oil MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 43 of 909

B2–12

TIMING BELT

Timing Belt, Timing Belt Auto Tensioner Installation Note

1. Measure the tensioned rod projection length.

•If not as specified, replace the timing belt auto

tensioner.

2. Inspect the timing belt auto tensioner for oil

leakage.

•If not as specified, replace the timing belt auto

tensioner.

Projection (free length)

12.9—14.6 mm {0.508—0.574 in}

Caution

•Placing the timing belt auto tensioner

horizontally can cause oil leakage and

damage the timing belt auto tensioner. Place the timing belt auto tensioner vertically when using a

vise.

3. Verify the thrust of the timing belt auto tensioner

rod in the following order:

•If the timing belt auto tensioner rod is rigid

when it is pushed with a force of

approximately 235 N {24 kgf, 53 Ibf}, push it

down slowly and fix the pin in the hole.

•If there is no resistance on the timing belt auto

tensioner rod and it moves slightly when it is

pushed with a force of approximately 235 N

{24 kgf, 53 Ibf};

(1) Push it down slowly two or three times to the

bottom end of the rod.

(2) If the rod protrudes approximately 8.1 mm

{0.32 in}, verify that there is resistance on the

timing belt auto tensioner rod.

Caution

•To prevent damage to the inside of the

timing belt auto tensioner, do not press

down the timing belt auto tensioner rod

with a force greater than the specified

235 N {24 kgf, 53 lbf}.

Be careful that the rod does not touch the

bottom.

•If the timing belt auto tensioner rod

projection is restored, push it down slowly and fix the pin in the hole.

—If the resistance is not restored, replace the timing belt auto tensoner.

A6E2316W105

PIN

A6E2316W106

Page 46 of 909

CYLINDER HEAD GASKET

B2–15

B2

End Of Sie

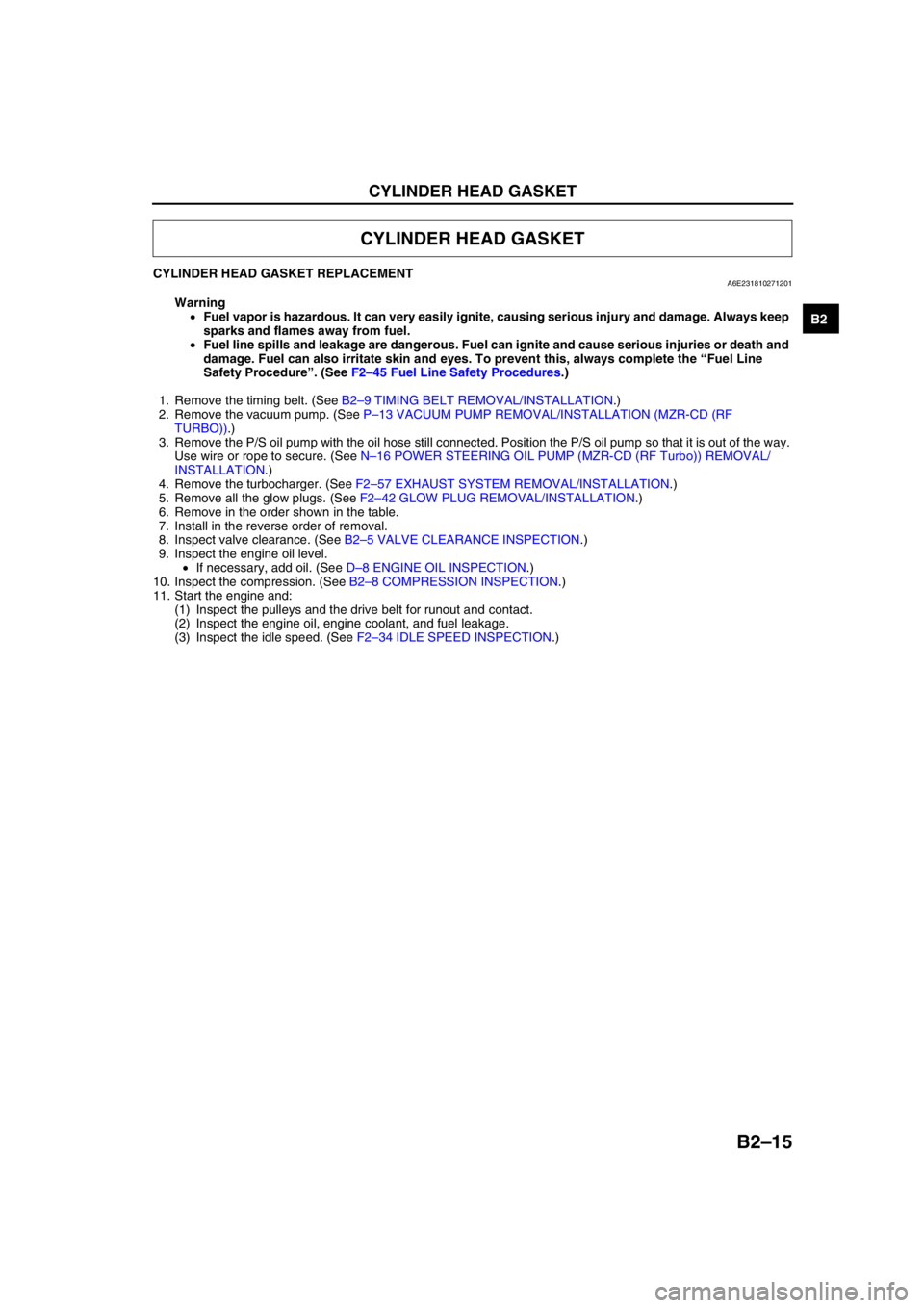

CYLINDER HEAD GASKET REPLACEMENTA6E231810271201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the vacuum pump. (See P–13 VACUUM PUMP REMOVAL/INSTALLATION (MZR-CD (RF

TURBO)).)

3. Remove the P/S oil pump with the oil hose still connected. Position the P/S oil pump so that it is out of the way.

Use wire or rope to secure. (See N–16 POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/

INSTALLATION.)

4. Remove the turbocharger. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

5. Remove all the glow plugs. (See F2–42 GLOW PLUG REMOVAL/INSTALLATION.)

6. Remove in the order shown in the table.

7. Install in the reverse order of removal.

8. Inspect valve clearance. (See B2–5 VALVE CLEARANCE INSPECTION.)

9. Inspect the engine oil level.

•If necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Inspect the compression. (See B2–8 COMPRESSION INSPECTION.)

11. Start the engine and:

(1) Inspect the pulleys and the drive belt for runout and contact.

(2) Inspect the engine oil, engine coolant, and fuel leakage.

(3) Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

CYLINDER HEAD GASKET

Page 47 of 909

B2–16

CYLINDER HEAD GASKET

.

SST

SST

SSTR

R

R

R

R

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

OILOIL

OILOIL

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf} 7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}55—64

{5.6—6.6, 41—47}

38—51

{3.8—5.3,

28—38}

52—61

{5.3—6.3,

39—45}

29 {3.0, 22}

+90 105

+90 105

+90 105

50—60

{5.0—6.0,

37—44}

19—25

{1.9—2.6,

14—18}

50—60 {5.0—6.0, 37—44}

46—58 {4.6—6.0, 34—43} 59—68

{6.0—7.0, 44—50}25—30

{2.5—3.1, 18—22}

38—51

{3.8—5.3,

28—38}19—25

{1.9—2.6,

14—18}

N·m {kgf·m, ft·lbf}

98

7

54

3

1

2

10

19

18

17

15

16

14

13

11

12

20

25

24

2321

22

6

SST

55—64

{5.6—6.6, 41—47}

—

— —

39—44

{4.0—4.4,

28.8—32.4}

22—26

{2.2—2.7,

16—19}

SEALANTSEALANT

A6E2318W100

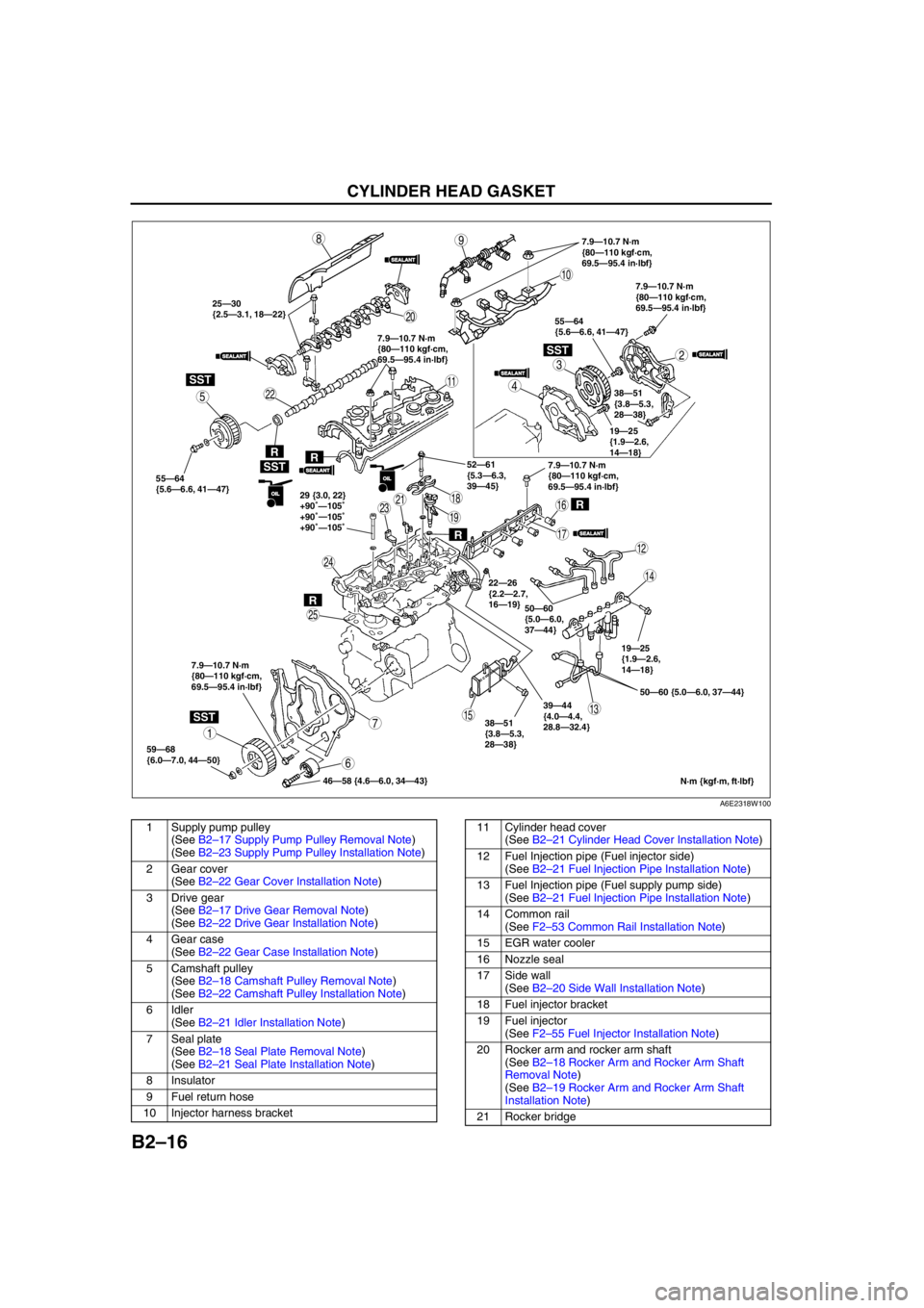

1 Supply pump pulley

(See B2–17 Supply Pump Pulley Removal Note)

(See B2–23 Supply Pump Pulley Installation Note)

2 Gear cover

(See B2–22 Gear Cover Installation Note)

3 Drive gear

(See B2–17 Drive Gear Removal Note)

(See B2–22 Drive Gear Installation Note)

4 Gear case

(See B2–22 Gear Case Installation Note)

5 Camshaft pulley

(See B2–18 Camshaft Pulley Removal Note)

(See B2–22 Camshaft Pulley Installation Note)

6 Idler

(See B2–21 Idler Installation Note)

7 Seal plate

(See B2–18 Seal Plate Removal Note)

(See B2–21 Seal Plate Installation Note)

8 Insulator

9 Fuel return hose

10 Injector harness bracket11 Cylinder head cover

(See B2–21 Cylinder Head Cover Installation Note)

12 Fuel Injection pipe (Fuel injector side)

(See B2–21 Fuel Injection Pipe Installation Note)

13 Fuel Injection pipe (Fuel supply pump side)

(See B2–21 Fuel Injection Pipe Installation Note)

14 Common rail

(See F2–53 Common Rail Installation Note)

15 EGR water cooler

16 Nozzle seal

17 Side wall

(See B2–20 Side Wall Installation Note)

18 Fuel injector bracket

19 Fuel injector

(See F2–55 Fuel Injector Installation Note)

20 Rocker arm and rocker arm shaft

(See B2–18 Rocker Arm and Rocker Arm Shaft

Removal Note)

(See B2–19 Rocker Arm and Rocker Arm Shaft

Installation Note)

21 Rocker bridge

Page 51 of 909

B2–20

CYLINDER HEAD GASKET

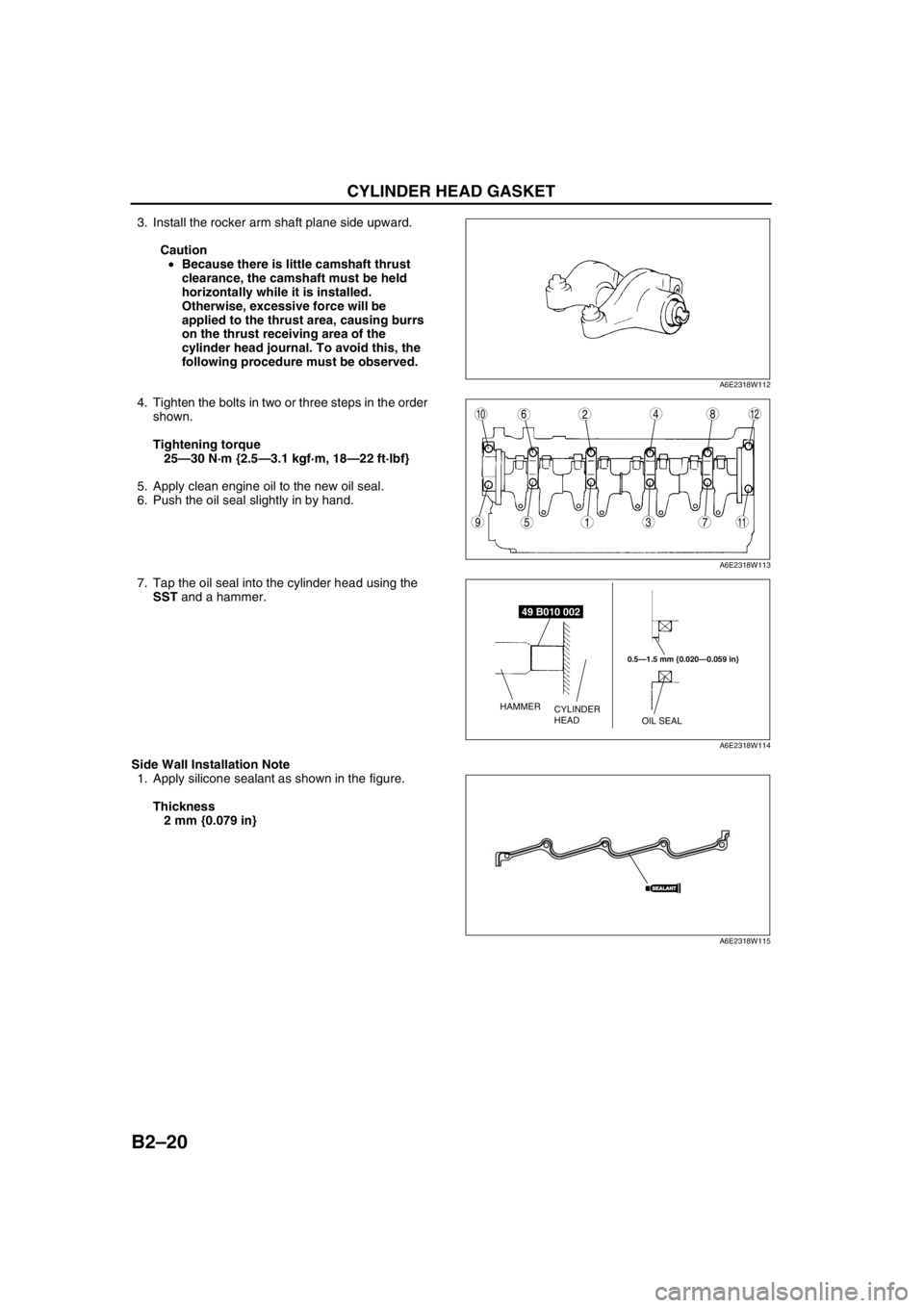

3. Install the rocker arm shaft plane side upward.

Caution

•Because there is little camshaft thrust

clearance, the camshaft must be held

horizontally while it is installed.

Otherwise, excessive force will be

applied to the thrust area, causing burrs

on the thrust receiving area of the

cylinder head journal. To avoid this, the

following procedure must be observed.

4. Tighten the bolts in two or three steps in the order

shown.

Tightening torque

25—30 N·m {2.5—3.1 kgf·m, 18—22 ft·lbf}

5. Apply clean engine oil to the new oil seal.

6. Push the oil seal slightly in by hand.

7. Tap the oil seal into the cylinder head using the

SST and a hammer.

Side Wall Installation Note

1. Apply silicone sealant as shown in the figure.

Thickness

2 mm {0.079 in}

A6E2318W112

9

8

75

4

3

10126

1

2

11

A6E2318W113

49 B010 002

0.5—1.5 mm {0.020—0.059 in}

OIL SEAL CYLINDER

HEAD HAMMER

A6E2318W114

SEALANTSEALANT

A6E2318W115

Page 55 of 909

B2–24

FRONT OIL SEAL

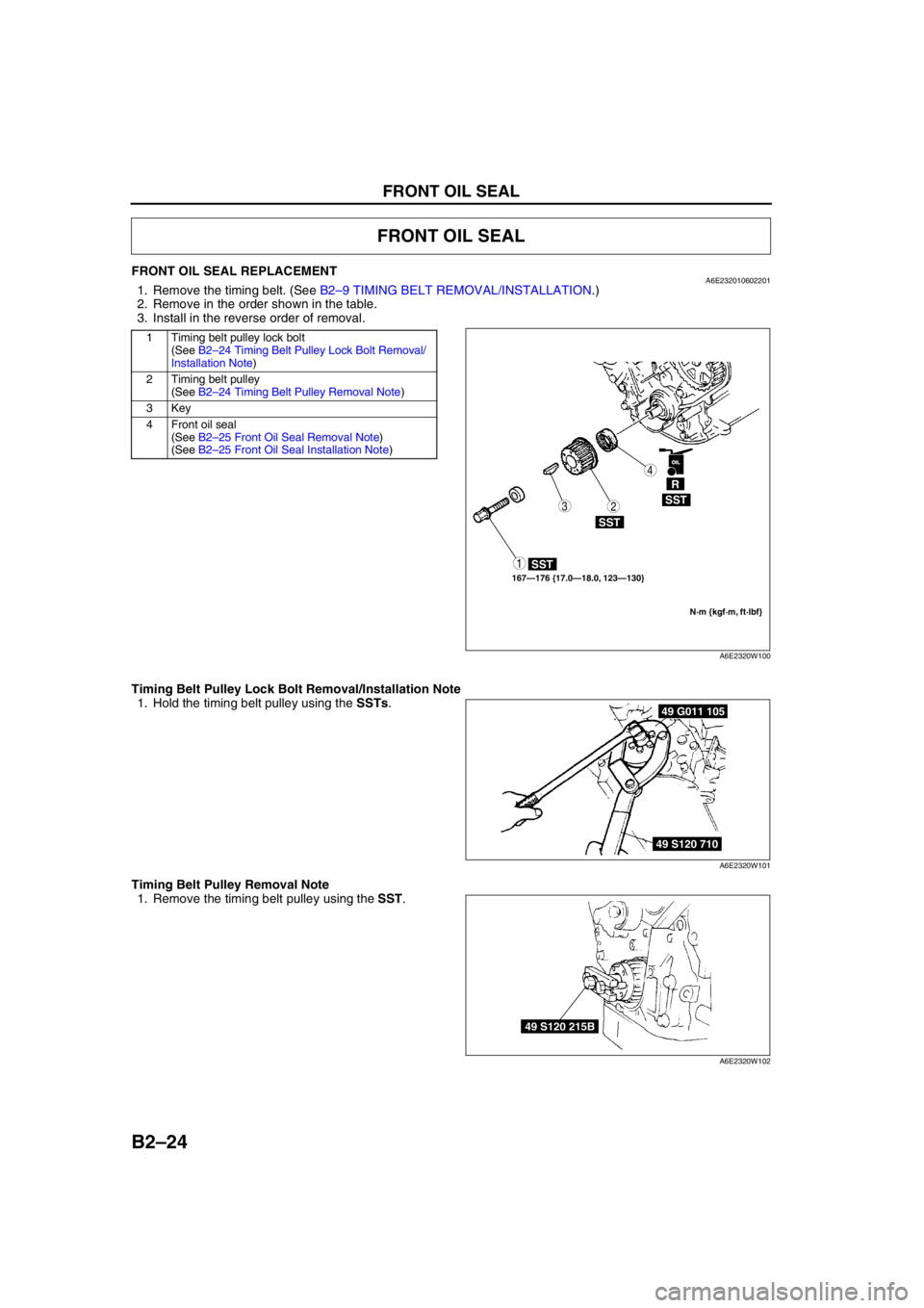

FRONT OIL SEAL REPLACEMENTA6E2320106022011. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove in the order shown in the table.

3. Install in the reverse order of removal.

.

Timing Belt Pulley Lock Bolt Removal/Installation Note

1. Hold the timing belt pulley using the SSTs.

Timing Belt Pulley Removal Note

1. Remove the timing belt pulley using the SST.

FRONT OIL SEAL

1 Timing belt pulley lock bolt

(See B2–24 Timing Belt Pulley Lock Bolt Removal/

Installation Note)

2 Timing belt pulley

(See B2–24 Timing Belt Pulley Removal Note)

3Key

4 Front oil seal

(See B2–25 Front Oil Seal Removal Note)

(See B2–25 Front Oil Seal Installation Note)

SST

SST

SST

R

OILOIL

167—176 {17.0—18.0, 123—130}

N·m {kgf·m, ft·lbf}

3

1

2

4

A6E2320W100

49 G011 105

49 S120 710

A6E2320W101

49 S120 215B

A6E2320W102

Page 56 of 909

FRONT OIL SEAL

B2–25

B2

Front Oil Seal Removal Note

1. Cut the oil seal lip using a razor knife.

2. Remove the oil seal using a screwdriver protected

with a rag.

Front Oil Seal Installation Note

1. Apply clean engine oil to the oil seal lip.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly using the SST and a

hammer. The oil seal must be tapped in until it is

flush with the edge of the oil pump body.

End Of Sie

OIL SEAL LIP

A6E2320W103

RAG

A6E2320W104

49 U027 003

0—0.5 mm {0—0.019 in}

HAMMEROIL PUMP BODY

FRONT OIL SEAL

A6E2320W105

Page 57 of 909

B2–26

REAR OIL SEAL

REAR OIL SEAL REPLACEMENTA6E2322113992011. Remove the flywheel. (See H–5 CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R manual transaxle

models).)

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

.

Rear Oil Seal Removal Note

1. Cut the oil seal lip using a razor knife.

2. Remove the oil seal using a screwdriver protected

with a rag.

Rear Oil Seal Installation Note

1. Apply clean engine oil to the oil seal lip.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly using the SST and a

hammer.

End Of Sie

REAR OIL SEAL

1 Rear oil seal

(See B2–26 Rear Oil Seal Removal Note)

(See B2–26 Rear Oil Seal Installation Note)

SST

R

OILOIL1

A6E2322W100

OIL SEAL LIP

A6E2322W101

RAG

A6E2322W102

0—0.5 mm

{0—0.019 in}

HAMMERREAR COVER

REAR OIL SEAL

49 G033 107A

A6E2322W103

Page 58 of 909

ENGINE

B2–27

B2

ENGINE REMOVAL/INSTALLATIONA6E232401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant, engine oil, and transaxle oil.

3. Remove the radiator.

4. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the air cleaner and air hose. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

6. Disconnect the fuel hose. (See F2–45 BEFORE REPAIR PROCEDURE.)

7. Remove the front pipe. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the battery and tray. (See G–5 BATTERY REMOVAL/INSTALLATION.)

9. Remove the shift cable, select cable and clutch release cylinder related to the transaxle. (See J2–7 MANUAL

TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the clutch release cylinder.

11. Remove the vacuum hose and the heater hose.

12. Disconnect the P/S oil pump pressure pipe and P/S oil pump relief hose from the P/S oil pump side. (See N–16

POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/INSTALLATION.)

Note

•The P/S oil pump will not be removed from the engine.

13. Remove the A/C compressor with the pipe still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure it. (See U–11 A/C COMPRESSOR REMOVAL/INSTALLATION.)

14. Remove the joint shaft.

15. Remove the front drive shaft (LH) from the transaxle.

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Fill the engine coolant, engine oil, and transaxle oil.

19. Bleed the air from the fuel line. (See F2–45 AFTER REPAIR PROCEDURE.)

20. Start the engine and:

•Inspect the pulleys and the drive belt for runout and contact.

•Inspect the engine oil, engine coolant transaxle oil, P/S fluid, and fuel for leakage.

•Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

21. Perform a road test.

22. Reinspect the engine oil, engine coolant, transaxle oil, and P/S fluid levels.

ENGINE

Page 63 of 909

B2–32

ENGINE

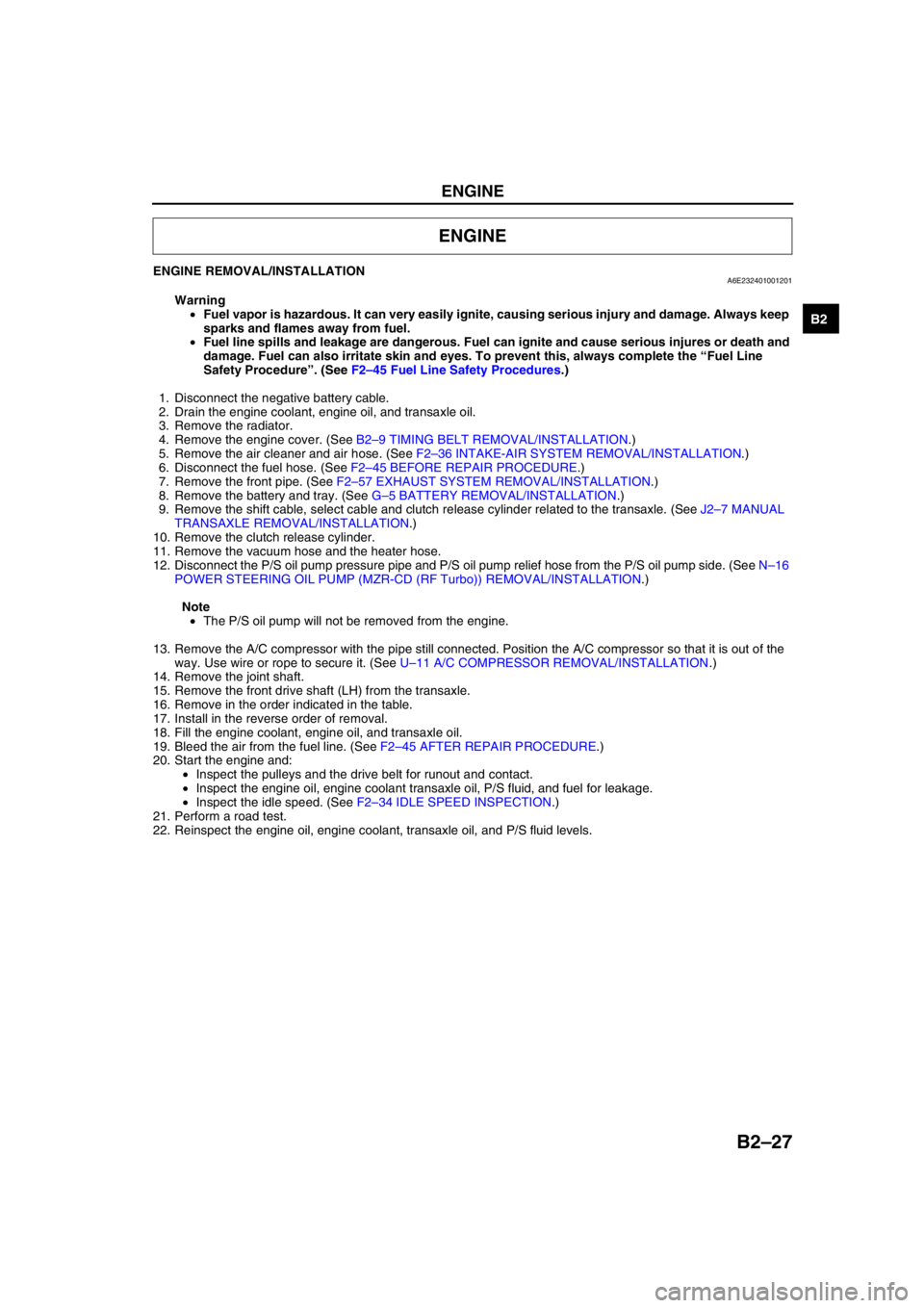

No.1 Engine Mount Bracket Installation Note

1. Tighten No.1 engine mount bracket bolt A.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

2. Tighten No.1 engine mount bracket bolt B.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

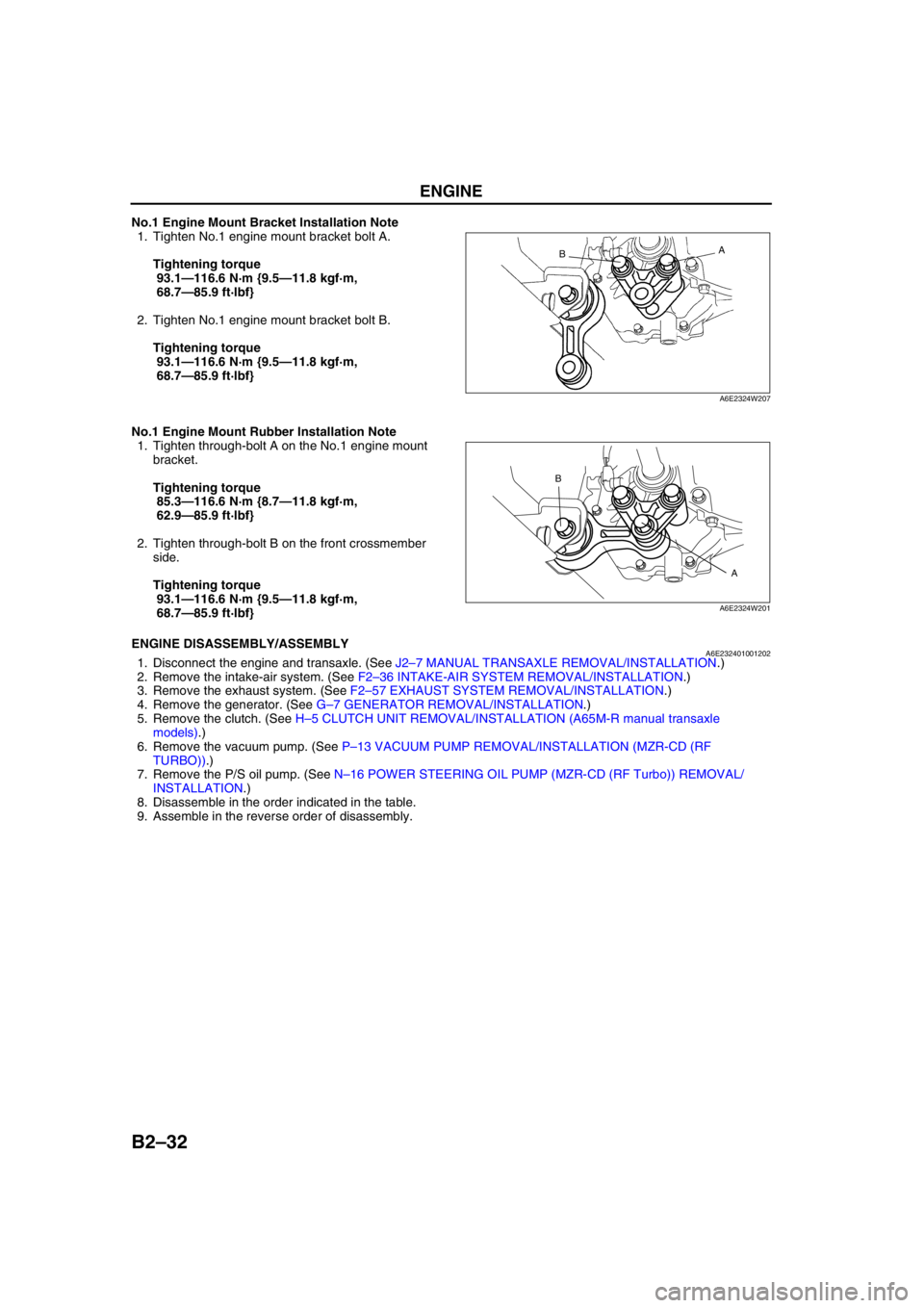

No.1 Engine Mount Rubber Installation Note

1. Tighten through-bolt A on the No.1 engine mount

bracket.

Tightening torque

85.3—116.6 N·m {8.7—11.8 kgf·m,

62.9—85.9 ft·lbf}

2. Tighten through-bolt B on the front crossmember

side.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

End Of SieENGINE DISASSEMBLY/ASSEMBLYA6E2324010012021. Disconnect the engine and transaxle. (See J2–7 MANUAL TRANSAXLE REMOVAL/INSTALLATION.)

2. Remove the intake-air system. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

3. Remove the exhaust system. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

4. Remove the generator. (See G–7 GENERATOR REMOVAL/INSTALLATION.)

5. Remove the clutch. (See H–5 CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R manual transaxle

models).)

6. Remove the vacuum pump. (See P–13 VACUUM PUMP REMOVAL/INSTALLATION (MZR-CD (RF

TURBO)).)

7. Remove the P/S oil pump. (See N–16 POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/

INSTALLATION.)

8. Disassemble in the order indicated in the table.

9. Assemble in the reverse order of disassembly.

A

B

A6E2324W207

A B

A6E2324W201

Page 65 of 909

D–1

D

DLUBRICATION SYSTEM

OUTLINE................................................................ D-2

OUTLINE OF CONSTRUCTION.......................... D-2

SPECIFICATIONS ............................................... D-2

STRUCTURAL VIEW ...........................................D-4

LUBRICATION SYSTEM........................................ D-5

LUBRICATION FLOW CHART ............................ D-5

OUTLINE................................................................ D-6

SUPPLEMENTAL SERVICE INFORMATION .....D-6

LUBRICATION SYSTEM........................................ D-6

LOCATION INDEX ............................................... D-6

OIL PRESSURE INSPECTION..............................D-7

OIL PRESSURE INSPECTION............................ D-7

ENGINE OIL........................................................... D-8

ENGINE OIL INSPECTION.................................. D-8

ENGINE OIL REPLACEMENT.............................D-8

OIL FILTER............................................................. D-9

OIL FILTER REPLACEMENT ..............................D-9

OIL COOLER.......................................................... D-9

OIL COOLER REMOVAL/INSTALLATION ..........D-9

OIL PAN................................................................ D-10

OIL PAN REMOVAL/INSTALLATION................ D-10 FEATURES

SERVICE