warning MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 83 of 909

E–8

ENGINE COOLANT

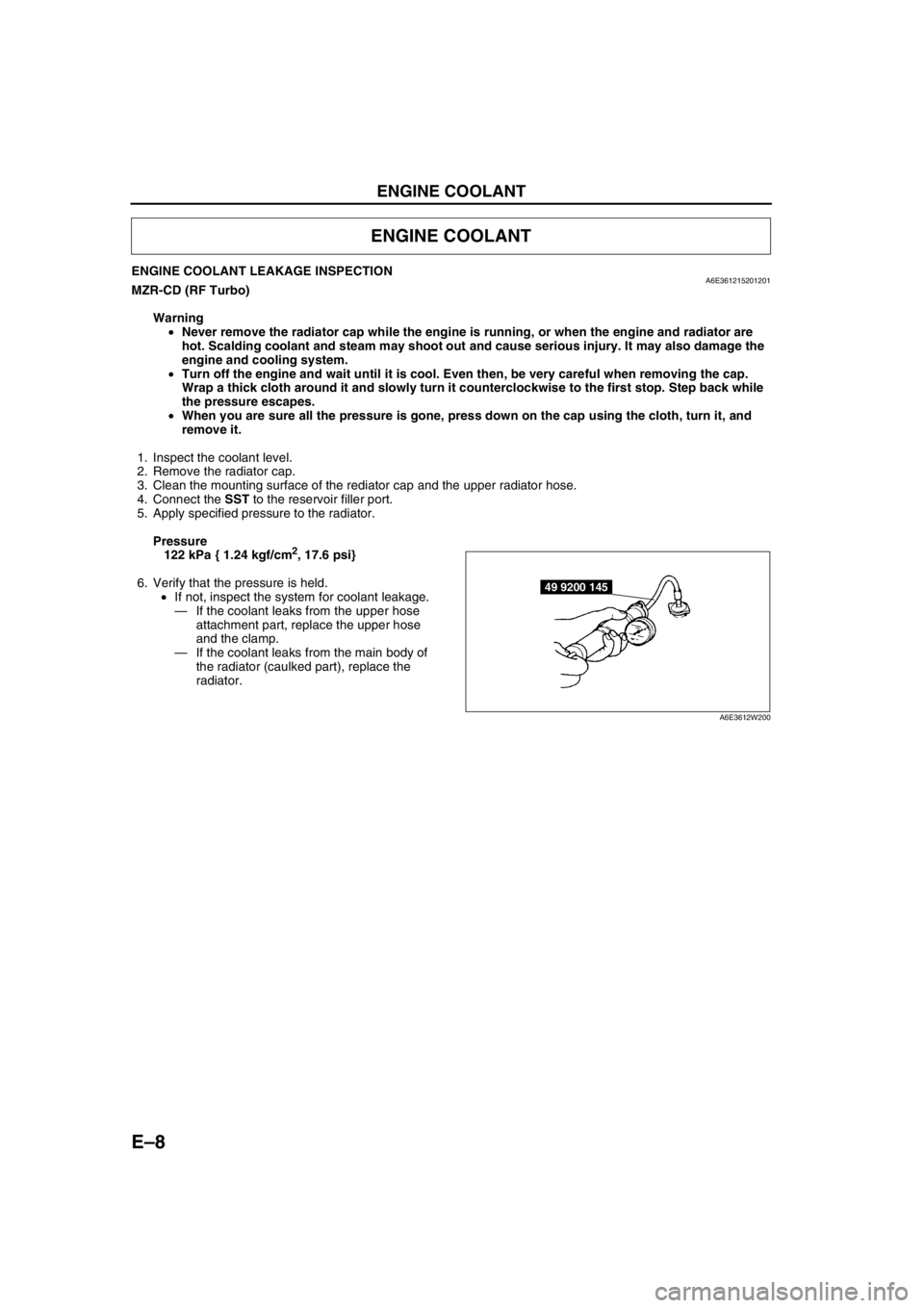

ENGINE COOLANT LEAKAGE INSPECTIONA6E361215201201MZR-CD (RF Turbo)

Warning

•Never remove the radiator cap while the engine is running, or when the engine and radiator are

hot. Scalding coolant and steam may shoot out and cause serious injury. It may also damage the

engine and cooling system.

•Turn off the engine and wait until it is cool. Even then, be very careful when removing the cap.

Wrap a thick cloth around it and slowly turn it counterclockwise to the first stop. Step back while

the pressure escapes.

•When you are sure all the pressure is gone, press down on the cap using the cloth, turn it, and

remove it.

1. Inspect the coolant level.

2. Remove the radiator cap.

3. Clean the mounting surface of the rediator cap and the upper radiator hose.

4. Connect the SST to the reservoir filler port.

5. Apply specified pressure to the radiator.

Pressure

122 kPa { 1.24 kgf/cm

2, 17.6 psi}

6. Verify that the pressure is held.

•If not, inspect the system for coolant leakage.

—If the coolant leaks from the upper hose

attachment part, replace the upper hose

and the clamp.

—If the coolant leaks from the main body of

the radiator (caulked part), replace the

radiator.

End Of Sie

ENGINE COOLANT

49 9200 145

A6E3612W200

Page 109 of 909

CONTROL SYSTEM

F1–21

F1

CONTROLLER AREA NETWORK (CAN)A6E394018880205•PCM transmit/received the information in the CAN. For detail information of the CAN, see the “MULTIPLEX

COMMUNICATION SYSTEM.” (See T–3 OUTLINE.)

Transmit Information (4WD ATX Model)

•Engine control condition

•Torque reduction inhibit

•Engine speed

•Vehicle Speed

•TP

•Engine torque (without torque reduction)

•Engine torque (with torque reduction)

•Battery reconnection

•Engine loss torque

•ECT

•Travelled distance

•Fuel injection information

•MIL condition

•Generator warning light conditions

•Engine displacement

•Number of cylinders

•Air induction type

•Fuel type and delivery

•Country

•Transmission/axle type

•Tire circumference (front/rear)

Received Information (4WD ATX Model)

From ABS HU/CM, ABS/TCS HU/CM, or DSC HU/CM

•Wheel speed

—Front left, Front right, Rear left, and Rear right

•Travelled distance

•Brake system status

•Torque reduction request

•Brake system configuration

From TCM

•Desired torque

•Upper torque limit

•Turbineshaft speed

•Vehicle speed

•Torque reduction request

•Idle speed up request

•Racing select determination

•MIL indicate request

•Desired gear/selector lever position

•AT warning indicator light condition

•TCC condition

End Of Sie

Page 111 of 909

FUEL SYSTEM

F1–23

F1

FUEL TANK REMOVAL/INSTALLATIONA6E391242110201

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

1. Level the vehicle.

2. Complete the “BEFORE REPAIR PROCEDURE”.

3. Disconnect the negative battery cable.

4. Remove the fuel pump unit. (See F1–26 FUEL PUMP UNIT REMOVAL/INSTALLATION.)

5. Remove the fuel gauge sender sub-unit. (See T–27 Fuel Gauge Sender Sub-Unit.)

6. Siphon the fuel from the service hole.

7. Remove the presilencer. (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the TWC. (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

9. Remove the propeller shaft. (See L–5 PROPELLER SHAFT REMOVAL/INSTALLATION.)

FUEL SYSTEM

Page 114 of 909

F1–26

FUEL SYSTEM

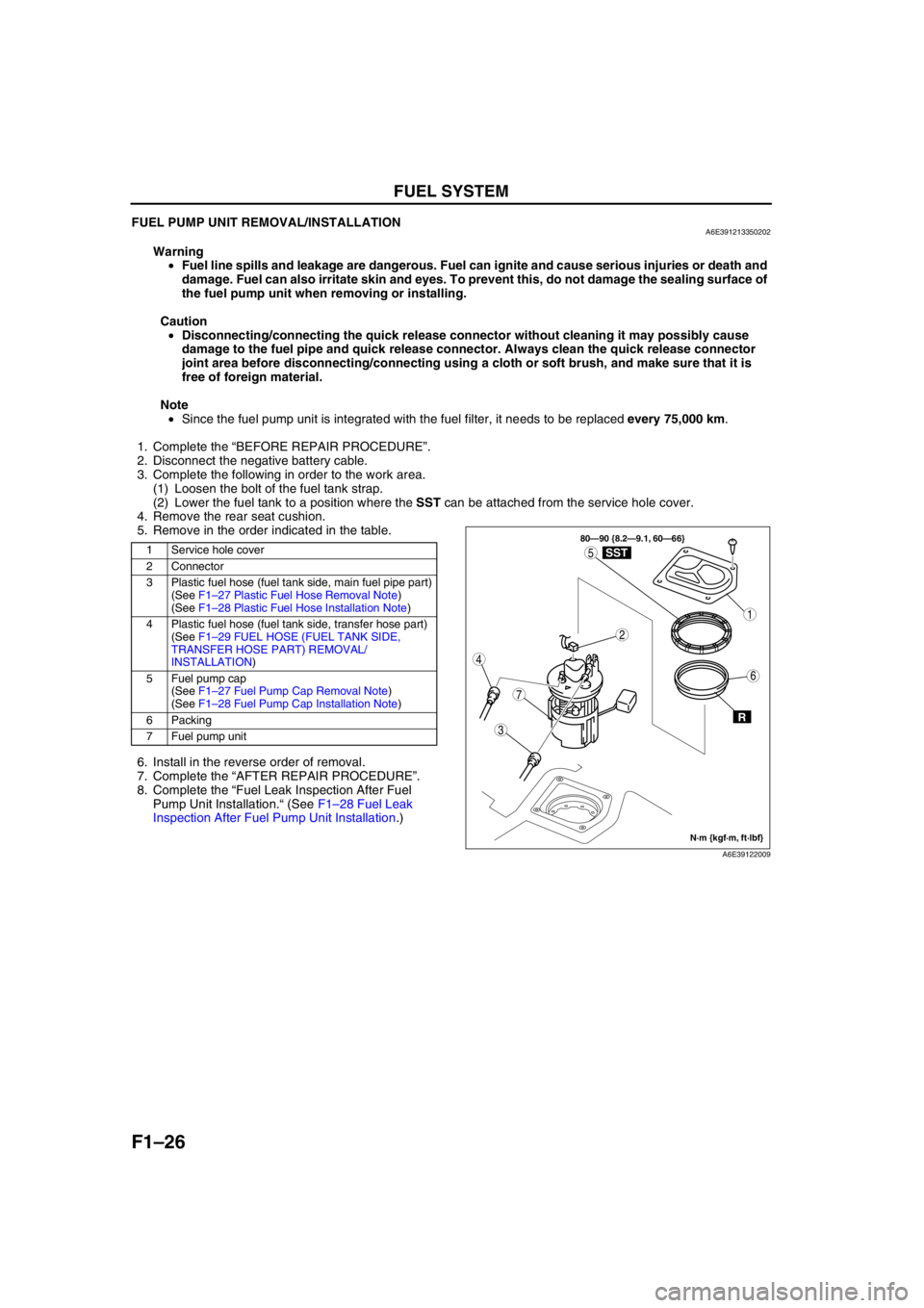

FUEL PUMP UNIT REMOVAL/INSTALLATIONA6E391213350202

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

•Since the fuel pump unit is integrated with the fuel filter, it needs to be replaced every 75,000 km.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel Leak Inspection After Fuel

Pump Unit Installation.“ (See F1–28 Fuel Leak

Inspection After Fuel Pump Unit Installation.)

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, main fuel pipe part)

(See F1–27 Plastic Fuel Hose Removal Note)

(See F1–28 Plastic Fuel Hose Installation Note)

4 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

5Fuel pump cap

(See F1–27 Fuel Pump Cap Removal Note)

(See F1–28 Fuel Pump Cap Installation Note)

6 Packing

7 Fuel pump unit

3

7

1

4

5

2

6

80—90 {8.2—9.1, 60—66}

R

SST

N·m {kgf·m, ft·lbf}

A6E39122009

Page 117 of 909

FUEL SYSTEM

F1–29

F1

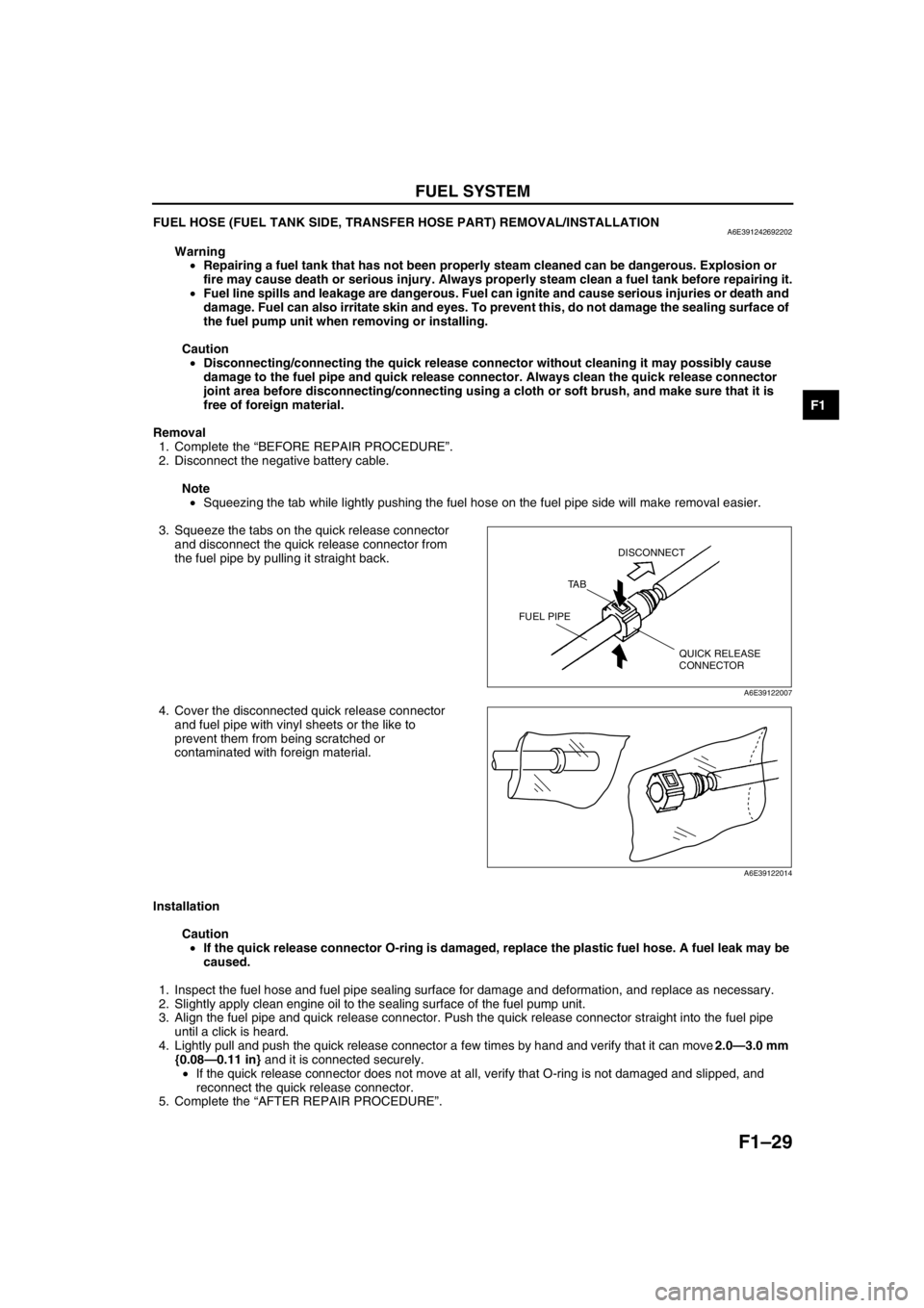

FUEL HOSE (FUEL TANK SIDE, TRANSFER HOSE PART) REMOVAL/INSTALLATIONA6E391242692202

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Removal

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

Note

•Squeezing the tab while lightly pushing the fuel hose on the fuel pipe side will make removal easier.

3. Squeeze the tabs on the quick release connector

and disconnect the quick release connector from

the fuel pipe by pulling it straight back.

4. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Installation

Caution

•If the quick release connector O-ring is damaged, replace the plastic fuel hose. A fuel leak may be

caused.

1. Inspect the fuel hose and fuel pipe sealing surface for damage and deformation, and replace as necessary.

2. Slightly apply clean engine oil to the sealing surface of the fuel pump unit.

3. Align the fuel pipe and quick release connector. Push the quick release connector straight into the fuel pipe

until a click is heard.

4. Lightly pull and push the quick release connector a few times by hand and verify that it can move 2.0—3.0 mm

{0.08—0.11 in} and it is connected securely.

•If the quick release connector does not move at all, verify that O-ring is not damaged and slipped, and

reconnect the quick release connector.

5. Complete the “AFTER REPAIR PROCEDURE”.

End Of Sie

QUICK RELEASE

CONNECTOR TA BDISCONNECT

FUEL PIPE

A6E39122007

A6E39122014

Page 118 of 909

F1–30

EXHAUST SYSTEM

EXHAUST SYSTEM REMOVAL/INSTALLATIONA6E391440000203

Warning

•When the engine and exhaust system are hot, they can badly burn. Turn off the engine and wait

until they are cool before removing the exhaust system.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

.

EXHAUST SYSTEM

R

37.3—52.0

{3.9—5.3, 28—38} 40—55

{4.1—5.6, 30—40} 43—64

{4.4—6.5, 32—47}

2

1

R

R

R

7

4

36

5

8

RA

SST

29—49 {3.0—4.9, 22—36}SST

R

A

10

38—51 {3.9—5.2, 29—37}N·m {kgf·m, ft·lbf} 38—51 {3.9—5.2, 29—37} 38—51 {3.9—5.2, 29—37} 38—51 {3.9—5.2, 29—37} 7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf}

7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf} 7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf} 29—49 {3.0—4.9, 22—36}

9

A6E39142004

Page 122 of 909

F1–34

CONTROL SYSTEM

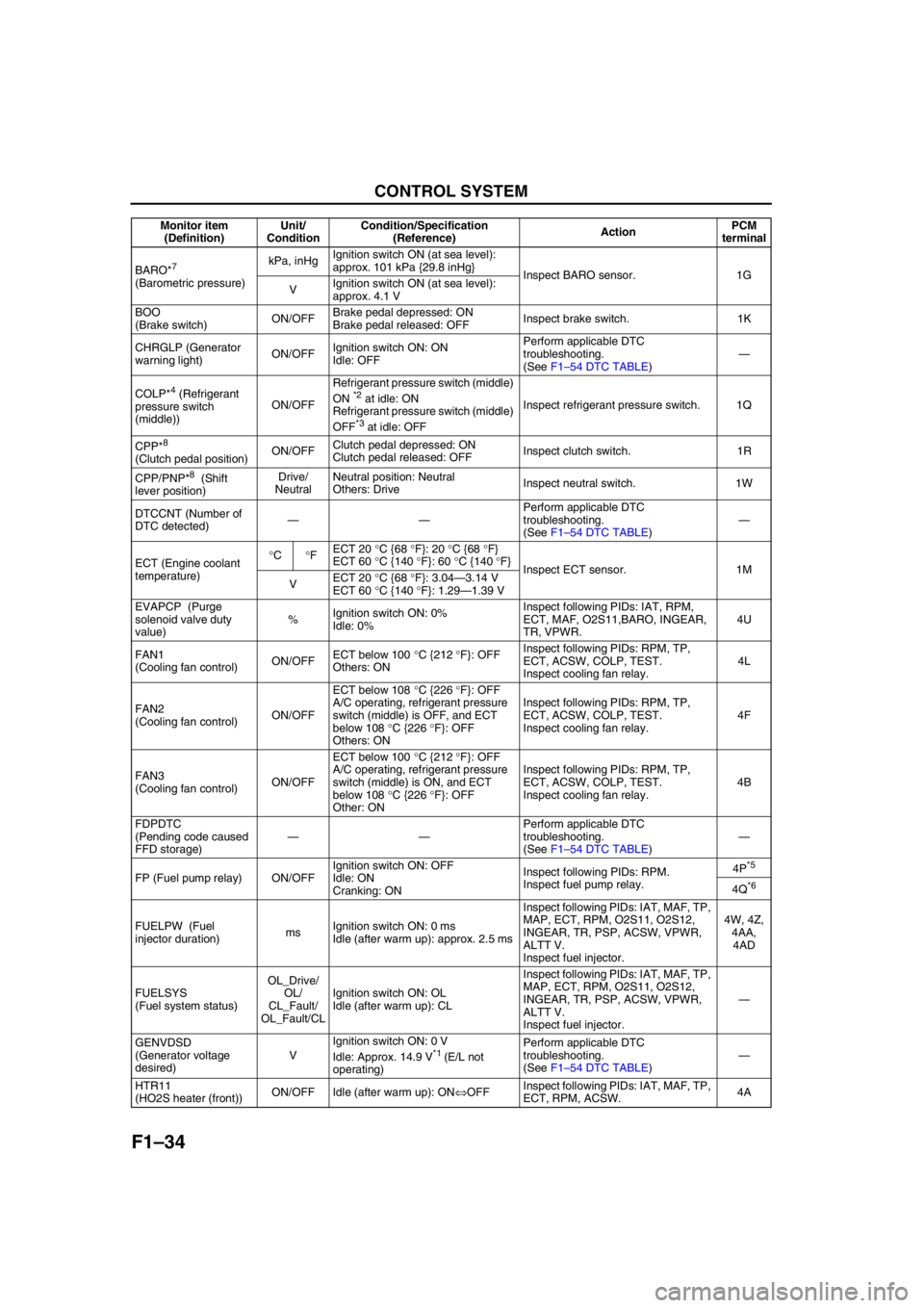

BARO*7

(Barometric pressure)kPa, inHgIgnition switch ON (at sea level):

approx. 101 kPa {29.8 inHg}

Inspect BARO sensor. 1G

VIgnition switch ON (at sea level):

approx. 4.1 V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Brake pedal released: OFFInspect brake switch. 1K

CHRGLP (Generator

warning light)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

COLP*

4 (Refrigerant

pressure switch

(middle))ON/OFFRefrigerant pressure switch (middle)

ON *2 at idle: ON

Refrigerant pressure switch (middle)

OFF

*3 at idle: OFFInspect refrigerant pressure switch. 1Q

CPP*

8

(Clutch pedal position)ON/OFFClutch pedal depressed: ON

Clutch pedal released: OFFInspect clutch switch. 1R

CPP/PNP*

8 (Shift

lever position)Drive/

NeutralNeutral position: Neutral

Others: DriveInspect neutral switch. 1W

DTCCNT (Number of

DTC detected)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

ECT (Engine coolant

temperature)°C°FECT 20 °C {68 °F}: 20 °C {68 °F}

ECT 60 °C {140 °F}: 60 °C {140 °F}

Inspect ECT sensor. 1M

VECT 20 °C {68 °F}: 3.04—3.14 V

ECT 60 °C {140 °F}: 1.29—1.39 V

EVAPCP (Purge

solenoid valve duty

value)%Ignition switch ON: 0%

Idle: 0%Inspect following PIDs: IAT, RPM,

ECT, MAF, O2S11,BARO, INGEAR,

TR, VPWR.4U

FAN1

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4L

FAN2

(Cooling fan control)ON/OFFECT below 108 °C {226 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is OFF, and ECT

below 108 °C {226 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4F

FAN3

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is ON, and ECT

below 108 °C {226 °F}: OFF

Other: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4B

FDPDTC

(Pending code caused

FFD storage)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

FP (Fuel pump relay) ON/OFFIgnition switch ON: OFF

Idle: ON

Cranking: ONInspect following PIDs: RPM.

Inspect fuel pump relay.4P

*5

4Q*6

FUELPW (Fuel

injector duration)msIgnition switch ON: 0 ms

Idle (after warm up): approx. 2.5 msInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.4W, 4Z,

4AA,

4AD

FUELSYS

(Fuel system status)OL_Drive/

OL/

CL_Fault/

OL_Fault/CLIgnition switch ON: OL

Idle (after warm up): CLInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.—

GENVDSD

(Generator voltage

desired)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

HTR11

(HO2S heater (front))ON/OFF Idle (after warm up): ON⇔OFFInspect following PIDs: IAT, MAF, TP,

ECT, RPM, ACSW.4A Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 150 of 909

F1–62

TROUBLESHOOTING

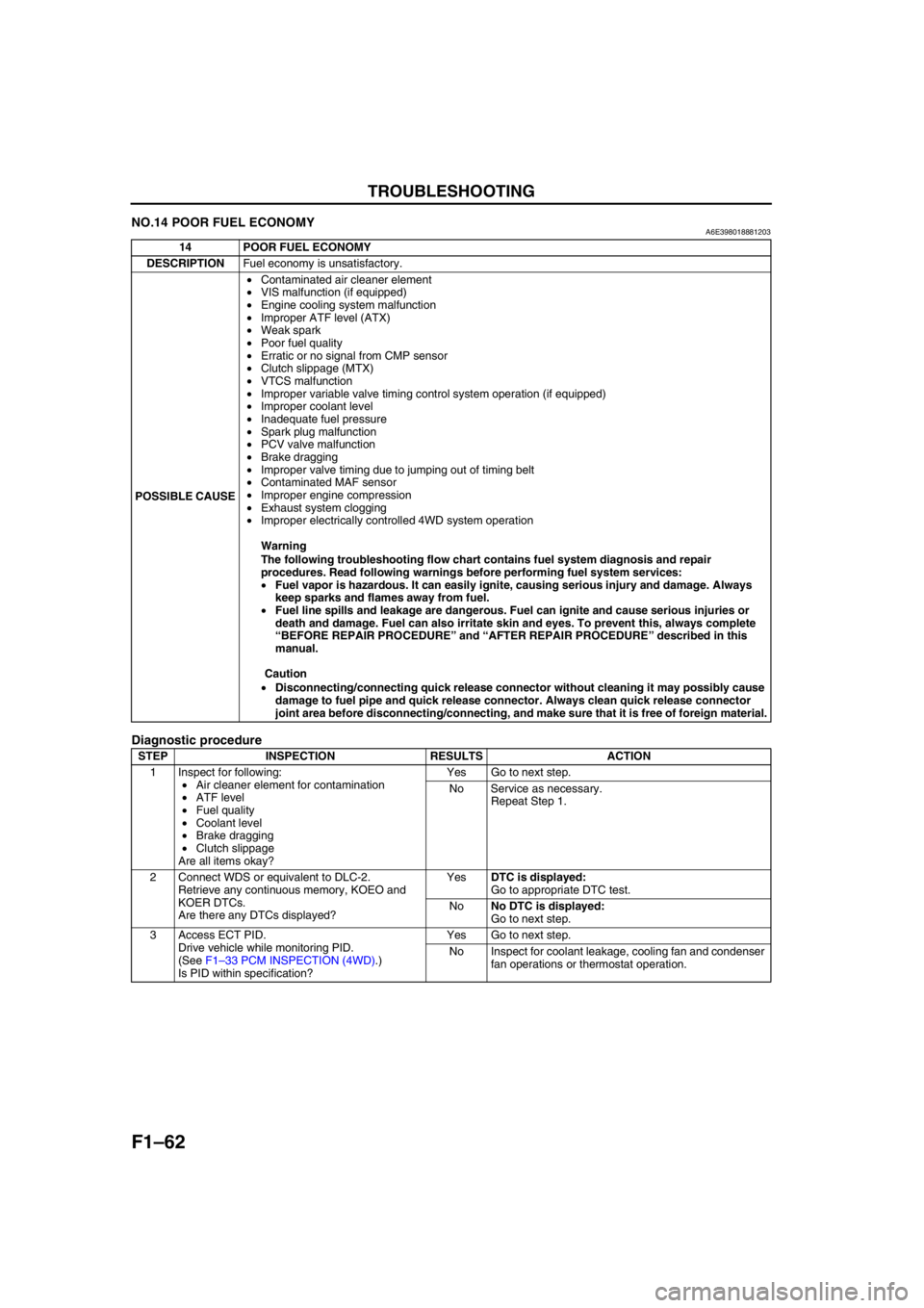

NO.14 POOR FUEL ECONOMYA6E398018881203

Diagnostic procedure

14 POOR FUEL ECONOMY

DESCRIPTIONFuel economy is unsatisfactory.

POSSIBLE CAUSE•Contaminated air cleaner element

•VIS malfunction (if equipped)

•Engine cooling system malfunction

•Improper ATF level (ATX)

•Weak spark

•Poor fuel quality

•Erratic or no signal from CMP sensor

•Clutch slippage (MTX)

•VTCS malfunction

•Improper variable valve timing control system operation (if equipped)

•Improper coolant level

•Inadequate fuel pressure

•Spark plug malfunction

•PCV valve malfunction

•Brake dragging

•Improper valve timing due to jumping out of timing belt

•Contaminated MAF sensor

•Improper engine compression

•Exhaust system clogging

•Improper electrically controlled 4WD system operation

Warning

The following troubleshooting flow chart contains fuel system diagnosis and repair

procedures. Read following warnings before performing fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

Caution

•Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Air cleaner element for contamination

•ATF level

•Fuel quality

•Coolant level

•Brake dragging

•Clutch slippage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?YesDTC is displayed:

Go to appropriate DTC test.

NoNo DTC is displayed:

Go to next step.

3 Access ECT PID.

Drive vehicle while monitoring PID.

(See F1–33 PCM INSPECTION (4WD).)

Is PID within specification?Yes Go to next step.

No Inspect for coolant leakage, cooling fan and condenser

fan operations or thermostat operation.

Page 188 of 909

F2–36

INTAKE-AIR SYSTEM

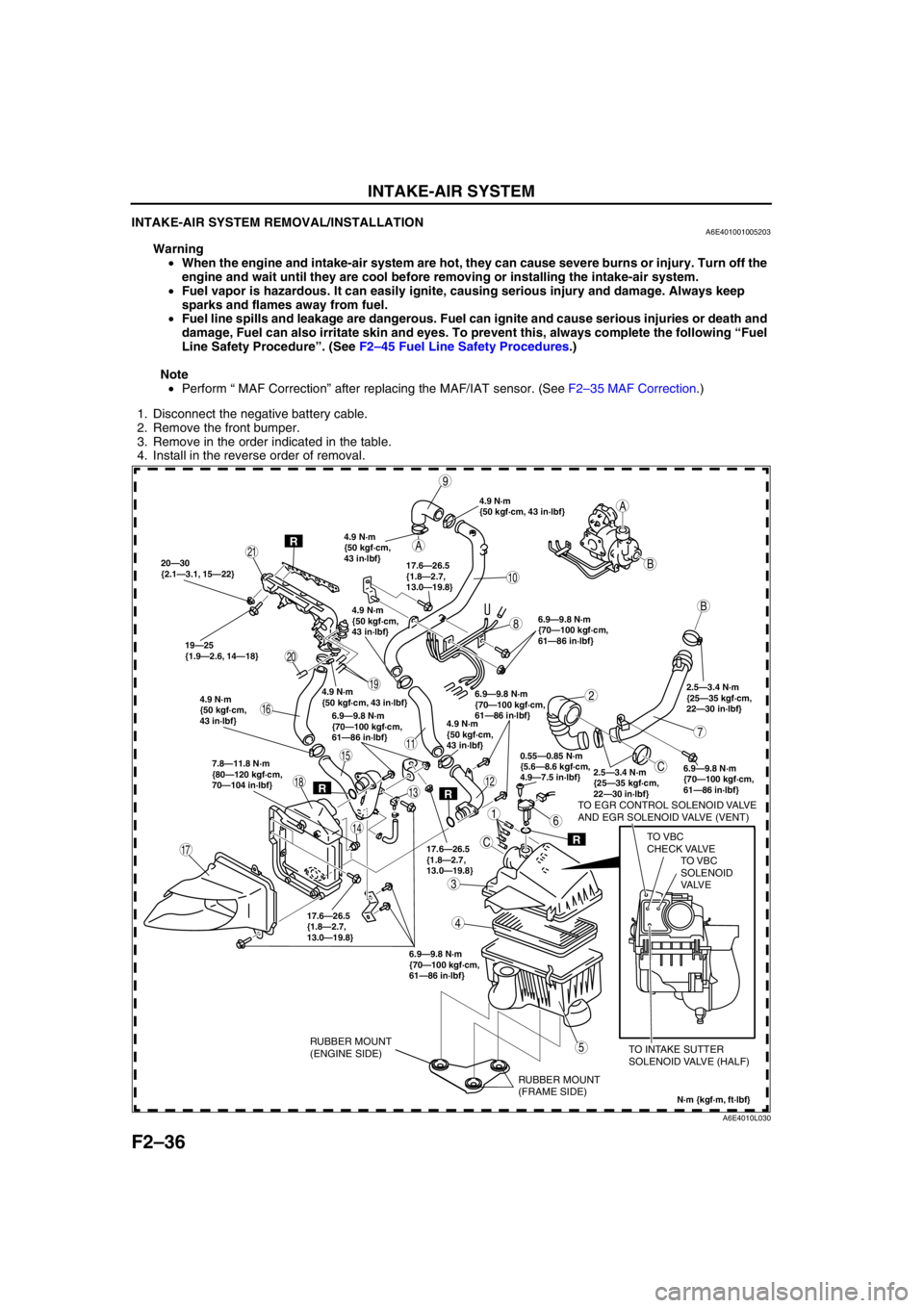

INTAKE-AIR SYSTEM REMOVAL/INSTALLATIONA6E401001005203

Warning

•When the engine and intake-air system are hot, they can cause severe burns or injury. Turn off the

engine and wait until they are cool before removing or installing the intake-air system.

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage, Fuel can also irritate skin and eyes. To prevent this, always complete the following “Fuel

Line Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

Note

•Perform “ MAF Correction” after replacing the MAF/IAT sensor. (See F2–35 MAF Correction.)

1. Disconnect the negative battery cable.

2. Remove the front bumper.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

A

A

C

C

B

B

20—30

{2.1—3.1, 15—22}

19—25

{1.9—2.6, 14—18}6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

2.5—3.4 N·m

{25—35 kgf·cm,

22—30 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf} 7.8—11.8 N·m

{80—120 kgf·cm,

70—104 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf} 17.6—26.5

{1.8—2.7,

13.0—19.8}6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

6.9—9.8 N·m

{70—100 kgf·cm,

61—86 in·lbf}

2.5—3.4 N·m

{25—35 kgf·cm,

22—30 in·lbf}

TO EGR CONTROL SOLENOID VALVE

AND EGR SOLENOID VALVE (VENT)

TO VBC

CHECK VALVE

TO INTAKE SUTTER

SOLENOID VALVE (HALF)

9

10

19

17

11

20

21

1

2

3

5

4

7

6

8

12

14

13

15

16

18

0.55—0.85 N·m

{5.6—8.6 kgf·cm,

4.9—7.5 in·lbf}

N·m {kgf·m, ft·lbf}

R

RR

R

17.6—26.5

{1.8—2.7,

13.0—19.8}17.6—26.5

{1.8—2.7,

13.0—19.8}

4.9 N·m

{50 kgf·cm, 43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm, 43 in·lbf}4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

4.9 N·m

{50 kgf·cm,

43 in·lbf}

RUBBER MOUNT

(FRAME SIDE) RUBBER MOUNT

(ENGINE SIDE)

TO VBC

SOLENOID

VA LV E

A6E4010L030

Page 197 of 909

FUEL SYSTEM

F2–45

F2

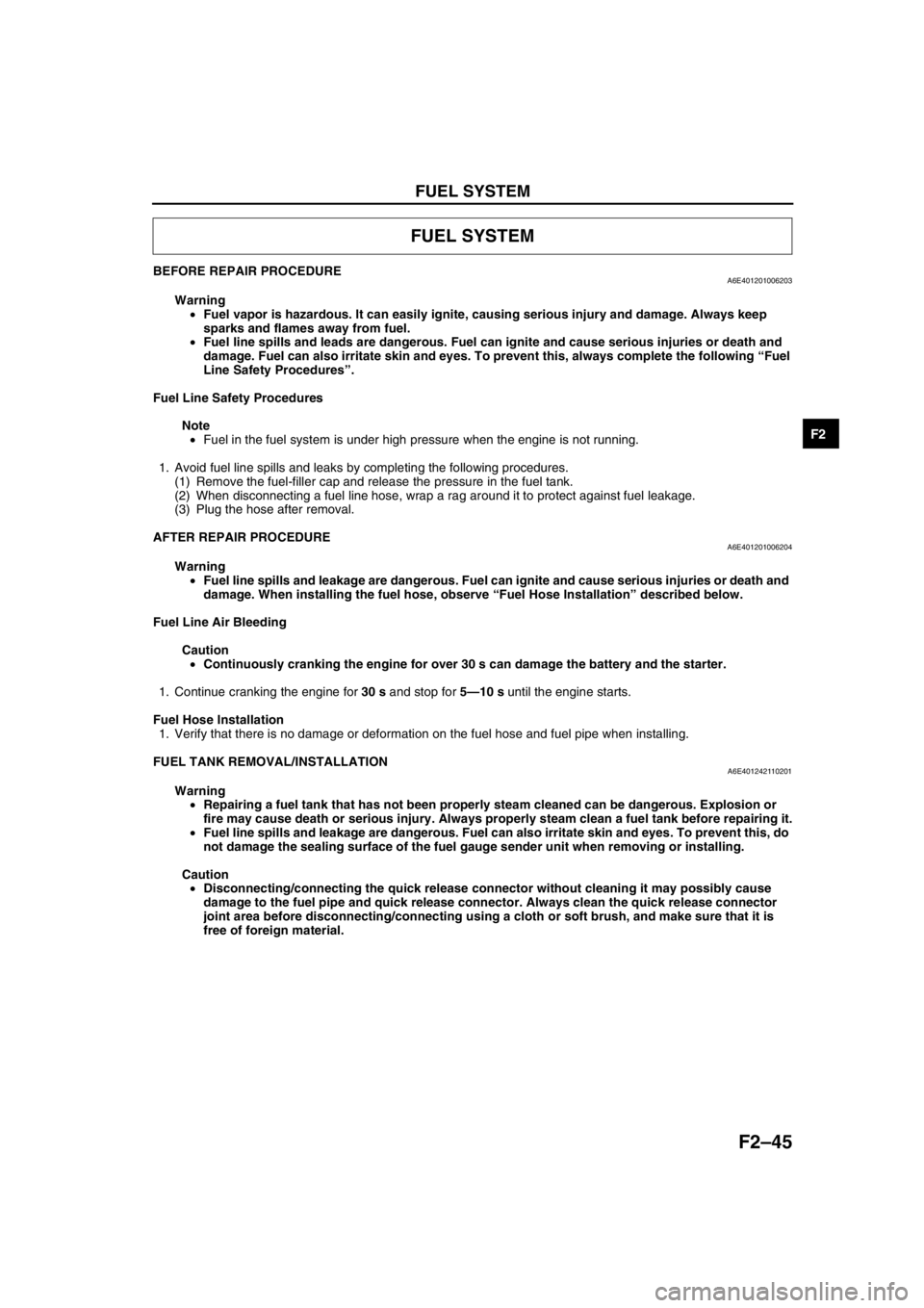

BEFORE REPAIR PROCEDUREA6E401201006203

Warning

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leads are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the following “Fuel

Line Safety Procedures”.

Fuel Line Safety Procedures

Note

•Fuel in the fuel system is under high pressure when the engine is not running.

1. Avoid fuel line spills and leaks by completing the following procedures.

(1) Remove the fuel-filler cap and release the pressure in the fuel tank.

(2) When disconnecting a fuel line hose, wrap a rag around it to protect against fuel leakage.

(3) Plug the hose after removal.

End Of Sie

AFTER REPAIR PROCEDUREA6E401201006204

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. When installing the fuel hose, observe “Fuel Hose Installation” described below.

Fuel Line Air Bleeding

Caution

•Continuously cranking the engine for over 30 s can damage the battery and the starter.

1. Continue cranking the engine for 30 s and stop for 5—10 s until the engine starts.

Fuel Hose Installation

1. Verify that there is no damage or deformation on the fuel hose and fuel pipe when installing.

End Of Sie

FUEL TANK REMOVAL/INSTALLATIONA6E401242110201

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can also irritate skin and eyes. To prevent this, do

not damage the sealing surface of the fuel gauge sender unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

FUEL SYSTEM