fuse MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 321 of 909

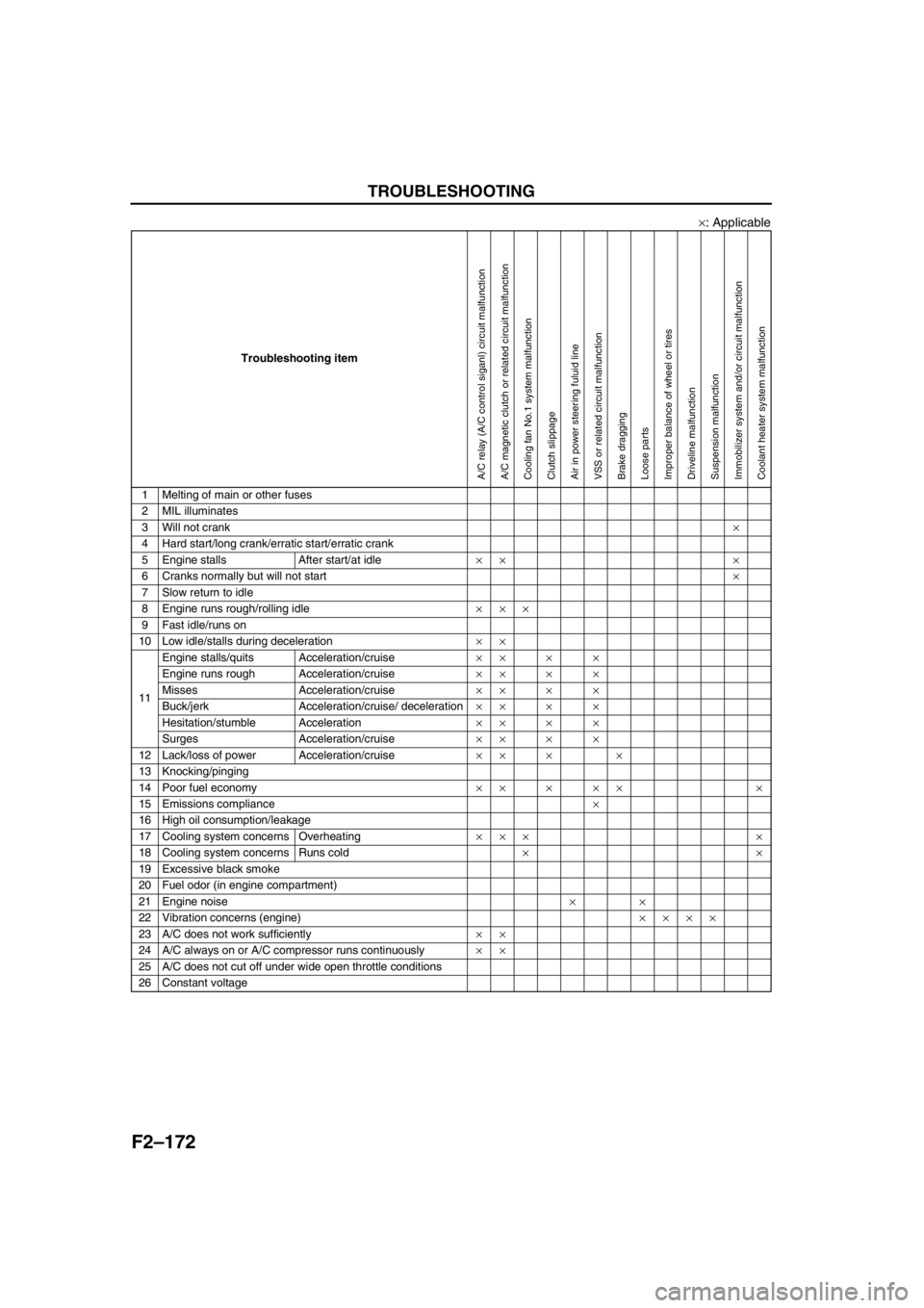

TROUBLESHOOTING

F2–169

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×× × ×

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×××××××

5 Engine stalls After start/at idle×× ×××××××

6 Cranks normally but will not start×× ×××××××

7 Slow return to idle××××××××

8 Engine runs rough/rolling idle×××××××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××××××××××

11Engine stalls/quits Acceleration/cruise× × ×××××××

Engine runs rough Acceleration/cruise× ××××××××××

Misses Acceleration/cruise× ××××××××××

Buck/jerk Acceleration/cruise/ deceleration× ××××××××××

Hesitation/stumble Acceleration× ××××××××××

Surges Acceleration/cruise× ×× ×××××××

12 Lack/loss of power Acceleration/cruise××× ×××××××××

13 Knocking/pinging××××× ××× × ×

14 Poor fuel economy××× ×××××× ×

15 Emissions compliance×××××××××××××

16 High oil consumption/leakage×

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××× × ××× ×××

20 Fuel odor (in engine compartment)××

21 Engine noise× ××× ×

22 Vibration concerns (engine)

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Turbocharger malfunctionCarge air cooler malfunctionVBC system malfunctionGlow system malfunctionIncorrect fuel injection timingIncorrect idle speedCKP sensor is damaged (e.g.: open or short circuits)CKP sensor pulse wheel is damagedImproper gap between CKP sensor and pulse wheelSupply pump malfunctionSuction control valve malfunctionFuel pressure limiter malfunctionFuel line restriction or clogging

Page 322 of 909

F2–170

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank× × ××××× ×

5 Engine stalls After start/at idle×××××××××

6 Cranks normally but will not start× × ×××× × ×

7 Slow return to idle××××

8 Engine runs rough/rolling idle× × ×××× ××

9 Fast idle/runs on××

10 Low idle/stalls during deceleration× × ×××× ×

11Engine stalls/quits Acceleration/cruise× ××××× ×

Engine runs rough Acceleration/cruise× ××××× ×

Misses Acceleration/cruise× ××××× ×

Buck/jerk Acceleration/cruise/ deceleration× ××××× ×

Hesitation/stumble Acceleration× ××××× ×

Surges Acceleration/cruise× ××××× ×

12 Lack/loss of power Acceleration/cruise× ××××× ×

13 Knocking/pinging××××

14 Poor fuel economy×××××××

15 Emissions compliance× ×××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)×

21 Engine noise××××

22 Vibration concerns (engine)×××

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage×

Fuel injectors malfunction (Leakage or clogging,

inoperative)Fuel leakage from fuel system (including insulator,

fuel injector)Fuel filter restriction or cloggingCMP sensor is damaged (e.g: open or short circuit)CMP sensor pulse wheel is damagedIDM or related circuit malfunctionExhaust system restriction or cloggingCatalyst converter malfunctionEGR system malfunctionEGR water cooler malfunctionV-reference voltage supply circuit malfunction

Page 323 of 909

TROUBLESHOOTING

F2–171

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×××××× × ×××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×× ×

5 Engine stalls After start/at idle×× × × × ××

6 Cranks normally but will not start×× ×

7 Slow return to idle××× × × ×××

8 Engine runs rough/rolling idle××× × × ××××

9 Fast idle/runs on×××

10 Low idle/stalls during deceleration××× × × ××××

11Engine stalls/quits Acceleration/cruise× × × × ××××

Engine runs rough Acceleration/cruise××× × × ××××

Misses Acceleration/cruise× × × × ××××

Buck/jerk Acceleration/cruise/ deceleration× ×××× × ××××

Hesitation/stumble Acceleration× ×××× × ××××

Surges Acceleration/cruise× ×××× × ××××

12 Lack/loss of power Acceleration/cruise× ×××× × ××××

13 Knocking/pinging××××× ×

14 Poor fuel economy× ×××× ×××

15 Emissions compliance×××××× × ×××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke×× ×

20 Fuel odor (in engine compartment)×

21 Engine noise××××× ×

22 Vibration concerns (engine)×× ××××

23 A/C does not work sufficiently×

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions××

26 Constant voltage××××× ×

PCM control relay malfunctionECT sensor or related circuit malfunctionNeutral switch or related circuit malfunctionMAF/IAT sensor or related circuit malfunctionIAT sensor No.2 or related circuit malfunctionBoost sensor or related circuit malfunctionAccelerator position sensor or related circuit malfunctionAccelerator position sensor misadjustment

(including looseness)Idle switch or related circuit malfunctionIdle switch misadjustment (including looseness)Fuel pressure sensor or related circuit malfunctionImproper refrigerant charging amount

Page 324 of 909

F2–172

TROUBLESHOOTING

×: Applicable

End Of Sie

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank×

4 Hard start/long crank/erratic start/erratic crank

5 Engine stalls After start/at idle×× ×

6 Cranks normally but will not start×

7 Slow return to idle

8 Engine runs rough/rolling idle×××

9 Fast idle/runs on

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise××××

Misses Acceleration/cruise××××

Buck/jerk Acceleration/cruise/ deceleration××××

Hesitation/stumble Acceleration××××

Surges Acceleration/cruise××××

12 Lack/loss of power Acceleration/cruise×× × ×

13 Knocking/pinging

14 Poor fuel economy××××× ×

15 Emissions compliance×

16 High oil consumption/leakage

17 Cooling system concerns Overheating××× ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)××××

23 A/C does not work sufficiently××

24 A/C always on or A/C compressor runs continuously××

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

A/C relay (A/C control siganl) circuit malfunctionA/C magnetic clutch or related circuit malfunctionCooling fan No.1 system malfunctionClutch slippageAir in power steering fuluid lineVSS or related circuit malfunctionBrake draggingLoose partsImproper balance of wheel or tiresDriveline malfunctionSuspension malfunctionImmobilizer system and/or circuit malfunctionCoolant heater system malfunction

Page 325 of 909

![MAZDA 6 2002 Suplement Owners Manual TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri MAZDA 6 2002 Suplement Owners Manual TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiri](/img/28/57057/w960_57057-324.png)

TROUBLESHOOTING

F2–173

F2

NO.1 MELTING OF MAIN OR OTHER FUSESA6E408018881203

End Of Sie

1 Melting of main or other fuses

[TROUBLESHOOTING HINTS]

Inspect condition of fuse.

Damaged fuse Related wiring harness

MAINMAIN fuse

•BTN fuse

•FAN fuse

•AD FAN fuse

•IG KEY 2 fuse

IG KEY 1IG KEY 1 fuse

•Engine switch

—ENGINE fuse

FUEL PUMPFUEL PUMP fuse

•Fuel warmer

•PCM control relay

BTNBTN fuse

•ROOM fuse

IG KEY 2IG KEY 2 fuse

•Engine switch

ROOMROOM fuse

•DLC-2

ENGINEENGINE fuse

•PCM

INJINJ fuse

•PCM

•IDM

•MAF/IAT sensor

•VSC solenoid valve

•VBC solenoid valve

•EGR control solenoid valve

•EGR solenoid valve (vacuum)

•EGR solenoid valve (vent)

•Intake shutter solenoid valve (half)

•Intake shutter solenoid valve (full)

GLOWGLOW fuse

•Glow plug relay

—Glow plug

—GLOW SIG

ENG+BENG+B fuse

•PCM

FANFAN fuse

•Cooling fan relay No.2

AD FANAD FAN fuse

•Cooling fan relay No.1

Shorted harness

Repair shorted harness and replace fuseFuseDeterioration

Replace fuse

Page 327 of 909

TROUBLESHOOTING

F2–175

F2

End Of Sie

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect following:

•Battery connection

•Battery condition

•Fuses

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11 Is clicking sound heard from starter when engine

switch is turned to START?Yes Go to Step 13.

No Go to next step.

12 Inspect starting system.

Is starting system okay?Yes Inspect for seized/hydrolocked engine, flywheel.

No Repair or replace components as required.

13 Do any other electrical accessories work? Yes Go to next step.

No Inspect charging system.

14 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Inspect for following:

•START circuit in engine switch

•Open circuit between engine switch and starter

15 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 331 of 909

TROUBLESHOOTING

F2–179

F2

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS-OVERHEATING”.

No Go to next step.

12Note

•Ignore DTC P0122, P0123, P0222 or

P0223 while performing this test.

Disconnect accelerator position sensor

connector.

Measure voltage at accelerator position sensor

connector VREF terminal (terminal D) with

engine switch ON.

Specification

4.5—5.5 V

Is voltage okay?Yes Go to next step.

No Go to symptom troubleshooting “NO.26 CONSTANT

VOLTAGE”.

13 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

14 Does engine start normally after warm-up? Yes Inspect glow system operation.

(See T–19 RELAY INSPECTION)

Replace any malfunctioning part as necessary.

If glow system is okay, go to next step.

No Go to next step. STEP INSPECTION RESULTS ACTION

Page 334 of 909

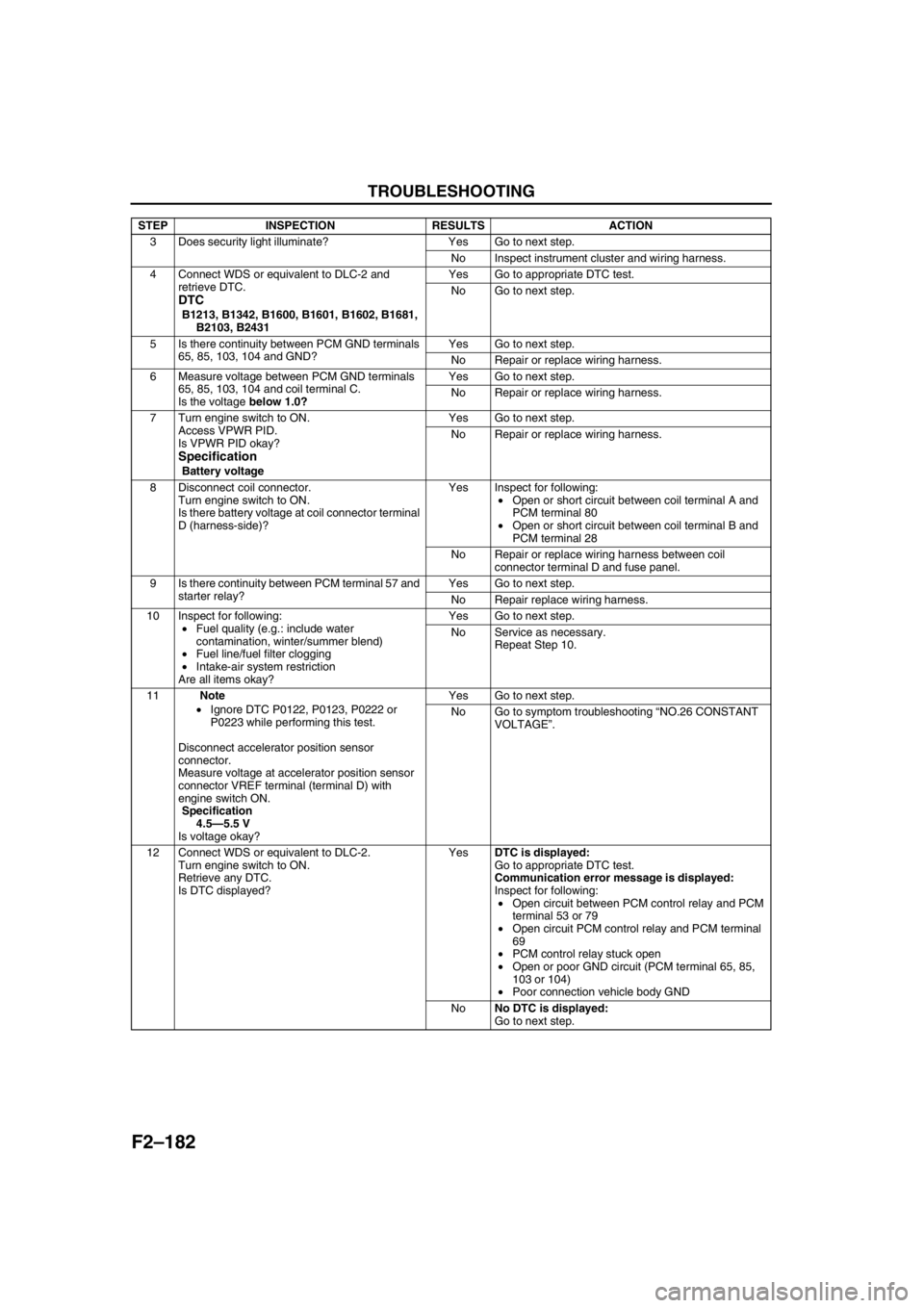

F2–182

TROUBLESHOOTING

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11Note

•Ignore DTC P0122, P0123, P0222 or

P0223 while performing this test.

Disconnect accelerator position sensor

connector.

Measure voltage at accelerator position sensor

connector VREF terminal (terminal D) with

engine switch ON.

Specification

4.5—5.5 V

Is voltage okay?Yes Go to next step.

No Go to symptom troubleshooting “NO.26 CONSTANT

VOLTAGE”.

12 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step. STEP INSPECTION RESULTS ACTION

Page 389 of 909

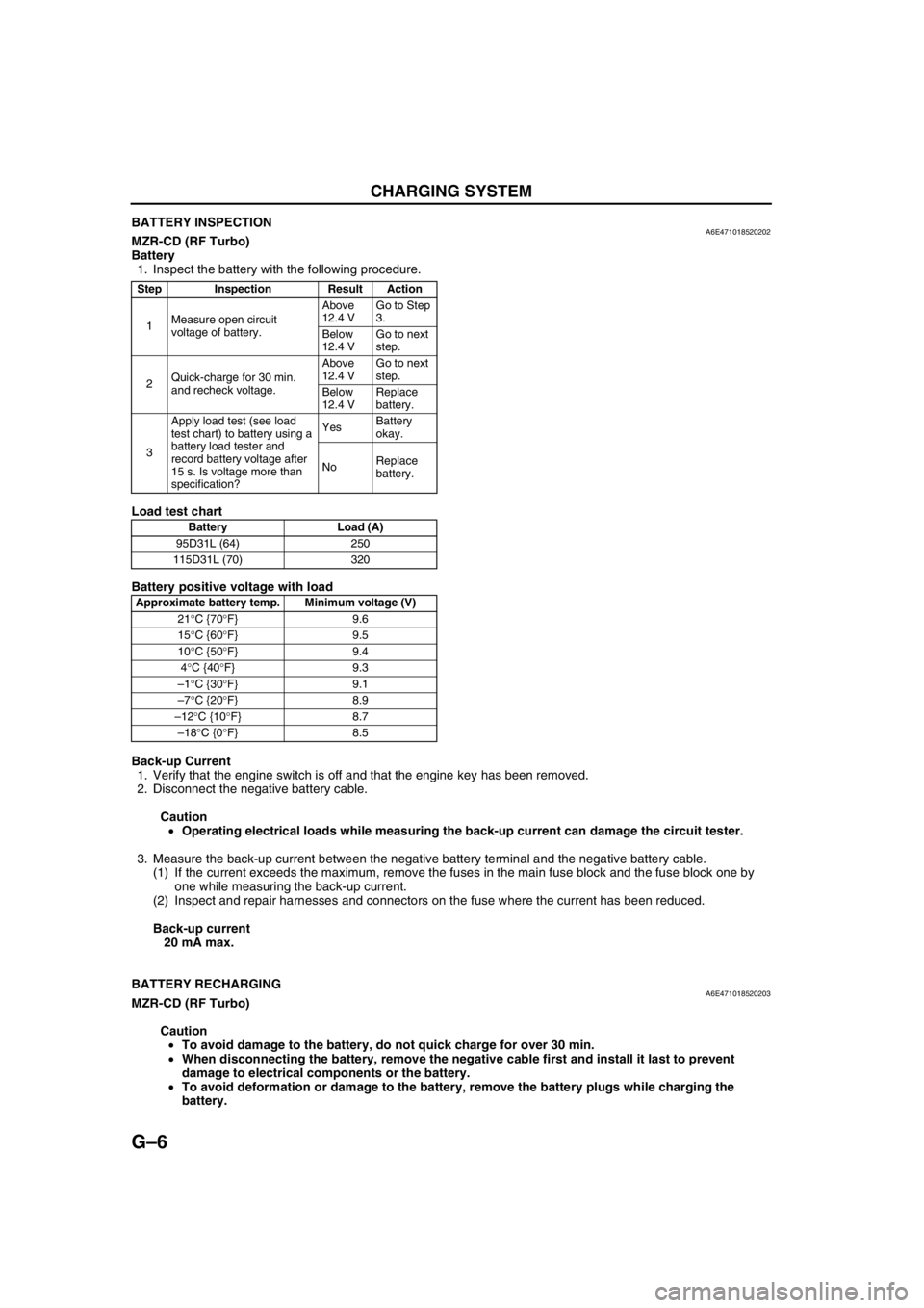

G–6

CHARGING SYSTEM

BATTERY INSPECTIONA6E471018520202MZR-CD (RF Turbo)

Battery

1. Inspect the battery with the following procedure.

Load test chart

Battery positive voltage with load

Back-up Current

1. Verify that the engine switch is off and that the engine key has been removed.

2. Disconnect the negative battery cable.

Caution

•Operating electrical loads while measuring the back-up current can damage the circuit tester.

3. Measure the back-up current between the negative battery terminal and the negative battery cable.

(1) If the current exceeds the maximum, remove the fuses in the main fuse block and the fuse block one by

one while measuring the back-up current.

(2) Inspect and repair harnesses and connectors on the fuse where the current has been reduced.

Back-up current

20 mA max.

End Of Sie

BATTERY RECHARGINGA6E471018520203MZR-CD (RF Turbo)

Caution

•To avoid damage to the battery, do not quick charge for over 30 min.

•When disconnecting the battery, remove the negative cable first and install it last to prevent

damage to electrical components or the battery.

•To avoid deformation or damage to the battery, remove the battery plugs while charging the

battery.

Step Inspection Result Action

1Measure open circuit

voltage of battery.Above

12.4 VGo to Step

3.

Below

12.4 VGo to next

step.

2Quick-charge for 30 min.

and recheck voltage.Above

12.4 VGo to next

step.

Below

12.4 VReplace

battery.

3Apply load test (see load

test chart) to battery using a

battery load tester and

record battery voltage after

15 s. Is voltage more than

specification?YesBattery

okay.

NoReplace

battery.

Battery Load (A)

95D31L (64) 250

115D31L (70) 320

Approximate battery temp. Minimum voltage (V)

21°C {70°F} 9.6

15°C {60°F} 9.5

10°C {50°F} 9.4

4°C {40°F} 9.3

–1°C {30°F} 9.1

–7°C {20°F} 8.9

–12°C {10°F} 8.7

–18°C {0°F} 8.5

Page 545 of 909

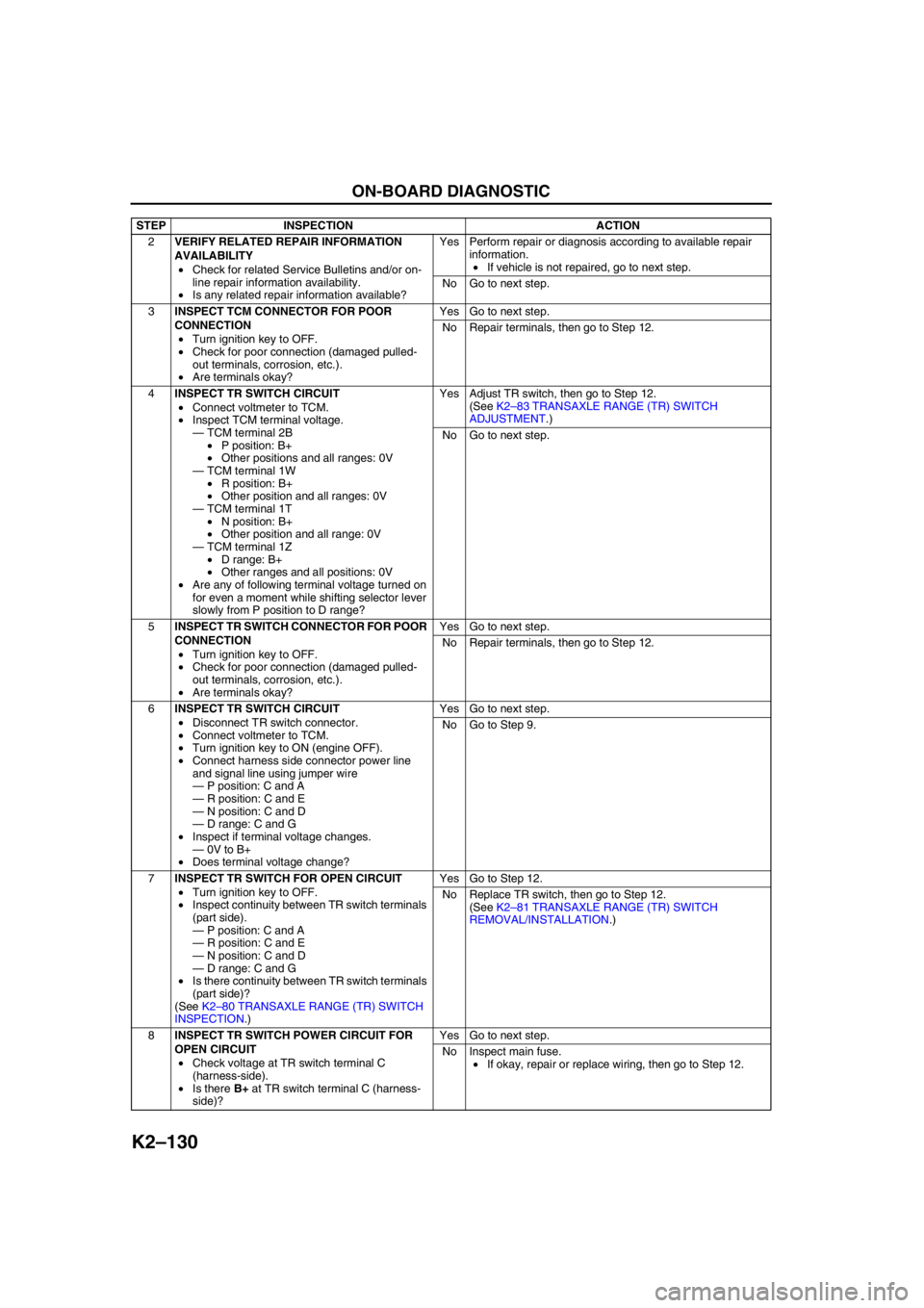

K2–130

ON-BOARD DIAGNOSTIC

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Turn ignition key to OFF.

•Check for poor connection (damaged pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

4INSPECT TR SWITCH CIRCUIT

•Connect voltmeter to TCM.

•Inspect TCM terminal voltage.

—TCM terminal 2B

•P position: B+

•Other positions and all ranges: 0V

—TCM terminal 1W

•R position: B+

•Other position and all ranges: 0V

—TCM terminal 1T

•N position: B+

•Other position and all range: 0V

—TCM terminal 1Z

•D range: B+

•Other ranges and all positions: 0V

•Are any of following terminal voltage turned on

for even a moment while shifting selector lever

slowly from P position to D range?Yes Adjust TR switch, then go to Step 12.

(See K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

No Go to next step.

5INSPECT TR SWITCH CONNECTOR FOR POOR

CONNECTION

•Turn ignition key to OFF.

•Check for poor connection (damaged pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

6INSPECT TR SWITCH CIRCUIT

•Disconnect TR switch connector.

•Connect voltmeter to TCM.

•Turn ignition key to ON (engine OFF).

•Connect harness side connector power line

and signal line using jumper wire

—P position: C and A

—R position: C and E

—N position: C and D

—D range: C and G

•Inspect if terminal voltage changes.

—0V to B+

•Does terminal voltage change?Yes Go to next step.

No Go to Step 9.

7INSPECT TR SWITCH FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Inspect continuity between TR switch terminals

(part side).

—P position: C and A

—R position: C and E

—N position: C and D

—D range: C and G

•Is there continuity between TR switch terminals

(part side)?

(See K2–80 TRANSAXLE RANGE (TR) SWITCH

INSPECTION.)Yes Go to Step 12.

No Replace TR switch, then go to Step 12.

(See K2–81 TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION.)

8INSPECT TR SWITCH POWER CIRCUIT FOR

OPEN CIRCUIT

•Check voltage at TR switch terminal C

(harness-side).

•Is there B+ at TR switch terminal C (harness-

side)?Yes Go to next step.

No Inspect main fuse.

•If okay, repair or replace wiring, then go to Step 12. STEP INSPECTION ACTION