fuse MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 215 of 909

EMISSION SYSTEM

F2–63

F2

INTAKE SHUTTER SOLENOID VALVE INSPECTIONA6E401613937201

Note

•Perform the following inspection only when directed.

•The inspection includes both intake shutter solenoid valve (half) and intake shutter solenoid valve (full).

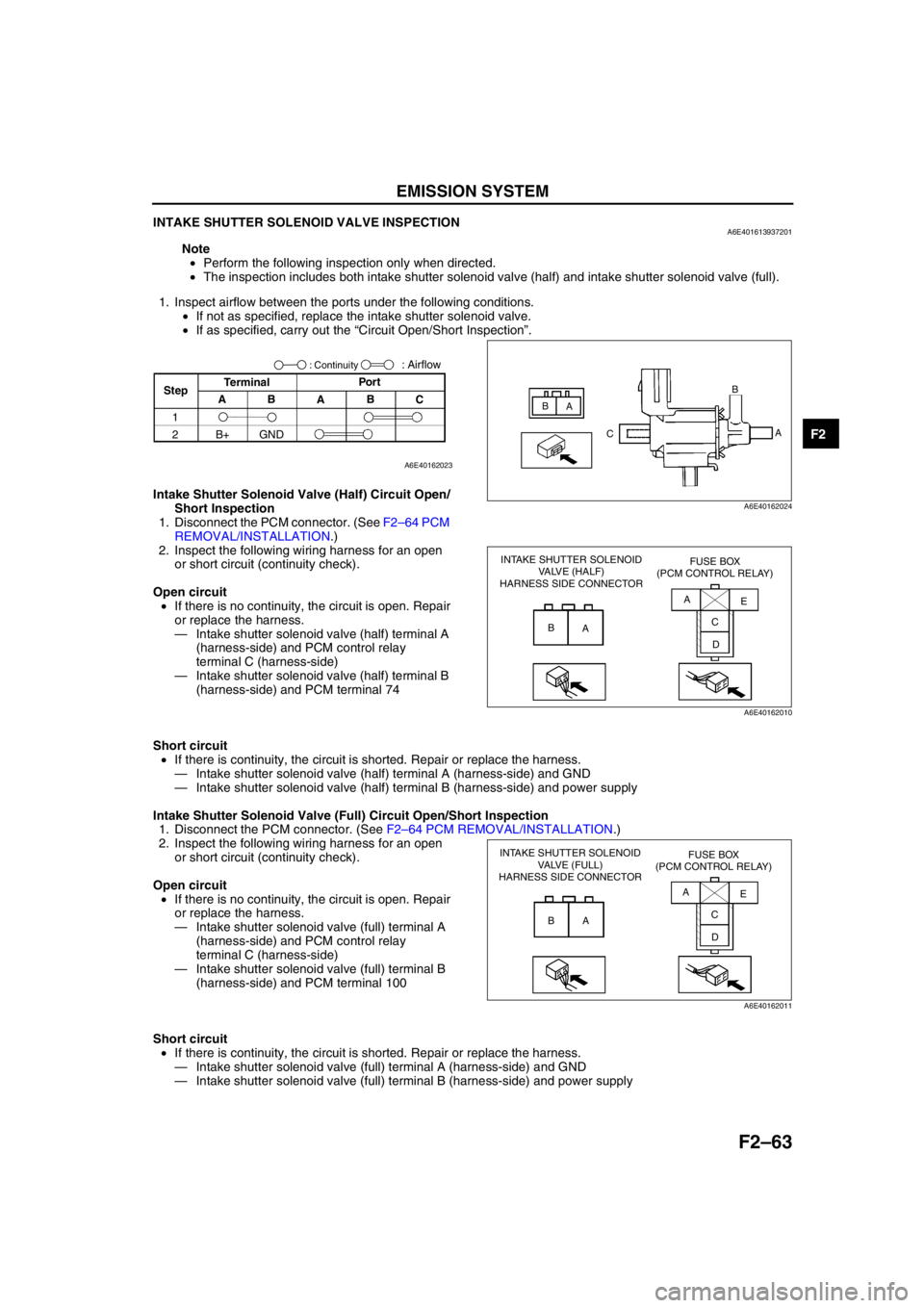

1. Inspect airflow between the ports under the following conditions.

•If not as specified, replace the intake shutter solenoid valve.

•If as specified, carry out the “Circuit Open/Short Inspection”.

Intake Shutter Solenoid Valve (Half) Circuit Open/

Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM

REMOVAL/INSTALLATION.)

2. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Intake shutter solenoid valve (half) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—Intake shutter solenoid valve (half) terminal B

(harness-side) and PCM terminal 74

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Intake shutter solenoid valve (half) terminal A (harness-side) and GND

—Intake shutter solenoid valve (half) terminal B (harness-side) and power supply

Intake Shutter Solenoid Valve (Full) Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM REMOVAL/INSTALLATION.)

2. Inspect the following wiring harness for an open

or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Intake shutter solenoid valve (full) terminal A

(harness-side) and PCM control relay

terminal C (harness-side)

—Intake shutter solenoid valve (full) terminal B

(harness-side) and PCM terminal 100

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Intake shutter solenoid valve (full) terminal A (harness-side) and GND

—Intake shutter solenoid valve (full) terminal B (harness-side) and power supply

End Of Sie

B

A

CB

A

A6E40162024

StepTerminal

C B

A B APor t: Airflow

1

2B+ GND

: Continuity

A6E40162023

INTAKE SHUTTER SOLENOID

VALVE (HALF)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

B

AA

E

C

D

A6E40162010

INTAKE SHUTTER SOLENOID

VALVE (FULL)

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

B

AA

C

DE

A6E40162011

Page 218 of 909

F2–66

CONTROL SYSTEM

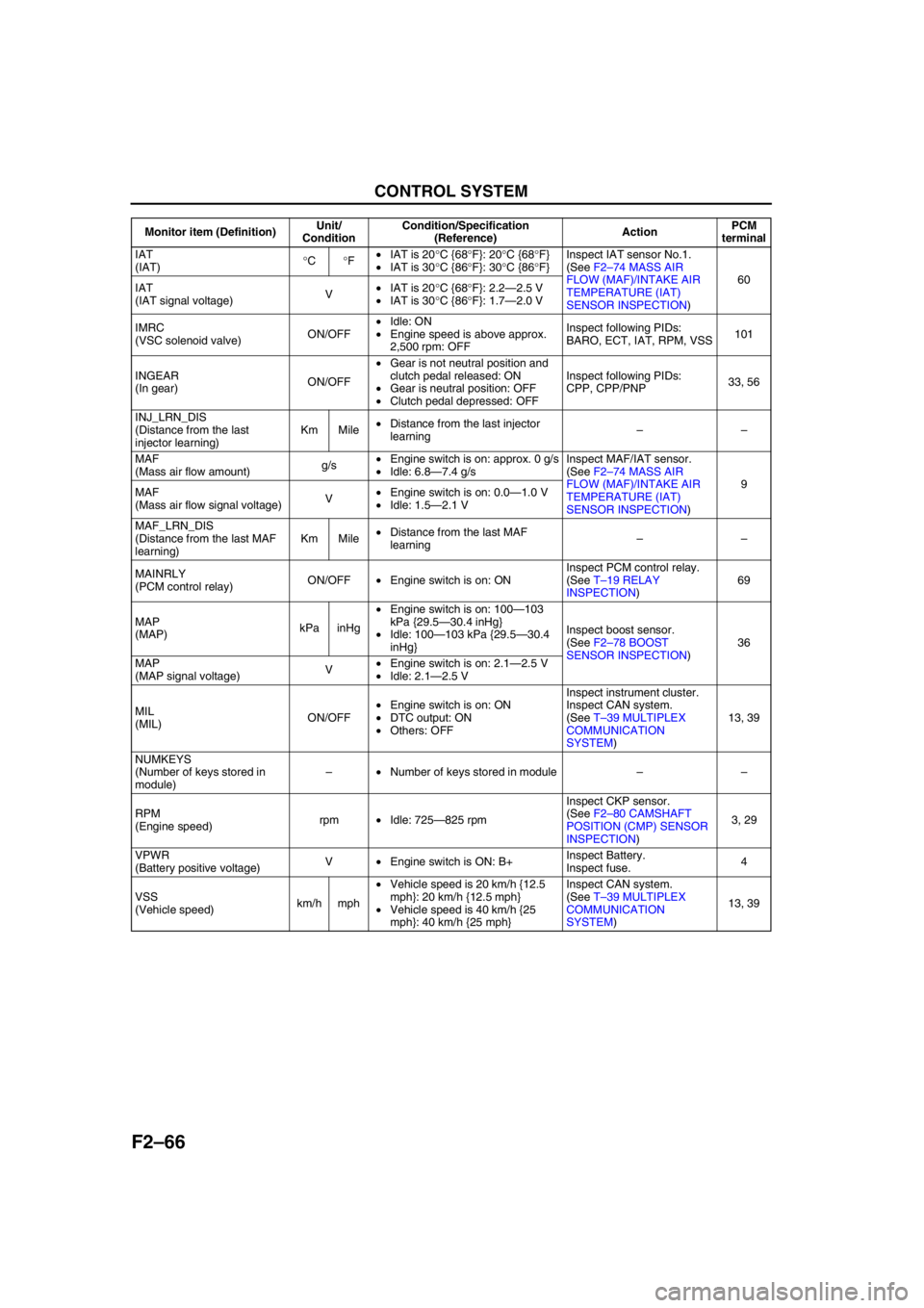

IAT

(IAT)°C°F•IAT is 20°C {68°F}: 20°C {68°F}

•IAT is 30°C {86°F}: 30°C {86°F}Inspect IAT sensor No.1.

(See F2–74 MASS AIR

FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT)

SENSOR INSPECTION)60

IAT

(IAT signal voltage)V•IAT is 20°C {68°F}: 2.2—2.5 V

•IAT is 30°C {86°F}: 1.7—2.0 V

IMRC

(VSC solenoid valve)ON/OFF•Idle: ON

•Engine speed is above approx.

2,500 rpm: OFFInspect following PIDs:

BARO, ECT, IAT, RPM, VSS101

INGEAR

(In gear)ON/OFF•Gear is not neutral position and

clutch pedal released: ON

•Gear is neutral position: OFF

•Clutch pedal depressed: OFFInspect following PIDs:

CPP, CPP/PNP33, 56

INJ_LRN_DIS

(Distance from the last

injector learning)Km Mile•Distance from the last injector

learning––

MAF

(Mass air flow amount)g/s•Engine switch is on: approx. 0 g/s

•Idle: 6.8—7.4 g/sInspect MAF/IAT sensor.

(See F2–74 MASS AIR

FLOW (MAF)/INTAKE AIR

TEMPERATURE (IAT)

SENSOR INSPECTION)9

MAF

(Mass air flow signal voltage)V•Engine switch is on: 0.0—1.0 V

•Idle: 1.5—2.1 V

MAF_LRN_DIS

(Distance from the last MAF

learning)Km Mile•Distance from the last MAF

learning––

MAINRLY

(PCM control relay)ON/OFF•Engine switch is on: ONInspect PCM control relay.

(See T–19 RELAY

INSPECTION)69

MAP

(MAP)kPa inHg•Engine switch is on: 100—103

kPa {29.5—30.4 inHg}

•Idle: 100—103 kPa {29.5—30.4

inHg}Inspect boost sensor.

(See F2–78 BOOST

SENSOR INSPECTION)36

MAP

(MAP signal voltage)V•Engine switch is on: 2.1—2.5 V

•Idle: 2.1—2.5 V

MIL

(MIL)ON/OFF•Engine switch is on: ON

•DTC output: ON

•Others: OFFInspect instrument cluster.

Inspect CAN system.

(See T–39 MULTIPLEX

COMMUNICATION

SYSTEM)13, 39

NUMKEYS

(Number of keys stored in

module)–•Number of keys stored in module––

RPM

(Engine speed)rpm•Idle: 725—825 rpmInspect CKP sensor.

(See F2–80 CAMSHAFT

POSITION (CMP) SENSOR

INSPECTION)3, 29

VPWR

(Battery positive voltage)V•Engine switch is ON: B+Inspect Battery.

Inspect fuse.4

VSS

(Vehicle speed)km/h mph•Vehicle speed is 20 km/h {12.5

mph}: 20 km/h {12.5 mph}

•Vehicle speed is 40 km/h {25

mph}: 40 km/h {25 mph}Inspect CAN system.

(See T–39 MULTIPLEX

COMMUNICATION

SYSTEM)13, 39 Monitor item (Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 295 of 909

ON-BOARD DIAGNOSTIC

F2–143

F2

DTC P0380A6E407001082233

Diagnostic procedure

DTC P0380 Glow plug relay circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from glow plug relay while engine is running. PCM determines glow plug relay

circuit malfunction if input voltage from glow plug relay is as following:

—1.0 V or below when glow plug relay is on.

—4.0 V or above when glow plug relay is off.

POSSIBLE

CAUSE•Glow plug relay malfunction

•Connector or terminal malfunction

•Short to GND in wiring between glow plug relay terminal D and PCM terminal 68

•Short to GND in wiring between glow plug fuse and glow plug relay terminal A

•Short to GND in wiring between glow plug relay terminal C and PCM terminal 86

•Short to power circuit in wiring between glow plug relay terminal D and PCM terminal 68

•Short to power circuit in wiring between glow plug relay terminal C and PCM terminal 86

•Glow plug relay power and signal circuits short each other

•Open circuit in wiring between glow plug fuse and glow plug relay terminal A

•Open circuit in wiring between glow plug relay terminal B and GND

•Open circuit in wiring between glow plug relay terminal D and PCM terminal 68

•Open circuit in wiring between glow plug relay terminal C and PCM terminal 86

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT POOR CONNECTION OF GLOW

PLUG RELAY CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

A

B

C

D

GLOW FUSE

GLOW PLUG RELAY

AD

BC

6886

68 86PCM

54362

262

23598

4398

PCM

HARNESS SIDE CONNECTOR

7

GLOW PLUG RELAY

HARNESS SIDE CONNECTOR

Page 296 of 909

F2–144

ON-BOARD DIAGNOSTIC

End Of Sie

3INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug relay terminal A and body GND.

—Glow plug relay terminal C and body GND.

—Glow plug relay terminal D and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 9.

No Go to next step.

4INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between following harnesses:

—Glow plug relay terminal C and body GND.

—Glow plug relay terminal D and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 9.

5INSPECT GLOW PLUG RELAY CIRCUIT FOR

SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between glow plug relay

terminals A and C.

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 7.

No Go to next step.

6INSPECT GLOW PLUG RELAY CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug fuse and glow plug relay terminal

A.

—Glow plug relay terminal B and body GND.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 9.

7INSPECT GLOW PLUG RELAY

•Inspect glow plug relay.

(See T–19 RELAY INSPECTION)

•Is there any malfunction?Yes Replace glow plug relay, go to Step 9.

No Go to next step.

8INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

9INSPECT GLOW PLUG RELAY CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—Glow plug relay terminal D and PCM

terminal 68.

—Glow plug relay terminal C and PCM

terminal 86.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

10VERIFY TROUBLESHOOTING OF DTC P0380

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

11VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 297 of 909

ON-BOARD DIAGNOSTIC

F2–145

F2

DTC P0504A6E407001082234

Diagnostic procedure

DTC P0504 Brake switch signal correlation malfunction

DETECTION

CONDITION•PCM monitors input signal from brake switch 1 and brake switch 2 while engine is running. PCM

determines brake switch signal correlation malfunction if input signal from brake switch 1 brake switch 2 is

as following:

—Brake switch 1 is ON and brake switch 2 is ON.

—Brake switch 1 is OFF and brake switch 2 is OFF.

POSSIBLE

CAUSE•Brake switch malfunction

•Connector or terminal malfunction

•Open circuit in wiring between main fuse and brake switch terminal B

•Open circuit in wiring between brake switch terminal D and PCM terminal 7

•Short to power circuit in wiring between brake switch terminal D and PCM terminal 7

•Open circuit in wiring between brake switch terminal C and GND

•Short to GND in wiring between brake switch terminal A and PCM terminal 34

•Open circuit in wiring between brake switch terminal A and PCM terminal 34

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR BRAKE SWITCH 2

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify that BOO PID is changed according to

brake pedal condition.

(See F2–65 PCM INSPECTION)

•Is BOO PID okay?Yes Go to Step 15.

No Go to next step.

3CLASSIFY HIGH INPUT OR LOW INPUT

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify BOO PID during brake pedal operation.

•Is BOO PID always OFF?Yes Go to next step.

No Go to Step 10.

MAIN FUSE

BRAKE SWITCH

A B

CD

BRAKE SWITCHPCM

7

34

PCM

HARNESS SIDE CONNECTOR

HARNESS SIDE CONNECTOR

A

B C

D

7 34

4

6

7

8

910

4

10

12

1918

17

1516

1413

2015

Page 298 of 909

F2–146

ON-BOARD DIAGNOSTIC

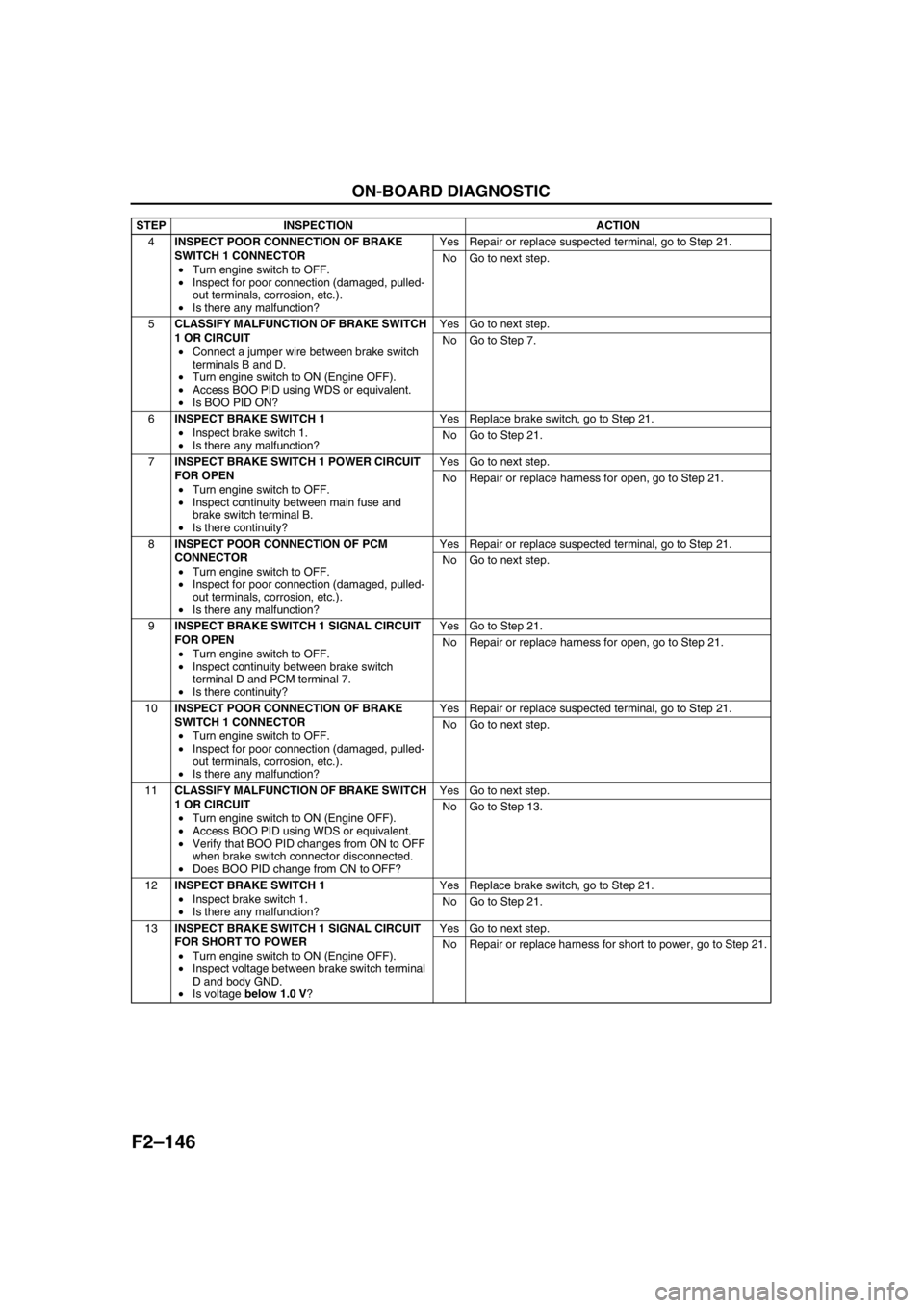

4INSPECT POOR CONNECTION OF BRAKE

SWITCH 1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

5CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR CIRCUIT

•Connect a jumper wire between brake switch

terminals B and D.

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Is BOO PID ON?Yes Go to next step.

No Go to Step 7.

6INSPECT BRAKE SWITCH 1

•Inspect brake switch 1.

•Is there any malfunction?Yes Replace brake switch, go to Step 21.

No Go to Step 21.

7INSPECT BRAKE SWITCH 1 POWER CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between main fuse and

brake switch terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 21.

8INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

9INSPECT BRAKE SWITCH 1 SIGNAL CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between brake switch

terminal D and PCM terminal 7.

•Is there continuity?Yes Go to Step 21.

No Repair or replace harness for open, go to Step 21.

10INSPECT POOR CONNECTION OF BRAKE

SWITCH 1 CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 21.

No Go to next step.

11CLASSIFY MALFUNCTION OF BRAKE SWITCH

1 OR CIRCUIT

•Turn engine switch to ON (Engine OFF).

•Access BOO PID using WDS or equivalent.

•Verify that BOO PID changes from ON to OFF

when brake switch connector disconnected.

•Does BOO PID change from ON to OFF?Yes Go to next step.

No Go to Step 13.

12INSPECT BRAKE SWITCH 1

•Inspect brake switch 1.

•Is there any malfunction?Yes Replace brake switch, go to Step 21.

No Go to Step 21.

13INSPECT BRAKE SWITCH 1 SIGNAL CIRCUIT

FOR SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between brake switch terminal

D and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 21. STEP INSPECTION ACTION

Page 302 of 909

F2–150

ON-BOARD DIAGNOSTIC

DTC P0512A6E407001082236

DTC P0512 Engine switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from engine switch while engine is running. If input voltage from engine switch

is B+ when engine speed is 1,200 rpm or above, PCM determines engine switch circuit malfunction.

POSSIBLE

CAUSE•Engine switch malfunction

•Connector or terminal malfunction

•Short to power circuit in wiring between engine switch terminal A and PCM terminal 57

•PCM malfunction

ENGINE SWITCH

F

AMAIN FUSE

E

FC

DA

B

57 57PCM

4

2

235

ENGINE SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 317 of 909

TROUBLESHOOTING

F2–165

F2

SYMPTOM DIAGNOSTIC INDEXA6E408018881201

TROUBLESHOOTING

No. TROUBLESHOOTING ITEM DESCRIPTION PAGE

1 Melting of main or other fuses—(See F2–173 NO.1 MELTING

OF MAIN OR OTHER FUSES)

2 MIL illuminates MIL is illuminated incorrectly.(See F2–174 NO.2 MIL

ILLUMINATES)

3 Will not crank Starter does not work.(See F2–174 NO.3 WILL NOT

CRANK)

4Hard start/long crank/erratic start/

erratic crankStarter cranks engine at normal speed but

engine requires excessive cranking time

before starting.(See F2–176 NO.4 HARD

START/LONG CRANK/

ERRATIC START/ERRATIC

CRANK)

5 Engine stalls After start/at idleEngine stops unexpectedly at idle and/or

after start.(See F2–178 NO.5 ENGINE

STALLS-AFTER START/AT

IDLE)

6 Cranks normally but will not startStarter cranks engine at normal speed but

engine will not run.(See F2–181 NO.6 CRANKS

NORMALLY BUT WILL NOT

START)

7 Slow return to idleEngine takes more time than normal to

return to idle speed.(See F2–184 NO.7 SLOW

RETURN TO IDLE)

8 Engine runs rough/rolling idleEngine speed fluctuates between specified

idle speed and lower speed and engine

shakes excessively.(See F2–186 NO.8 ENGINE

RUNS ROUGH/ROLLING

IDLE)

9 Fast idle/runs onEngine speed continues at fast idle after

warm-up.

Engine runs after engine switch is turned to

OFF.(See F2–189 NO.9 FAST

IDLE/RUNS ON)

10 Low idle/stalls during decelerationEngine stops unexpectedly at beginning of

deceleration or recovery from deceleration.(See F2–190 NO.10 LOW

IDLE/STALLS DURING

DECELERATION)

11Engine stalls/quitsAcceleration/

cruiseEngine stops unexpectedly at beginning of

acceleration or during acceleration.

Engine stops unexpectedly while cruising.

(See F2–192 NO.11 ENGINE

STALLS/QUITS, ENGINE

RUNS ROUGH, MISSES,

BUCK/JERK, HESITATION/

STUMBLE, SURGES) Engine runs roughAcceleration/

cruiseEngine speed fluctuates during acceleration

or cruising.

MissesAcceleration/

cruiseEngine misses during acceleration or

cruising.

Buck/jerkAcceleration/

cruise/

decelerationVehicle bucks/jerks during acceleration,

cruising, or deceleration.

Hesitation/stumble AccelerationMomentary pause at beginning of

acceleration or during acceleration.

SurgesAcceleration/

cruiseMomentary minor irregularity in engine

output.

12 Lack/loss of powerAcceleration/

cruisePerformance is poor under load (e.g. power

down when climbing hills).(See F2–195 NO.12 LACK/

LOSS OF POWER-

ACCELERATION/CRUISE)

13 Knocking/pingingExcessive shrilly knocking sound from

engine.(See F2–199 NO.13

KNOCKING/PINGING)

14 Poor fuel economy Fuel economy is unsatisfactory.(See F2–202 NO.14 POOR

FUEL ECONOMY)

15 Emissions compliance Fails emissions test.(See F2–205 NO.15

EMISSION COMPLIANCE)

16 High oil consumption/leakage Oil consumption is excessive.(See F2–209 NO.16 HIGH OIL

CONSUMPTION/LEAKAGE)

17Cooling system

concernsOverheatingEngine runs at higher than normal

temperature/overheats.(See F2–210 NO.17 COOLING

SYSTEM CONCERNS-

OVERHEATING)

Page 319 of 909

TROUBLESHOOTING

F2–167

F2

SYMPTOM QUICK DIAGNOSIS CHARTA6E408018881202

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank×× ×× × ×

4 Hard start/long crank/erratic start/erratic crank×× ×

5 Engine stalls After start/at idle××

6 Cranks normally but will not start××

7 Slow return to idle

8 Engine runs rough/rolling idle××

9 Fast idle/runs on

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××

Engine runs rough Acceleration/cruise××

Misses Acceleration/cruise××

Buck/jerk Acceleration/cruise/ deceleration××

Hesitation/stumble Acceleration××

Surges Acceleration/cruise××

12 Lack/loss of power Acceleration/cruise××

13 Knocking/pinging××

14 Poor fuel economy××

15 Emissions compliance×× ×

16 High oil consumption/leakage××××

17 Cooling system concerns Overheating××

18 Cooling system concerns Runs cold

19 Excessive black smoke×

20 Fuel odor (in engine compartment)

21 Engine noise×× × ×

22 Vibration concerns (engine)×

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Starter motor malfunction (Mechanical or electrical)Starter circuit including engine switch is openImproper engine oil levelLow or dead bateryCharging system malfunctionLow engine compressionImproper valve timingHydrolocked egineImproper engine oil viscosityImproper dipstickBase engine malfunctionSeized flywheelImproper tension or damaged drivebelts

Page 320 of 909

F2–168

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×××

5 Engine stalls After start/at idle×××

6 Cranks normally but will not start××

7 Slow return to idle×

8 Engine runs rough/rolling idle××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise×××× ×

Misses Acceleration/cruise××××××

Buck/jerk Acceleration/cruise/ deceleration××××××

Hesitation/stumble Acceleration××××××

Surges Acceleration/cruise××××××

12 Lack/loss of power Acceleration/cruise×××××××

13 Knocking/pinging×××××

14 Poor fuel economy××××

15 Emissions compliance× ××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×× × ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)×× ×

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Improper engine coolant levelWater and anti-freeze mixture is improperCooling system malfunction (Radiator, hose,

over-flow system, thermostat, etc.)Cooling fan system malfunctionEngine or transaxle mounts are improperly installedCooling fan No.1 or No.2 seat are improperFuel qualityEngine overheatingIntake-air system clogging or restrictionAir leakage from intake-air systemVSC system malfunctionVacuum leakage