coolant MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 86 of 909

WATER PUMP

E–11

E

WATER PUMP REMOVAL/INSTALLATIONA6E362015010201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the thermostat. (See E–9 THERMOSTAT REMOVAL/INSTALLATION.)

6. Remove in the order indicated in the table.

7. Install in the reverse order of removal.

8. Insect the drive belt. (See B2–4 DRIVE BELT INSPECTION.)

9. Fill the radiator with the specified amount and type of engine coolant.

10. Inspect the engine coolant leakage. (See E–8 ENGINE COOLANT LEAKAGE INSPECTION.)

End Of Sie

WATER PUMP

3

1

2

1

19—25

{1.9—2.6, 14—18}

N·m {kgf·m, ft·lbf} 38—51

{3.8—5.3, 28—38}

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf} 38—51

{3.8—5.3, 28—38}

R

R

A6E3620W100

1Hose

2 Water pump

3 Thermostat case

Page 122 of 909

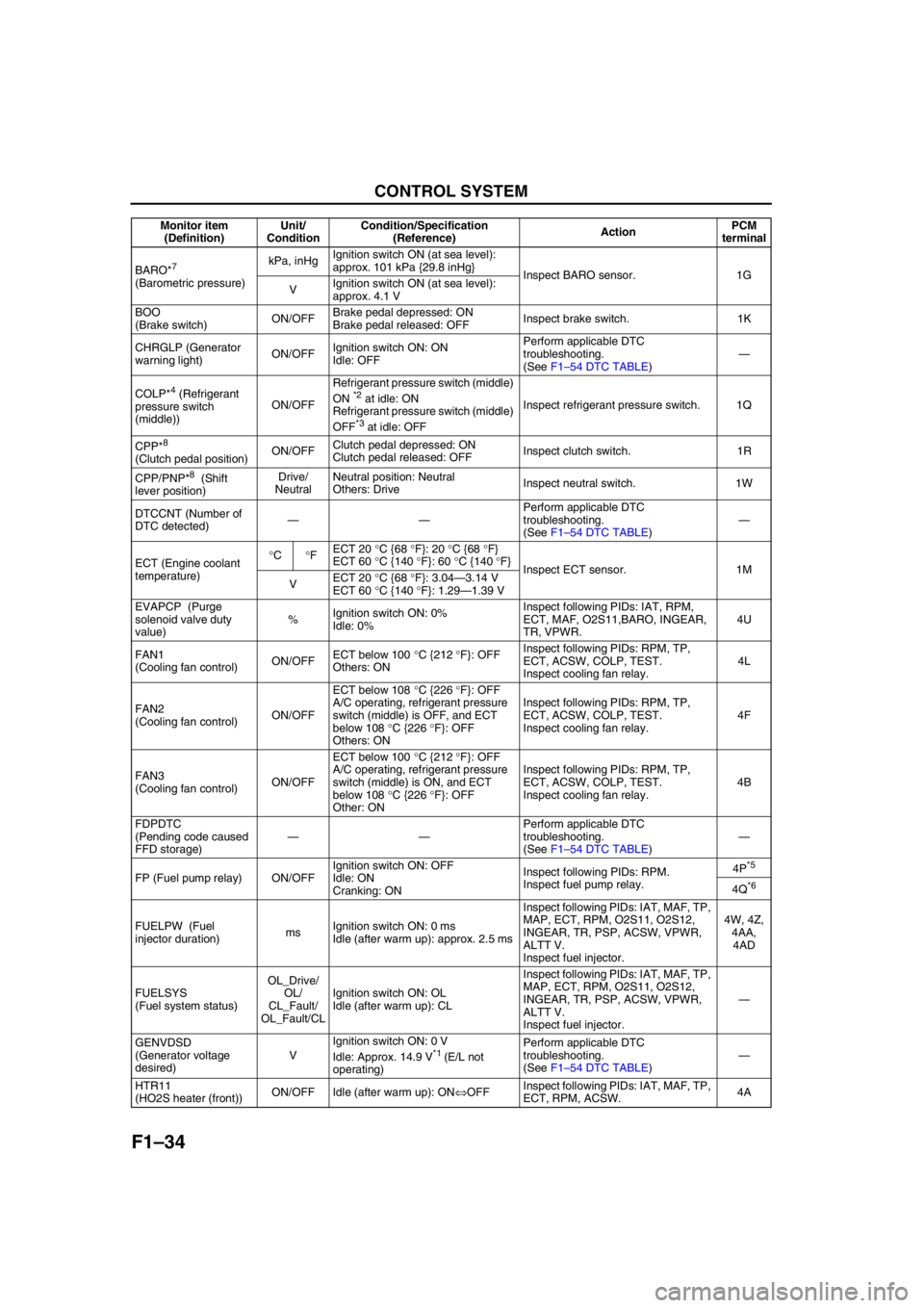

F1–34

CONTROL SYSTEM

BARO*7

(Barometric pressure)kPa, inHgIgnition switch ON (at sea level):

approx. 101 kPa {29.8 inHg}

Inspect BARO sensor. 1G

VIgnition switch ON (at sea level):

approx. 4.1 V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Brake pedal released: OFFInspect brake switch. 1K

CHRGLP (Generator

warning light)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

COLP*

4 (Refrigerant

pressure switch

(middle))ON/OFFRefrigerant pressure switch (middle)

ON *2 at idle: ON

Refrigerant pressure switch (middle)

OFF

*3 at idle: OFFInspect refrigerant pressure switch. 1Q

CPP*

8

(Clutch pedal position)ON/OFFClutch pedal depressed: ON

Clutch pedal released: OFFInspect clutch switch. 1R

CPP/PNP*

8 (Shift

lever position)Drive/

NeutralNeutral position: Neutral

Others: DriveInspect neutral switch. 1W

DTCCNT (Number of

DTC detected)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

ECT (Engine coolant

temperature)°C°FECT 20 °C {68 °F}: 20 °C {68 °F}

ECT 60 °C {140 °F}: 60 °C {140 °F}

Inspect ECT sensor. 1M

VECT 20 °C {68 °F}: 3.04—3.14 V

ECT 60 °C {140 °F}: 1.29—1.39 V

EVAPCP (Purge

solenoid valve duty

value)%Ignition switch ON: 0%

Idle: 0%Inspect following PIDs: IAT, RPM,

ECT, MAF, O2S11,BARO, INGEAR,

TR, VPWR.4U

FAN1

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4L

FAN2

(Cooling fan control)ON/OFFECT below 108 °C {226 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is OFF, and ECT

below 108 °C {226 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4F

FAN3

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is ON, and ECT

below 108 °C {226 °F}: OFF

Other: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4B

FDPDTC

(Pending code caused

FFD storage)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

FP (Fuel pump relay) ON/OFFIgnition switch ON: OFF

Idle: ON

Cranking: ONInspect following PIDs: RPM.

Inspect fuel pump relay.4P

*5

4Q*6

FUELPW (Fuel

injector duration)msIgnition switch ON: 0 ms

Idle (after warm up): approx. 2.5 msInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.4W, 4Z,

4AA,

4AD

FUELSYS

(Fuel system status)OL_Drive/

OL/

CL_Fault/

OL_Fault/CLIgnition switch ON: OL

Idle (after warm up): CLInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.—

GENVDSD

(Generator voltage

desired)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

HTR11

(HO2S heater (front))ON/OFF Idle (after warm up): ON⇔OFFInspect following PIDs: IAT, MAF, TP,

ECT, RPM, ACSW.4A Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 146 of 909

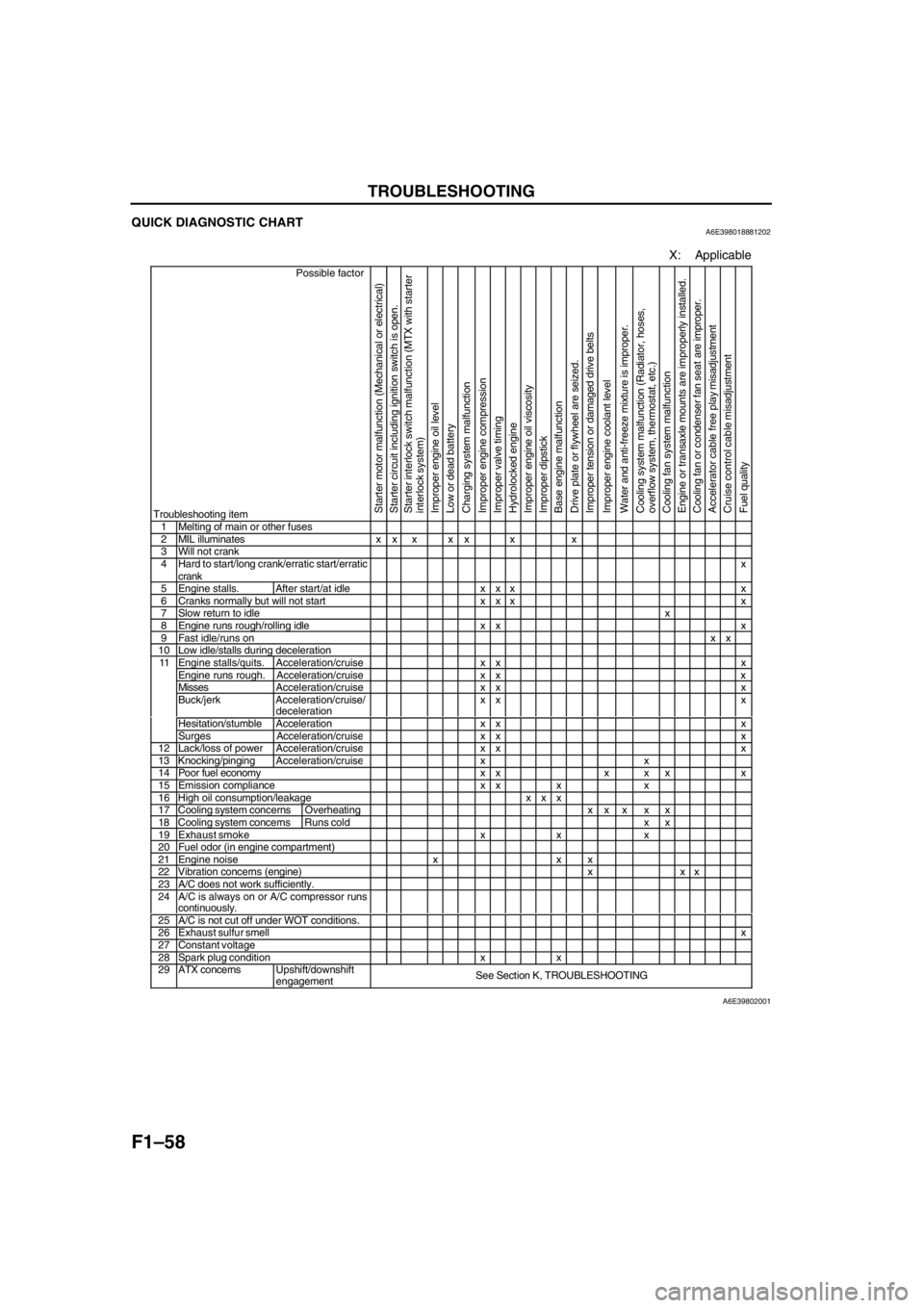

F1–58

TROUBLESHOOTING

QUICK DIAGNOSTIC CHARTA6E398018881202

X: Applicable

Possible factor

Troubleshooting item

Starter motor malfunction (Mechanical or electrical)

Starter circuit including ignition switch is open.

Starter interlock switch malfunction (MTX with starter

interlock system)

Improper engine oil level

Low or dead battery

Charging system malfunction

Improper engine compression

Improper valve timing

Hydrolocked engine

Improper engine oil viscosity

Improper dipstick

Base engine malfunction

Drive plate or flywheel are seized.

Improper tension or damaged drive belts

Improper engine coolant level

Water and anti-freeze mixture is improper.

Cooling system malfunction (Radiator, hoses,

overflow system, thermostat, etc.)

Cooling fan system malfunction

Engine or transaxle mounts are improperly installed.

Cooling fan or condenser fan seat are improper.

Accelerator cable free play misadjustment

Cruise control cable misadjustment

Fuel quality

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx

5 Engine stalls. After start/at idle x x x x6 Cranks normally but will not start x x x x7 Slow return to idlex8 Engine runs rough/rolling idle x x x9 Fast idle/runs onxx10 Low idle/stalls during decelerationEngine stalls/quits. Acceleration/cruise x x xEngine runs rough. Acceleration/cruise x x xMissesAcceleration/cruise x x xBuck/jerk Acceleration/cruise/

decelerationxx x

Hesitation/stumble Acceleration x x x

11

Surges Acceleration/cruis

exx x12 Lack/loss of powerAcceleration/cruisexx x13 Knocking/pingingAcceleration/cruisexx14 Poor fuel economy x x x x x x15 Emission compliance x x x x16 High oil consumption/leakage x x x17 Cooling system concerns Overheatingxx x x x18 Cooling system concernsRuns cold x x19 Exhaust smoke x x x20 Fuel odor (in engine compartment)21 Engine noise x x x22 Vibration concerns (engine) x x x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smellx27 Constant voltage28 Spark plug condition x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802001

Page 150 of 909

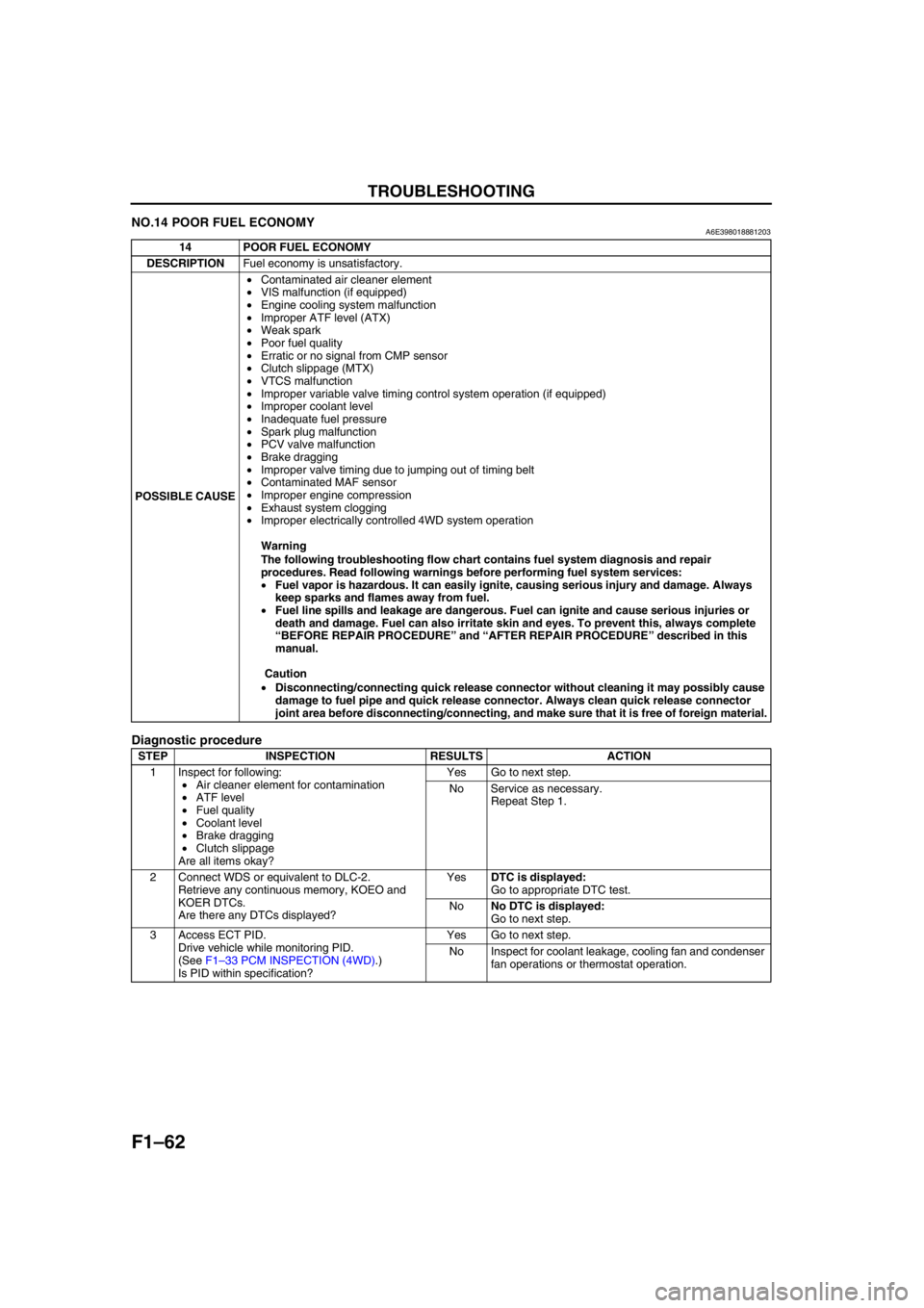

F1–62

TROUBLESHOOTING

NO.14 POOR FUEL ECONOMYA6E398018881203

Diagnostic procedure

14 POOR FUEL ECONOMY

DESCRIPTIONFuel economy is unsatisfactory.

POSSIBLE CAUSE•Contaminated air cleaner element

•VIS malfunction (if equipped)

•Engine cooling system malfunction

•Improper ATF level (ATX)

•Weak spark

•Poor fuel quality

•Erratic or no signal from CMP sensor

•Clutch slippage (MTX)

•VTCS malfunction

•Improper variable valve timing control system operation (if equipped)

•Improper coolant level

•Inadequate fuel pressure

•Spark plug malfunction

•PCV valve malfunction

•Brake dragging

•Improper valve timing due to jumping out of timing belt

•Contaminated MAF sensor

•Improper engine compression

•Exhaust system clogging

•Improper electrically controlled 4WD system operation

Warning

The following troubleshooting flow chart contains fuel system diagnosis and repair

procedures. Read following warnings before performing fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

Caution

•Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Air cleaner element for contamination

•ATF level

•Fuel quality

•Coolant level

•Brake dragging

•Clutch slippage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?YesDTC is displayed:

Go to appropriate DTC test.

NoNo DTC is displayed:

Go to next step.

3 Access ECT PID.

Drive vehicle while monitoring PID.

(See F1–33 PCM INSPECTION (4WD).)

Is PID within specification?Yes Go to next step.

No Inspect for coolant leakage, cooling fan and condenser

fan operations or thermostat operation.

Page 154 of 909

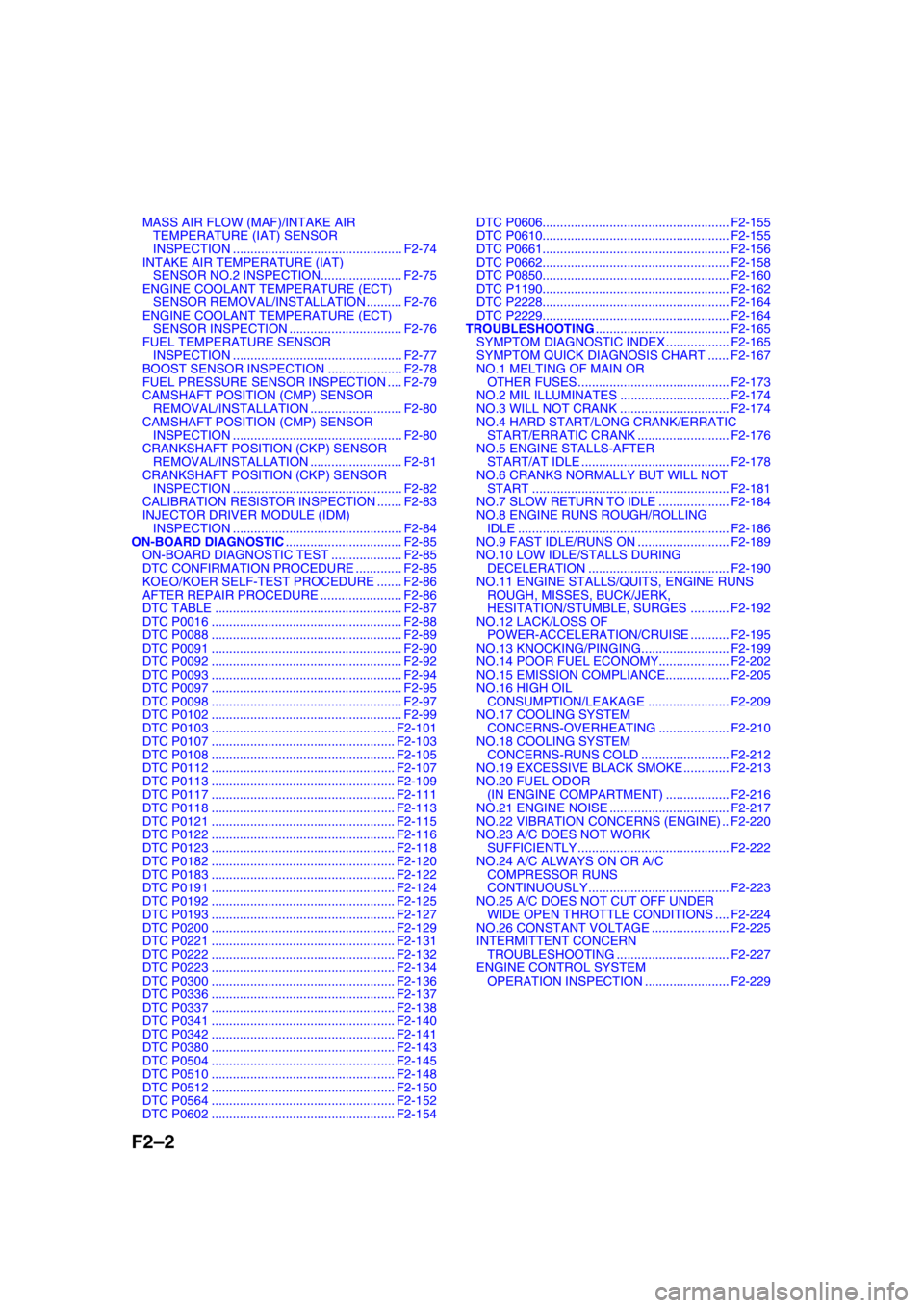

F2–2

MASS AIR FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT) SENSOR

INSPECTION ................................................ F2-74

INTAKE AIR TEMPERATURE (IAT)

SENSOR NO.2 INSPECTION....................... F2-75

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR REMOVAL/INSTALLATION .......... F2-76

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR INSPECTION ................................ F2-76

FUEL TEMPERATURE SENSOR

INSPECTION ................................................ F2-77

BOOST SENSOR INSPECTION ..................... F2-78

FUEL PRESSURE SENSOR INSPECTION .... F2-79

CAMSHAFT POSITION (CMP) SENSOR

REMOVAL/INSTALLATION .......................... F2-80

CAMSHAFT POSITION (CMP) SENSOR

INSPECTION ................................................ F2-80

CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION .......................... F2-81

CRANKSHAFT POSITION (CKP) SENSOR

INSPECTION ................................................ F2-82

CALIBRATION RESISTOR INSPECTION ....... F2-83

INJECTOR DRIVER MODULE (IDM)

INSPECTION ................................................ F2-84

ON-BOARD DIAGNOSTIC................................. F2-85

ON-BOARD DIAGNOSTIC TEST .................... F2-85

DTC CONFIRMATION PROCEDURE ............. F2-85

KOEO/KOER SELF-TEST PROCEDURE ....... F2-86

AFTER REPAIR PROCEDURE ....................... F2-86

DTC TABLE ..................................................... F2-87

DTC P0016 ...................................................... F2-88

DTC P0088 ...................................................... F2-89

DTC P0091 ...................................................... F2-90

DTC P0092 ...................................................... F2-92

DTC P0093 ...................................................... F2-94

DTC P0097 ...................................................... F2-95

DTC P0098 ...................................................... F2-97

DTC P0102 ...................................................... F2-99

DTC P0103 .................................................... F2-101

DTC P0107 .................................................... F2-103

DTC P0108 .................................................... F2-105

DTC P0112 .................................................... F2-107

DTC P0113 .................................................... F2-109

DTC P0117 .................................................... F2-111

DTC P0118 .................................................... F2-113

DTC P0121 .................................................... F2-115

DTC P0122 .................................................... F2-116

DTC P0123 .................................................... F2-118

DTC P0182 .................................................... F2-120

DTC P0183 .................................................... F2-122

DTC P0191 .................................................... F2-124

DTC P0192 .................................................... F2-125

DTC P0193 .................................................... F2-127

DTC P0200 .................................................... F2-129

DTC P0221 .................................................... F2-131

DTC P0222 .................................................... F2-132

DTC P0223 .................................................... F2-134

DTC P0300 .................................................... F2-136

DTC P0336 .................................................... F2-137

DTC P0337 .................................................... F2-138

DTC P0341 .................................................... F2-140

DTC P0342 .................................................... F2-141

DTC P0380 .................................................... F2-143

DTC P0504 .................................................... F2-145

DTC P0510 .................................................... F2-148

DTC P0512 .................................................... F2-150

DTC P0564 .................................................... F2-152

DTC P0602 .................................................... F2-154DTC P0606..................................................... F2-155

DTC P0610..................................................... F2-155

DTC P0661..................................................... F2-156

DTC P0662..................................................... F2-158

DTC P0850..................................................... F2-160

DTC P1190..................................................... F2-162

DTC P2228..................................................... F2-164

DTC P2229..................................................... F2-164

TROUBLESHOOTING...................................... F2-165

SYMPTOM DIAGNOSTIC INDEX .................. F2-165

SYMPTOM QUICK DIAGNOSIS CHART ...... F2-167

NO.1 MELTING OF MAIN OR

OTHER FUSES ........................................... F2-173

NO.2 MIL ILLUMINATES ............................... F2-174

NO.3 WILL NOT CRANK ............................... F2-174

NO.4 HARD START/LONG CRANK/ERRATIC

START/ERRATIC CRANK .......................... F2-176

NO.5 ENGINE STALLS-AFTER

START/AT IDLE .......................................... F2-178

NO.6 CRANKS NORMALLY BUT WILL NOT

START ........................................................ F2-181

NO.7 SLOW RETURN TO IDLE .................... F2-184

NO.8 ENGINE RUNS ROUGH/ROLLING

IDLE ............................................................ F2-186

NO.9 FAST IDLE/RUNS ON .......................... F2-189

NO.10 LOW IDLE/STALLS DURING

DECELERATION ........................................ F2-190

NO.11 ENGINE STALLS/QUITS, ENGINE RUNS

ROUGH, MISSES, BUCK/JERK,

HESITATION/STUMBLE, SURGES ........... F2-192

NO.12 LACK/LOSS OF

POWER-ACCELERATION/CRUISE ........... F2-195

NO.13 KNOCKING/PINGING......................... F2-199

NO.14 POOR FUEL ECONOMY.................... F2-202

NO.15 EMISSION COMPLIANCE.................. F2-205

NO.16 HIGH OIL

CONSUMPTION/LEAKAGE ....................... F2-209

NO.17 COOLING SYSTEM

CONCERNS-OVERHEATING .................... F2-210

NO.18 COOLING SYSTEM

CONCERNS-RUNS COLD ......................... F2-212

NO.19 EXCESSIVE BLACK SMOKE ............. F2-213

NO.20 FUEL ODOR

(IN ENGINE COMPARTMENT) .................. F2-216

NO.21 ENGINE NOISE .................................. F2-217

NO.22 VIBRATION CONCERNS (ENGINE) .. F2-220

NO.23 A/C DOES NOT WORK

SUFFICIENTLY ........................................... F2-222

NO.24 A/C ALWAYS ON OR A/C

COMPRESSOR RUNS

CONTINUOUSLY........................................ F2-223

NO.25 A/C DOES NOT CUT OFF UNDER

WIDE OPEN THROTTLE CONDITIONS .... F2-224

NO.26 CONSTANT VOLTAGE ...................... F2-225

INTERMITTENT CONCERN

TROUBLESHOOTING ................................ F2-227

ENGINE CONTROL SYSTEM

OPERATION INSPECTION ........................ F2-229

Page 176 of 909

F2–24

CONTROL SYSTEM, ON-BOARD DIAGNOSTIC

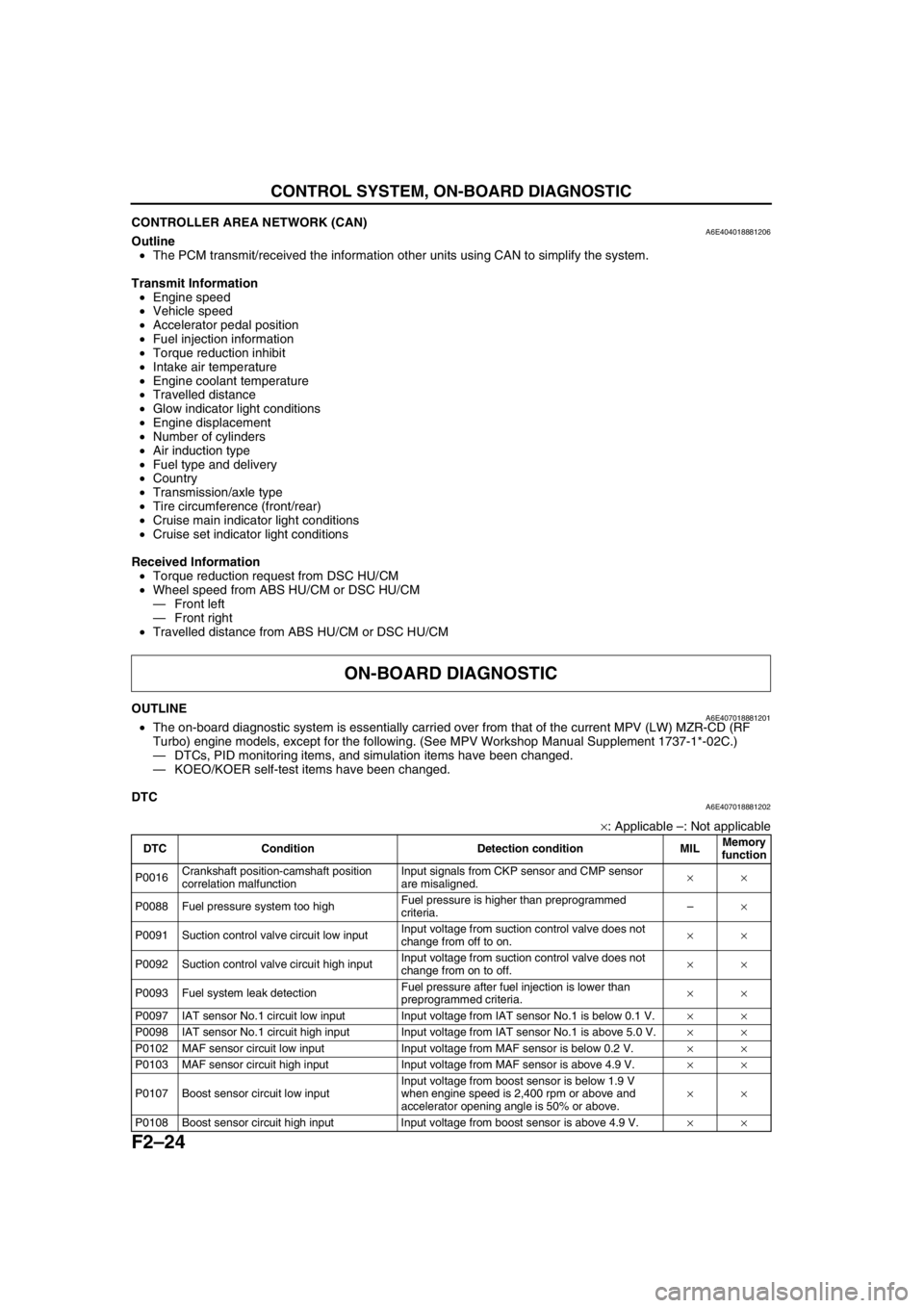

CONTROLLER AREA NETWORK (CAN)A6E404018881206Outline

•The PCM transmit/received the information other units using CAN to simplify the system.

Transmit Information

•Engine speed

•Vehicle speed

•Accelerator pedal position

•Fuel injection information

•Torque reduction inhibit

•Intake air temperature

•Engine coolant temperature

•Travelled distance

•Glow indicator light conditions

•Engine displacement

•Number of cylinders

•Air induction type

•Fuel type and delivery

•Country

•Transmission/axle type

•Tire circumference (front/rear)

•Cruise main indicator light conditions

•Cruise set indicator light conditions

Received Information

•Torque reduction request from DSC HU/CM

•Wheel speed from ABS HU/CM or DSC HU/CM

—Front left

—Front right

•Travelled distance from ABS HU/CM or DSC HU/CM

End Of Sie

OUTLINEA6E407018881201•The on-board diagnostic system is essentially carried over from that of the current MPV (LW) MZR-CD (RF

Turbo) engine models, except for the following. (See MPV Workshop Manual Supplement 1737-1*-02C.)

—DTCs, PID monitoring items, and simulation items have been changed.

—KOEO/KOER self-test items have been changed.

End Of Sie

DTCA6E407018881202

×: Applicable –: Not applicable

ON-BOARD DIAGNOSTIC

DTC Condition Detection condition MILMemory

function

P0016Crankshaft position-camshaft position

correlation malfunctionInput signals from CKP sensor and CMP sensor

are misaligned.××

P0088 Fuel pressure system too highFuel pressure is higher than preprogrammed

criteria.–×

P0091 Suction control valve circuit low inputInput voltage from suction control valve does not

change from off to on.××

P0092 Suction control valve circuit high inputInput voltage from suction control valve does not

change from on to off.××

P0093 Fuel system leak detectionFuel pressure after fuel injection is lower than

preprogrammed criteria.××

P0097 IAT sensor No.1 circuit low input Input voltage from IAT sensor No.1 is below 0.1 V.××

P0098 IAT sensor No.1 circuit high input Input voltage from IAT sensor No.1 is above 5.0 V.××

P0102 MAF sensor circuit low input Input voltage from MAF sensor is below 0.2 V.××

P0103 MAF sensor circuit high input Input voltage from MAF sensor is above 4.9 V.××

P0107 Boost sensor circuit low inputInput voltage from boost sensor is below 1.9 V

when engine speed is 2,400 rpm or above and

accelerator opening angle is 50% or above.××

P0108 Boost sensor circuit high input Input voltage from boost sensor is above 4.9 V.××

Page 179 of 909

ON-BOARD DIAGNOSTIC

F2–27

F2

PID/DATA MONITOR AND RECORDA6E407018881204PID monitoring item table

End Of Sie

SIMULATION TESTA6E407018881205Simulation test item table

×: Applicable

Item Definition Condition/unit PCM terminal

ACCS A/C relay ON/OFF 73

ACSW A/C switch ON/OFF 84

APS1 Accelerator position sensor No.1 signal voltage V 10

APS2 Accelerator position sensor No.2 signal voltage V 88

BAROBarometric pressure kPa, inHg

-

Barometric pressure signal voltage V

BOO Brake switch ON/OFF 7

CPP Clutch switch ON/OFF 33

CPP/PNP Neutral switch Neutral/Drive 56

CRUISESW Cruise control switch ON/OFF 64

DTCCNT DTC count - -

ECTEngine coolant temperature°C, °F

87

Engine coolant temperature signal voltage V

FAN2 Cooling fan relay No.2 ON/OFF 76

FAN3 Cooling fan relay No.1 ON/OFF 102

IATIntake air temperature°C, °F

60

Intake air temperature signal voltage V

IMRC VSC solenoid valve ON/OFF 101

INGEAR In gear ON/OFF 33, 56

INJ_LRN_DIS Distance from the last injector learning Km, Mile -

MAFMass air flow amount g/s

9

Mass air flow signal voltage V

MAF_LRN_DIS Distance from the last MAF learning Km, Mile -

MAINRLY PCM control relay ON/OFF 69

MAPManifold absolute pressure kPa, inHg

36

Manifold absolute pressure signal voltage V

MIL Malfunction indicator lamp ON/OFF 71

NUMKEYS Number of keys stored in module - -

RPM Engine speed rpm 3, 29

VPWR Battery positive voltage V 27

VSS Vehicle speed km/h, mph 13, 39

Item Definition OperationTest condition

PCM

terminal

Key ON Idle

ACCS A/C relay ON or OFF××73

EGRA EGR solenoid valve (vent)Actuated by any duty value

(0—100%)××72

EGRV EGR solenoid valve (vacuum)Actuated by any duty value

(0—100%)××99

EGRV2 EGR control solenoid valve ON or OFF××77

FAN Cooling fan No.2 ON or OFF××76

FAN3 Cooling fan No.1 ON or OFF××102

GP_LMP Glow indicator light ON or OFF××97

GPC Glow plug relay ON or OFF××68

IASV Intake shutter solenoid valve (half) ON or OFF××74

IASV2 Intake shutter solenoid valve (full) ON or OFF××100

IMRC VSC solenoid valve ON or OFF××101

VBCV VBC solenoid valveActuated by any duty value

(0—100%)××67

Page 185 of 909

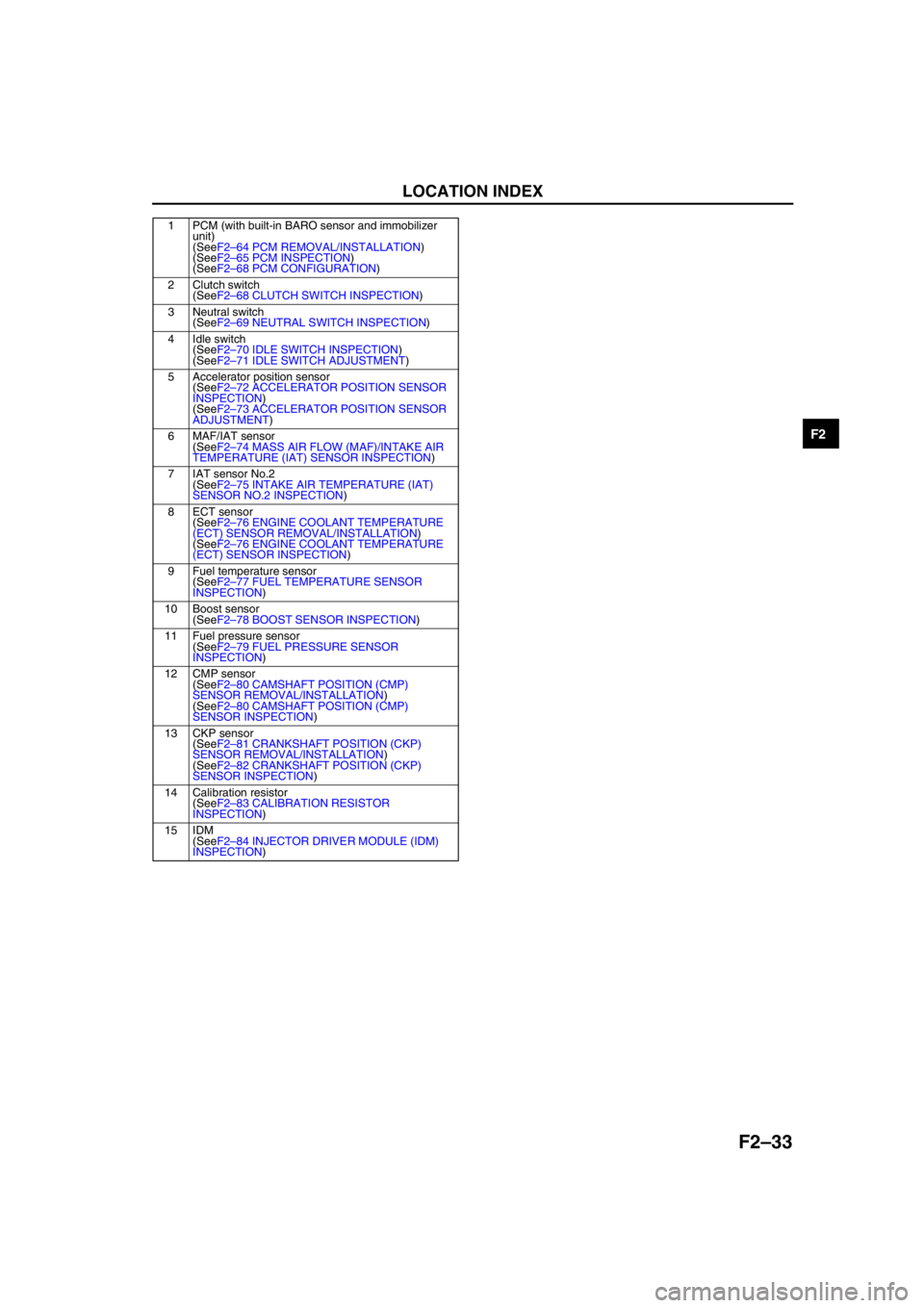

LOCATION INDEX

F2–33

F2

End Of Sie

1 PCM (with built-in BARO sensor and immobilizer

unit)

(SeeF2–64 PCM REMOVAL/INSTALLATION)

(SeeF2–65 PCM INSPECTION)

(SeeF2–68 PCM CONFIGURATION)

2 Clutch switch

(SeeF2–68 CLUTCH SWITCH INSPECTION)

3 Neutral switch

(SeeF2–69 NEUTRAL SWITCH INSPECTION)

4 Idle switch

(SeeF2–70 IDLE SWITCH INSPECTION)

(SeeF2–71 IDLE SWITCH ADJUSTMENT)

5 Accelerator position sensor

(SeeF2–72 ACCELERATOR POSITION SENSOR

INSPECTION)

(SeeF2–73 ACCELERATOR POSITION SENSOR

ADJUSTMENT)

6 MAF/IAT sensor

(SeeF2–74 MASS AIR FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT) SENSOR INSPECTION)

7 IAT sensor No.2

(SeeF2–75 INTAKE AIR TEMPERATURE (IAT)

SENSOR NO.2 INSPECTION)

8ECT sensor

(SeeF2–76 ENGINE COOLANT TEMPERATURE

(ECT) SENSOR REMOVAL/INSTALLATION)

(SeeF2–76 ENGINE COOLANT TEMPERATURE

(ECT) SENSOR INSPECTION)

9 Fuel temperature sensor

(SeeF2–77 FUEL TEMPERATURE SENSOR

INSPECTION)

10 Boost sensor

(SeeF2–78 BOOST SENSOR INSPECTION)

11 Fuel pressure sensor

(SeeF2–79 FUEL PRESSURE SENSOR

INSPECTION)

12 CMP sensor

(SeeF2–80 CAMSHAFT POSITION (CMP)

SENSOR REMOVAL/INSTALLATION)

(SeeF2–80 CAMSHAFT POSITION (CMP)

SENSOR INSPECTION)

13 CKP sensor

(SeeF2–81 CRANKSHAFT POSITION (CKP)

SENSOR REMOVAL/INSTALLATION)

(SeeF2–82 CRANKSHAFT POSITION (CKP)

SENSOR INSPECTION)

14 Calibration resistor

(SeeF2–83 CALIBRATION RESISTOR

INSPECTION)

15 IDM

(SeeF2–84 INJECTOR DRIVER MODULE (IDM)

INSPECTION)

Page 210 of 909

F2–58

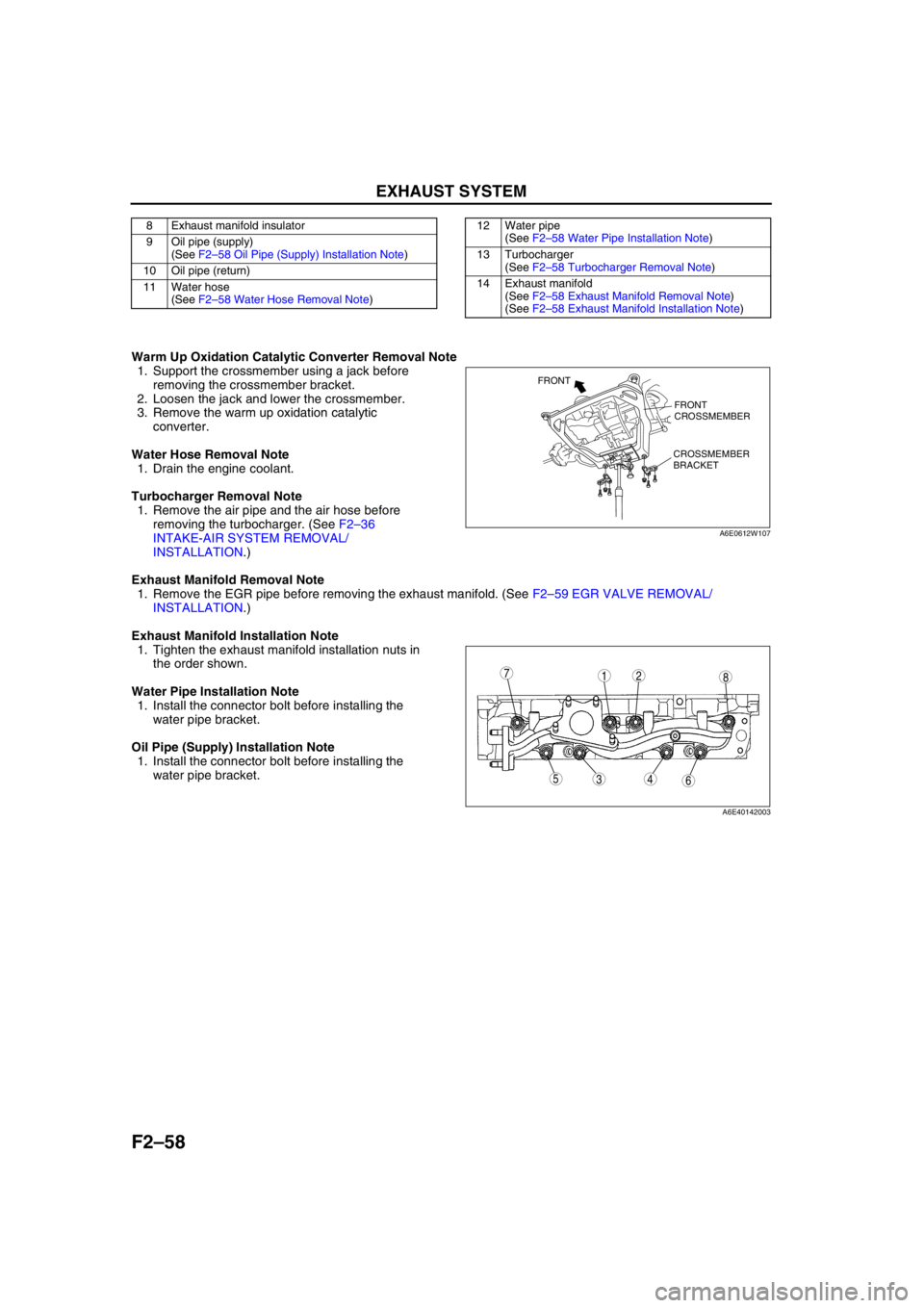

EXHAUST SYSTEM

Warm Up Oxidation Catalytic Converter Removal Note

1. Support the crossmember using a jack before

removing the crossmember bracket.

2. Loosen the jack and lower the crossmember.

3. Remove the warm up oxidation catalytic

converter.

Water Hose Removal Note

1. Drain the engine coolant.

Turbocharger Removal Note

1. Remove the air pipe and the air hose before

removing the turbocharger. (See F2–36

INTAKE-AIR SYSTEM REMOVAL/

INSTALLATION.)

Exhaust Manifold Removal Note

1. Remove the EGR pipe before removing the exhaust manifold. (See F2–59 EGR VALVE REMOVAL/

INSTALLATION.)

Exhaust Manifold Installation Note

1. Tighten the exhaust manifold installation nuts in

the order shown.

Water Pipe Installation Note

1. Install the connector bolt before installing the

water pipe bracket.

Oil Pipe (Supply) Installation Note

1. Install the connector bolt before installing the

water pipe bracket.

End Of Sie

8 Exhaust manifold insulator

9 Oil pipe (supply)

(See F2–58 Oil Pipe (Supply) Installation Note)

10 Oil pipe (return)

11 Water hose

(See F2–58 Water Hose Removal Note)12 Water pipe

(See F2–58 Water Pipe Installation Note)

13 Turbocharger

(See F2–58 Turbocharger Removal Note)

14 Exhaust manifold

(See F2–58 Exhaust Manifold Removal Note)

(See F2–58 Exhaust Manifold Installation Note)

FRONT

CROSSMEMBER

CROSSMEMBER

BRACKET FRONT

A6E0612W107

87

5436

12

A6E40142003

Page 217 of 909

CONTROL SYSTEM

F2–65

F2

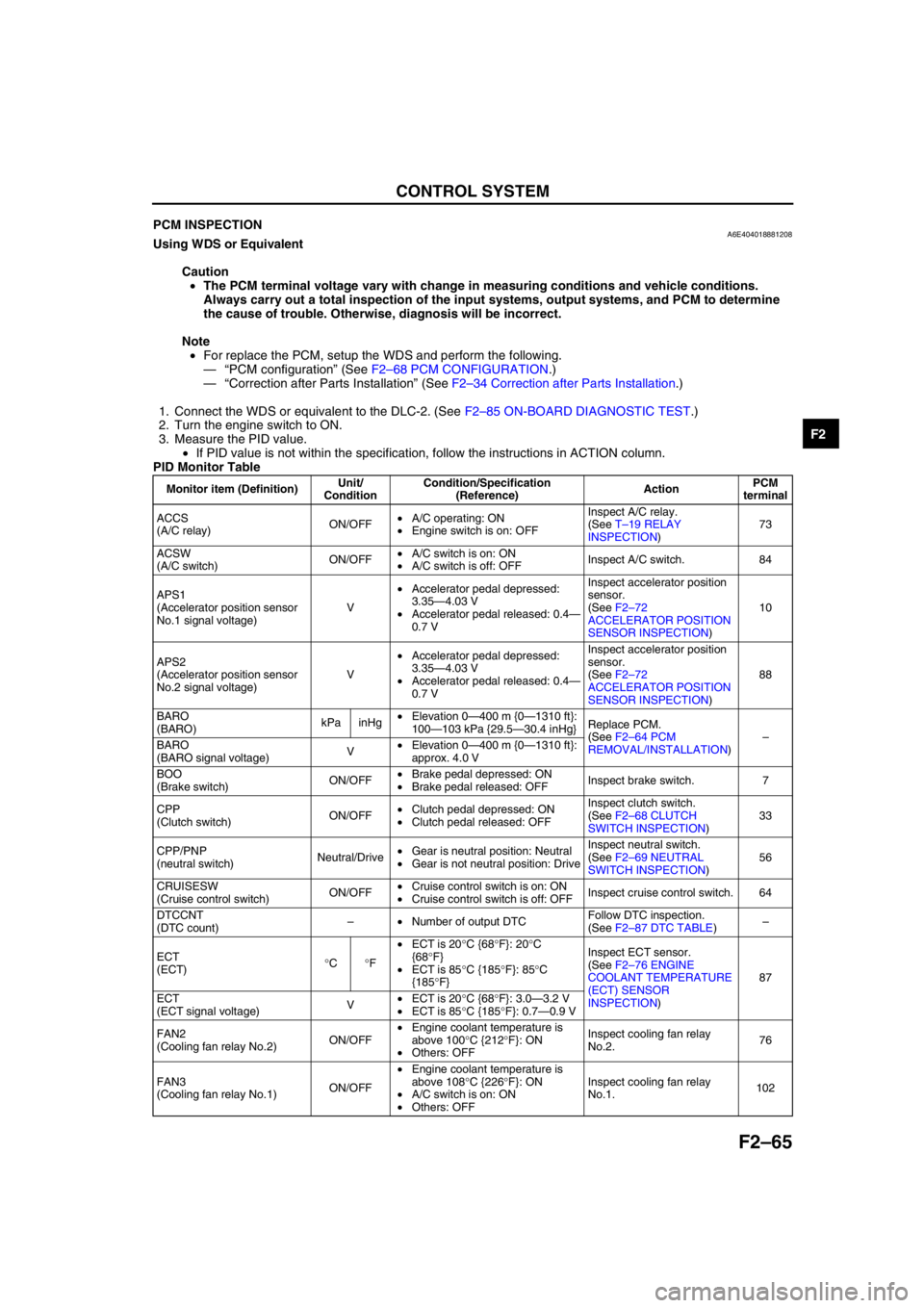

End Of SiePCM INSPECTIONA6E404018881208Using WDS or Equivalent

Caution

•The PCM terminal voltage vary with change in measuring conditions and vehicle conditions.

Always carry out a total inspection of the input systems, output systems, and PCM to determine

the cause of trouble. Otherwise, diagnosis will be incorrect.

Note

•For replace the PCM, setup the WDS and perform the following.

—“PCM configuration” (See F2–68 PCM CONFIGURATION.)

—“Correction after Parts Installation” (See F2–34 Correction after Parts Installation.)

1. Connect the WDS or equivalent to the DLC-2. (See F2–85 ON-BOARD DIAGNOSTIC TEST.)

2. Turn the engine switch to ON.

3. Measure the PID value.

•If PID value is not within the specification, follow the instructions in ACTION column.

PID Monitor Table

Monitor item (Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

ACCS

(A/C relay)ON/OFF•A/C operating: ON

•Engine switch is on: OFFInspect A/C relay.

(See T–19 RELAY

INSPECTION)73

ACSW

(A/C switch)ON/OFF•A/C switch is on: ON

•A/C switch is off: OFFInspect A/C switch. 84

APS1

(Accelerator position sensor

No.1 signal voltage)V•Accelerator pedal depressed:

3.35—4.03 V

•Accelerator pedal released: 0.4—

0.7 VInspect accelerator position

sensor.

(See F2–72

ACCELERATOR POSITION

SENSOR INSPECTION)10

APS2

(Accelerator position sensor

No.2 signal voltage)V•Accelerator pedal depressed:

3.35—4.03 V

•Accelerator pedal released: 0.4—

0.7 VInspect accelerator position

sensor.

(See F2–72

ACCELERATOR POSITION

SENSOR INSPECTION)88

BARO

(BARO)kPa inHg•Elevation 0—400 m {0—1310 ft}:

100—103 kPa {29.5—30.4 inHg}Replace PCM.

(See F2–64 PCM

REMOVAL/INSTALLATION)–

BARO

(BARO signal voltage)V•Elevation 0—400 m {0—1310 ft}:

approx. 4.0 V

BOO

(Brake switch)ON/OFF•Brake pedal depressed: ON

•Brake pedal released: OFFInspect brake switch. 7

CPP

(Clutch switch)ON/OFF•Clutch pedal depressed: ON

•Clutch pedal released: OFFInspect clutch switch.

(See F2–68 CLUTCH

SWITCH INSPECTION)33

CPP/PNP

(neutral switch)Neutral/Drive•Gear is neutral position: Neutral

•Gear is not neutral position: DriveInspect neutral switch.

(See F2–69 NEUTRAL

SWITCH INSPECTION)56

CRUISESW

(Cruise control switch)ON/OFF•Cruise control switch is on: ON

•Cruise control switch is off: OFFInspect cruise control switch. 64

DTCCNT

(DTC count)–•Number of output DTCFollow DTC inspection.

(See F2–87 DTC TABLE)–

ECT

(ECT)°C°F•ECT is 20°C {68°F}: 20°C

{68°F}

•ECT is 85°C {185°F}: 85°C

{185°F}Inspect ECT sensor.

(See F2–76 ENGINE

COOLANT TEMPERATURE

(ECT) SENSOR

INSPECTION)87

ECT

(ECT signal voltage)V•ECT is 20°C {68°F}: 3.0—3.2 V

•ECT is 85°C {185°F}: 0.7—0.9 V

FAN2

(Cooling fan relay No.2)ON/OFF•Engine coolant temperature is

above 100°C {212°F}: ON

•Others: OFFInspect cooling fan relay

No.2.76

FAN3

(Cooling fan relay No.1)ON/OFF•Engine coolant temperature is

above 108°C {226°F}: ON

•A/C switch is on: ON

•Others: OFFInspect cooling fan relay

No.1.102