radiator MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 522 of 909

AUTOMATIC TRANSAXLE

K2–107

K2

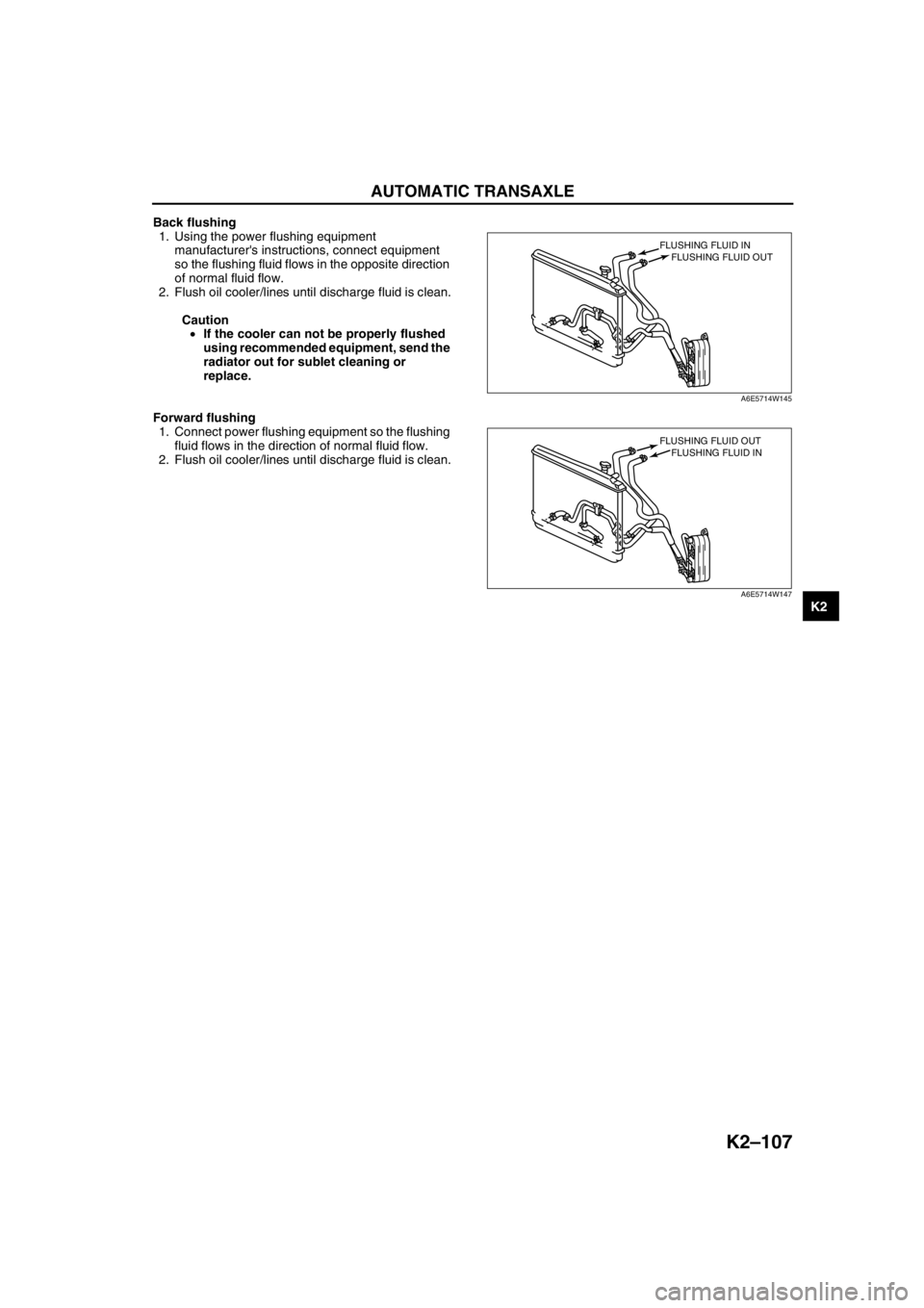

Back flushing

1. Using the power flushing equipment

manufacturer's instructions, connect equipment

so the flushing fluid flows in the opposite direction

of normal fluid flow.

2. Flush oil cooler/lines until discharge fluid is clean.

Caution

•If the cooler can not be properly flushed

using recommended equipment, send the

radiator out for sublet cleaning or

replace.

Forward flushing

1. Connect power flushing equipment so the flushing

fluid flows in the direction of normal fluid flow.

2. Flush oil cooler/lines until discharge fluid is clean.

End Of Sie

FLUSHING FLUID OUT FLUSHING FLUID IN

A6E5714W145

FLUSHING FLUID IN FLUSHING FLUID OUT

A6E5714W147

Page 523 of 909

K2–108

AUTOMATIC TRANSAXLE

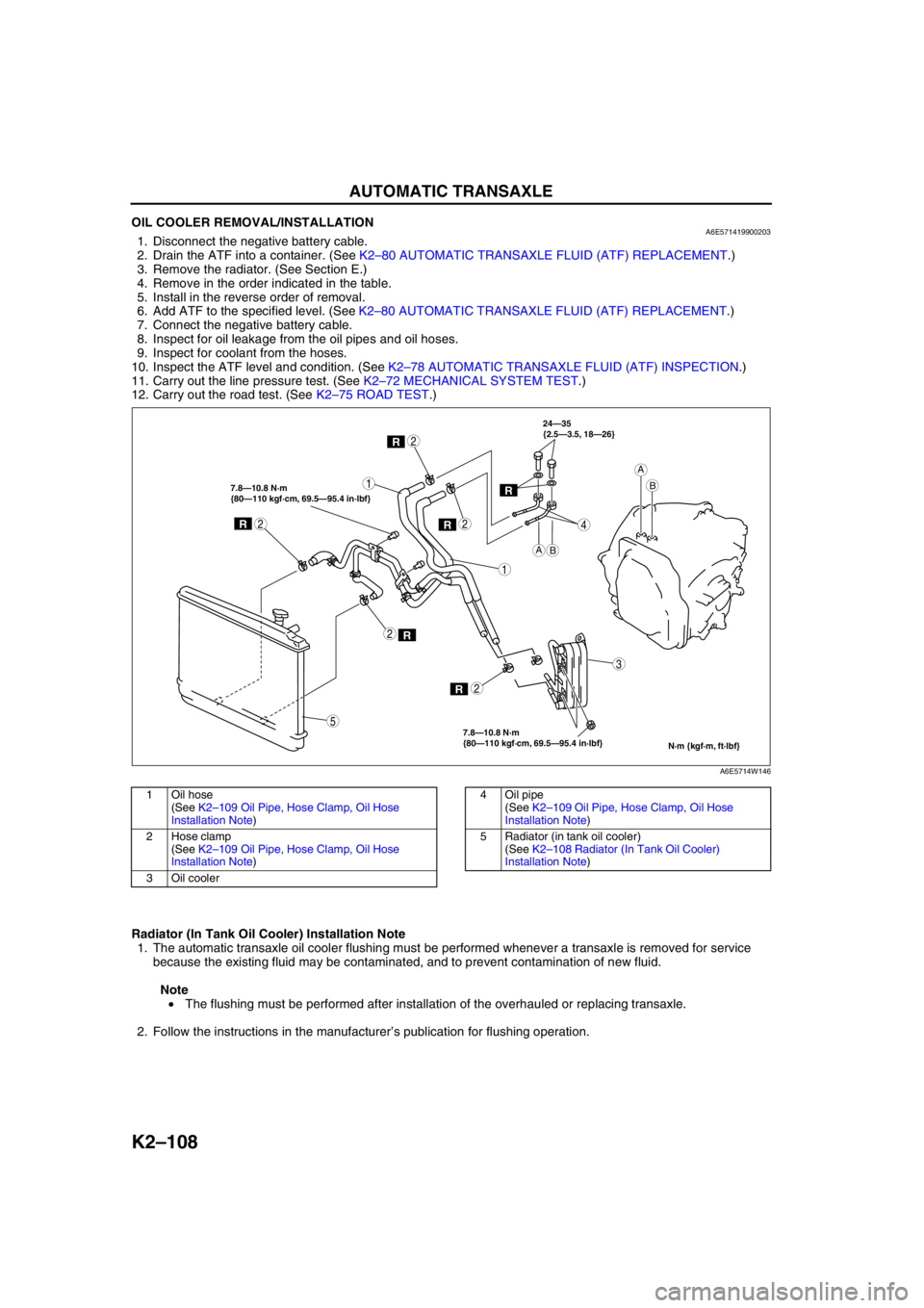

OIL COOLER REMOVAL/INSTALLATIONA6E5714199002031. Disconnect the negative battery cable.

2. Drain the ATF into a container. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

3. Remove the radiator. (See Section E.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Add ATF to the specified level. (See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

7. Connect the negative battery cable.

8. Inspect for oil leakage from the oil pipes and oil hoses.

9. Inspect for coolant from the hoses.

10. Inspect the ATF level and condition. (See K2–78 AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION.)

11. Carry out the line pressure test. (See K2–72 MECHANICAL SYSTEM TEST.)

12. Carry out the road test. (See K2–75 ROAD TEST.)

.

Radiator (In Tank Oil Cooler) Installation Note

1. The automatic transaxle oil cooler flushing must be performed whenever a transaxle is removed for service

because the existing fluid may be contaminated, and to prevent contamination of new fluid.

Note

• The flushing must be performed after installation of the overhauled or replacing transaxle.

2. Follow the instructions in the manufacturer’s publication for flushing operation.

R

R

1

2

1

3

4

2

R2

R2

R

7.8—10.8 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf} 7.8—10.8 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf}24—35

{2.5—3.5, 18—26}

2

5

AB

A

B

N·m {kgf·m, ft·lbf}

R

A6E5714W146

1Oil hose

(See K2–109 Oil Pipe, Hose Clamp, Oil Hose

Installation Note)

2 Hose clamp

(See K2–109 Oil Pipe, Hose Clamp, Oil Hose

Installation Note)

3Oil cooler4 Oil pipe

(See K2–109 Oil Pipe, Hose Clamp, Oil Hose

Installation Note)

5 Radiator (in tank oil cooler)

(See K2–108 Radiator (In Tank Oil Cooler)

Installation Note)

Page 525 of 909

K2–110

AUTOMATIC TRANSAXLE

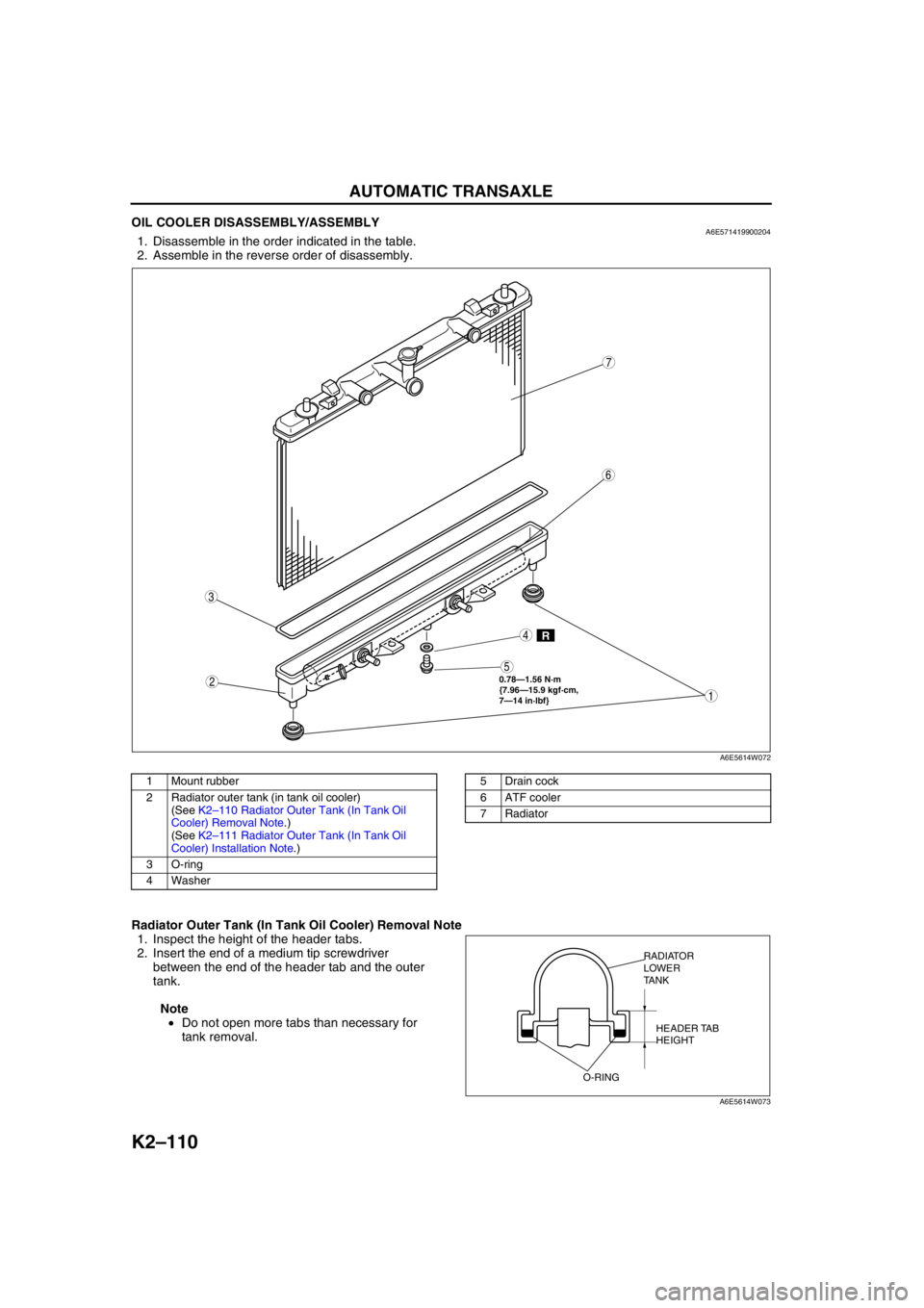

OIL COOLER DISASSEMBLY/ASSEMBLYA6E5714199002041. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

.

Radiator Outer Tank (In Tank Oil Cooler) Removal Note

1. Inspect the height of the header tabs.

2. Insert the end of a medium tip screwdriver

between the end of the header tab and the outer

tank.

Note

•Do not open more tabs than necessary for

tank removal.

R

0.78—1.56 N·m

{7.96—15.9 kgf·cm,

7—14 in·lbf}

7

4

3

6

2

5

1

A6E5614W072

1 Mount rubber

2 Radiator outer tank (in tank oil cooler)

(See K2–110 Radiator Outer Tank (In Tank Oil

Cooler) Removal Note.)

(See K2–111 Radiator Outer Tank (In Tank Oil

Cooler) Installation Note.)

3 O-ring

4 Washer5 Drain cock

6 ATF cooler

7Radiator

RADIATOR

LOWER

TANK

HEADER TAB

HEIGHT

O-RING

A6E5614W073

Page 526 of 909

AUTOMATIC TRANSAXLE

K2–111

K2

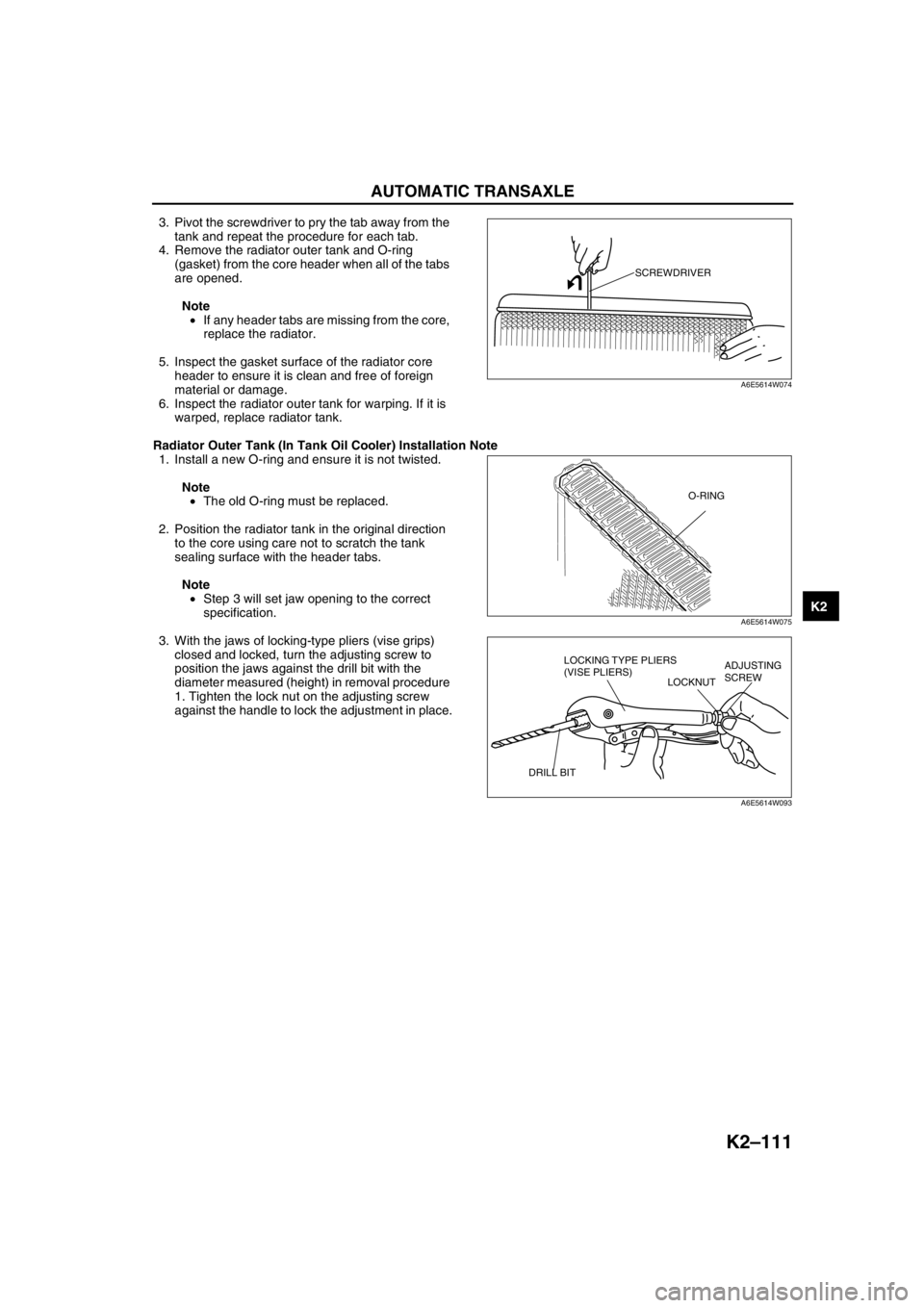

3. Pivot the screwdriver to pry the tab away from the

tank and repeat the procedure for each tab.

4. Remove the radiator outer tank and O-ring

(gasket) from the core header when all of the tabs

are opened.

Note

•If any header tabs are missing from the core,

replace the radiator.

5. Inspect the gasket surface of the radiator core

header to ensure it is clean and free of foreign

material or damage.

6. Inspect the radiator outer tank for warping. If it is

warped, replace radiator tank.

Radiator Outer Tank (In Tank Oil Cooler) Installation Note

1. Install a new O-ring and ensure it is not twisted.

Note

•The old O-ring must be replaced.

2. Position the radiator tank in the original direction

to the core using care not to scratch the tank

sealing surface with the header tabs.

Note

•Step 3 will set jaw opening to the correct

specification.

3. With the jaws of locking-type pliers (vise grips)

closed and locked, turn the adjusting screw to

position the jaws against the drill bit with the

diameter measured (height) in removal procedure

1. Tighten the lock nut on the adjusting screw

against the handle to lock the adjustment in place.

SCREWDRIVER

A6E5614W074

O-RING

A6E5614W075

LOCKING TYPE PLIERS

(VISE PLIERS)

LOCKNUTADJUSTING

SCREW

DRILL BIT

A6E5614W093

Page 527 of 909

K2–112

AUTOMATIC TRANSAXLE

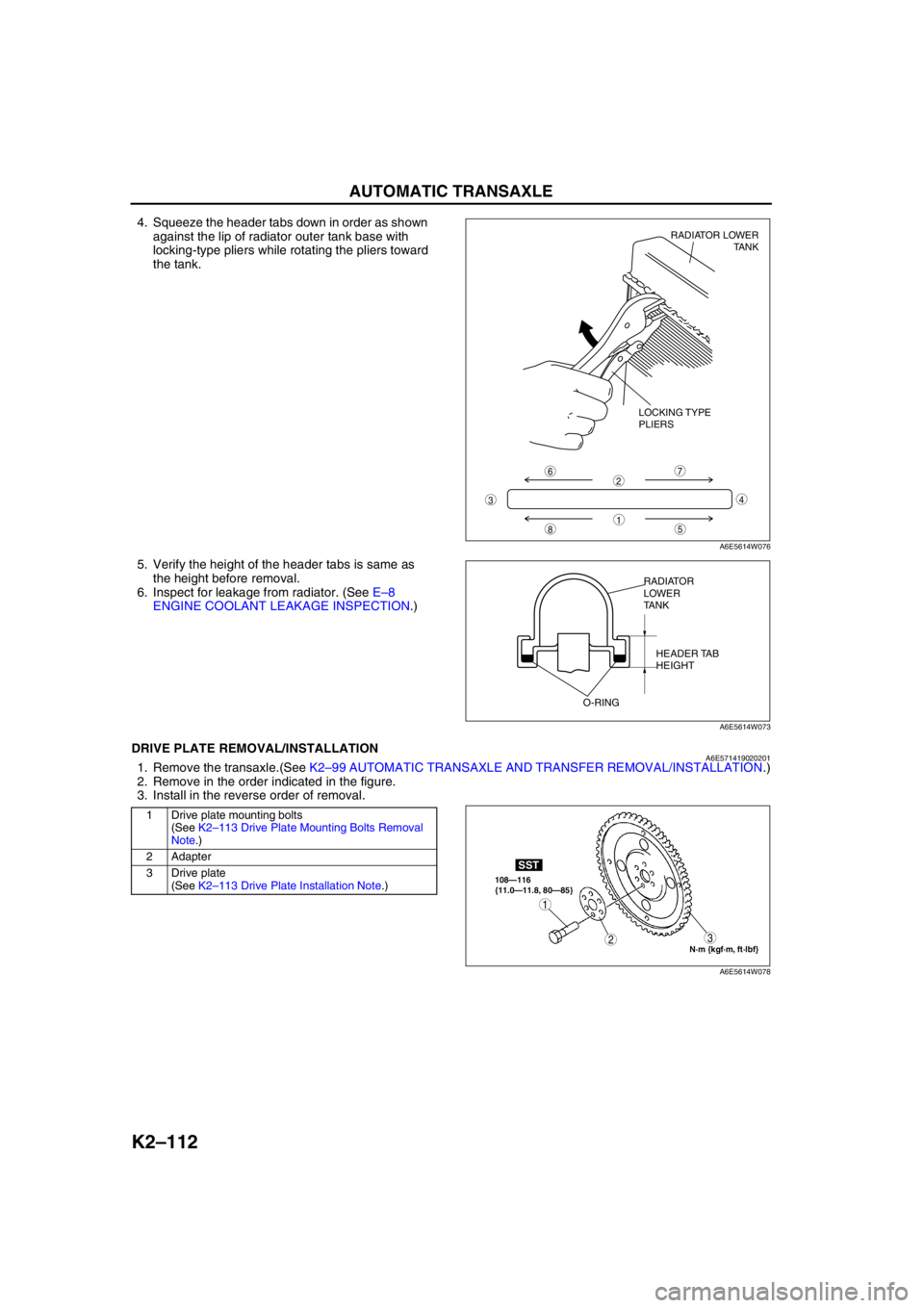

4. Squeeze the header tabs down in order as shown

against the lip of radiator outer tank base with

locking-type pliers while rotating the pliers toward

the tank.

5. Verify the height of the header tabs is same as

the height before removal.

6. Inspect for leakage from radiator. (See E–8

ENGINE COOLANT LEAKAGE INSPECTION.)

End Of SieDRIVE PLATE REMOVAL/INSTALLATIONA6E5714190202011. Remove the transaxle.(See K2–99 AUTOMATIC TRANSAXLE AND TRANSFER REMOVAL/INSTALLATION.)

2. Remove in the order indicated in the figure.

3. Install in the reverse order of removal.

.

8

7

5

43

6

1

2

LOCKING TYPE

PLIERSRADIATOR LOWER

TANK

A6E5614W076

RADIATOR

LOWER

TANK

HEADER TAB

HEIGHT

O-RING

A6E5614W073

1 Drive plate mounting bolts

(See K2–113 Drive Plate Mounting Bolts Removal

Note.)

2 Adapter

3 Drive plate

(See K2–113 Drive Plate Installation Note.)

N·m {kgf·m, ft·lbf} 108—116

{11.0—11.8, 80—85}

SST

3

1

2

A6E5614W078

Page 895 of 909

TECHNICAL DATA

TD–3

TD

Recommended engine oil

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

End Of Sie

COOLING SYSTEMA6E931001001203

End Of Sie

FUEL AND EMISSION CONTROL SYSTEMA6E931001001204

*1: Excludes temporary idle speed drop just after the electrical loads are turned on.

End Of Sie

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3

B3B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Coolant capacity (L {US qt, Imp qt}) 9.0 {9.5, 7.9}

Radiator capCap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

ThermostatType Wax, bottom-bypass

Initial-opening temperature (°C {°F})80—84

{176—183}

Full-opening temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

Cooling fan Motor Current (A)4.4—7.4 (Cooling fan motor No.1)

6.3—9.3 (Cooling fan motor No.2)

ItemEngine

L3 (4WD)

Idle speed

*1(rpm) 650—750 (700±50)

ItemEngine

MZR-CD (RF Turbo)

Idle speed (rpm) 725—825 (775±50)

Idle-up speed (rpm) When A/C is operated 725—825 (775±50)

Boost relief pressure (kPa {mmHg, inHg}) Approx. –14.5 {–108, –4.27}

Page 903 of 909

ST–2

SPECIAL TOOLS

ENGINEA6E941001001205

End Of Sie

LUBRICATION SYSTEMA6E941001001206

End Of Sie

COOLING SYSTEMA6E941001001207

End Of Sie

SPECIAL TOOLS

49 S120 710

Coupling flange

holder 49 G033 107A

Dust cover

installer49 S120 215B

Pulley puller

49 G011 106

Camshaft pulley

puller49 S013 1A1

Compression

gauge set49 B010 002

Oil seal installer

49 G012 0A0

Tappet adjust

wrench set49 G011 105

Crankshaft lock

tool49 U027 003

Oil seal installer

WDS 49 E017 5A0

Engine support

set

—

49 0187 280A

Oil pressure

gauge

——

49 9200 145

Radiator cap

tester adapter

set——