oil MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 106 of 909

F1–18

CONTROL SYSTEM

*1: For MTX model

*2: For 2WD ATX model

*3: For L3 engine

End Of Sie

1 MAF/IAT sensor

2 TP sensor

3 MAP sensor

4 CMP sensor

5 CKP sensor

6 ECT sensor

7 Knock sensor

8 HO2S (front, rear)

9 PSP switch

10 Vehicle speedometer sensor

11

Clutch switch*

1

12

Neutral switch*1

13

TR switch*2

14 Brake switch

15 A/C switch

16 Refrigerant pressure switch

17 Generator (terminal P: generation voltage)

18 Battery

19

VAD control solenoid valve*

3

20 IAC valve

21

VIC solenoid valve*

3

22 Variable tumble control solenoid valve

23

OCV*

3

24 Fuel injector

25 Fuel pump relay

26 Ignition coil

27 Purge solenoid valve

28 EGR valve

29 Oxygen sensor heater (front, rear)

30 A/C relay

31 Cooling fan relay

32 Generator (terminal D: field coil)

33

VAD control*

3

34 IAC

35

VIC*

3

36 VTCS

37

Variable valve timing control*

3

38 Fuel injection control

39 Fuel pump control

40 Electronic spark advance (ESA) control

41 Purge control

42 EGR control

43 Oxygen sensor heater control

44 A/C cut-off control

45 Electrical fan control

46 Generator control

Page 107 of 909

CONTROL SYSTEM

F1–19

F1

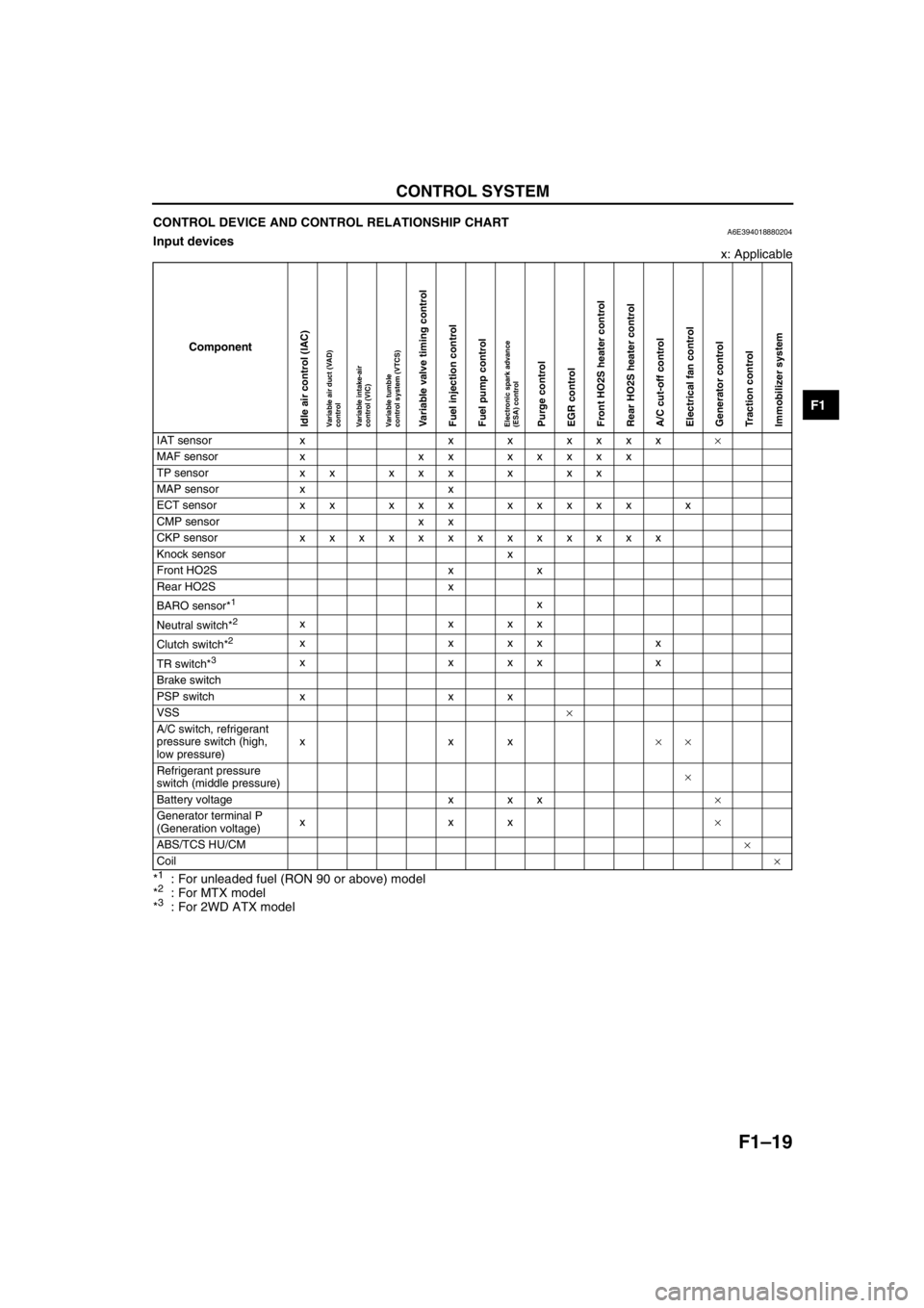

CONTROL DEVICE AND CONTROL RELATIONSHIP CHARTA6E394018880204Input devices

x: Applicable

*

1: For unleaded fuel (RON 90 or above) model

*2: For MTX model

*3: For 2WD ATX model

Component

IAT sensor x x x xxxx×

MAF sensor x xx xxxxx

TP sensor x x x x x x x x

MAP sensor x x

ECT sensor xx xxx xxxxx x

CMP sensor x x

CKP sensor xxxxxxxxxxxxx

Knock sensor x

Front HO2S x x

Rear HO2S x

BARO sensor*

1x

Neutral switch*

2xxxx

Clutch switch*

2xxxxx

TR switch*

3xxxxx

Brake switch

PSP switch x x x

VSS×

A/C switch, refrigerant

pressure switch (high,

low pressure)xxx××

Refrigerant pressure

switch (middle pressure)×

Battery voltage x x x×

Generator terminal P

(Generation voltage)xxx×

ABS/TCS HU/CM×

Coil×

Idle air control (IAC)Variable air duct (VAD)

controlVariable intake-air

control (VIC)Variable tumble

control system (VTCS)Variable valve timing controlFuel injection controlFuel pump controlElectronic spark advance

(ESA) controlPurge controlEGR controlFront HO2S heater controlRear HO2S heater controlA/C cut-off controlElectrical fan controlGenerator controlTraction controlImmobilizer system

Page 108 of 909

F1–20

CONTROL SYSTEM

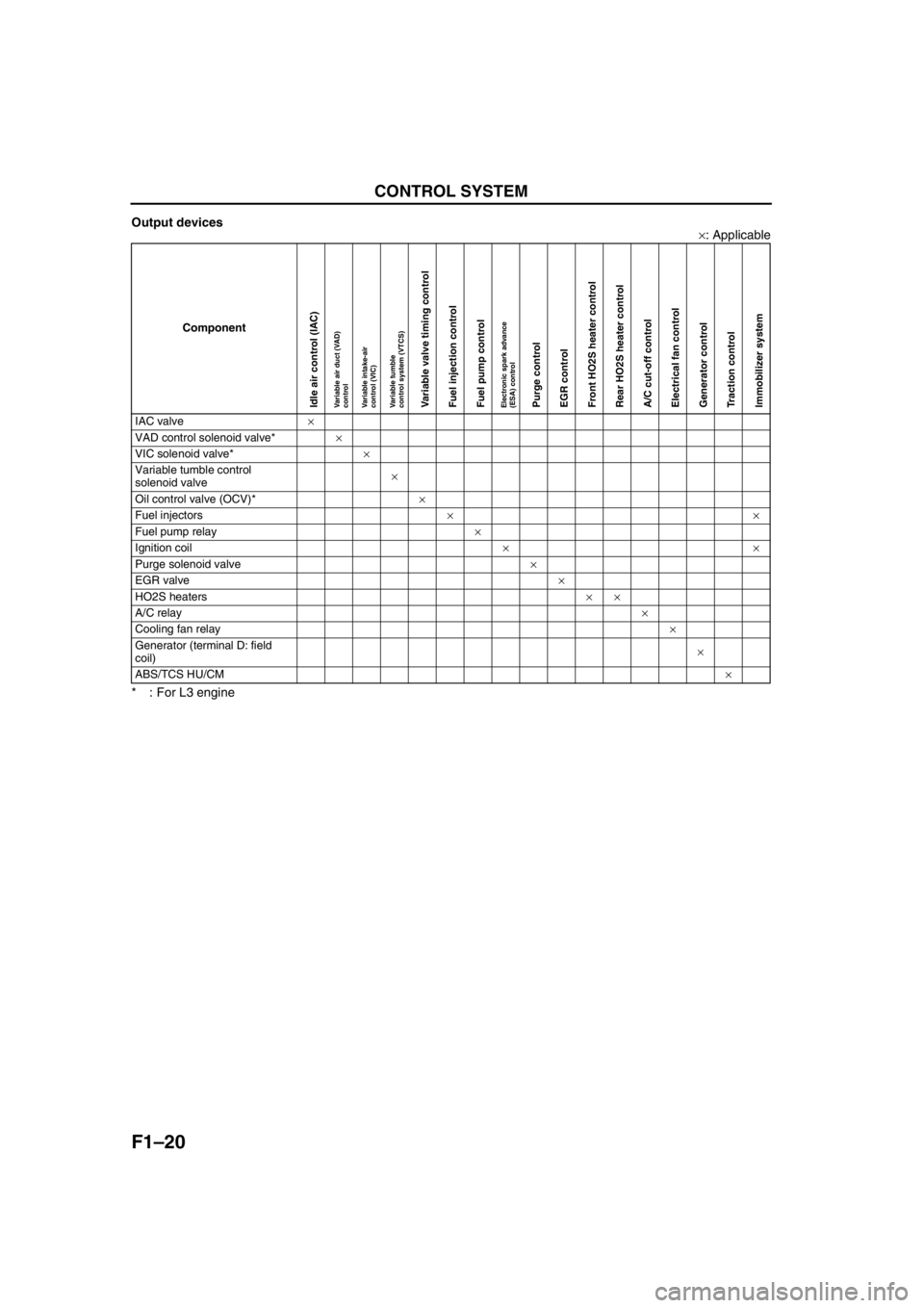

Output devices

×: Applicable

* : For L3 engine

End Of Sie

Component

IAC valve×

VAD control solenoid valve*×

VIC solenoid valve*×

Variable tumble control

solenoid valve×

Oil control valve (OCV)*×

Fuel injectors××

Fuel pump relay×

Ignition coil××

Purge solenoid valve×

EGR valve×

HO2S heaters××

A/C relay×

Cooling fan relay×

Generator (terminal D: field

coil)×

ABS/TCS HU/CM×

Idle air control (IAC)Variable air duct (VAD)

controlVariable intake-air

control (VIC)Variable tumble

control system (VTCS)Variable valve timing controlFuel injection controlFuel pump controlElectronic spark advance

(ESA) controlPurge controlEGR controlFront HO2S heater controlRear HO2S heater controlA/C cut-off controlElectrical fan controlGenerator controlTraction controlImmobilizer system

Page 116 of 909

F1–28

FUEL SYSTEM

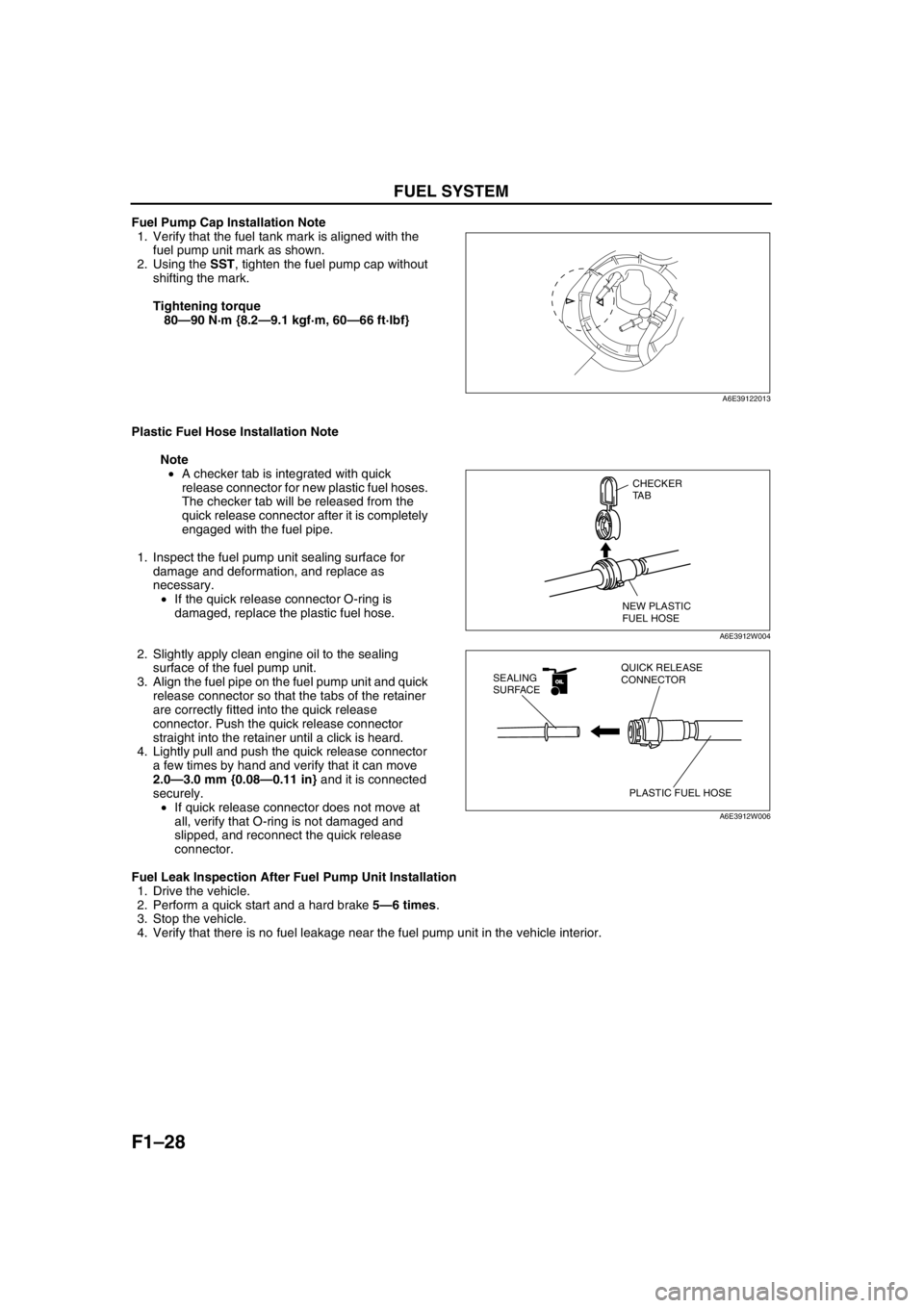

Fuel Pump Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump unit mark as shown.

2. Using the SST, tighten the fuel pump cap without

shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

2. Slightly apply clean engine oil to the sealing

surface of the fuel pump unit.

3. Align the fuel pipe on the fuel pump unit and quick

release connector so that the tabs of the retainer

are correctly fitted into the quick release

connector. Push the quick release connector

straight into the retainer until a click is heard.

4. Lightly pull and push the quick release connector

a few times by hand and verify that it can move

2.0—3.0 mm {0.08—0.11 in} and it is connected

securely.

•If quick release connector does not move at

all, verify that O-ring is not damaged and

slipped, and reconnect the quick release

connector.

Fuel Leak Inspection After Fuel Pump Unit Installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

A6E39122013

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

Page 117 of 909

FUEL SYSTEM

F1–29

F1

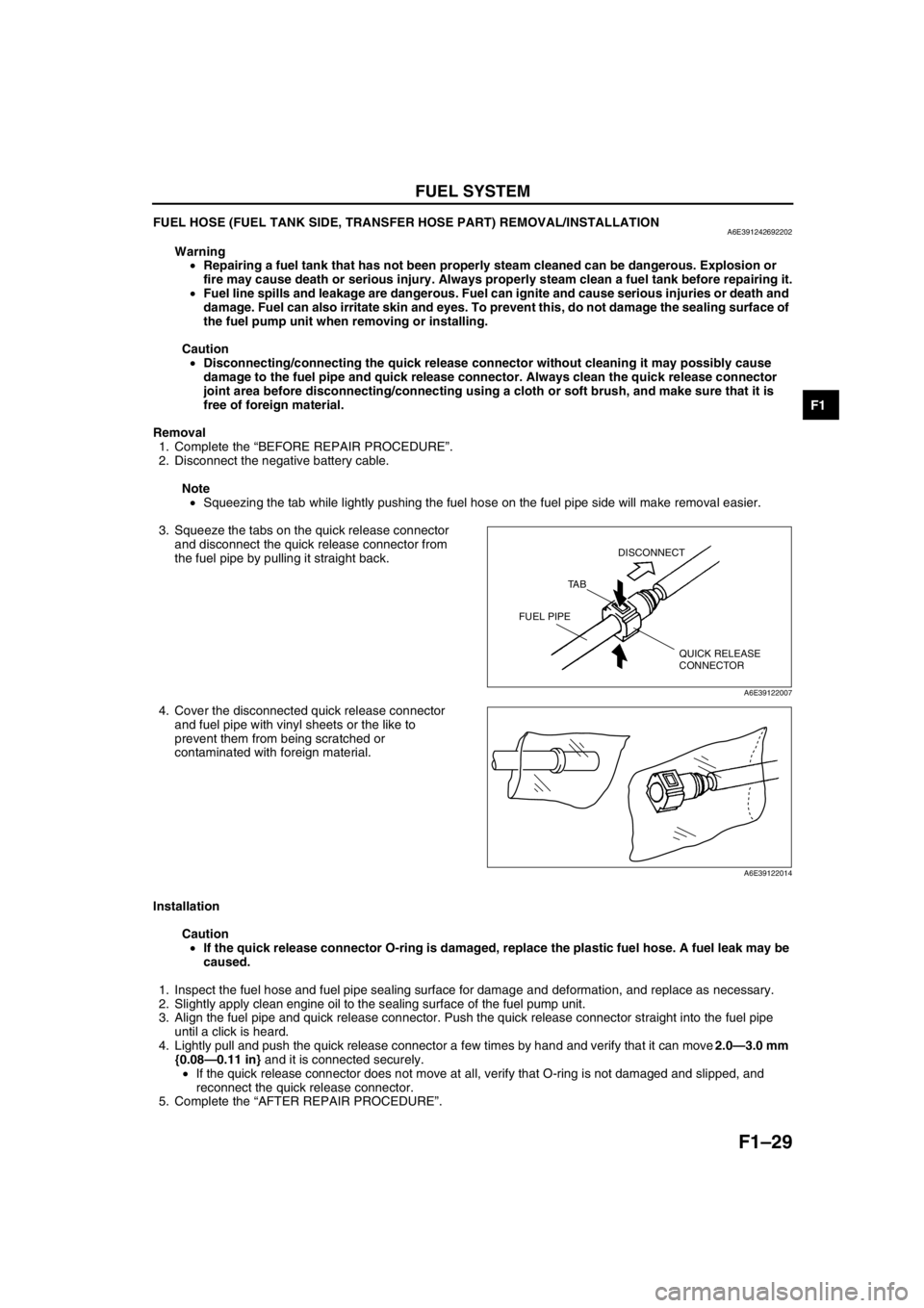

FUEL HOSE (FUEL TANK SIDE, TRANSFER HOSE PART) REMOVAL/INSTALLATIONA6E391242692202

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Removal

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

Note

•Squeezing the tab while lightly pushing the fuel hose on the fuel pipe side will make removal easier.

3. Squeeze the tabs on the quick release connector

and disconnect the quick release connector from

the fuel pipe by pulling it straight back.

4. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Installation

Caution

•If the quick release connector O-ring is damaged, replace the plastic fuel hose. A fuel leak may be

caused.

1. Inspect the fuel hose and fuel pipe sealing surface for damage and deformation, and replace as necessary.

2. Slightly apply clean engine oil to the sealing surface of the fuel pump unit.

3. Align the fuel pipe and quick release connector. Push the quick release connector straight into the fuel pipe

until a click is heard.

4. Lightly pull and push the quick release connector a few times by hand and verify that it can move 2.0—3.0 mm

{0.08—0.11 in} and it is connected securely.

•If the quick release connector does not move at all, verify that O-ring is not damaged and slipped, and

reconnect the quick release connector.

5. Complete the “AFTER REPAIR PROCEDURE”.

End Of Sie

QUICK RELEASE

CONNECTOR TA BDISCONNECT

FUEL PIPE

A6E39122007

A6E39122014

Page 121 of 909

CONTROL SYSTEM

F1–33

F1

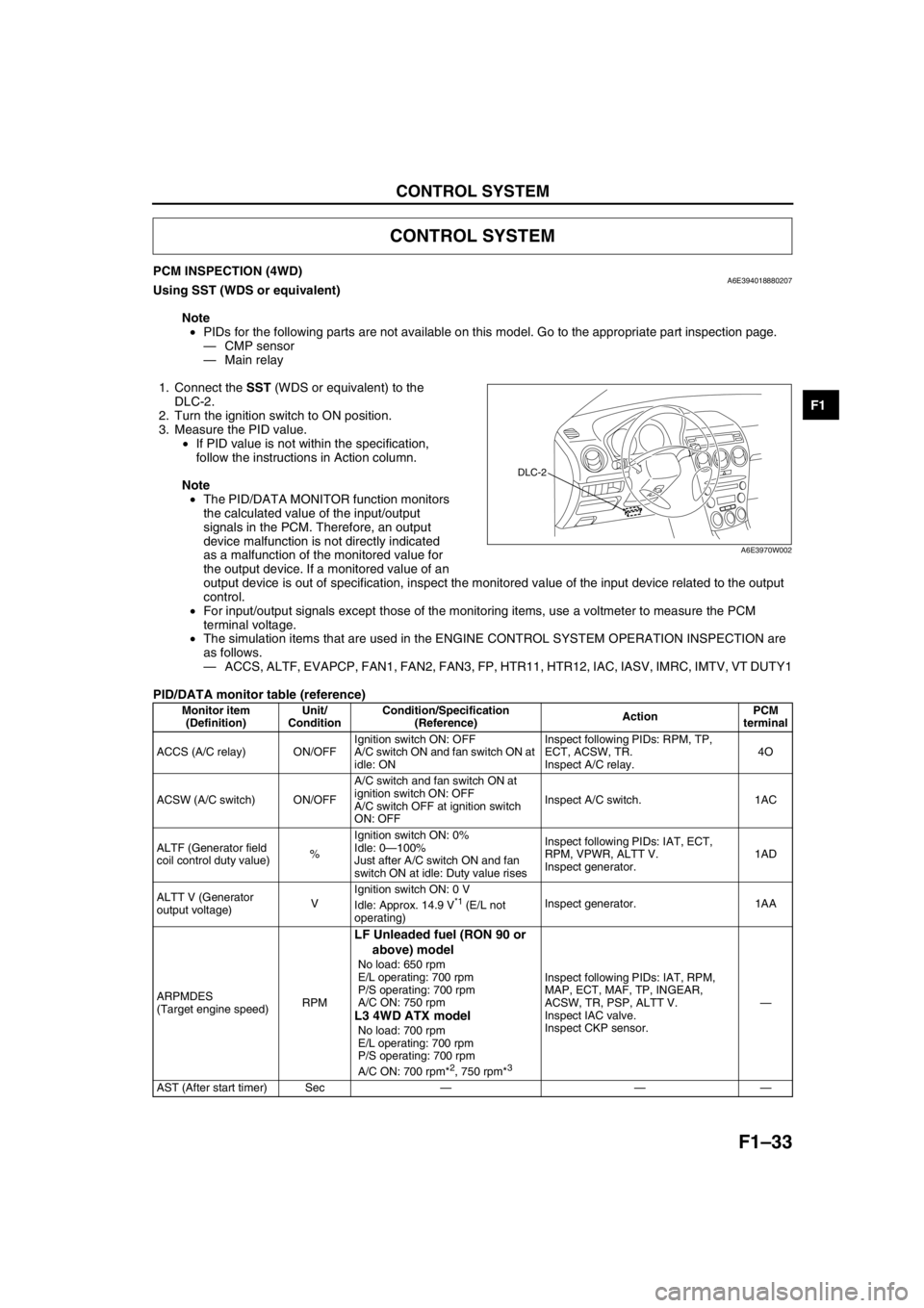

PCM INSPECTION (4WD)A6E394018880207Using SST (WDS or equivalent)

Note

•PIDs for the following parts are not available on this model. Go to the appropriate part inspection page.

—CMP sensor

—Main relay

1. Connect the SST (WDS or equivalent) to the

DLC-2.

2. Turn the ignition switch to ON position.

3. Measure the PID value.

•If PID value is not within the specification,

follow the instructions in Action column.

Note

•The PID/DATA MONITOR function monitors

the calculated value of the input/output

signals in the PCM. Therefore, an output

device malfunction is not directly indicated

as a malfunction of the monitored value for

the output device. If a monitored value of an

output device is out of specification, inspect the monitored value of the input device related to the output

control.

•For input/output signals except those of the monitoring items, use a voltmeter to measure the PCM

terminal voltage.

•The simulation items that are used in the ENGINE CONTROL SYSTEM OPERATION INSPECTION are

as follows.

—ACCS, ALTF, EVAPCP, FAN1, FAN2, FAN3, FP, HTR11, HTR12, IAC, IASV, IMRC, IMTV, VT DUTY1

PID/DATA monitor table (reference)

CONTROL SYSTEM

DLC-2

A6E3970W002

Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

ACCS (A/C relay) ON/OFFIgnition switch ON: OFF

A/C switch ON and fan switch ON at

idle: ONInspect following PIDs: RPM, TP,

ECT, ACSW, TR.

Inspect A/C relay.4O

ACSW (A/C switch) ON/OFFA/C switch and fan switch ON at

ignition switch ON: OFF

A/C switch OFF at ignition switch

ON: OFFInspect A/C switch. 1AC

ALTF (Generator field

coil control duty value)%Ignition switch ON: 0%

Idle: 0—100%

Just after A/C switch ON and fan

switch ON at idle: Duty value risesInspect following PIDs: IAT, ECT,

RPM, VPWR, ALTT V.

Inspect generator.1AD

ALTT V (Generator

output voltage)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Inspect generator. 1AA

ARPMDES

(Target engine speed)RPM

LF Unleaded fuel (RON 90 or

above) model

No load: 650 rpm

E/L operating: 700 rpm

P/S operating: 700 rpm

A/C ON: 750 rpm

L3 4WD ATX model

No load: 700 rpm

E/L operating: 700 rpm

P/S operating: 700 rpm

A/C ON: 700 rpm*

2, 750 rpm*3

Inspect following PIDs: IAT, RPM,

MAP, ECT, MAF, TP, INGEAR,

ACSW, TR, PSP, ALTT V.

Inspect IAC valve.

Inspect CKP sensor.—

AST (After start timer) Sec———

Page 125 of 909

CONTROL SYSTEM

F1–37

F1

Without Using the SST

Caution

•The PCM terminal voltages vary with change in measuring conditions and vehicle conditions.

Always carry out a total inspection of the input systems, output systems, and PCM to determine

the cause of trouble. Otherwise, a wrong diagnosis will be made.

1. Measure the voltage at each terminal.

•If any incorrect voltage is detected, inspect the related system(s), wiring harnesses and connector(s)

referring to the Action column in the terminal voltage table.

Terminal voltage table (Reference)

Terminal Signal Connected to Test conditionVoltage

(V)Action

1A IGT1Ignition coil (No. 1,

4 cylinders)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect ignition coil

•Inspect related

harness

1B IGT2Ignition coil (No. 2,

3 cylinders)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect ignition coil

•Inspect related

harness

1C GND GND Under any condition Below 1.0•Inspect related

harness

1D GND GND Under any condition Below 1.0•Inspect related

harness

1E—— — ——

1F—— — ——

1G BARO BARO sensor Ignition switch ON (at sea level)Approx.

4.1 V•Inspect BARO sensor

•Inspect related

harness

1H—— — ——

1I—— — ——

1JManifold absolute

pressureMAP sensorIgnition switch ON (Engine OFF)Approx.

4.1•Inspect MAP sensor

•Inspect related

harness

IdleApprox.

1.5

1K Brake Brake switchBrake pedal depressed B+•Inspect brake switch

•Inspect related

harness Brake pedal released Below 1.0

1L—— — ——

1M ECT ECT sensorIgnition switch

ONECT 20 °C

{68 °F}3.04—

3.14•Inspect ECT sensor

•Inspect related

harness ECT 60 °C

{140 °F}1.29—

1.39

1N—— — ——

1O—— — ——

1P MAF MAF sensorIgnition switch ONApprox.

0.7•Inspect MAF sensor

•Inspect related

harness

Idle (after warm up)Approx.

1.3

1B 1A

1E 1D

1C 1H 1G 1J

1F 1I 1M

1L 1N 1K 1T 1Q1P 1S

1O 1R 1W1V

1Z 1Y

1X1AC1AB

1AA 1AD1U 2B 2A

2E 2D

2C 2H 2G 2J

2F 2I 2M

2L 2N 2K 2T 2Q2P 2S

2O 2R 2W2V

2Z 2Y

2X2AC2AB

2AA 2AD2U 3B 3A

3E 3D

3C 3H 3G 3J

3F 3I 3M

3L 3N 3K 3T 3Q3P 3S

3O 3R 3W3V

3Z 3Y

3X3AA3U 4B 4A

4E 4D

4C 4H 4G 4J

4F 4I 4M

4L 4N 4K 4T 4Q4P 4S

4O 4R 4W4V

4Z 4Y

4X4AC4AB

4AA 4AD4U

A6A3940W002

Page 126 of 909

F1–38

CONTROL SYSTEM

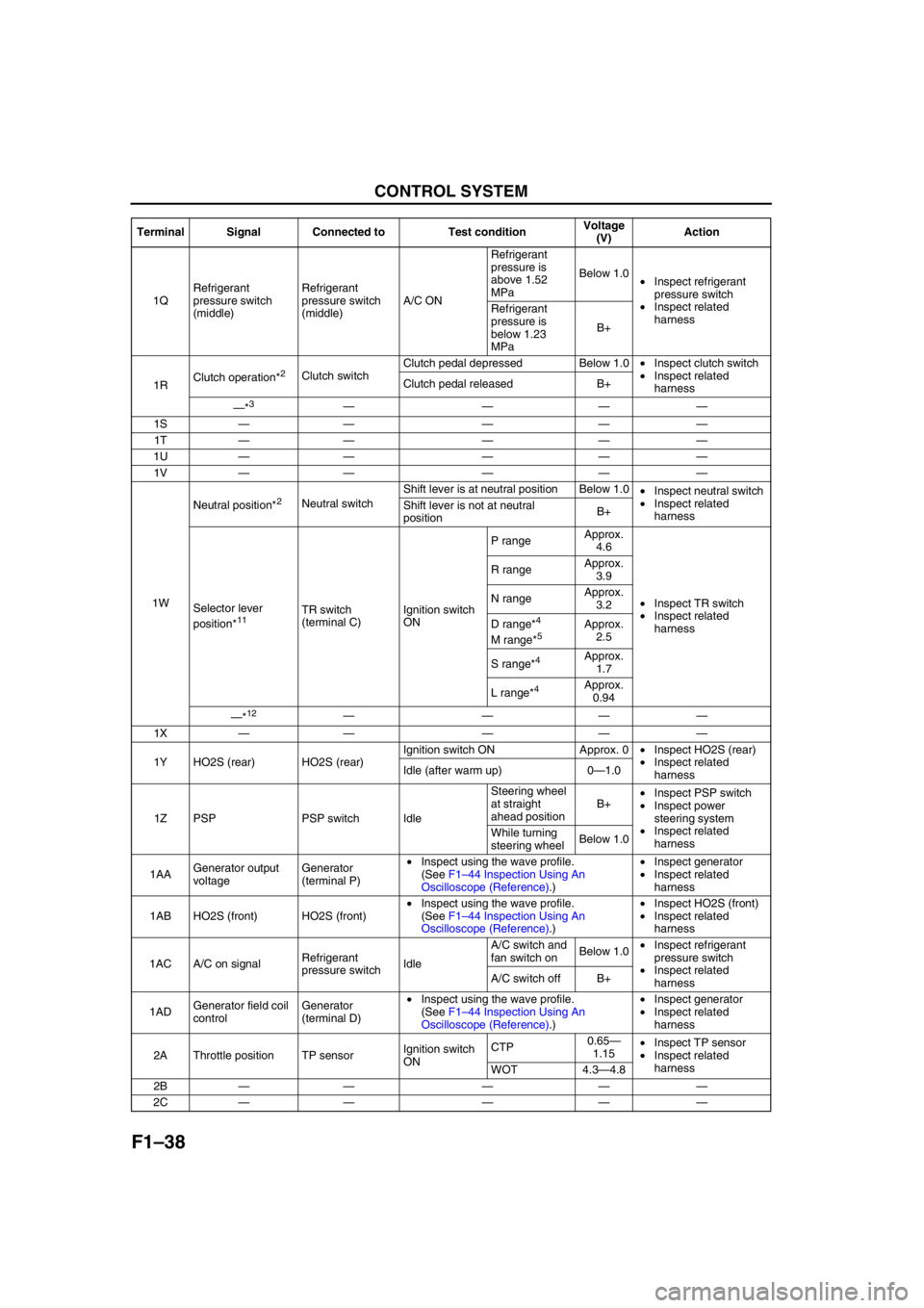

1QRefrigerant

pressure switch

(middle)Refrigerant

pressure switch

(middle)A/C ONRefrigerant

pressure is

above 1.52

MPaBelow 1.0

•Inspect refrigerant

pressure switch

•Inspect related

harness Refrigerant

pressure is

below 1.23

MPaB+

1RClutch operation*

2Clutch switchClutch pedal depressed Below 1.0•Inspect clutch switch

•Inspect related

harness Clutch pedal released B+

—*

3————

1S—— — ——

1T—— — ——

1U—— — ——

1V—— — ——

1WNeutral position*

2Neutral switchShift lever is at neutral position Below 1.0

•Inspect neutral switch

•Inspect related

harness Shift lever is not at neutral

positionB+

Selector lever

position*

11TR switch

(terminal C)Ignition switch

ONP rangeApprox.

4.6

•Inspect TR switch

•Inspect related

harness R rangeApprox.

3.9

N rangeApprox.

3.2

D range*4

M range*5Approx.

2.5

S range*

4Approx.

1.7

L range*

4Approx.

0.94

—*

12————

1X—— — ——

1Y HO2S (rear) HO2S (rear)Ignition switch ON Approx. 0•Inspect HO2S (rear)

•Inspect related

harness Idle (after warm up) 0—1.0

1Z PSP PSP switch IdleSteering wheel

at straight

ahead positionB+•Inspect PSP switch

•Inspect power

steering system

•Inspect related

harness While turning

steering wheelBelow 1.0

1AAGenerator output

voltageGenerator

(terminal P)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect generator

•Inspect related

harness

1AB HO2S (front) HO2S (front)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect HO2S (front)

•Inspect related

harness

1AC A/C on signalRefrigerant

pressure switchIdleA/C switch and

fan switch onBelow 1.0•Inspect refrigerant

pressure switch

•Inspect related

harness A/C switch off B+

1ADGenerator field coil

controlGenerator

(terminal D)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect generator

•Inspect related

harness

2A Throttle position TP sensorIgnition switch

ONCTP0.65—

1.15•Inspect TP sensor

•Inspect related

harness

WOT 4.3—4.8

2B—— — ——

2C—— — —— Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 127 of 909

CONTROL SYSTEM

F1–39

F1

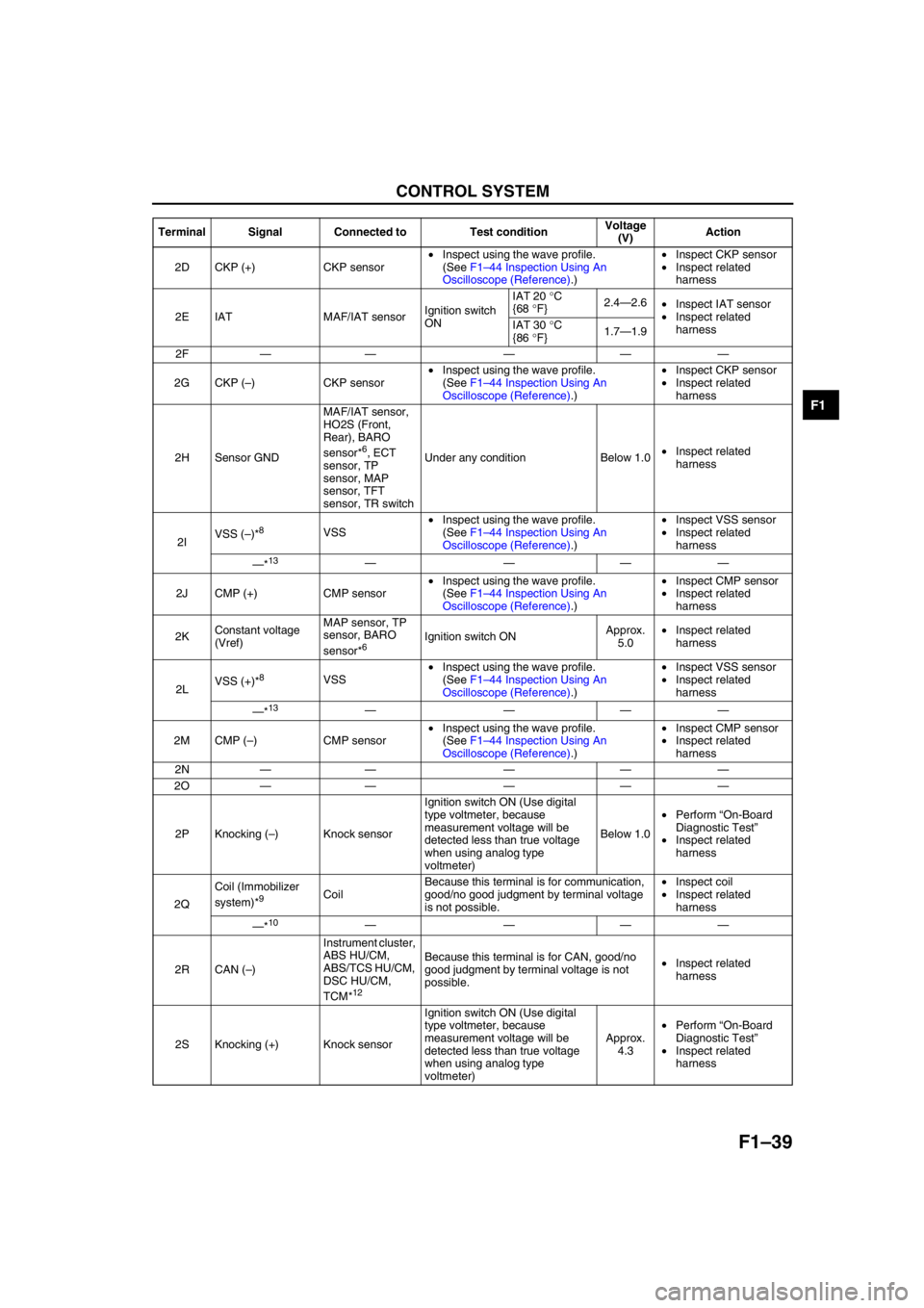

2D CKP (+) CKP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CKP sensor

•Inspect related

harness

2E IAT MAF/IAT sensorIgnition switch

ONIAT 20 °C

{68 °F}2.4—2.6

•Inspect IAT sensor

•Inspect related

harness IAT 30 °C

{86 °F}1.7—1.9

2F—— — ——

2G CKP (–) CKP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CKP sensor

•Inspect related

harness

2H Sensor GNDMAF/IAT sensor,

HO2S (Front,

Rear), BARO

sensor*

6, ECT

sensor, TP

sensor, MAP

sensor, TFT

sensor, TR switchUnder any condition Below 1.0•Inspect related

harness

2IVSS (–)*

8VSS•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect VSS sensor

•Inspect related

harness

—*

13————

2J CMP (+) CMP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CMP sensor

•Inspect related

harness

2KConstant voltage

(Vref)MAP sensor, TP

sensor, BARO

sensor*

6Ignition switch ONApprox.

5.0•Inspect related

harness

2LVSS (+)*

8VSS•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect VSS sensor

•Inspect related

harness

—*

13————

2M CMP (–) CMP sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect CMP sensor

•Inspect related

harness

2N—— — ——

2O—— — ——

2P Knocking (–) Knock sensorIgnition switch ON (Use digital

type voltmeter, because

measurement voltage will be

detected less than true voltage

when using analog type

voltmeter)Below 1.0•Perform “On-Board

Diagnostic Test”

•Inspect related

harness

2QCoil (Immobilizer

system)*

9CoilBecause this terminal is for communication,

good/no good judgment by terminal voltage

is not possible.•Inspect coil

•Inspect related

harness

—*

10————

2R CAN (–)Instrument cluster,

ABS HU/CM,

ABS/TCS HU/CM,

DSC HU/CM,

TCM*

12

Because this terminal is for CAN, good/no

good judgment by terminal voltage is not

possible.•Inspect related

harness

2S Knocking (+) Knock sensorIgnition switch ON (Use digital

type voltmeter, because

measurement voltage will be

detected less than true voltage

when using analog type

voltmeter)Approx.

4.3•Perform “On-Board

Diagnostic Test”

•Inspect related

harness Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 128 of 909

F1–40

CONTROL SYSTEM

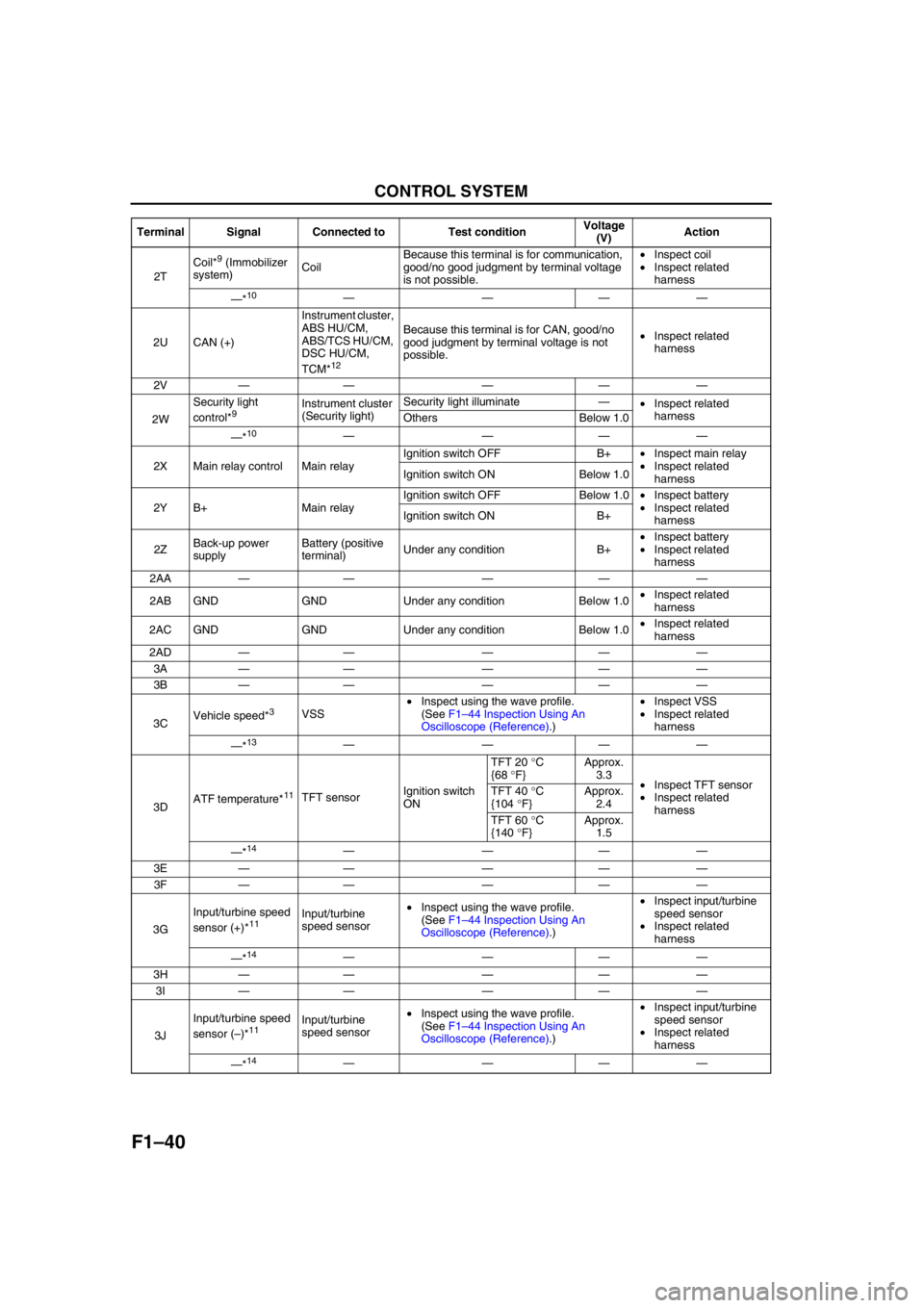

2TCoil*

9 (Immobilizer

system)CoilBecause this terminal is for communication,

good/no good judgment by terminal voltage

is not possible.•Inspect coil

•Inspect related

harness

—*

10————

2U CAN (+)Instrument cluster,

ABS HU/CM,

ABS/TCS HU/CM,

DSC HU/CM,

TCM*

12

Because this terminal is for CAN, good/no

good judgment by terminal voltage is not

possible.•Inspect related

harness

2V—— — ——

2WSecurity light

control*

9Instrument cluster

(Security light)Security light illuminate—

•Inspect related

harness

Others Below 1.0

—*

10————

2X Main relay control Main relayIgnition switch OFF B+•Inspect main relay

•Inspect related

harness Ignition switch ON Below 1.0

2Y B+ Main relayIgnition switch OFF Below 1.0•Inspect battery

•Inspect related

harness Ignition switch ON B+

2ZBack-up power

supplyBattery (positive

terminal)Under any condition B+•Inspect battery

•Inspect related

harness

2AA—— — ——

2AB GND GND Under any condition Below 1.0•Inspect related

harness

2AC GND GND Under any condition Below 1.0•Inspect related

harness

2AD—— — ——

3A—— — ——

3B—— — ——

3CVehicle speed*

3VSS•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect VSS

•Inspect related

harness

—*

13————

3DATF temperature*

11TFT sensorIgnition switch

ONTFT 20 °C

{68 °F}Approx.

3.3

•Inspect TFT sensor

•Inspect related

harness TFT 40 °C

{104 °F}Approx.

2.4

TFT 60 °C

{140 °F}Approx.

1.5

—*

14————

3E—— — ——

3F—— — ——

3GInput/turbine speed

sensor (+)*

11Input/turbine

speed sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect input/turbine

speed sensor

•Inspect related

harness

—*

14————

3H—— — ——

3I—— — ——

3JInput/turbine speed

sensor (–)*

11Input/turbine

speed sensor•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect input/turbine

speed sensor

•Inspect related

harness

—*

14———— Terminal Signal Connected to Test conditionVoltage

(V)Action