sensor MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 557 of 909

K2–142

ON-BOARD DIAGNOSTIC

End Of SieDTC P0740A6E577018901212

Diagnostic procedure

12VERIFY TROUBLESHOOTING OF DTC P0720

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above for 2 second or more

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0740 TCC system malfunction

DETECTION

CONDITION•RPM difference between crankshaft (engine speed signal) and reverse clutch drum (input/turbine speed

sensor signal) exceeds the pre-programmed value.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•ATF level low.

•Deteriorated ATF.

•TCC solenoid valve and pressure control solenoid stuck.

•Line pressure low.

•Oil pump malfunction.

•Control valve stuck

•Torque convert clutch malfunction

•TCM malfunction.

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Clear red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes Go to next step.

No If ATF color milky or reddish brown, replace ATF, then go to

Step 5.

(See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF)

REPLACEMENT.)

4CHECK ATF LEVEL

•Start engine.

•Warm up ATX.

•Is ATF level within specification?

(See K2–79 Automatic Transaxle Fluid (ATF)

Level Inspection.)Yes Go to next step.

No Adjust ATF level, then go to Step 9.

(See K2–79 Automatic Transaxle Fluid (ATF) Level

Inspection.)

Page 587 of 909

K2–172

ON-BOARD DIAGNOSTIC

DTC P0791A6E577018901227

DTC P0791 Intermediate sensor circuit malfunction (open/short)

DETECTION

CONDITION•Rotation speed of output gear (intermediate sensor) is low when vehicle speed and engine speed exceed

the preprogrammed value.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Intermediate sensor malfunction.

•Short to ground between intermediate sensor terminal B and TCM terminal 1K

•Short to ground between intermediate sensor terminal A and TCM terminal 1X

•Open circuit between intermediate sensor terminal B and TCM terminal 1K

•Open circuit between intermediate sensor terminal A and TCM terminal 1X

•Damaged connectors between intermediate sensor and TCM.

•TCM malfunction.

D

B

AC

1K

1X CDTCM

AT X

TCM

HARNESS SIDE CONNECTOR

TERMINAL COMPONENT

NO.2(8-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(8-PIN)

PART SIDE CONNECTORINTERMEDIATE SENSOR

HARNESS SIDE CONNECTOR INTERMEDIATE

SENSOR

Page 588 of 909

ON-BOARD DIAGNOSTIC

K2–173

K2

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CONNECTOR FOR POOR CONNECTION

•Turn ignition key to OFF.

•Disconnect terminal component No.2 (8-pin)

connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair or replace terminals, then go to Step 12.

4INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between terminal

component No.2 (8-pin) (transaxle case side).

•Is resistance within 513—627 ohms between

terminal component No.2 (8-pin) terminal C

and D (transaxle case side)?Yes Go to next step.

No Go to Step 8

5INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Disconnect TCM connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

6INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CIRCUIT FOR OPEN

•Check terminal component No.2 (8-pin)

terminals (harness-side) and TCM terminals

(harness-side).

—C and 1K

—D and 1X

•Is there continuity?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

7INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CIRCUIT FOR SHORT TO GROUND

•Check terminal component No.2 (8-pin)

terminal (harness-side) and body ground.

—C and body ground

—D and body ground

•Is there any continuity?Yes Repair or replace harness, then go to Step 12.

No Go to Step 12.

8INSPECT COUPLER COMPONENT (8-PIN)

CONNECTOR FOR POOR CONNECTION

•Disassemble the control valve body cover.

•Disconnect coupler component (8-pin)

connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

9INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between coupler

component (8-pin).

•Is resistance within 513—627 ohms between

coupler component (8-pin) terminal D and C

(part side)?Yes Repair or replace coupler component, then go to Step 12.

No Go to next step.

Page 589 of 909

K2–174

ON-BOARD DIAGNOSTIC

End Of Sie

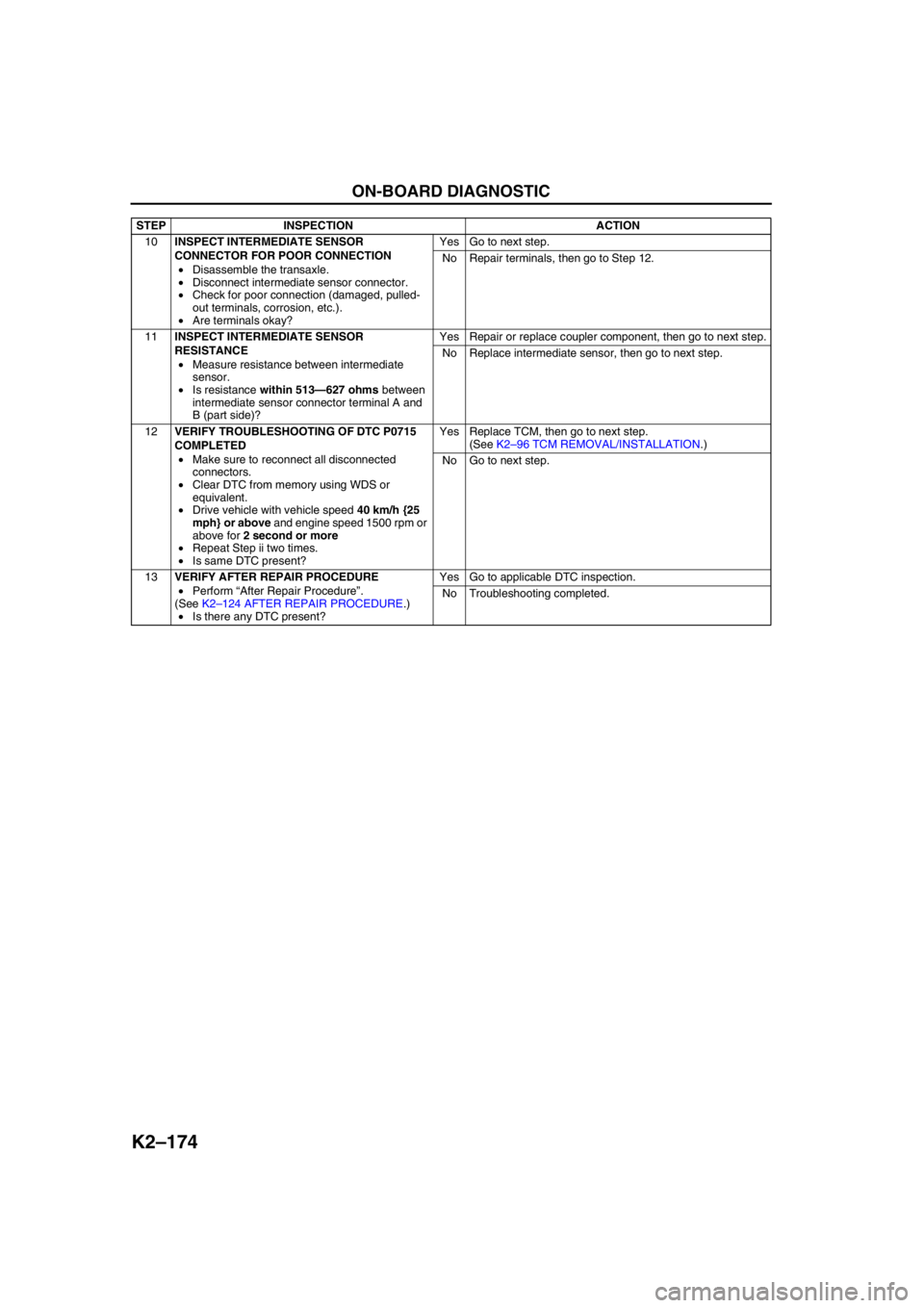

10INSPECT INTERMEDIATE SENSOR

CONNECTOR FOR POOR CONNECTION

•Disassemble the transaxle.

•Disconnect intermediate sensor connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

11INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between intermediate

sensor.

•Is resistance within 513—627 ohms between

intermediate sensor connector terminal A and

B (part side)?Yes Repair or replace coupler component, then go to next step.

No Replace intermediate sensor, then go to next step.

12VERIFY TROUBLESHOOTING OF DTC P0715

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above and engine speed 1500 rpm or

above for 2 second or more

•Repeat Step ii two times.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 595 of 909

K2–180

ON-BOARD DIAGNOSTIC

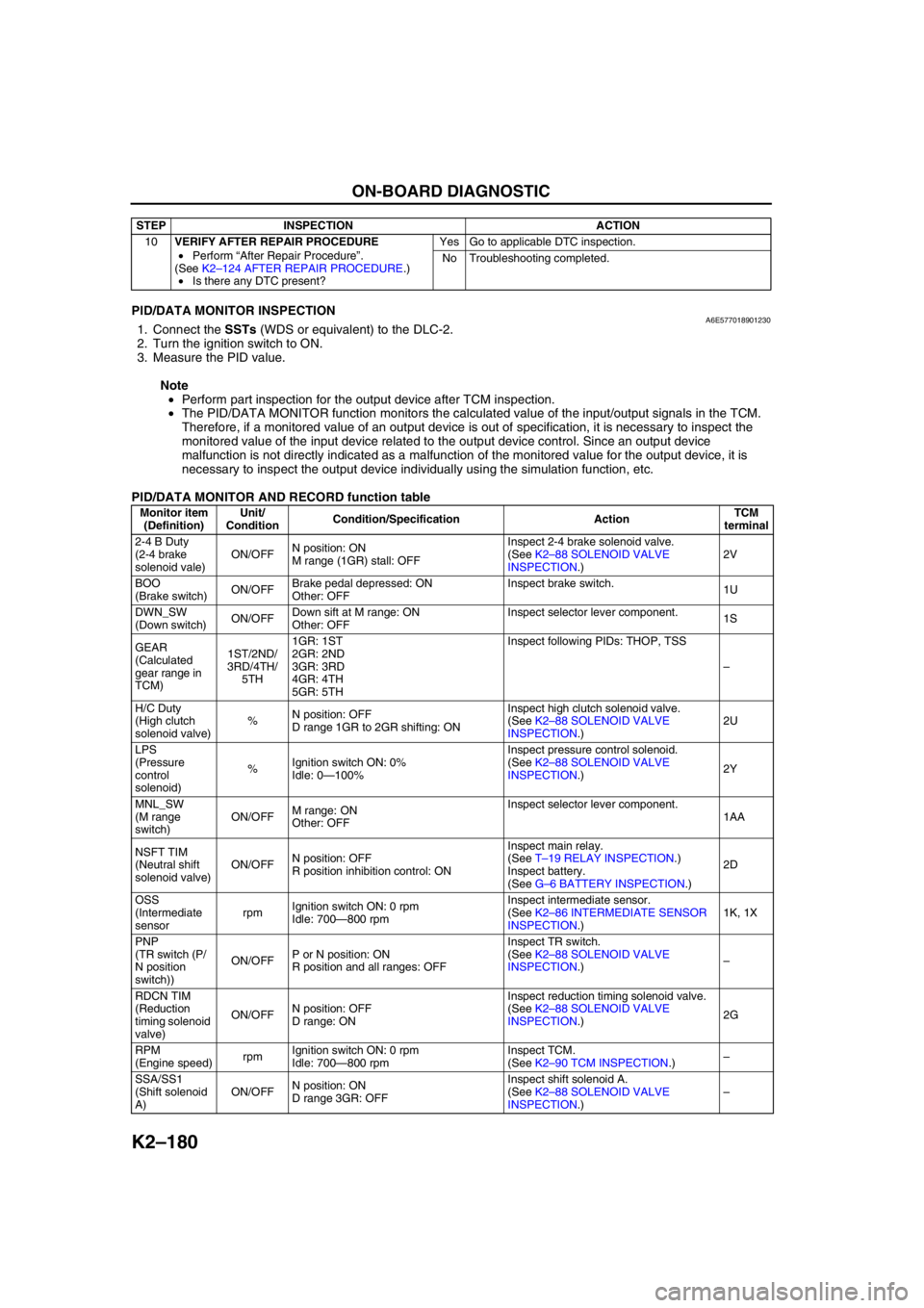

End Of SiePID/DATA MONITOR INSPECTIONA6E5770189012301. Connect the SSTs (WDS or equivalent) to the DLC-2.

2. Turn the ignition switch to ON.

3. Measure the PID value.

Note

•Perform part inspection for the output device after TCM inspection.

•The PID/DATA MONITOR function monitors the calculated value of the input/output signals in the TCM.

Therefore, if a monitored value of an output device is out of specification, it is necessary to inspect the

monitored value of the input device related to the output device control. Since an output device

malfunction is not directly indicated as a malfunction of the monitored value for the output device, it is

necessary to inspect the output device individually using the simulation function, etc.

PID/DATA MONITOR AND RECORD function table

10VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Monitor item

(Definition)Unit/

ConditionCondition/Specification ActionTCM

terminal

2-4 B Duty

(2-4 brake

solenoid vale)ON/OFFN position: ON

M range (1GR) stall: OFFInspect 2-4 brake solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Other: OFFInspect brake switch.

1U

DWN_SW

(Down switch)ON/OFFDown sift at M range: ON

Other: OFFInspect selector lever component.

1S

GEAR

(Calculated

gear range in

TCM)1ST/2ND/

3RD/4TH/

5TH1GR: 1ST

2GR: 2ND

3GR: 3RD

4GR: 4TH

5GR: 5THInspect following PIDs: THOP, TSS

–

H/C Duty

(High clutch

solenoid valve)%N position: OFF

D range 1GR to 2GR shifting: ONInspect high clutch solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2U

LPS

(Pressure

control

solenoid)%Ignition switch ON: 0%

Idle: 0—100%Inspect pressure control solenoid.

(See K2–88 SOLENOID VALVE

INSPECTION.)2Y

MNL_SW

(M range

switch)ON/OFFM range: ON

Other: OFFInspect selector lever component.

1AA

NSFT TIM

(Neutral shift

solenoid valve)ON/OFFN position: OFF

R position inhibition control: ONInspect main relay.

(See T–19 RELAY INSPECTION.)

Inspect battery.

(See G–6 BATTERY INSPECTION.)2D

OSS

(Intermediate

sensorrpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect intermediate sensor.

(See K2–86 INTERMEDIATE SENSOR

INSPECTION.)1K, 1X

PNP

(TR switch (P/

N position

switch))ON/OFFP or N position: ON

R position and all ranges: OFFInspect TR switch.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

RDCN TIM

(Reduction

timing solenoid

valve)ON/OFFN position: OFF

D range: ONInspect reduction timing solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2G

RPM

(Engine speed)rpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect TCM.

(See K2–90 TCM INSPECTION.)–

SSA/SS1

(Shift solenoid

A)ON/OFFN position: ON

D range 3GR: OFFInspect shift solenoid A.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

Page 596 of 909

ON-BOARD DIAGNOSTIC

K2–181

K2

End Of Sie

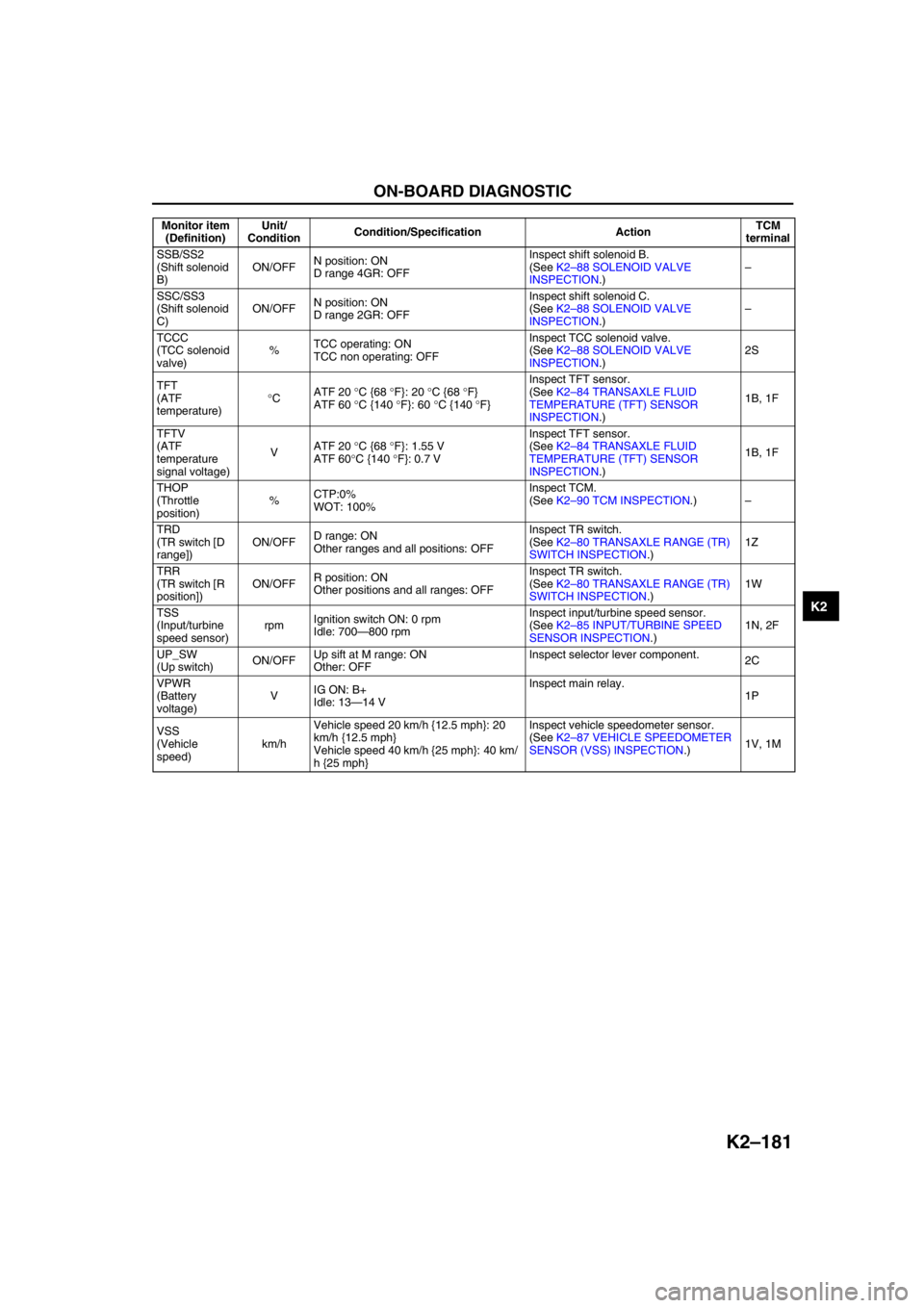

SSB/SS2

(Shift solenoid

B)ON/OFFN position: ON

D range 4GR: OFFInspect shift solenoid B.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

SSC/SS3

(Shift solenoid

C)ON/OFFN position: ON

D range 2GR: OFFInspect shift solenoid C.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

TCCC

(TCC solenoid

valve)%TCC operating: ON

TCC non operating: OFFInspect TCC solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2S

TFT

(ATF

temperature)°CATF 20 °C {68 °F}: 20 °C {68 °F}

ATF 60 °C {140 °F}: 60 °C {140 °F}Inspect TFT sensor.

(See K2–84 TRANSAXLE FLUID

TEMPERATURE (TFT) SENSOR

INSPECTION.)1B, 1F

TFTV

(ATF

temperature

signal voltage)VATF 20 °C {68 °F}: 1.55 V

ATF 60°C {140 °F}: 0.7 VInspect TFT sensor.

(See K2–84 TRANSAXLE FLUID

TEMPERATURE (TFT) SENSOR

INSPECTION.)1B, 1F

THOP

(Throttle

position)%CTP:0%

WOT: 100%Inspect TCM.

(See K2–90 TCM INSPECTION.)–

TRD

(TR switch [D

range])ON/OFFD range: ON

Other ranges and all positions: OFFInspect TR switch.

(See K2–80 TRANSAXLE RANGE (TR)

SWITCH INSPECTION.)1Z

TRR

(TR switch [R

position])ON/OFFR position: ON

Other positions and all ranges: OFFInspect TR switch.

(See K2–80 TRANSAXLE RANGE (TR)

SWITCH INSPECTION.)1W

TSS

(Input/turbine

speed sensor)rpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect input/turbine speed sensor.

(See K2–85 INPUT/TURBINE SPEED

SENSOR INSPECTION.)1N, 2F

UP_SW

(Up switch)ON/OFFUp sift at M range: ON

Other: OFFInspect selector lever component.

2C

VPWR

(Battery

voltage)VIG ON: B+

Idle: 13—14 VInspect main relay.

1P

VSS

(Vehicle

speed)km/hVehicle speed 20 km/h {12.5 mph}: 20

km/h {12.5 mph}

Vehicle speed 40 km/h {25 mph}: 40 km/

h {25 mph}Inspect vehicle speedometer sensor.

(See K2–87 VEHICLE SPEEDOMETER

SENSOR (VSS) INSPECTION.)1V, 1M Monitor item

(Definition)Unit/

ConditionCondition/Specification ActionTCM

terminal

Page 600 of 909

TROUBLESHOOTING

K2–185

K2

Quick Diagnosis Chart

Vehicle dose not move in D range, or in R position X X

X

X

X

X

X

X

X

X

XX X

XX

XX

XX

XX

X X X

X

XX X

XX

X XXXXX

XX X

XX

XX X X

X

X

X XX

X

XX

X

X

XX

X

XXX

X

XXX

X

X X XX

X

XXXX XX

X

XX

X

X X

XX XX

X

X

X 1

Excessive creep 4

No creep at all 5

Low maximum speed and poor acceleration 6

No shifting 7

Does not shift to fifth gear (5GR) 8

Abnormal shifting 9

Frequent shifting 10

Shift point is high or low 11

Torque converter clutch (TCC) non-operation 12

No kickdown 13

Engine flares up or slips when upshifting or downshifting 14

Engine flares up or slip when accelerating vehicle 15

Judder upon torque converter clutch (TCC) operation 16

Excessive shift shock from N to D or N to R position/range 17

Excessive shift shock on torque converter clutch (TCC) 19

No engine braking in 1GR position of M range 22

Transaxle overheats 23

Engine stalls when shifted to D range, or in R position 24

Engine stalls when driving at slow speeds or stopping 25

Starter does not work 26Excessive shift shock is given when upshifting and

downshifting 18

Noise occurs at idle when vehicle is stopped in all

positions/ranges 20

Noise occurs at idle when vehicle is stopped in D

range, or in R position 21

Gear position indicator light illuminates in D range or P, N,

R positions 28Gear position indicator light does not illuminate in M range

Electrical system components

ATX outer parts 27

Does not shift up in M range

29

Does not shift down in M range

Symptom item

Cause of trouble

Selector lever is misadjisted

Not within line pressure specification

Idle speed is misadjusted

IG timing is misadjusted

TR switch is misadjusted

Open/short

Abnormal signal is inputed

Abnormal signal is inputed Signal is not inputed

Signal is not inputed

Abnormal signal is inputed Signal is not inputed

Abnormal signal is inputed Signal is not inputed

Abnormal signal is inputed Signal is not inputed

Abnormal signal is inputed Signal is not inputed

Abnormal signal is inputed

Abnormal signal is inputed Signal is not inputedCAN signal

CAN signal Engine speed signal

Vehicle speedometer sensor

Input/turbine speed sensor

Intermediate sensor

D range switch

M range switch

Up switch

Down switch

Throttle opening

30Vehicle moves in N position 2

Vehicle moves in P position, or parking gear does not

disengage when P is disengaged 3

X X X

X X X

X

X

A6E5780W001

Page 601 of 909

K2–186

TROUBLESHOOTING

CAN signal

Vehicle dose not move in D range, or in R position

X

XXX X

X

X X

X

XX

X

X

X

X

X

XX

XX

XX

XXX

XX

XX

X

XXX X

XX X

XX X

XX X

XXX

XX

X

XX

X XX XX

X

XX

XX

X XX

X XXXX

XXXX

XXXXX XX XXX

X

X

XX

X

X

X

X

X

X

X

X

X

X X

X

X

X X

XXX

XX

XX X X

X 1

Excessive creep 4

No creep at all 5

Low maximum speed and poor acceleration 6

No shifting 7

Does not shift to fifth gear (5GR) 8

Abnormal shifting 9

Frequent shifting 10

Shift point is high or low 11

Torque converter clutch (TCC) non-operation 12

No kickdown 13

Engine flares up or slips when upshifting or downshifting 14

Engine flares up or slip when accelerating vehicle 15

Judder upon torque converter clutch (TCC) operation 16

Excessive shift shock from N to D or N to R position/range 17

Excessive shift shock on torque converter clutch (TCC) 19

No engine braking in 1GR position of M range 22

Transaxle overheats 23

Engine stalls when shifted to D range, or in R position 24

Engine stalls when driving at slow speeds or stopping 25

Starter does not work 26Excessive shift shock is given when upshifting and

downshifting 18

Noise occurs at idle when vehicle is stopped in all

positions/ranges 20

Noise occurs at idle when vehicle is stopped in D

range, or in R position 21

Gear position indicator light illuminates in D range or P, N,

R positions 28Gear position indicator light does not illuminate in M range

Electrical system components

ATX inner parts

ATX outer parts

Hydraulic system

components

Control valve body 27

Does not shift up in M range

29

Does not shift down in M rangeSymptom item

Cause of trouble

Open/short

Malfunction signal is inputed Signal is inputed

Open/short

Open/short Open/short

Open/short

Open/short

Open/short

Open/short

Open/short Open/short

Open/short

Open/short Open/short

Control valve spool is not operating properly ATF amount

2-4 brake accumulator is not operating properly Low clutch solenoid accumulator is not operating properly

Direct clutch accumulator is not operating properly High clutch accumulator is not operating properly2-4 brake solenoid valve Pressure control solenoid

TCC solenoid valve

High clutch solenoid valve TFT sensor N-D select

Transaxle range switch

Power supply, GND

Shift solenoid A

Shift solenoid B

Shift solenoid C

Neutral shift solenoid valve

Reducation timing solenoid

GND return line

30Vehicle moves in N position 2

Vehicle moves in P position, or parking gear does not

disengage when P is disengaged 3

A6E5780W002

Page 603 of 909

K2–188

TROUBLESHOOTING

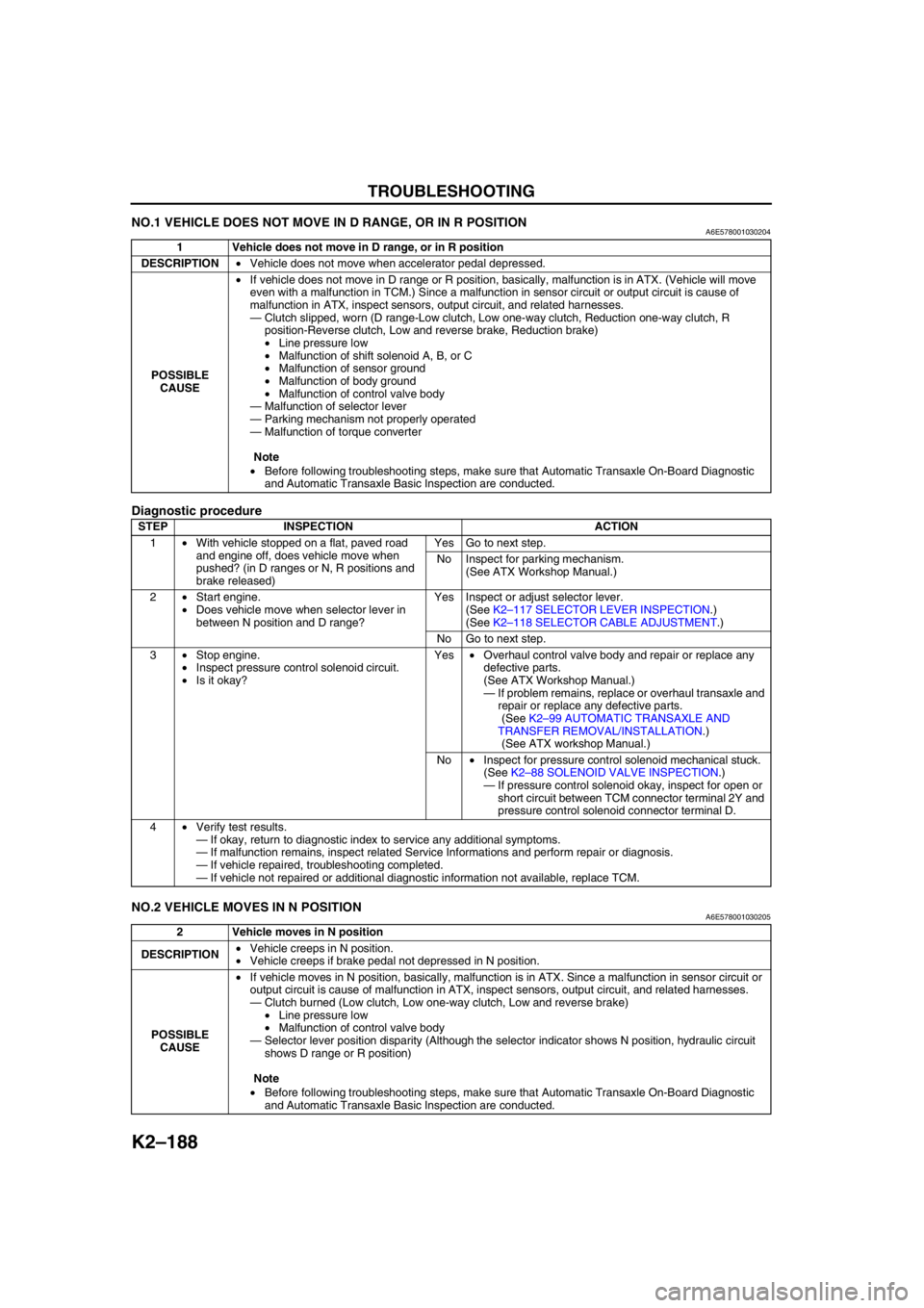

NO.1 VEHICLE DOES NOT MOVE IN D RANGE, OR IN R POSITIONA6E578001030204

Diagnostic procedure

End Of SieNO.2 VEHICLE MOVES IN N POSITIONA6E578001030205

1 Vehicle does not move in D range, or in R position

DESCRIPTION•Vehicle does not move when accelerator pedal depressed.

POSSIBLE

CAUSE•If vehicle does not move in D range or R position, basically, malfunction is in ATX. (Vehicle will move

even with a malfunction in TCM.) Since a malfunction in sensor circuit or output circuit is cause of

malfunction in ATX, inspect sensors, output circuit, and related harnesses.

—Clutch slipped, worn (D range-Low clutch, Low one-way clutch, Reduction one-way clutch, R

position-Reverse clutch, Low and reverse brake, Reduction brake)

•Line pressure low

•Malfunction of shift solenoid A, B, or C

•Malfunction of sensor ground

•Malfunction of body ground

•Malfunction of control valve body

—Malfunction of selector lever

—Parking mechanism not properly operated

—Malfunction of torque converter

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•With vehicle stopped on a flat, paved road

and engine off, does vehicle move when

pushed? (in D ranges or N, R positions and

brake released)Yes Go to next step.

No Inspect for parking mechanism.

(See ATX Workshop Manual.)

2•Start engine.

•Does vehicle move when selector lever in

between N position and D range?Yes Inspect or adjust selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

No Go to next step.

3•Stop engine.

•Inspect pressure control solenoid circuit.

•Is it okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX workshop Manual.)

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

—If pressure control solenoid okay, inspect for open or

short circuit between TCM connector terminal 2Y and

pressure control solenoid connector terminal D.

4•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

2 Vehicle moves in N position

DESCRIPTION•Vehicle creeps in N position.

•Vehicle creeps if brake pedal not depressed in N position.

POSSIBLE

CAUSE•If vehicle moves in N position, basically, malfunction is in ATX. Since a malfunction in sensor circuit or

output circuit is cause of malfunction in ATX, inspect sensors, output circuit, and related harnesses.

—Clutch burned (Low clutch, Low one-way clutch, Low and reverse brake)

•Line pressure low

•Malfunction of control valve body

—Selector lever position disparity (Although the selector indicator shows N position, hydraulic circuit

shows D range or R position)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

Page 605 of 909

K2–190

TROUBLESHOOTING

Diagnostic procedure

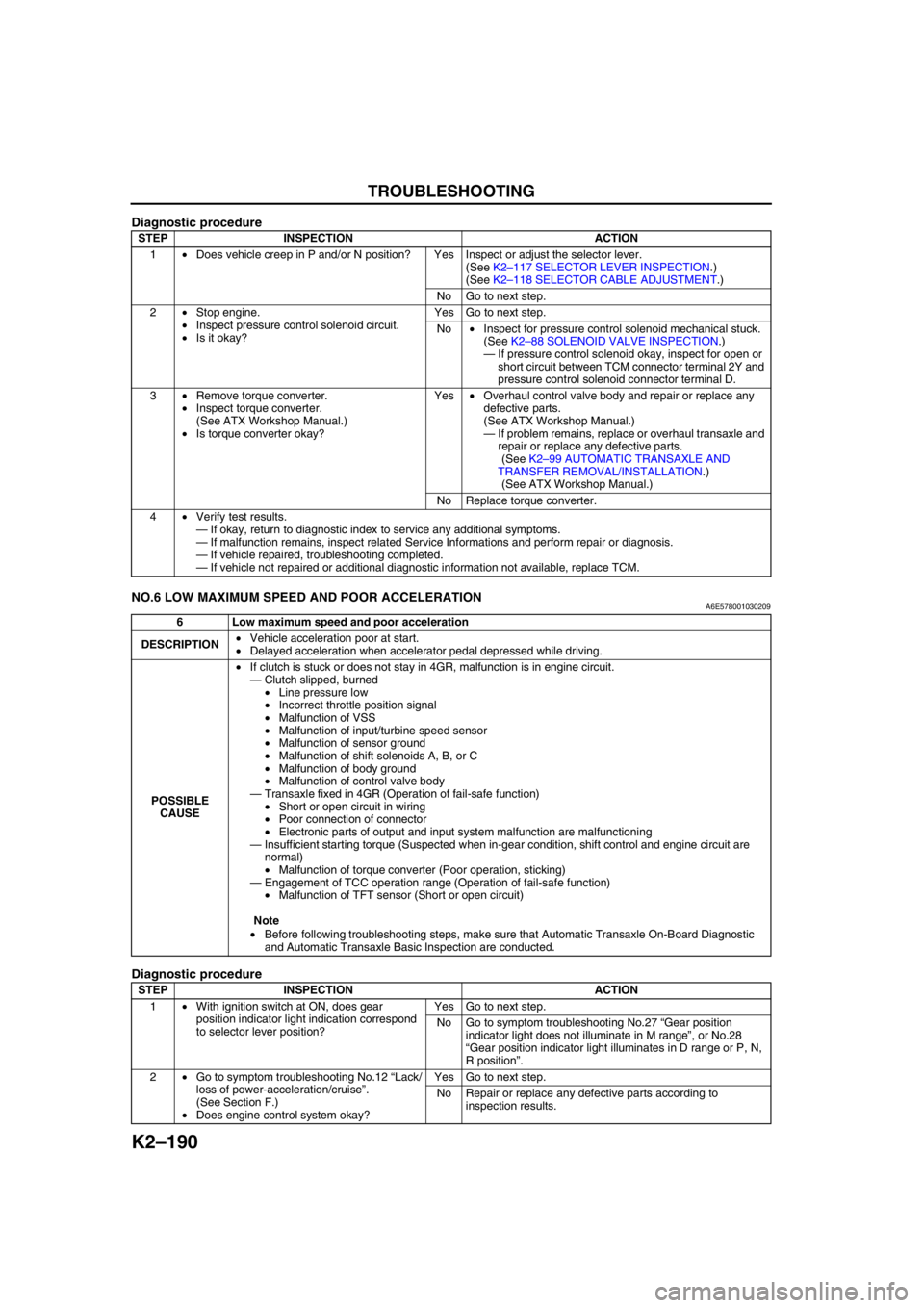

End Of SieNO.6 LOW MAXIMUM SPEED AND POOR ACCELERATIONA6E578001030209

Diagnostic procedure

STEP INSPECTION ACTION

1•Does vehicle creep in P and/or N position? Yes Inspect or adjust the selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

No Go to next step.

2•Stop engine.

•Inspect pressure control solenoid circuit.

•Is it okay?Yes Go to next step.

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

—If pressure control solenoid okay, inspect for open or

short circuit between TCM connector terminal 2Y and

pressure control solenoid connector terminal D.

3•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX Workshop Manual.)

No Replace torque converter.

4•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

6 Low maximum speed and poor acceleration

DESCRIPTION•Vehicle acceleration poor at start.

•Delayed acceleration when accelerator pedal depressed while driving.

POSSIBLE

CAUSE•If clutch is stuck or does not stay in 4GR, malfunction is in engine circuit.

—Clutch slipped, burned

•Line pressure low

•Incorrect throttle position signal

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of shift solenoids A, B, or C

•Malfunction of body ground

•Malfunction of control valve body

—Transaxle fixed in 4GR (Operation of fail-safe function)

•Short or open circuit in wiring

•Poor connection of connector

•Electronic parts of output and input system malfunction are malfunctioning

—Insufficient starting torque (Suspected when in-gear condition, shift control and engine circuit are

normal)

•Malfunction of torque converter (Poor operation, sticking)

—Engagement of TCC operation range (Operation of fail-safe function)

•Malfunction of TFT sensor (Short or open circuit)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•With ignition switch at ON, does gear

position indicator light indication correspond

to selector lever position?Yes Go to next step.

No Go to symptom troubleshooting No.27 “Gear position

indicator light does not illuminate in M range”, or No.28

“Gear position indicator light illuminates in D range or P, N,

R position”.

2•Go to symptom troubleshooting No.12 “Lack/

loss of power-acceleration/cruise”.

(See Section F.)

•Does engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.