fuse MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 615 of 909

K2–200

TROUBLESHOOTING

Diagnostic procedure

End Of SieNO.25 ENGINE STALLS WHEN DRIVING AT SLOW SPEED OR STOPPINGA6E578001030228

Diagnostic procedure

End Of SieNO.26 STARTER DOES NOT WORKA6E578001030229

End Of SieNO.27 GEAR POSITION INDICATOR LIGHT DOES NOT ILLUMINATE IN M RANGEA6E578001030230

Diagnostic procedure

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.4

“Engine stalls-after start/at idle”.

(See Section F.)

•Is engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Inspect for bend, damage or kinks of oil cooler line

pipes. If okay, overhaul control valve body and repair or

replace any defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace torque converter.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

25 Engine stalls when driving at slow speeds or stopping

DESCRIPTION•Engine stalls when brake pedal depressed while driving at low speed or stopping.

POSSIBLE

CAUSE•Malfunction is on engine control side (e.g. Fuel injection control, IAC system)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.10 “Low

idle/stalls during deceleration”.

(See Section F.)

•Is engine control system okay?Yes Go to symptom troubleshooting No.24 “Engine stalls when

shifted to D range, or in R position”.

No Repair or replace any defective parts according to

inspection results.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

26Starter does not work

DESCRIPTION•Starter does not work even when P or N position.

POSSIBLE

CAUSE•Selector lever misadjustment.

•TR switch misadjustment.

•Open or short circuit in TR switch.

27 Gear position indicator light does not illuminate in M range

DESCRIPTION•Gear position indicator light in instrument cluster does not illuminate in M range and ignition switch at

on.

POSSIBLE

CAUSE•M range switch, gear position indicator light or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Are other indicator lights illuminated with

ignition switch on? Yes Go to next step.

No Inspect meter fuse.

Page 697 of 909

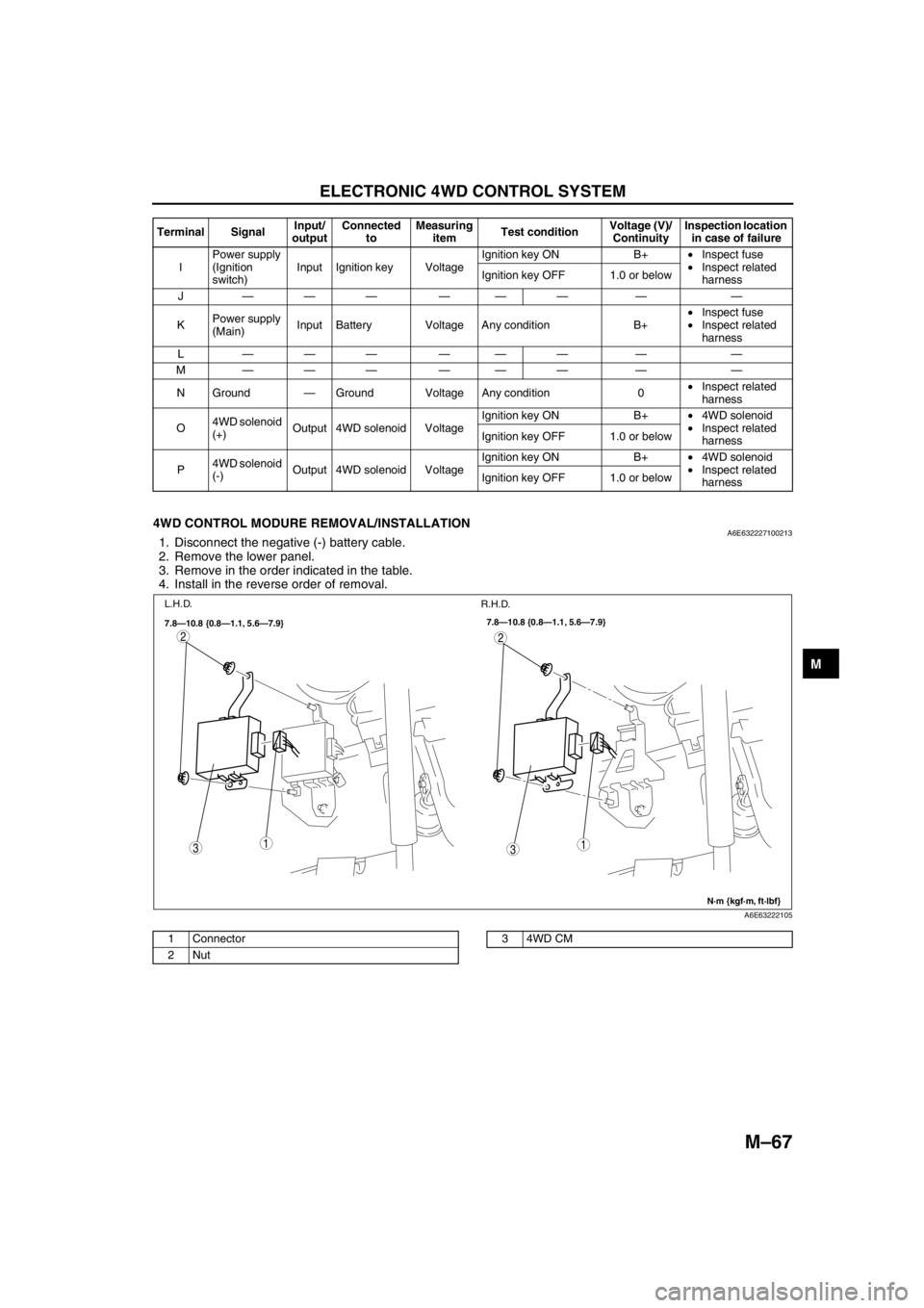

ELECTRONIC 4WD CONTROL SYSTEM

M–67

M

End Of Sie

4WD CONTROL MODURE REMOVAL/INSTALLATIONA6E6322271002131. Disconnect the negative (-) battery cable.

2. Remove the lower panel.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

IPower supply

(Ignition

switch)Input Ignition key VoltageIgnition key ON B+•Inspect fuse

•Inspect related

harness Ignition key OFF 1.0 or below

J——— ——— — —

KPower supply

(Main)Input Battery Voltage Any condition B+•Inspect fuse

•Inspect related

harness

L——— ——— — —

M——— ——— — —

N Ground—Ground Voltage Any condition 0•Inspect related

harness

O4WD solenoid

(+)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below

P4WD solenoid

(-)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

31

2

31

2

7.8—10.8 {0.8—1.1, 5.6—7.9}

N·m {kgf·m, ft·lbf} 7.8—10.8 {0.8—1.1, 5.6—7.9}

L.H.D.

R.H.D.

A6E63222105

1 Connector

2Nut34WD CM

Page 707 of 909

ON-BOARD DIAGNOSTIC

M–77

M

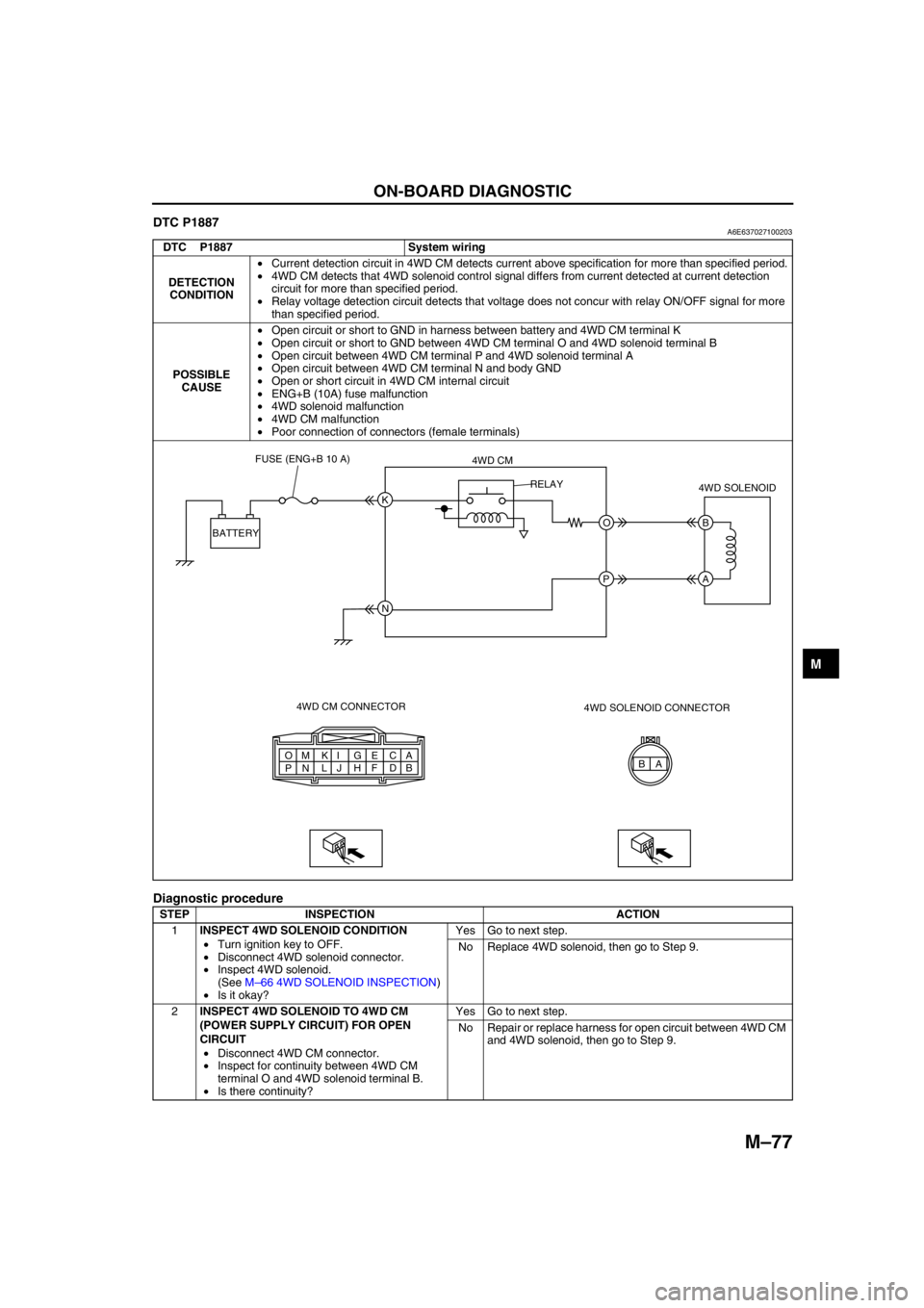

DTC P1887A6E637027100203

Diagnostic procedure

DTC P1887 System wiring

DETECTION

CONDITION•Current detection circuit in 4WD CM detects current above specification for more than specified period.

•4WD CM detects that 4WD solenoid control signal differs from current detected at current detection

circuit for more than specified period.

•Relay voltage detection circuit detects that voltage does not concur with relay ON/OFF signal for more

than specified period.

POSSIBLE

CAUSE•Open circuit or short to GND in harness between battery and 4WD CM terminal K

•Open circuit or short to GND between 4WD CM terminal O and 4WD solenoid terminal B

•Open circuit between 4WD CM terminal P and 4WD solenoid terminal A

•Open circuit between 4WD CM terminal N and body GND

•Open or short circuit in 4WD CM internal circuit

•ENG+B (10A) fuse malfunction

•4WD solenoid malfunction

•4WD CM malfunction

•Poor connection of connectors (female terminals)

STEP INSPECTION ACTION

1INSPECT 4WD SOLENOID CONDITION

•Turn ignition key to OFF.

•Disconnect 4WD solenoid connector.

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is it okay?Yes Go to next step.

No Replace 4WD solenoid, then go to Step 9.

2INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector.

•Inspect for continuity between 4WD CM

terminal O and 4WD solenoid terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

A A

B C

D E

F G

H I

J K

L M

N O

PB K

O B

A

N P BATTERYFUSE (ENG+B 10 A)

4WD CM

4WD CM CONNECTOR4WD SOLENOID

4WD SOLENOID CONNECTOR RELAY

Page 708 of 909

M–78

ON-BOARD DIAGNOSTIC

End Of Sie

3INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal O and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and 4WD solenoid, then go to Step 9.

No Go to next step.

4INSPECT 4WD SOLENOID TO 4WD CM

(GROUND CIRCUIT) FOR OPEN CIRCUIT

•Inspect for continuity between 4WD CM

terminal P and 4WD solenoid terminal A.

•Is there continuity?Yes Replace 4WD CM, then go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

5INSPECT 4WD CM POWER SUPPLY CIRCUIT

FOR OPEN CIRCUIT

•Measure voltage between 4WD CM terminal

K and ground.

•Is voltage B+?Yes Replace 4WD CM, then go to Step 9.

No Go to next step.

6INSPECT 4WD CM TO BATTERY FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector and battery

positive terminal.

•Inspect for continuity between 4WD CM

terminal K and battery positive terminal.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and battery positive terminal, then go to Step 9.

7INSPECT 4WD CM TO BATTERY FOR SHORT

TO GROUND

•Inspect for continuity between 4WD CM

terminal K and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and battery positive terminal, then go to Step 9.

No Replace 4WD CM, then go to step 9.

8INSPECT FUSE CONDITION

•Turn ignition key to OFF.

•Is ENG+B fuse (10A) okay?Yes Go to next step.

No Replace fuse, then go to Step 9.

9VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

10VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 714 of 909

M–84

TROUBLESHOOTING

End Of Sie

NO.3 ABNORMAL NOISE AND/OR VIBRATION FROM COUPLING COMPONENTA6E638027100206

Diagnostic procedure

End Of Sie

6INSPECT 4WD SOLENOID

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is it okay?Yes Inspect harness between 4WD solenoid and 4WD CM, then

go to next step.

No Replace coupling component. STEP INSPECTION ACTION

3 Abnormal noise and/or vibration from coupling component

[TROUBLESHOOTING HINTS]

•Abnormal noise and/or vibration from coupling component during driving

•Propeller shaft is malfunctioning or attached improperly.

•Engine mount or differential mount malfunction

•Resonance of rotating parts on vehicle (engine, propeller shaft, rear differential, tire, etc.)

•Resonance with engine vibration (mainly with exhaust system parts)

•Rear differential malfunction

•Coupling component malfunction

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCS

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY INSTALLATION CONDITION OF

VEHICLE PARTS

•Verify installation condition for following:

—Propeller shaft (including bending and

joint operation)

—Center bearing

—Engine mount

—Differential mount

—Hub bearing

—Exhaust system parts

—ABS wheel-speed sensor

•Are they properly installed?Yes Go to next step.

No Repair or replace malfunctioning part.

3DETERMINE IF MALFUNCTION IS CAUSED

BY REAR DIFFERENTIAL

•Install tires of another brand.

Note

•When tires of another brand are

installed, the same malfunction can

occur due to conditions different from

customer explanation. Be careful not

to confuse it with customer complaint.

•Perform simulation driving at the same

engine speed, gear position, and vehicle

speed that customer vehicle had

malfunction.

•Does the same malfunction occur?Yes Reinstall customer’s vehicle tire. Go to next step.

No 4WD system is okay.

Reinstall customer’s vehicle tire.

4INSPECT REAR DIFFERENTIAL

•Inspect rear differential for following:

—Backlash

—Teeth contact

(See M–56 REAR DIFFERENTIAL

ASSEMBLY)

•Are they okay?Yes Replace coupling component.

No Inspect malfunctioning part and adjust it if necessary.

Page 738 of 909

ABS/TCS

P–5

P

System Diagram

.

End Of Sie

9

9

8

7

5

43

12

6

18

17

15

16

14

13

11

12

RF

FL

RR

RL

PCMG

E

FI Z

U

D

A

B

C

Y

AC

X

V O

R ADAB AA

ABS/TCS HU/CM

pP

9

10

19

920

A6E6921W201

1 IG switch

2SUS 15 A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 TCS OFF light

8 TCS indicator light

9CAN driver

10 Brake light11 Cruise actuator

12 TCS OFF switch

13 DLC-2

14 CAN-H

15 CAN-L

16 ABS Wheel-speed sensor

17 Battery

18 Brake switch

19 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

20 TCM, 4WD CM

Page 740 of 909

DYNAMIC STABILITY CONTROL

P–7

P

Wiring Diagram

.

9

RF

FL

RR

RL

PCM

G

E

M

I

F

K

H

Q

NJ

P

S

T

V

O

Y

X

W

U

R

L

Z

AC

D

B

AG

AF

AE

AC

AA

AB

C

F

D

A

B

EDSC HU/CM

A

B

C

D

F

1

3

2

8

7

5

4

6

9

9

9

10

11

13

12

15

14

18

17

16

1920

2122

24

23

A6E6921W203

1 IG switch

2SUS 15A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 DSC OFF light

8 DSC indicator light

9CAN driver

10 Battery

11 Cruise actuator

12 DSC OFF switch13 DLC-2

14 CAN-H

15 CAN-L

16 Wheel-speed sensor

17 Combine sensor

18 Steering angle sensor

19 Brake switch

20 Brake light

21 Back-up light switch (MTX only)

22 Back-up light (MTX only)

23 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

24 TCM, 4WD CM

Page 826 of 909

LOCATION INDEX

T–15

T

POWER SYSTEMA6E810001072201

.

End Of Sie

EXTERIOR LIGHTING SYSTEMA6E810001052201

.

LOCATION INDEX

1

A6E81101124

1 Main fuse block

(See T–19 RELAY LOCATION)

(See T–19 RELAY INSPECTION)

11

2

A6E81121162

1 High-mount brake light

(See T–20 HIGH-MOUNT BRAKE LIGHT

REMOVAL/INSTALLATION)2 Rear auto leveling sensor (4WD)

(See T–20 REAR AUTO LEVELING SENSOR

REMOVAL/INSTALLATION)

Page 879 of 909

U–16

CONTROL SYSTEM

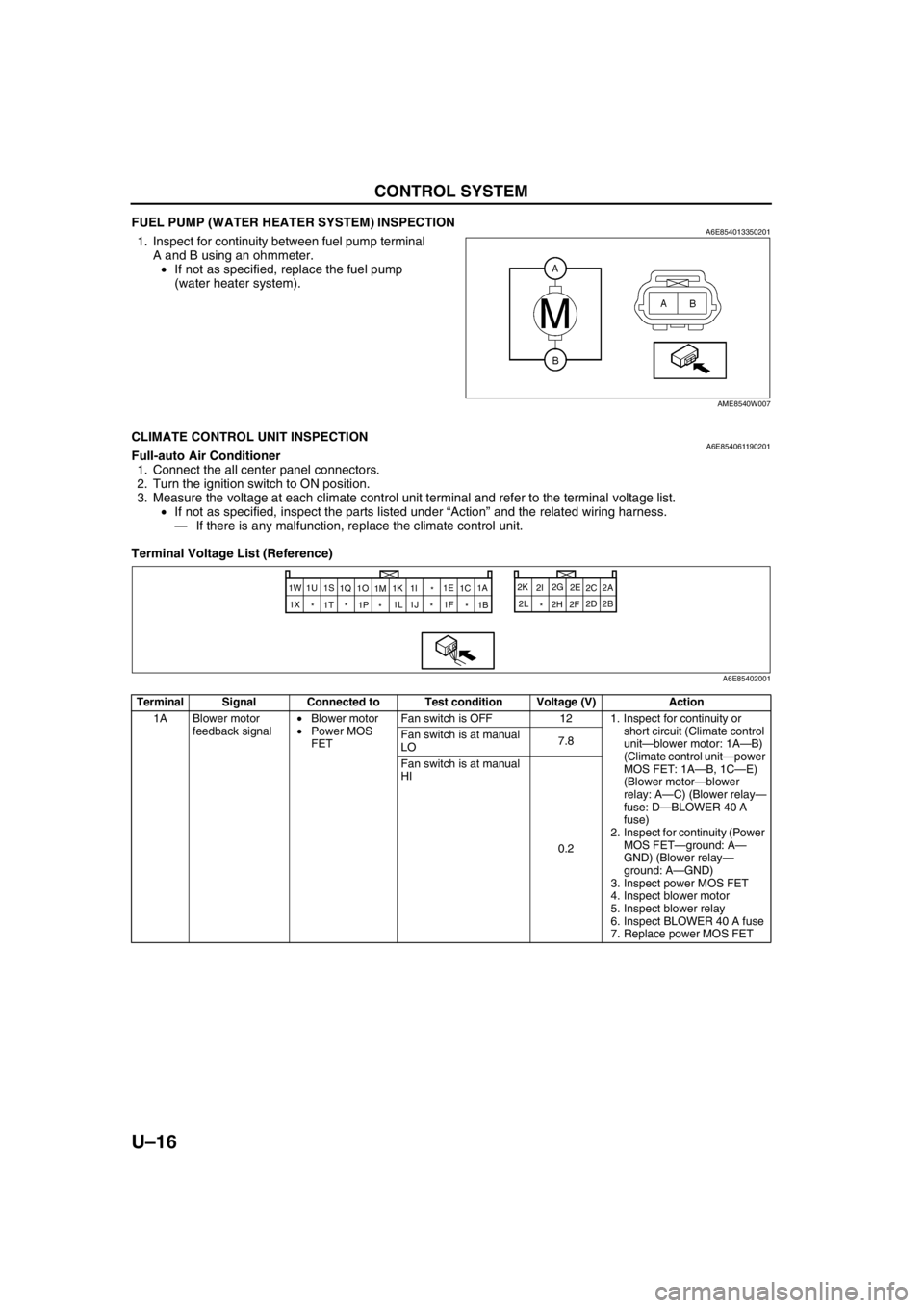

FUEL PUMP (WATER HEATER SYSTEM) INSPECTIONA6E8540133502011. Inspect for continuity between fuel pump terminal

A and B using an ohmmeter.

•If not as specified, replace the fuel pump

(water heater system).

End Of Sie

CLIMATE CONTROL UNIT INSPECTIONA6E854061190201Full-auto Air Conditioner

1. Connect the all center panel connectors.

2. Turn the ignition switch to ON position.

3. Measure the voltage at each climate control unit terminal and refer to the terminal voltage list.

•If not as specified, inspect the parts listed under “Action” and the related wiring harness.

—If there is any malfunction, replace the climate control unit.

Terminal Voltage List (Reference)

AME8540W007

Terminal Signal Connected to Test condition Voltage (V) Action

1A Blower motor

feedback signal•Blower motor

•Power MOS

FETFan switch is OFF 12 1. Inspect for continuity or

short circuit (Climate control

unit—blower motor: 1A—B)

(Climate control unit—power

MOS FET: 1A—B, 1C—E)

(Blower motor—blower

relay: A—C) (Blower relay—

fuse: D—BLOWER 40 A

fuse)

2. Inspect for continuity (Power

MOS FET—ground: A—

GND) (Blower relay—

ground: A—GND)

3. Inspect power MOS FET

4. Inspect blower motor

5. Inspect blower relay

6. Inspect BLOWER 40 A fuse

7. Replace power MOS FET Fan switch is at manual

LO7.8

Fan switch is at manual

HI

0.2

2A

1W

2B 2C

2D 2E

2F 2G

2H 2I 2K

2L

* 1A

1B

* *

* *

* 1X1C 1E

1F * 1I

1K

1M 1O

1P 1Q 1S

1T 1U

1J 1L

A6E85402001

Page 883 of 909

U–20

CONTROL SYSTEM

2B TNS signal TNS relay Headlight switch OFF

Below 1.0•Inspect for short circuit

(Climate control unit—TNS

relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

Headlight switch ON

12•Inspect for continuity or

short circuit (Climate control

unit—TNS relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

2C Motor drive signal Air mix actuator Moving to COLD 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2D—

D, 2C—F)

•Inspect air mix actuator Moving to HOT

Below 1.0

2D Motor drive signal Air mix actuator Moving to HOT 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2C—

F, 2D—D)

•Inspect air mix actuator Moving to COLD

Below 1.0

2E Motor drive signal Airflow mode

actuatorMoving to DEFROSTER 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2E—F, 2G—D)

•Inspect airflow mode

actuator Moving to VENT

Below 1.0

2F Backup power

supply ROOM 15 A fuse Under any condition

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2F— ROOM 15

A fuse)

•Inspect ROOM 15 A fuse

2G Motor drive signal Airflow mode

actuatorMoving to VENT 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2G—D, 2E—F)

•Inspect airflow mode

actuator Moving to DEFROSTER

Below 1.0

2H IG2 A/C 15 A fuse Ignition switch at ON

position

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2H—A/C 15 A

fuse)

•Inspect A/C 15 A fuse

Ignition switch at LOCK

position Below 1.0•Inspect for short circuit

(Climate control unit—fuse:

2H—A/C 15 A fuse)

2I Motor drive signal Air intake actuator Moving to

RECIRCULATE12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2I—F, 2K—D)

•Inspect air intake actuator Moving to FRESH

Below 1.0

2J—— —— —

2K Motor drive signal Air intake actuator Moving to FRESH 12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2K—D, 2I—F)

•Inspect air intake actuator Moving to

RECIRCULATE

Below 1.0

2L GND Ground Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 2L—GND) Terminal Signal Connected to Test condition Voltage (V) Action