sensor MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 478 of 909

AUTOMATIC TRANSAXLE

K2–63

K2

Determination of Torque Converter Clutch (TCC) Cancellation

The TCC control is canceled when any of the following condition are met:

•Engine coolant temperature is low.

•ATF temperature is low.

•Brake switch is on (when depressing the brake pedal).

•Accelerator depressing speed and accelerator opening angle are above the set value.

•Engine speed signal is below the set value.

•Failure is in the TCC control system detected by diagnosis function.

End Of Sie

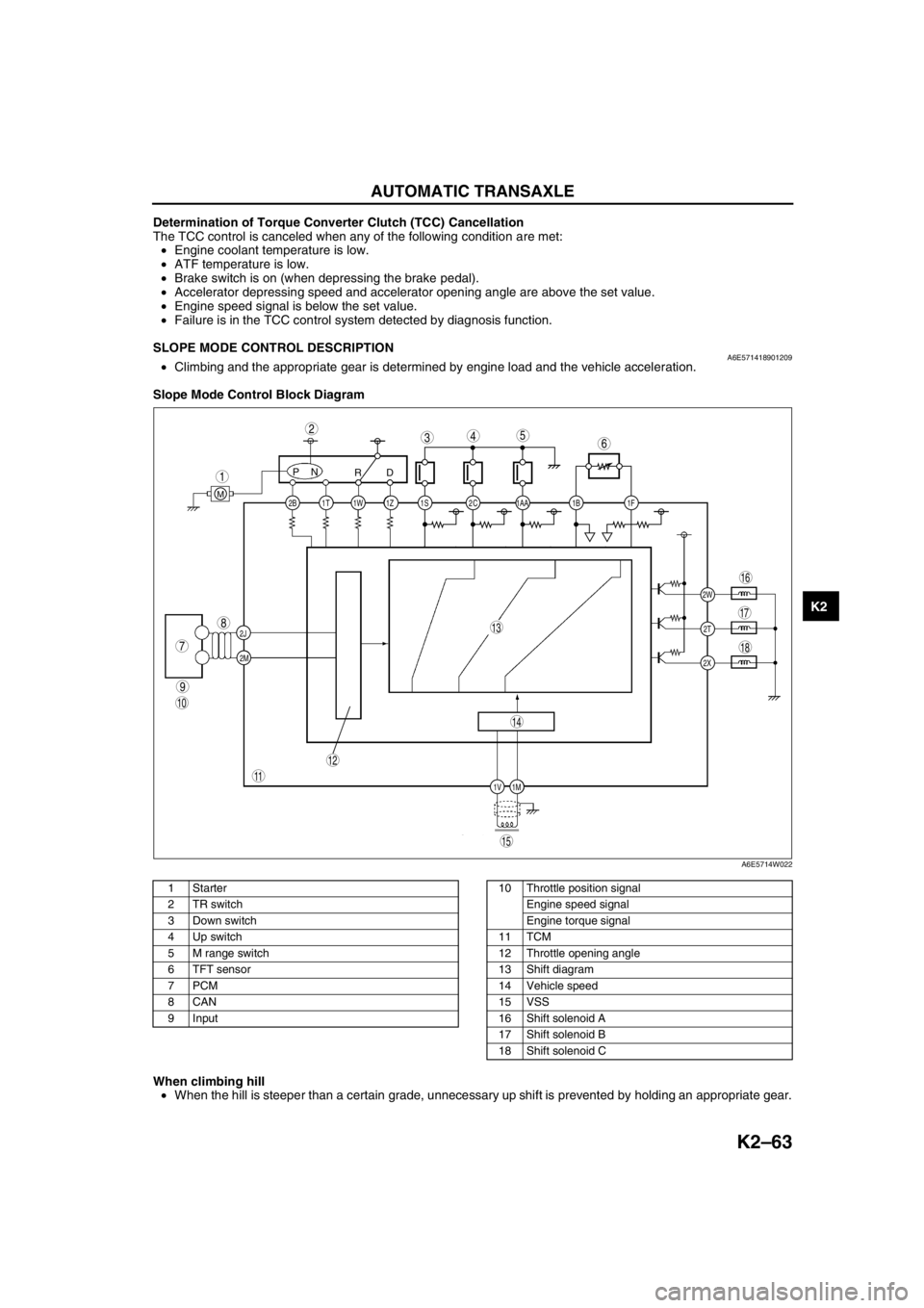

SLOPE MODE CONTROL DESCRIPTIONA6E571418901209•Climbing and the appropriate gear is determined by engine load and the vehicle acceleration.

Slope Mode Control Block Diagram

.

When climbing hill

•When the hill is steeper than a certain grade, unnecessary up shift is prevented by holding an appropriate gear.

End Of Sie

2C 2B

2J

2M1AA 1S 1T 1Z1W 1B 1F

2W

1M 1V2T

2X

PN

RD

M

9

8

7

543

1

2

10

18

17

15

16

14

13

11

12

6

A6E5714W022

1Starter

2 TR switch

3 Down switch

4 Up switch

5 M range switch

6 TFT sensor

7PCM

8CAN

9 Input10 Throttle position signal

Engine speed signal

Engine torque signal

11 TCM

12 Throttle opening angle

13 Shift diagram

14 Vehicle speed

15 VSS

16 Shift solenoid A

17 Shift solenoid B

18 Shift solenoid C

Page 479 of 909

K2–64

AUTOMATIC TRANSAXLE

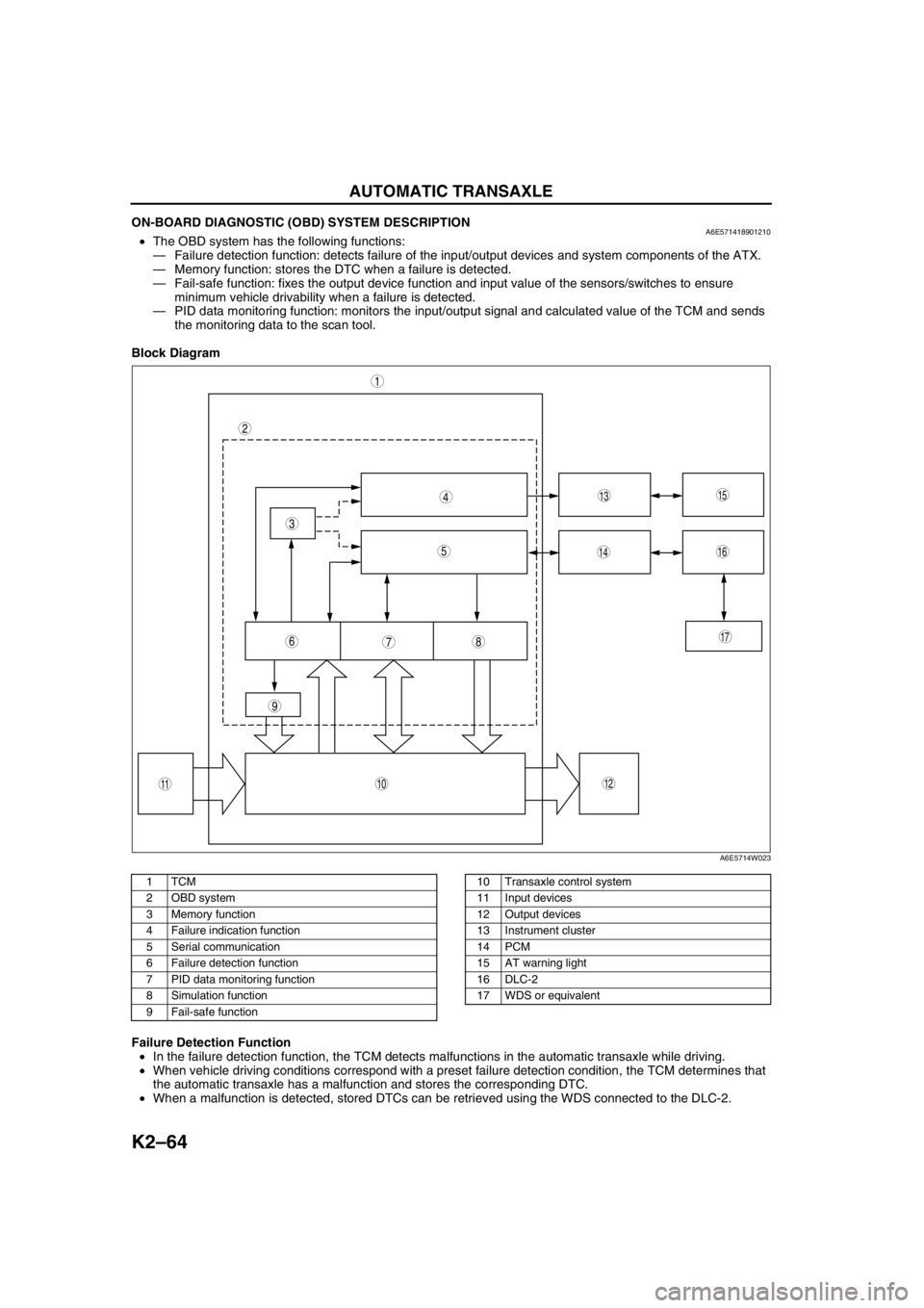

ON-BOARD DIAGNOSTIC (OBD) SYSTEM DESCRIPTIONA6E571418901210•The OBD system has the following functions:

—Failure detection function: detects failure of the input/output devices and system components of the ATX.

—Memory function: stores the DTC when a failure is detected.

—Fail-safe function: fixes the output device function and input value of the sensors/switches to ensure

minimum vehicle drivability when a failure is detected.

—PID data monitoring function: monitors the input/output signal and calculated value of the TCM and sends

the monitoring data to the scan tool.

Block Diagram

.

Failure Detection Function

•In the failure detection function, the TCM detects malfunctions in the automatic transaxle while driving.

•When vehicle driving conditions correspond with a preset failure detection condition, the TCM determines that

the automatic transaxle has a malfunction and stores the corresponding DTC.

•When a malfunction is detected, stored DTCs can be retrieved using the WDS connected to the DLC-2.

9

87

5

4

3

1

2

10

17

15

1614

13

1112

6

A6E5714W023

1TCM

2 OBD system

3 Memory function

4 Failure indication function

5 Serial communication

6 Failure detection function

7 PID data monitoring function

8 Simulation function

9 Fail-safe function10 Transaxle control system

11 Input devices

12 Output devices

13 Instrument cluster

14 PCM

15 AT warning light

16 DLC-2

17 WDS or equivalent

Page 480 of 909

AUTOMATIC TRANSAXLE

K2–65

K2

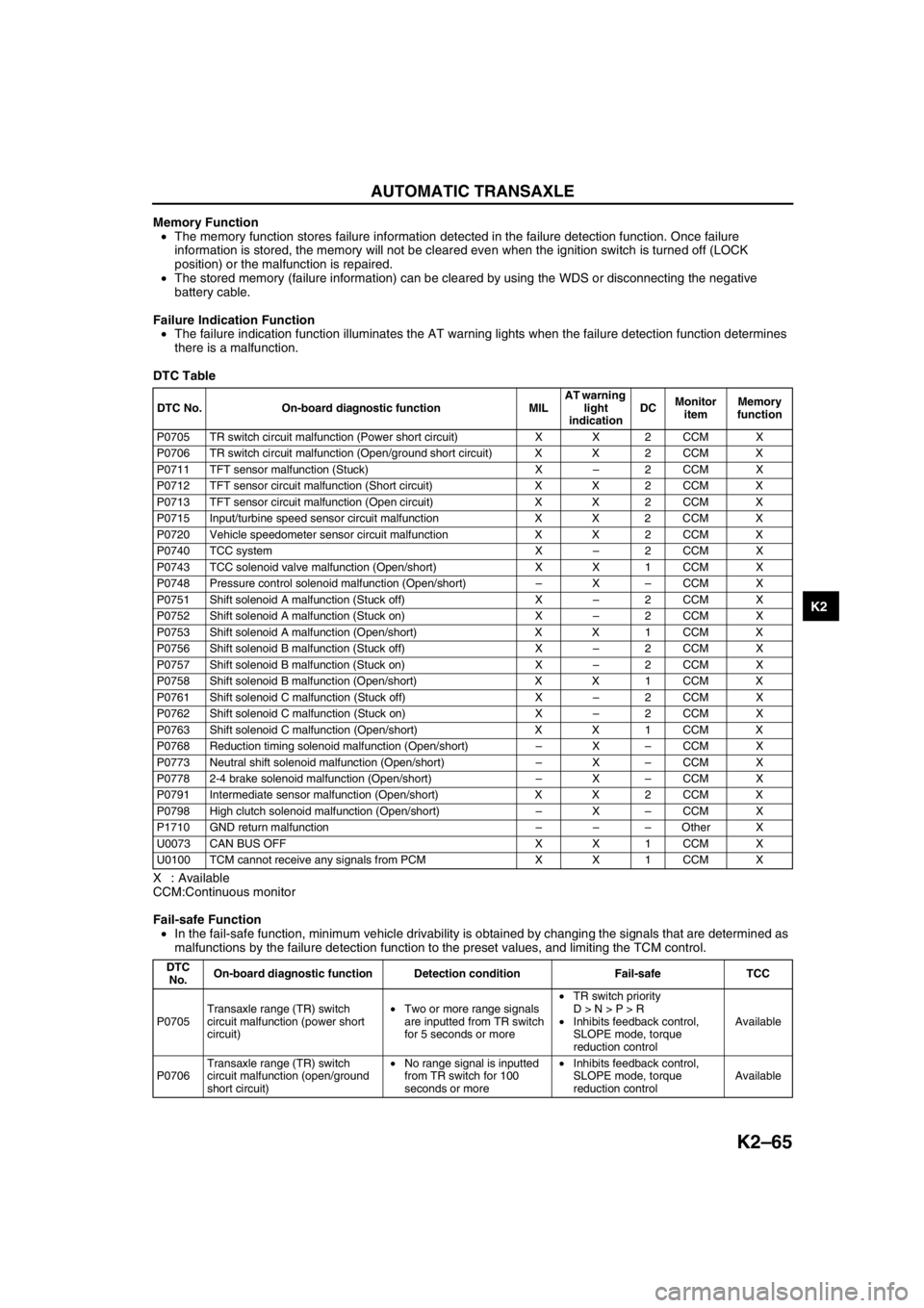

Memory Function

•The memory function stores failure information detected in the failure detection function. Once failure

information is stored, the memory will not be cleared even when the ignition switch is turned off (LOCK

position) or the malfunction is repaired.

•The stored memory (failure information) can be cleared by using the WDS or disconnecting the negative

battery cable.

Failure Indication Function

•The failure indication function illuminates the AT warning lights when the failure detection function determines

there is a malfunction.

DTC Table

X : Available

CCM:Continuous monitor

Fail-safe Function

•In the fail-safe function, minimum vehicle drivability is obtained by changing the signals that are determined as

malfunctions by the failure detection function to the preset values, and limiting the TCM control.

DTC No. On-board diagnostic function MILAT warning

light

indicationDCMonitor

itemMemory

function

P0705 TR switch circuit malfunction (Power short circuit) X X 2 CCM X

P0706 TR switch circuit malfunction (Open/ground short circuit) X X 2 CCM X

P0711 TFT sensor malfunction (Stuck) X–2 CCM X

P0712 TFT sensor circuit malfunction (Short circuit) X X 2 CCM X

P0713 TFT sensor circuit malfunction (Open circuit) X X 2 CCM X

P0715 Input/turbine speed sensor circuit malfunction X X 2 CCM X

P0720 Vehicle speedometer sensor circuit malfunction X X 2 CCM X

P0740 TCC system X–2 CCM X

P0743 TCC solenoid valve malfunction (Open/short) X X 1 CCM X

P0748 Pressure control solenoid malfunction (Open/short)–X–CCM X

P0751 Shift solenoid A malfunction (Stuck off) X–2 CCM X

P0752 Shift solenoid A malfunction (Stuck on) X–2 CCM X

P0753 Shift solenoid A malfunction (Open/short) X X 1 CCM X

P0756 Shift solenoid B malfunction (Stuck off) X–2 CCM X

P0757 Shift solenoid B malfunction (Stuck on) X–2 CCM X

P0758 Shift solenoid B malfunction (Open/short) X X 1 CCM X

P0761 Shift solenoid C malfunction (Stuck off) X–2 CCM X

P0762 Shift solenoid C malfunction (Stuck on) X–2 CCM X

P0763 Shift solenoid C malfunction (Open/short) X X 1 CCM X

P0768 Reduction timing solenoid malfunction (Open/short)–X–CCM X

P0773 Neutral shift solenoid malfunction (Open/short)–X–CCM X

P0778 2-4 brake solenoid malfunction (Open/short)–X–CCM X

P0791 Intermediate sensor malfunction (Open/short) X X 2 CCM X

P0798 High clutch solenoid malfunction (Open/short)–X–CCM X

P1710 GND return malfunction–––Other X

U0073 CAN BUS OFF X X 1 CCM X

U0100 TCM cannot receive any signals from PCM X X 1 CCM X

DTC

No.On-board diagnostic function Detection condition Fail-safe TCC

P0705Transaxle range (TR) switch

circuit malfunction (power short

circuit)•Two or more range signals

are inputted from TR switch

for 5 seconds or more•TR switch priority

D > N > P > R

•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

P0706Transaxle range (TR) switch

circuit malfunction (open/ground

short circuit)•No range signal is inputted

from TR switch for 100

seconds or more•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

Page 481 of 909

K2–66

AUTOMATIC TRANSAXLE

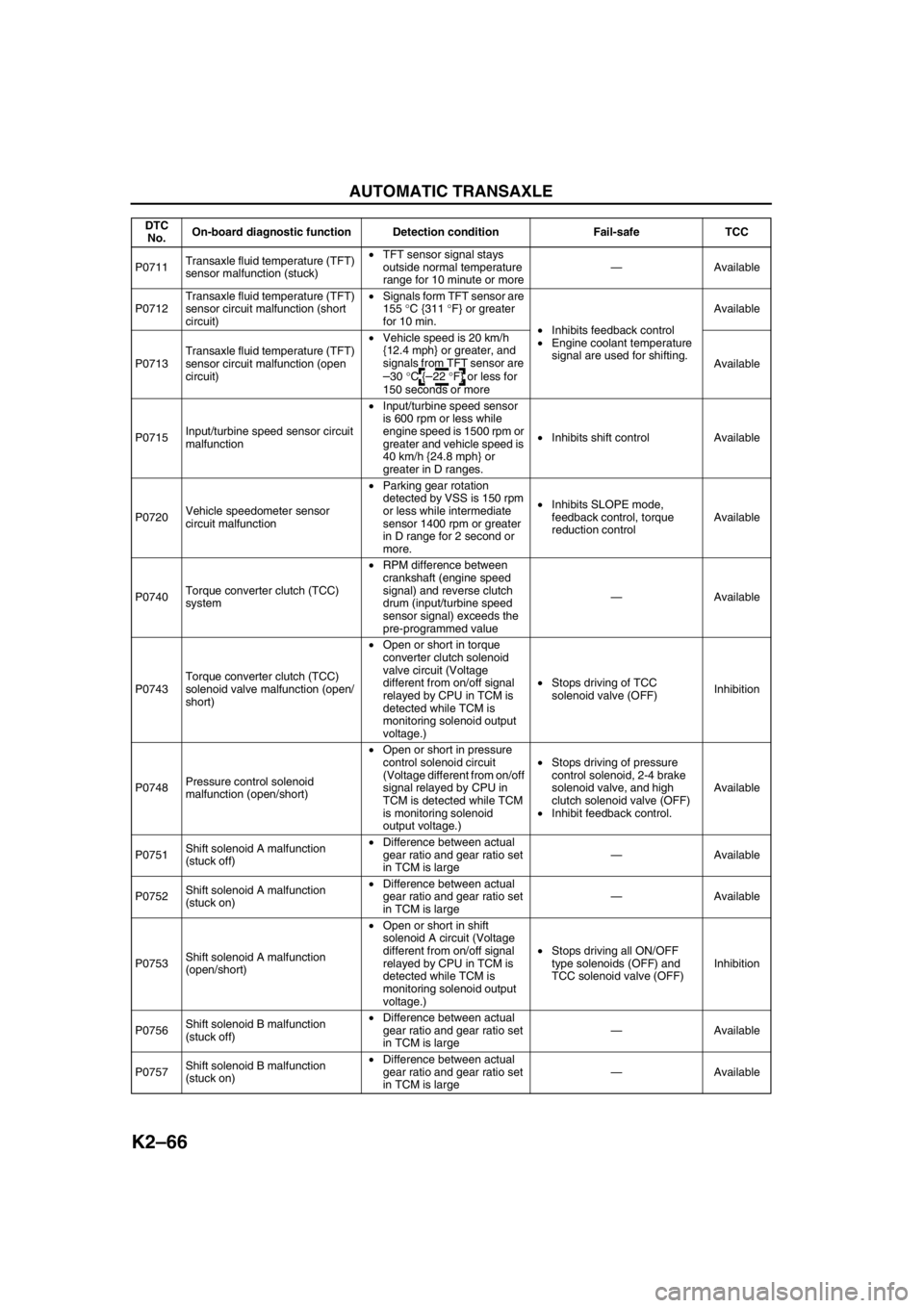

P0711Transaxle fluid temperature (TFT)

sensor malfunction (stuck)•TFT sensor signal stays

outside normal temperature

range for 10 minute or more—Available

P0712Transaxle fluid temperature (TFT)

sensor circuit malfunction (short

circuit)•Signals form TFT sensor are

155 °C {311 °F} or greater

for 10 min.

•Inhibits feedback control

•Engine coolant temperature

signal are used for shifting.Available

P0713Transaxle fluid temperature (TFT)

sensor circuit malfunction (open

circuit)•Vehicle speed is 20 km/h

{12.4 mph} or greater, and

signals from TFT sensor are

–30 °C {–22 °F} or less for

150 seconds or moreAvailable

P0715Input/turbine speed sensor circuit

malfunction•Input/turbine speed sensor

is 600 rpm or less while

engine speed is 1500 rpm or

greater and vehicle speed is

40 km/h {24.8 mph} or

greater in D ranges.•Inhibits shift control Available

P0720Vehicle speedometer sensor

circuit malfunction•Parking gear rotation

detected by VSS is 150 rpm

or less while intermediate

sensor 1400 rpm or greater

in D range for 2 second or

more.•Inhibits SLOPE mode,

feedback control, torque

reduction controlAvailable

P0740Torque converter clutch (TCC)

system•RPM difference between

crankshaft (engine speed

signal) and reverse clutch

drum (input/turbine speed

sensor signal) exceeds the

pre-programmed value—Available

P0743Torque converter clutch (TCC)

solenoid valve malfunction (open/

short)•Open or short in torque

converter clutch solenoid

valve circuit (Voltage

different from on/off signal

relayed by CPU in TCM is

detected while TCM is

monitoring solenoid output

voltage.)•Stops driving of TCC

solenoid valve (OFF)Inhibition

P0748Pressure control solenoid

malfunction (open/short)•Open or short in pressure

control solenoid circuit

(Voltage different from on/off

signal relayed by CPU in

TCM is detected while TCM

is monitoring solenoid

output voltage.)•Stops driving of pressure

control solenoid, 2-4 brake

solenoid valve, and high

clutch solenoid valve (OFF)

•Inhibit feedback control.Available

P0751Shift solenoid A malfunction

(stuck off)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available

P0752Shift solenoid A malfunction

(stuck on)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available

P0753Shift solenoid A malfunction

(open/short)•Open or short in shift

solenoid A circuit (Voltage

different from on/off signal

relayed by CPU in TCM is

detected while TCM is

monitoring solenoid output

voltage.)•Stops driving all ON/OFF

type solenoids (OFF) and

TCC solenoid valve (OFF)Inhibition

P0756Shift solenoid B malfunction

(stuck off)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available

P0757Shift solenoid B malfunction

(stuck on)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available DTC

No.On-board diagnostic function Detection condition Fail-safe TCC

Page 482 of 909

AUTOMATIC TRANSAXLE

K2–67

K2

P0758Shift solenoid B malfunction

(open/short)•Open or short in shift

solenoid B circuit (Voltage

different from on/off signal

relayed by CPU in TCM is

detected while TCM is

monitoring solenoid output

voltage.)•Stops driving all ON/OFF

type solenoids (OFF) and

TCC solenoid valve (OFF)Inhibition

P0761Shift solenoid C malfunction

(stuck off)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available

P0762Shift solenoid C malfunction

(stuck on)•Difference between actual

gear ratio and gear ratio set

in TCM is large—Available

P0763Shift solenoid C malfunction

(open/short)•Open or short in shift

solenoid C circuit (Voltage

different from on/off signal

relayed by CPU in TCM is

detected while TCM is

monitoring solenoid output

voltage.)•Stops driving all ON/OFF

type solenoids (OFF) and

TCC solenoid valve (OFF)Inhibition

P0768Reduction timing solenoid valve

malfunction (open/short)•Open or short in reduction

timing solenoid valve circuit

(Voltage different from on/off

signal relayed by CPU in

TCM is detected while TCM

is monitoring solenoid

output voltage.)•Stops driving of reduction

timing solenoid valve (OFF)Available

P0773Neutral shift solenoid valve

malfunction (open/short)•Open or short in neutral shift

solenoid valve circuit

(Voltage different from on/off

signal relayed by CPU in

TCM is detected while TCM

is monitoring solenoid

output voltage.)•Stops driving of neutral shift

solenoid valve (OFF)Available

P07782-4 brake solenoid valve

malfunction (open/short)•Open or short in 2-4 brake

solenoid valve circuit

(Voltage different from on/off

signal relayed by CPU in

TCM is detected while TCM

is monitoring solenoid

output voltage.)•Stops driving of pressure

control solenoid, 2-4 brake

solenoid valve, and high

clutch solenoid valve (OFF)

•Inhibit feedback control.Available

P0791Intermediate sensor malfunction

(open/short)•Rotation speed of output

gear (intermediate sensor)

is low when vehicle speed

and engine speed exceed

the pre programmed value•Inhibit feedback control

•Inhibits torque reduction

controlAvailable

P0798High clutch solenoid valve

malfunction (open/short)•Open or short in high clutch

solenoid valve circuit

(Voltage different from on/off

signal relayed by CPU in

TCM is detected while TCM

is monitoring solenoid

output voltage.)•Stops driving of pressure

control solenoid, 2-4 brake

solenoid valve, and high

clutch solenoid valve (OFF)

•Inhibit feedback control.Available

P1710 GND return malfunction•TCM detects open in GND

return signal of solenoid.—Available

U0073 CAN BUS OFF•CAN controller damaged.•Throttle valve opening angle

is fixed (4/8) at the time in

order to determine shift

•Maximizes line pressureInhibition

U0100TCM cannot receive any signals

from PCM•TCM cannot receive any

signals from PCM DTC

No.On-board diagnostic function Detection condition Fail-safe TCC

Page 483 of 909

K2–68

AUTOMATIC TRANSAXLE

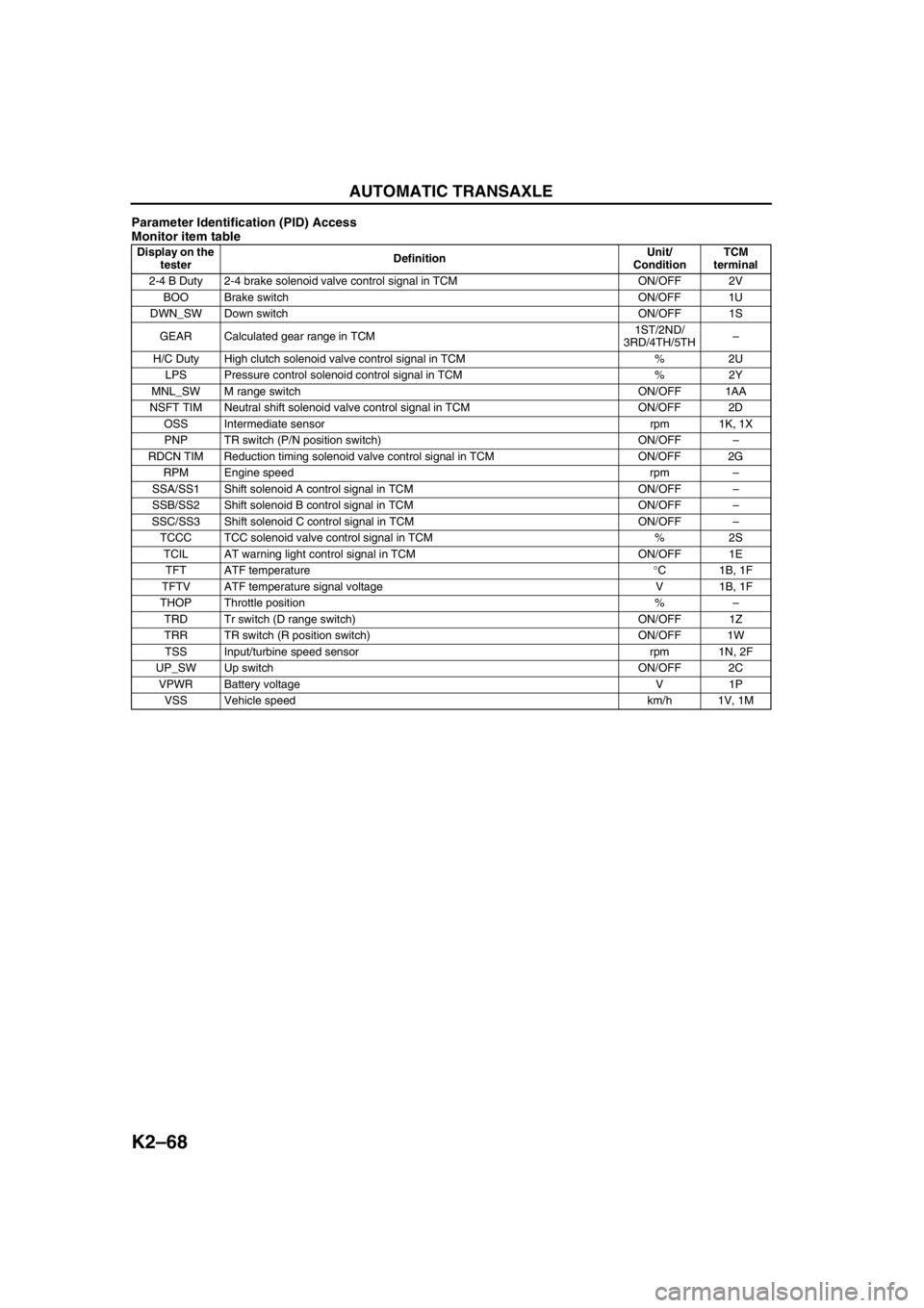

Parameter Identification (PID) Access

Monitor item table

End Of Sie

Display on the

testerDefinitionUnit/

ConditionTCM

terminal

2-4 B Duty 2-4 brake solenoid valve control signal in TCM ON/OFF 2V

BOO Brake switch ON/OFF 1U

DWN_SW Down switch ON/OFF 1S

GEAR Calculated gear range in TCM1ST/2ND/

3RD/4TH/5TH–

H/C Duty High clutch solenoid valve control signal in TCM % 2U

LPS Pressure control solenoid control signal in TCM % 2Y

MNL_SW M range switch ON/OFF 1AA

NSFT TIM Neutral shift solenoid valve control signal in TCM ON/OFF 2D

OSS Intermediate sensor rpm 1K, 1X

PNP TR switch (P/N position switch) ON/OFF–

RDCN TIM Reduction timing solenoid valve control signal in TCM ON/OFF 2G

RPM Engine speed rpm–

SSA/SS1 Shift solenoid A control signal in TCM ON/OFF–

SSB/SS2 Shift solenoid B control signal in TCM ON/OFF–

SSC/SS3 Shift solenoid C control signal in TCM ON/OFF–

TCCC TCC solenoid valve control signal in TCM % 2S

TCIL AT warning light control signal in TCM ON/OFF 1E

TFT ATF temperature°C1B, 1F

TFTV ATF temperature signal voltage V 1B, 1F

THOP Throttle position %–

TRD Tr switch (D range switch) ON/OFF 1Z

TRR TR switch (R position switch) ON/OFF 1W

TSS Input/turbine speed sensor rpm 1N, 2F

UP_SW Up switch ON/OFF 2C

VPWR Battery voltage V 1P

VSS Vehicle speed km/h 1V, 1M

Page 486 of 909

LOCATION INDEX

K2–71

K2

End Of Sie

1 Automatic transaxle fluid (ATF)

(See K2–78 AUTOMATIC TRANSAXLE FLUID

(ATF) INSPECTION)

(See K2–80 AUTOMATIC TRANSAXLE FLUID

(ATF) REPLACEMENT)

2 Transaxle range (TR) switch

(See K2–80 TRANSAXLE RANGE (TR) SWITCH

INSPECTION)

(See K2–81 TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION)

(See K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT)

3 Transaxle fluid temperature (TFT) sensor

(See K2–84 TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR INSPECTION)

(See K2–85 TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR REMOVAL/INSTALLATION)

4 Input/turbine speed sensor

(See K2–85 INPUT/TURBINE SPEED SENSOR

INSPECTION)

(See K2–86 INPUT/TURBINE SPEED SENSOR

REMOVAL/INSTALLATION)

5 Intermediate sensor

(See K2–86 INTERMEDIATE SENSOR

INSPECTION)

(See K2–86 INTERMEDIATE SENSOR REMOVAL/

INSTALLATION)

6 Vehicle speedometer sensor (VSS)

(See K2–87 VEHICLE SPEEDOMETER SENSOR

(VSS) INSPECTION)

(See K2–87 VEHICLE SPEEDOMETER SENSOR

(VSS) REMOVAL/INSTALLATION)

7 Solenoid valve

(See K2–88 SOLENOID VALVE INSPECTION)

(See K2–90 SOLENOID VALVE REMOVAL/

INSTALLATION)

8TCM

(See K2–90 TCM INSPECTION)

(See K2–96 TCM REMOVAL/INSTALLATION)9 Transfer oil

(See K2–114 TRANSFER OIL INSPECTION)

(See K2–114 TRANSFER OIL REPLACEMENT)

10 Automatic transaxle

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION)

11 Transfer

(See K2–115 TRANSFER REMOVAL/

INSTALLATION)

(See K2–116 BREATHER PLUG REMOVAL/

INSTALLATION)

12 Oil seal

(See K2–104 OIL SEAL REMOVAL/

INSTALLATION)

13 Control valve body

(See K2–105 CONTROL VALVE BODY REMOVAL/

INSTALLATION)

14 Oil cooler

(See K2–106 OIL COOLER FLUSHING)

(See K2–108 OIL COOLER REMOVAL/

INSTALLATION)

(See K2–110 OIL COOLER DISASSEMBLY/

ASSEMBLY)

15 Drive plate

(See K2–112 DRIVE PLATE REMOVAL/

INSTALLATION)

16 Selector lever

(See K2–117 SELECTOR LEVER INSPECTION)

(See K2–117 SELECTOR LEVER COMPONENT

INSPECTION)

(See K2–119 SELECTOR LEVER REMOVAL/

INSTALLATION)

(See K2–122 SELECTOR LEVER DISASSEMBLY/

ASSEMBLY)

17 Selector cable

(See K2–118 SELECTOR CABLE ADJUSTMENT)

Page 489 of 909

K2–74

AUTOMATIC TRANSAXLE

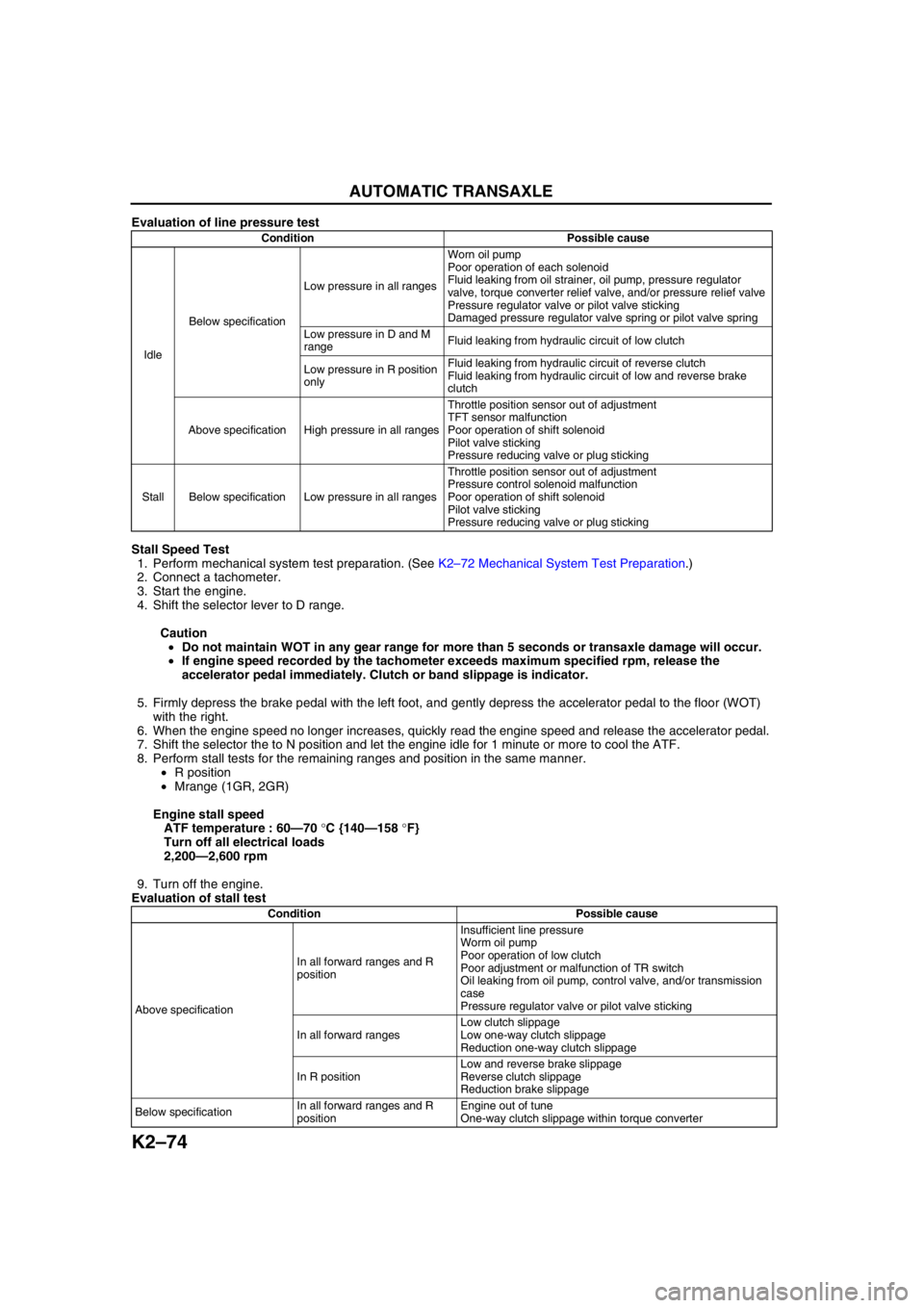

Evaluation of line pressure test

Stall Speed Test

1. Perform mechanical system test preparation. (See K2–72 Mechanical System Test Preparation.)

2. Connect a tachometer.

3. Start the engine.

4. Shift the selector lever to D range.

Caution

•Do not maintain WOT in any gear range for more than 5 seconds or transaxle damage will occur.

•If engine speed recorded by the tachometer exceeds maximum specified rpm, release the

accelerator pedal immediately. Clutch or band slippage is indicator.

5. Firmly depress the brake pedal with the left foot, and gently depress the accelerator pedal to the floor (WOT)

with the right.

6. When the engine speed no longer increases, quickly read the engine speed and release the accelerator pedal.

7. Shift the selector the to N position and let the engine idle for 1 minute or more to cool the ATF.

8. Perform stall tests for the remaining ranges and position in the same manner.

•R position

•Mrange (1GR, 2GR)

Engine stall speed

ATF temperature : 60—70 °C {140—158 °F}

Turn off all electrical loads

2,200—2,600 rpm

9. Turn off the engine.

Evaluation of stall test

Condition Possible cause

IdleBelow specificationLow pressure in all rangesWorn oil pump

Poor operation of each solenoid

Fluid leaking from oil strainer, oil pump, pressure regulator

valve, torque converter relief valve, and/or pressure relief valve

Pressure regulator valve or pilot valve sticking

Damaged pressure regulator valve spring or pilot valve spring

Low pressure in D and M

rangeFluid leaking from hydraulic circuit of low clutch

Low pressure in R position

onlyFluid leaking from hydraulic circuit of reverse clutch

Fluid leaking from hydraulic circuit of low and reverse brake

clutch

Above specification High pressure in all rangesThrottle position sensor out of adjustment

TFT sensor malfunction

Poor operation of shift solenoid

Pilot valve sticking

Pressure reducing valve or plug sticking

Stall Below specification Low pressure in all rangesThrottle position sensor out of adjustment

Pressure control solenoid malfunction

Poor operation of shift solenoid

Pilot valve sticking

Pressure reducing valve or plug sticking

Condition Possible cause

Above specificationIn all forward ranges and R

positionInsufficient line pressure

Worm oil pump

Poor operation of low clutch

Poor adjustment or malfunction of TR switch

Oil leaking from oil pump, control valve, and/or transmission

case

Pressure regulator valve or pilot valve sticking

In all forward ranges Low clutch slippage

Low one-way clutch slippage

Reduction one-way clutch slippage

In R positionLow and reverse brake slippage

Reverse clutch slippage

Reduction brake slippage

Below specificationIn all forward ranges and R

positionEngine out of tune

One-way clutch slippage within torque converter

Page 493 of 909

K2–78

AUTOMATIC TRANSAXLE

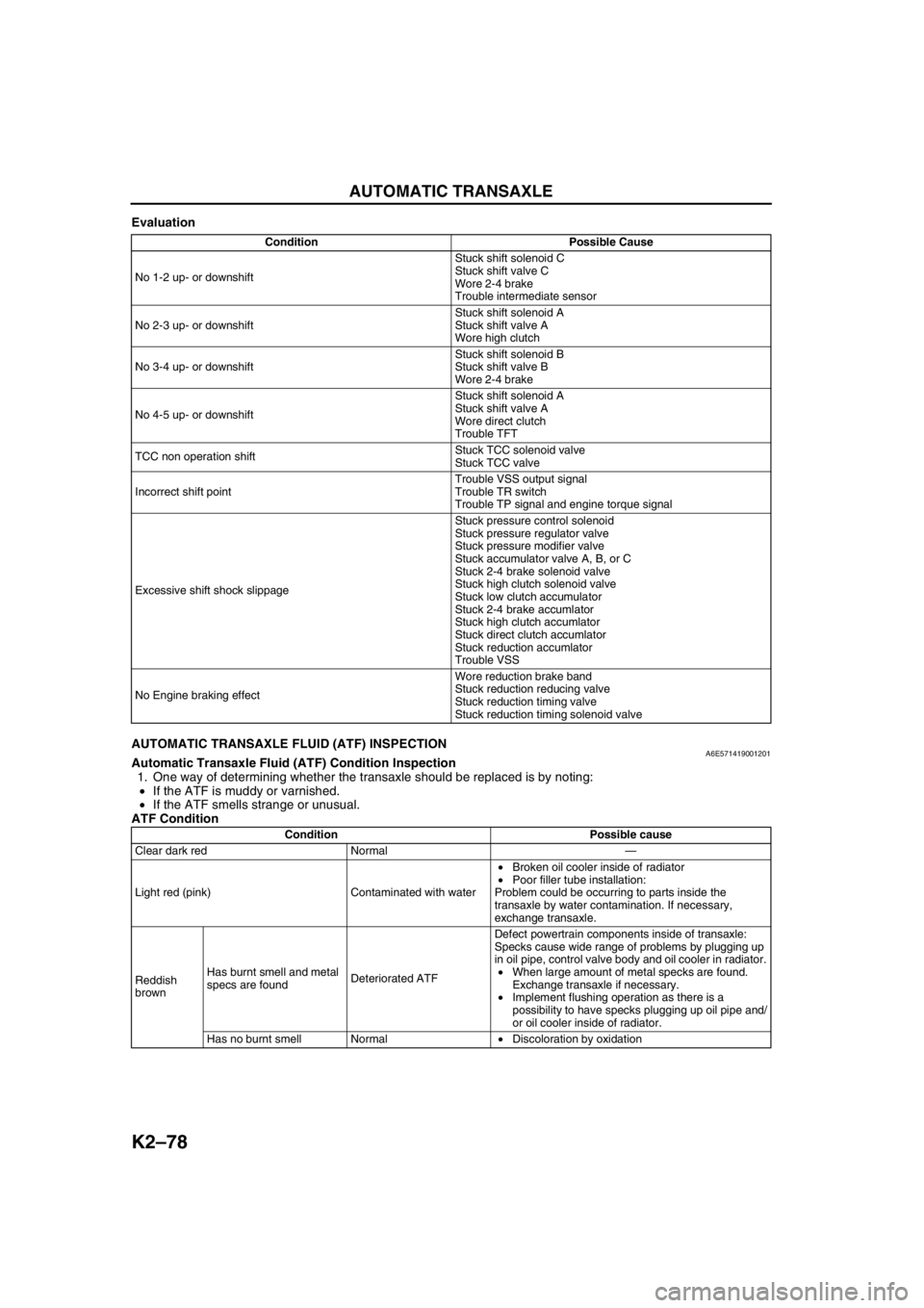

Evaluation

End Of SieAUTOMATIC TRANSAXLE FLUID (ATF) INSPECTIONA6E571419001201Automatic Transaxle Fluid (ATF) Condition Inspection

1. One way of determining whether the transaxle should be replaced is by noting:

•If the ATF is muddy or varnished.

•If the ATF smells strange or unusual.

ATF Condition

Condition Possible Cause

No 1-2 up- or downshiftStuck shift solenoid C

Stuck shift valve C

Wore 2-4 brake

Trouble intermediate sensor

No 2-3 up- or downshiftStuck shift solenoid A

Stuck shift valve A

Wore high clutch

No 3-4 up- or downshiftStuck shift solenoid B

Stuck shift valve B

Wore 2-4 brake

No 4-5 up- or downshiftStuck shift solenoid A

Stuck shift valve A

Wore direct clutch

Trouble TFT

TCC non operation shiftStuck TCC solenoid valve

Stuck TCC valve

Incorrect shift pointTrouble VSS output signal

Trouble TR switch

Trouble TP signal and engine torque signal

Excessive shift shock slippageStuck pressure control solenoid

Stuck pressure regulator valve

Stuck pressure modifier valve

Stuck accumulator valve A, B, or C

Stuck 2-4 brake solenoid valve

Stuck high clutch solenoid valve

Stuck low clutch accumulator

Stuck 2-4 brake accumlator

Stuck high clutch accumlator

Stuck direct clutch accumlator

Stuck reduction accumlator

Trouble VSS

No Engine braking effect Wore reduction brake band

Stuck reduction reducing valve

Stuck reduction timing valve

Stuck reduction timing solenoid valve

Condition Possible cause

Clear dark red Normal—

Light red (pink) Contaminated with water•Broken oil cooler inside of radiator

•Poor filler tube installation:

Problem could be occurring to parts inside the

transaxle by water contamination. If necessary,

exchange transaxle.

Reddish

brownHas burnt smell and metal

specs are foundDeteriorated ATFDefect powertrain components inside of transaxle:

Specks cause wide range of problems by plugging up

in oil pipe, control valve body and oil cooler in radiator.

•When large amount of metal specks are found.

Exchange transaxle if necessary.

•Implement flushing operation as there is a

possibility to have specks plugging up oil pipe and/

or oil cooler inside of radiator.

Has no burnt smell Normal•Discoloration by oxidation

Page 499 of 909

K2–84

AUTOMATIC TRANSAXLE

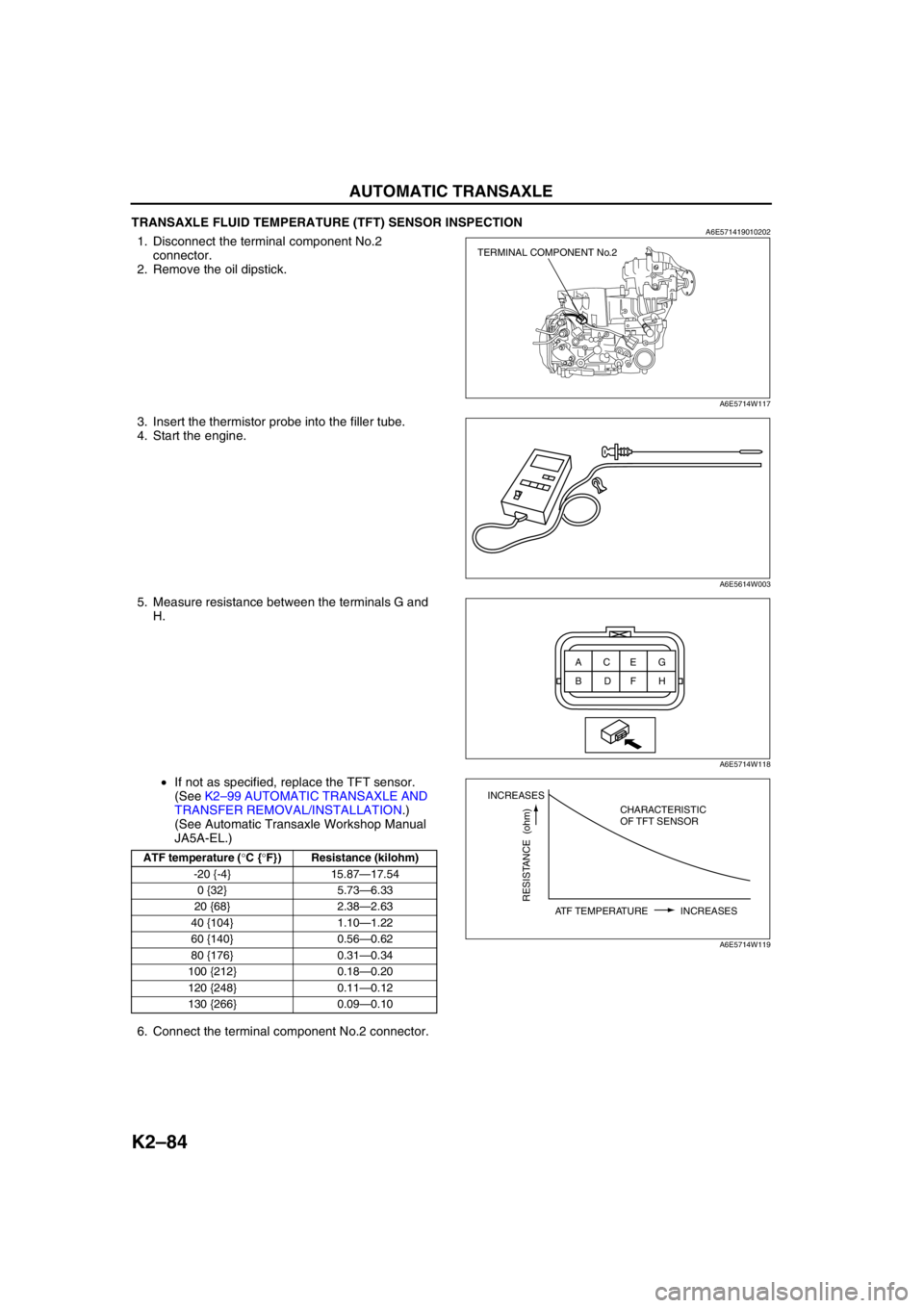

TRANSAXLE FLUID TEMPERATURE (TFT) SENSOR INSPECTIONA6E5714190102021. Disconnect the terminal component No.2

connector.

2. Remove the oil dipstick.

3. Insert the thermistor probe into the filler tube.

4. Start the engine.

5. Measure resistance between the terminals G and

H.

•If not as specified, replace the TFT sensor.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See Automatic Transaxle Workshop Manual

JA5A-EL.)

6. Connect the terminal component No.2 connector.

End Of Sie

ATF temperature (°C {°F}) Resistance (kilohm)

-20 {-4} 15.87—17.54

0 {32} 5.73—6.33

20 {68} 2.38—2.63

40 {104} 1.10—1.22

60 {140} 0.56—0.62

80 {176} 0.31—0.34

100 {212} 0.18—0.20

120 {248} 0.11—0.12

130 {266} 0.09—0.10

TERMINAL COMPONENT No.2

A6E5714W117

A6E5614W003

ACEG

BDFH

A6E5714W118

INCREASES

RESISTANCE (ohm)

ATF TEMPERATURE INCREASESCHARACTERISTIC

OF TFT SENSOR

A6E5714W119