAFT PRE-INSPECTION ........ M-42

REAR DRIVE SHAFT

REMOVAL/INSTALLATION ........................... M-43

REAR DRIVE SHAFT

DISASSEMBLY/ASSEMBLY ......................... M-45

REAR DIFFERENTIAL........................................ M-48

DIFFERENTIAL OIL INSPECTION ................... M-48

DIFFERENTIAL OIL REPLACEMENT .............. M-48

OIL SEAL (SIDE GEAR) REPLACEMENT ....... M-49

OIL SEAL (COMPANION FLANGE)

REPLACEMENT ............................................ M-49

REAR DIFFERENTIAL

REMOVAL/INSTALLATION ........................... M-51

REAR DIFFERENTIAL DISASSEMBLY ........... M-52

REAR DIFFERENTIAL ASSEMBLY ................. M-56

ELECTRONIC 4WD CONTROL SYSTEM.......... M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR INSPECTION ................................. M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR REMOVAL/INSTALLATION ........... M-65

4WD SOLENOID INSPECTION........................ M-66

4WD CONTROL MODURE INSPECTION ........ M-66

4WD CONTROL MODURE

REMOVAL/INSTALLATION ........................... M-67

COUPLING COMPONENT

REMOVAL/INSTALLATION ........................... M-68

COUPLING COMPONENT

DISASSEMBLY .............................................. M-69

COUPLING COMPONENT ASSEMBLY........... M-72

ON-BOARD DIAGNOSTIC.................................. M-75

WIRING DIAGRAM ........................................... M-75

ELECTRONIC 4WD CONTROL SYSTEM

ON-BOARD DIAGNOSIS ............................... M-76

DTC P1887 ....................................................... M-77

DTC P1888 ....................................................... M-79

DTC U0100 ....................................................... M-80

DTC U0101 ....................................................... M-80

DTC U0121 ....................................................... M-80

TROUBLESHOOTING......................................... M-81

SYSTEM WIRING DIAGRAM ........................... M-81

FOREWORD ..................................................... M-82

SYMPTOM TROUBLESHOOTING ................... M-82

NO.1 FREQUENT FRONT WHEEL SLIP ......... M-82

NO.2 TIGHT CORNER BRAKING .................... M-83

NO.3 ABNORMAL NOISE AND/OR

VIBRATION FROM COUPLING

COMPONENT ................................................ M-84 FEATURES

SERVICE

Page 632 of 909

M–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E630201018201•The construction and operation of the front and rear axles is the same as that of the current Mazda6 (GG)

model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E630201018202Improved rigidity, reduced noise and vibration

•Concurrent with the MZR-CD (RF Turbo) engine, the configuration of the front drive shaft and the joint shaft

has been optimized.

•Concurrent with the 4WD system, the configuration of the rear axle, the front/rear drive shafts and the joint

shaft has been optimized.

Improved handling stability and marketability

•An electronic 4WD control system has been adopted.

End Of Sie

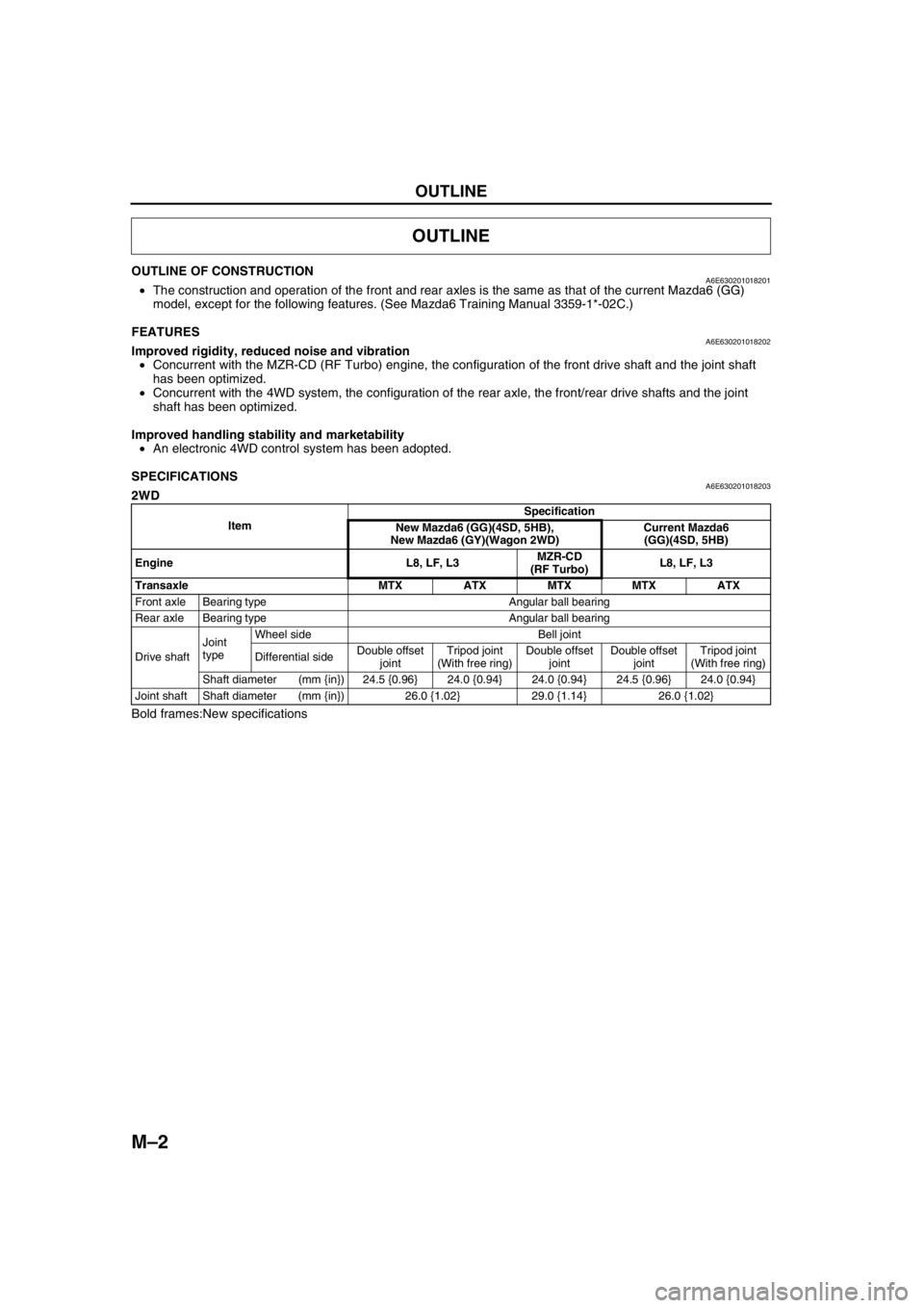

SPECIFICATIONSA6E6302010182032WD

Bold frames:New specifications

OUTLINE

ItemSpecification

New Mazda6 (GG)(4SD, 5HB),

New Mazda6 (GY)(Wagon 2WD)Current Mazda6

(GG)(4SD, 5HB)

Engine L8, LF, L3MZR-CD

(RF Turbo)L8, LF, L3

Transaxle MTX ATX MTX MTX ATX

Front axle Bearing type Angular ball bearing

Rear axle Bearing type Angular ball bearing

Drive shaftJoint

typeWheel side Bell joint

Differential sideDouble offset

jointTripod joint

(With free ring)Double offset

jointDouble offset

jointTripod joint

(With free ring)

Shaft diameter (mm {in}) 24.5 {0.96} 24.0 {0.94} 24.0 {0.94} 24.5 {0.96} 24.0 {0.94}

Joint shaft Shaft diameter (mm {in}) 26.0 {1.02} 29.0 {1.14} 26.0 {1.02}

Page 633 of 909

OUTLINE

M–3

M

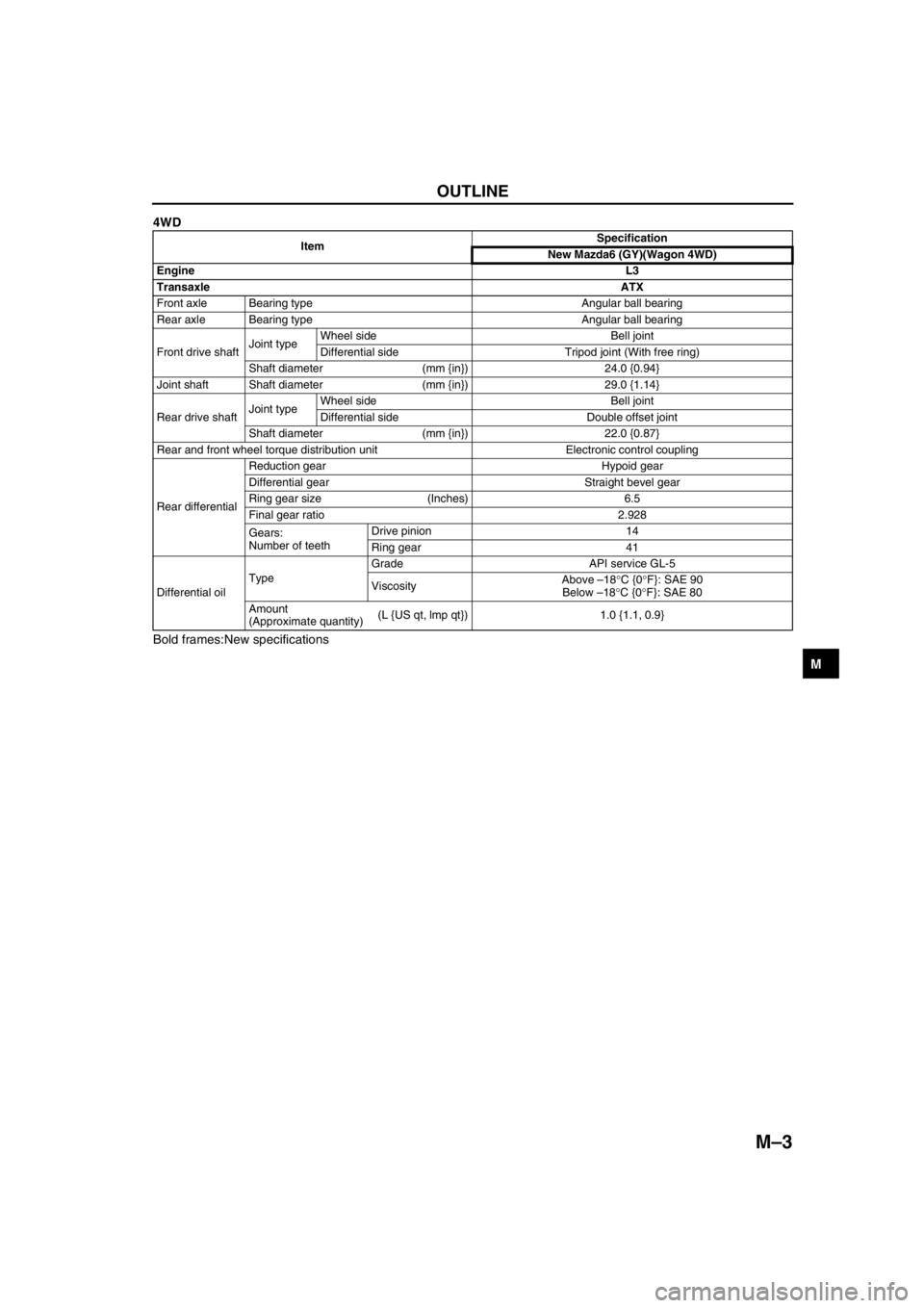

4WD

Bold frames:New specifications

End Of Sie

ItemSpecification

New Mazda6 (GY)(Wagon 4WD)

EngineL3

TransaxleATX

Front axle Bearing type Angular ball bearing

Rear axle Bearing type Angular ball bearing

Front drive shaftJoint typeWheel side Bell joint

Differential side Tripod joint (With free ring)

Shaft diameter (mm {in}) 24.0 {0.94}

Joint shaft Shaft diameter (mm {in}) 29.0 {1.14}

Rear drive shaftJoint typeWheel side Bell joint

Differential side Double offset joint

Shaft diameter (mm {in}) 22.0 {0.87}

Rear and front wheel torque distribution unit Electronic control coupling

Rear differentialReduction gear Hypoid gear

Differential gear Straight bevel gear

Ring gear size (Inches) 6.5

Final gear ratio 2.928

Gears:

Number of teethDrive pinion 14

Ring gear 41

Differential oilTypeGrade API service GL-5

ViscosityAbove –18°C {0°F}: SAE 90

Below –18°C {0°F}: SAE 80

Amount

(Approximate quantity)(L {US qt, lmp qt}) 1.0 {1.1, 0.9}