tow MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 622 of 909

L–6

PROPELLER SHAFT

Nut Removal Note

Caution

•Do not mark with the ponch to prevent unbalance.

1. Before removing the nut, put marks on the front

companion flange, tripod joint and the rear

companion flange, rear universal joint yoke for

proper reinstallation.

Propeller Shaft Heat Shield Installation Note

Caution

•When assembling the propeller shaft heat shield to the bearing support, narrowing the bolt hole

inner diameter can lower serviceability. Align the bolt hole edge of the propeller shaft heat shield

with the bolt hole inner side of the bearing support to assemble.

1. Set the propeller shaft heat shield to the bearing

support.

Front side

Rear side

2. Bend the edges of the propeller shaft heat shield

toward the bearing support as shown.

A6J6110W006

OK NGBOLT HOLE OF

PROPELLER SHAFT HEAT SHIELD

BOLT HOLE OF

BEARING SUPPORT

A6E6110W022

PROPELLER SHAFT

HEAT SHIELDBEARING SUPPORT

EDGE

4.5—4.7

mm

A6E6110W016

4.5—4.7

mm

PROPELLER SHAFT

HEAT SHIELDBEARING SUPPORT

EDGE

A6E6110W017

Page 641 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–11

M

4WD solenoid control current is ON

•When the 4WD solenoid control current is ON, current flows from the 4WD CM to the 4WD solenoid, and the

coupling operates in the following manner.

1. Magnetic flux forms at the electromagnetic coil of the 4WD solenoid.

2. Due to the magnetic flux in the armature, the pilot clutch is suctioned towards the magnetic coil side and

made to engage. This causes frictional torque to generate in the pilot clutch.

3. The torque is transmitted to the pilot cam, which is engaged with the pilot clutch.

4. A rotational difference is created between the pilot cam and the main cam. Due to this relative torsion, the

cam mechanism operates, transmitting torque from the pilot cam to the ball and then to the main cam. In

this way, the push force exerted on the main clutch is amplified.

5. As the main clutch engages, the drive torque from the front wheels is transmitted to the rear wheels.

•The amount of push force exerted on the main clutch by the main cam (that is, the strength of the drive torque

transmitted to the rear wheels) changes in accordance with the proportion of the force acting upon the pilot

cam, engaged with the pilot clutch. Therefore, by changing the periodicity of the electric current from the 4WD

CM to the 4WD solenoid (ON/OFF rate of the 4WD solenoid = force acting on the pilot cam), the module

controls the transmission of drive torque to the rear wheels.

.

End Of Sie

98

75

4

3

10

11

6

12

56

7

12

A6E63222005

1 Main clutch

2Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)

5Main cam

6Pilot cam7Ball

8Armature

9 Drive torque

10 Magnetic flux

11 Input

12 Output

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

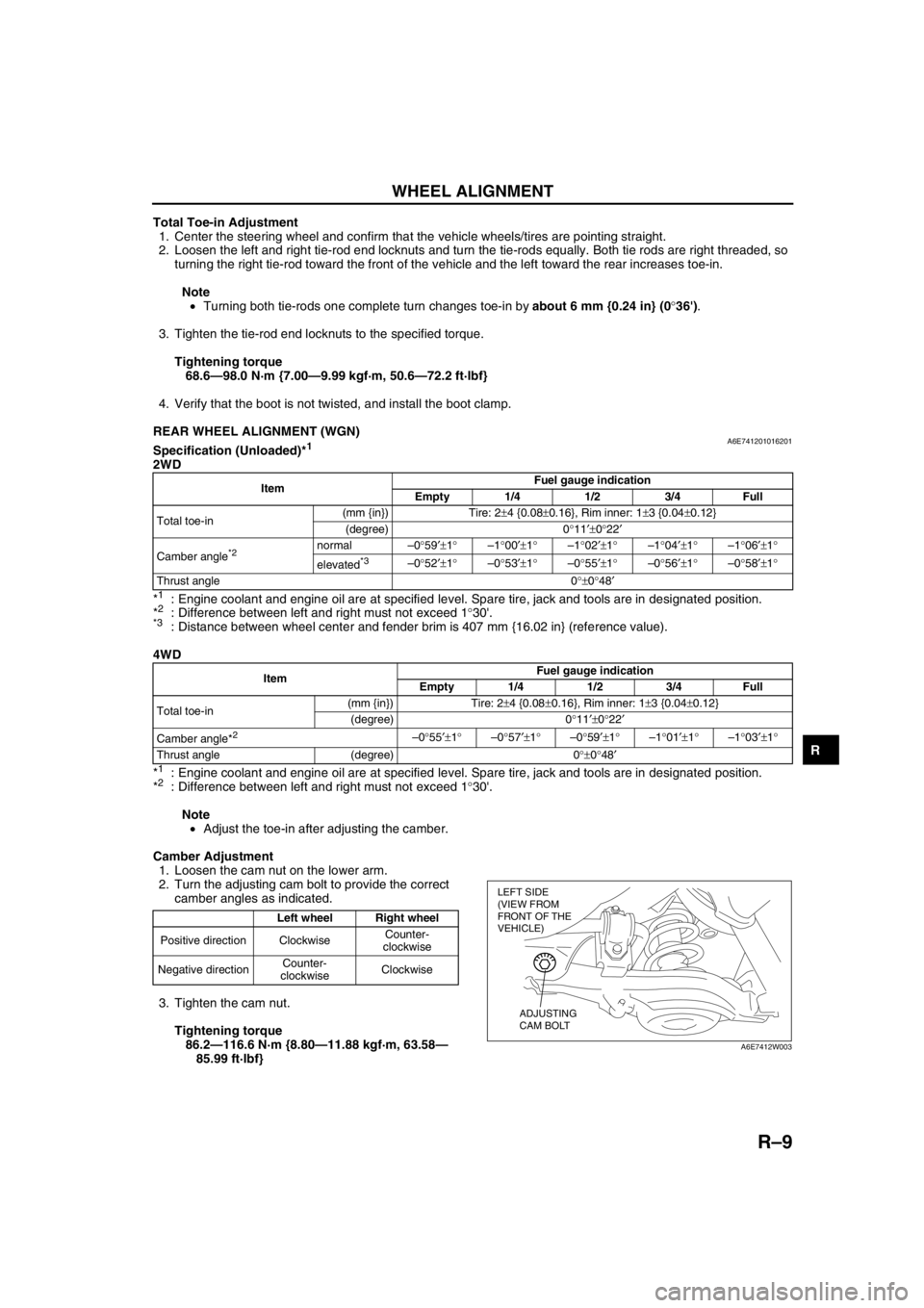

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 803 of 909

S–22

TRIM

3. Remove the screw, then remove the bracket.

4. Remove the cargo hooks.

5. Remove the fasteners, then remove the trunk

side trim.

6. Install in the reverse order of removal.

End Of Sie

TRUNK SIDE UPPER TRIM REMOVAL/INSTALLATIONA6E774468860202WGN

1. Remove the tire house trim.

2. Remove the rear seat remote lever.

3. Remove the cargo hooks.

4. Remove the screw.

5. Pull the trunk side upper trim toward you, then

remove the hooks A, C, D and clips B, pin E from

the body.

6. Remove the trunk side upper trim.

7. Install in the reverse order of removal.

End Of Sie

FASTENER

TRUNK SIDE TRIM

CARGO HOOK FRONT

SCREW

BRACKET

A6E77441106

B AD C

A B

C

ED

SCREW TRUNK SIDE UPPER TRIM

CARGO HOOK FRONT

HOOK C

HOOK D HOOK A

PIN E CLIP B

A6A7744W107

Page 804 of 909

TRIM

S–23

S

TRUNK END TRIM REMOVAL/INSTALLATIONA6E774468890201WGN

1. Pull the trunk end trim upward, then disengage

clips A and pins B from the body.

2. Remove the trunk end trim.

3. Install in the reverse order of removal.

End Of Sie

LIFTGATE UPPER TRIM REMOVAL/INSTALLATIONA6E774468930201WGN

Without rear spoiler

Caution

•Removing the liftgate upper trim by pulling on the middle section of the trim could damage the

high-mount brake light. When removing the trim, be sure to pull on the side edges of the trim only.

1. Pull the liftgate upper trim on the side edges

towards you, then disengage pins A from the

body.

2. Pull the middle section of the trim towards you

and disengage clips B and pin C from the body.

3. Remove the liftgate upper trim.

4. Install in the reverse order of removal.

With rear spoiler

1. Pull the liftgate upper trim toward you, then

disengage the pin A, C and clip B from the body.

2. Remove the liftgate upper trim.

3. Install in the reverse order of removal.

End Of Sie

AB

A

A

B

A

A

A B

TRUNK END TRIM

PIN B

CLIP A

A6A7744W108

AC B

AB

CLIP B

PIN A LIFTGATE UPPER TRIM

PIN C

A6A7744W109

ABAB

C

CLIP BPIN C LIFTGATE UPPER TRIM

PIN A

A6A7744W110

Page 805 of 909

S–24

TRIM

LIFTGATE SIDE TRIM REMOVAL/INSTALLATIONA6E774468940201WGN

1. Remove the liftgate upper trim. (SeeS–23 LIFTGATE UPPER TRIM REMOVAL/INSTALLATION)

2. Remove the fastener.

3. Pull the liftgate side trim toward you, then

disengage the clips A and hook B, C from the

body.

4. Remove the liftgate side trim.

5. Install in the reverse order of removal.

End Of Sie

LIFTGATE LOWER TRIM REMOVAL/INSTALLATIONA6E774468960201WGN

1. Remove the liftgate upper trim. (SeeS–23 LIFTGATE UPPER TRIM REMOVAL/INSTALLATION)

2. Remove the liftgate side trim.

3. Pull the handle toward you, then remove it.

4. Pull the liftgate lower trim toward you, then

disengage the clips A and pins B, C from the

body.

5. Remove the liftgate lower trim.

6. Install in the reverse order of removal.

End Of Sie

AAC

BHOOK C

CLIP AHOOK B

FASTENERLIFTGATE SIDE TRIM

A6A7744W111

HANDLE

LIFTGATE

LOWER TRIM

A6A7744W112

AC B

A

A

AB

AA A A

A A A

CLIP A LIFTGATE

LOWER TRIM

PIN C

PIN B

A6A7744W113