engine MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 730 of 909

N–16

ENGINE SPEED SENSING POWER STEERING

POWER STEERING OIL PUMP (MZR-CD (RF TURBO)) REMOVAL/INSTALLATIONA6E6614326502011. Remove the air cleaner.

2. Remove the battery and battery tray.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

OILOILR

R

R

4

3

1

229.4—44.1

{3.00—4.49, 21.7—32.5} 18.6—25.5

{1.90—2.60,

13.8—18.8}

N·m {kgf·m, ft·lbf}

A6E66142006

1 Pressure pipe

2 Return hose3 Power steering oil pump

4 O-ring

Page 731 of 909

ENGINE SPEED SENSING POWER STEERING

N–17

N

POWER STEERING OIL PUMP (MZR-CD (RF TURBO)) DISASSEMBLY/ASSEMBLYA6E661432650202

Note

•The following procedure is for replacement of the O-ring and oil seal only. Replace the pump component if

other repairs are necessary.

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

.

9

8

7

5

4

3

10

6

1

2

15

16

14

13

11

12

SST

R

ATFTF

22—26

{2.3—2.6, 17—19}

N·m {kgf·m, ft·lbf}

R

ATFTF

R

R

ATFTF

ATFTF

ATFTF

R

31.1—47.0

{3.18—4.79, 23.0—34.6}

31.1—47.0

{3.18—4.79, 23.0—34.6}

A6E66142007

1 Power steering oil pump component

(See N–18 Power Steering Oil Pump Component

Disassembly Note)

2Clip

(See N–18 Clip Disassembly Note)

(See N–19 Clip Assembly Note)

3 Reservoir tank4 O-ring

5Joint

6 Connector

7 O-ring

8 Control valve

9Spring

Page 732 of 909

N–18

ENGINE SPEED SENSING POWER STEERING

Power Steering Oil Pump Component Disassembly Note

1. Secure the power pressure oil pump using the SST.

Caution

•Use the SST to prevent damage to the

pump when securing it in a vise.

Clip Disassembly Note

1. Lift up the clip tab using a flathead screwdriver.

2. Remove the clip by pushing it with a flathead

screwdriver and a hammer as shown in the figure.

Vane Assembly Note

1. Place the vanes in the rotor with the rounded

edges contacting the cam.

10 Rear pump body

(See N–19 Rear Pump Body Assembly Note)

11 Gasket

12 Cam ring

(See N–19 Cam Ring Assembly Note)13 Rotor

14 Vane

(See N–18 Vane Assembly Note)

15 Side plate

16 Power steering oil pump

49 F032 301

A6E66142010

CLIP

R

A6E66142008

A6E6316W013

Page 733 of 909

ENGINE SPEED SENSING POWER STEERING

N–19

N

Cam Ring Assembly Note

1. Install the cam ring in the front pump body with

the mark facing upward.

Rear Pump Body Assembly Note

1. After installing the rear body, manually turn the shaft to verify that it rotates smoothly.

Clip Assembly Note

1. Push the clip slowly in the direction shown in the

figure.

2. Confirm that the clip tab is securely fastened.

End Of Sie

A6E6316W014

CLIP

R

A6E66142009

Page 735 of 909

P–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E690201020201•The construction and operation of the braking system is the same as that of the current Mazda6 (GG) L8, LF,

L3 engine 2WD model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E690201020202Modifications to match vehicle characteristics

•Due to the addition of the MZR-CD (RF Turbo) engine, the vacuum pump and vacuum switch have been

added.

•Due to the addition of the 4WD model, DSC HU/CM uses the forward-G signal from combine sensor to control

DSC.

End Of Sie

SPECIFICATIONSA6E690201020203

Bold frames: New specifications

End Of Sie

OUTLINE

ItemSpecification

New Mazda6 (GG, GW) Current Mazda6 (GG)

Brake pedalType Suspended

Pedal lever ratio 2.7

Max. stroke (mm {in}) 128.5 {5.06}

Master

cylinderType Tandem (with level sensor)

Cylinder diameter (mm {in}) 20.64 {0.813}

Front disc

brakeType Ventilated disc

Cylinder bore (mm {in}) 57.15 {2.250}

Pad dimensions (area × thickness) L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

4,010 {6.42} × 12.0 {0.47}L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.) specs.),

L3: 4,010 {6.42} × 12.0 {0.47} (mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

283 {11.1} × 25.0 {0.984}L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.) specs.),

L3: 283 {11.1} × 25.0 {0.984} (mm {in} × mm {in})

Rear brake

(disc)Type Solid disc

Cylinder bore (mm {in}) 34.93 {1.375}

Pad dimensions (area × thickness)

2,810 {4.51} × 8.0 {0.31}

(mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)

280 {11.0} × 10.0 {0.39}

(mm {in})

Power brake

unitType Vacuum multiplier, single diaphragm

Diameter (mm {in}) 279 {10.9}

Braking force

control deviceTypeWith ABS: EBD (Electronic Brakeforce Distribution)

Without ABS: Dual proportioning valve

Parking brakeType Mechanical two-rear-wheel control

Operation system Center lever type

Brake fluid TypeEuropean (L.H.D. U.K.) specs.: SAE J1703, FMVSS116 DOT3 OR DOT4

GCC specs.: SAE J1703, FMVSS116 DOT3

Page 737 of 909

P–4

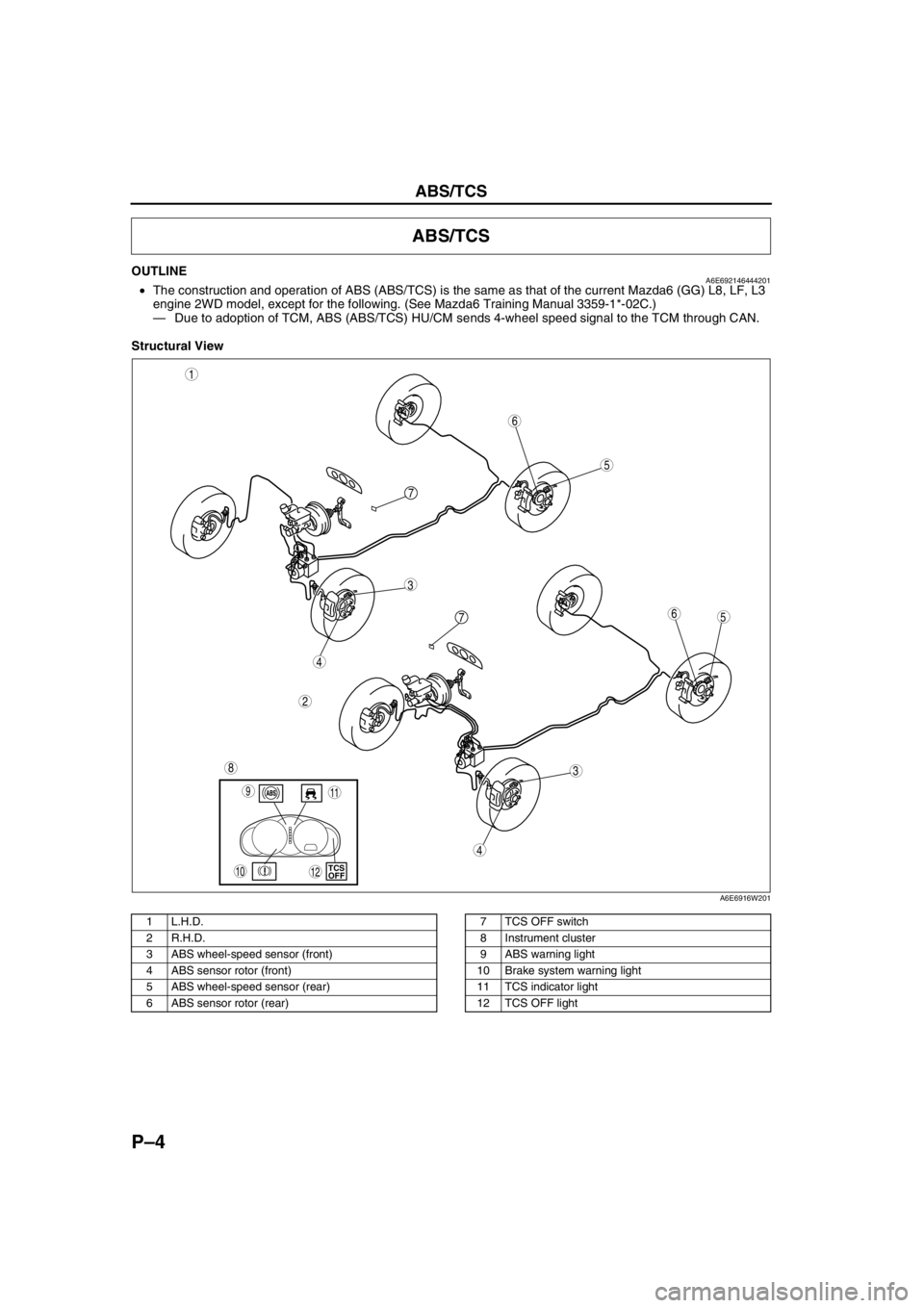

ABS/TCS

OUTLINEA6E692146444201•The construction and operation of ABS (ABS/TCS) is the same as that of the current Mazda6 (GG) L8, LF, L3

engine 2WD model, except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

—Due to adoption of TCM, ABS (ABS/TCS) HU/CM sends 4-wheel speed signal to the TCM through CAN.

Structural View

.

ABS/TCS

5

3

1

2

6

7

5

3

6

8

4

4

7

9

10TCS

OFF

11

12

A6E6916W201

1 L.H.D.

2 R.H.D.

3 ABS wheel-speed sensor (front)

4 ABS sensor rotor (front)

5 ABS wheel-speed sensor (rear)

6 ABS sensor rotor (rear)7 TCS OFF switch

8 Instrument cluster

9 ABS warning light

10 Brake system warning light

11 TCS indicator light

12 TCS OFF light

Page 741 of 909

P–8

DYNAMIC STABILITY CONTROL

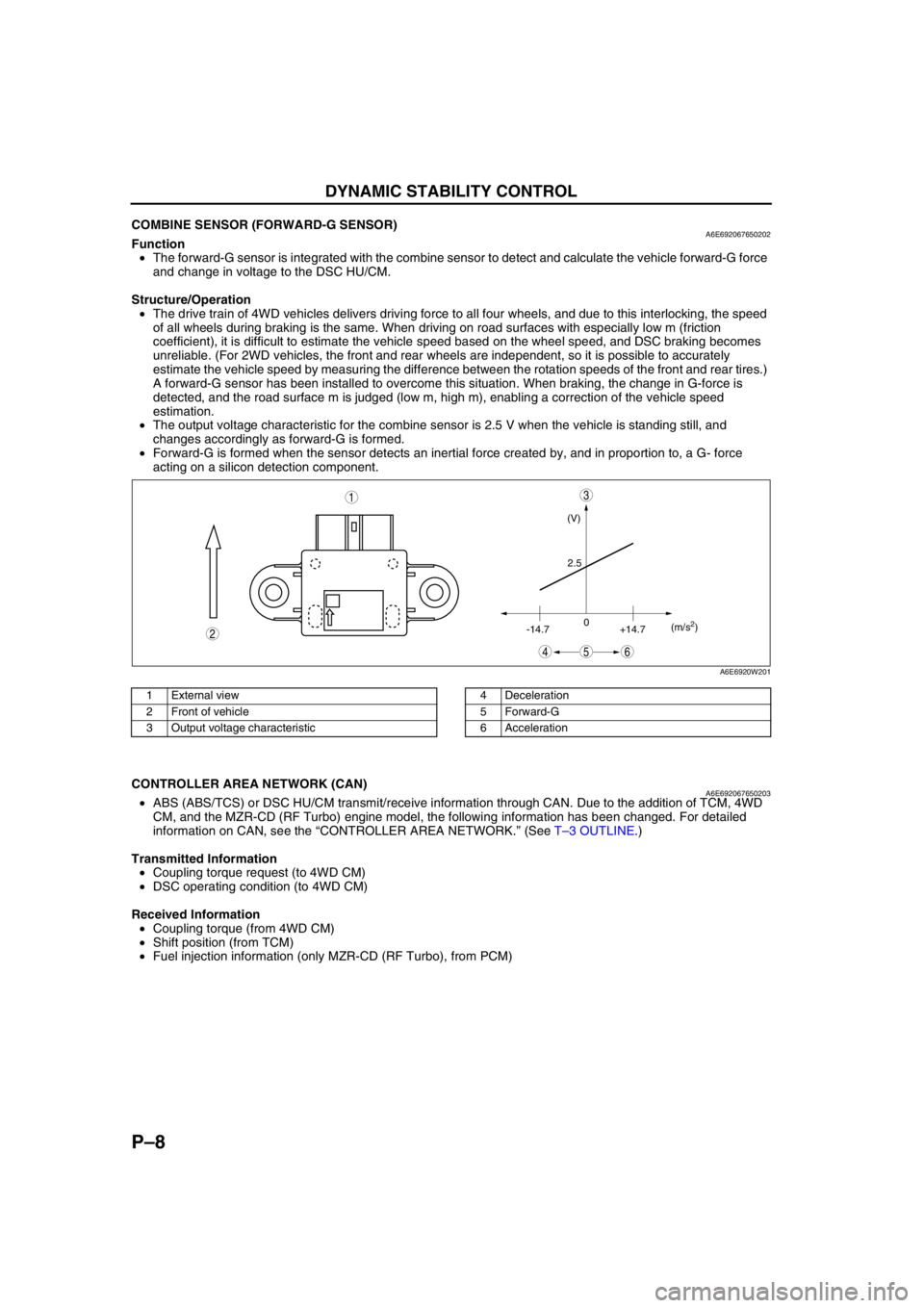

End Of SieCOMBINE SENSOR (FORWARD-G SENSOR)A6E692067650202Function

•The forward-G sensor is integrated with the combine sensor to detect and calculate the vehicle forward-G force

and change in voltage to the DSC HU/CM.

Structure/Operation

•The drive train of 4WD vehicles delivers driving force to all four wheels, and due to this interlocking, the speed

of all wheels during braking is the same. When driving on road surfaces with especially low m (friction

coefficient), it is difficult to estimate the vehicle speed based on the wheel speed, and DSC braking becomes

unreliable. (For 2WD vehicles, the front and rear wheels are independent, so it is possible to accurately

estimate the vehicle speed by measuring the difference between the rotation speeds of the front and rear tires.)

A forward-G sensor has been installed to overcome this situation. When braking, the change in G-force is

detected, and the road surface m is judged (low m, high m), enabling a correction of the vehicle speed

estimation.

•The output voltage characteristic for the combine sensor is 2.5 V when the vehicle is standing still, and

changes accordingly as forward-G is formed.

•Forward-G is formed when the sensor detects an inertial force created by, and in proportion to, a G- force

acting on a silicon detection component.

.

End Of Sie

CONTROLLER AREA NETWORK (CAN)A6E692067650203•ABS (ABS/TCS) or DSC HU/CM transmit/receive information through CAN. Due to the addition of TCM, 4WD

CM, and the MZR-CD (RF Turbo) engine model, the following information has been changed. For detailed

information on CAN, see the “CONTROLLER AREA NETWORK.” (See T–3 OUTLINE.)

Transmitted Information

•Coupling torque request (to 4WD CM)

•DSC operating condition (to 4WD CM)

Received Information

•Coupling torque (from 4WD CM)

•Shift position (from TCM)

•Fuel injection information (only MZR-CD (RF Turbo), from PCM)

End Of Sie

(V)

2.5

-14.70

+14.7(m/s

2)

45

3

6

2

1

A6E6920W201

1 External view

2 Front of vehicle

3 Output voltage characteristic4 Deceleration

5 Forward-G

6 Acceleration

Page 742 of 909

ON-BOARD DIAGNOSTIC

P–9

P

OUTLINEA6E697043000201•The operation of the on-board diagnostic system for ABS (ABS/TCS) or DSC is the same as that of the current

Mazda6 (GG) L8, LF, L3 engine 2WD model, except for the following. (See Mazda6 Training Manual

3359-1*-02C.)

— Due to the addition of the 4WD model, DTCs and PID data monitor has been added.

—Due to the addition of the MZR-CD (RF Turbo) engine model, the DTC C1119 fail-safe function and the

detection condition have been changed.

Fail-safe Function

Fail-safe function table

*1: When engine speed signal through CAN is out of specification, the light illuminates.*2: When engine speed signal through CAN is out of specification, the system is suspended.*3: When engine speed signal value through CAN is invalid, only brake TCS is available.*4: When fuel injection information through CAN is out of specification or invalid, only brake TCS is available.*5: When engine speed signal value through CAN is invalid, only brake DSC is available.*6: When the engine control system has a malfunction, only brake DSC is available.

PID/DATA Monitor Table

End Of Sie

ON-BOARD DIAGNOSTIC

Malfunc-

tion

locationDTC Fail-safe function

WDS

or

equiva-

lentWarning light illumination condition Control condition

ABS

warning

lightBRAKE

system

warning

light

(when

parking

brake is

released)DSC

(TCS)

OFF lightDSC

(TCS)

indicator

light ABS

controlEBD

controlTCS

controlDSC

controlBrake

assist

control

PCM and/

or engine

speed

signal lineC1119Not

Illuminated Not

Illuminated Not

Illuminated

*1Illuminated Available AvailableAvailable*2, *3, *4Available*2, *5, *6Available

Combine

sensor

(forward-

G) lineC1949

Illuminated Not

Illuminated Illuminated IlluminatedNot

availableAvailable—Not

availableNot

available

C1950

CAN line U2511Not

Illuminated Not

Illuminated Not

Illuminated Illuminated Available Available—Available Available

PID name input/output part Operation/unit

ACCLMTR Accelerometer ACCELERATION

Page 745 of 909

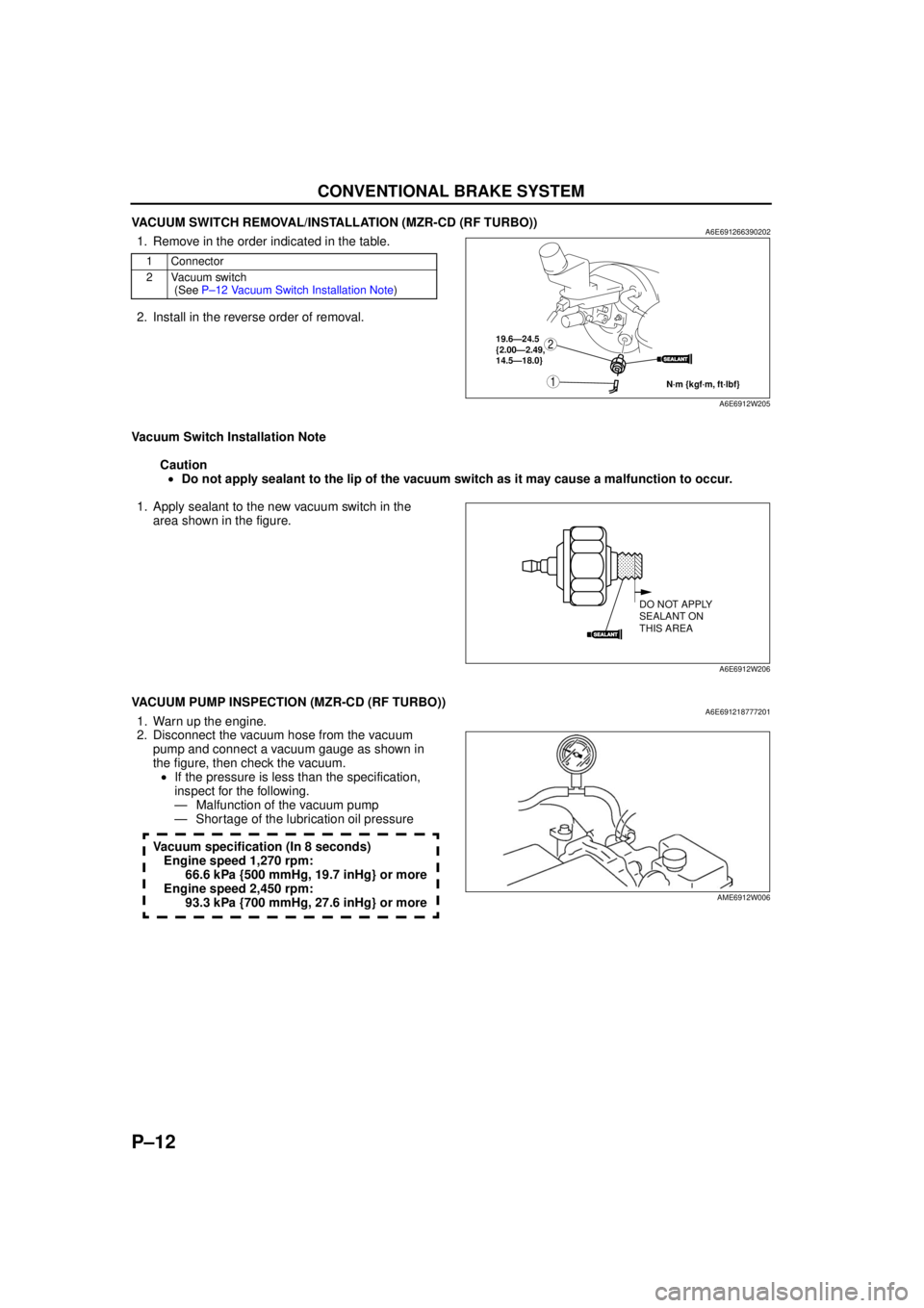

P–12

CONVENTIONAL BRAKE SYSTEM

VACUUM SWITCH REMOVAL/INSTALLATION (MZR-CD (RF TURBO))A6E6912663902021. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

Vacuum Switch Installation Note Caution• Do not apply sealant to the lip of the vacuum switch as it may cause a malfunction to occur.

1. Apply sealant to the new vacuum switch in the area shown in the figure.

End Of Sie

VACUUM PUMP INSPECTION (MZR-CD (RF TURBO))A6E6912187772011. Warn up the engine.

2. Disconnect the vacuum hose from the vacuum pump and connect a vacuum gauge as shown in

the figure, then check the vacuum.• If the pressure is less than the specification,

inspect for the following.

— Malfunction of the vacuum pump

— Shortage of the lubrication oil pressure

Vacuum specification (In 8 seconds) Engine speed 1,270 rpm: 66.6 kPa {500 mmHg, 19.7 inHg} or more

Engine speed 2,450 rpm: 93.3 kPa {700 mmHg, 27.6 inHg} or more

End Of Sie

1 Connector

2 Vacuum switch (See P –12 Vacu um S w itch Ins tal lat ion Note )

SEALANT

1

219.6—24.5

{2.00—2.49,

14.5—18.0}

N·m {kgf·m, ft·lbf}

A6E6912W205

SEALANT

DO NOT APPLY

SEALANT ON

THIS AREA

A6E6912W206

AME6912W006

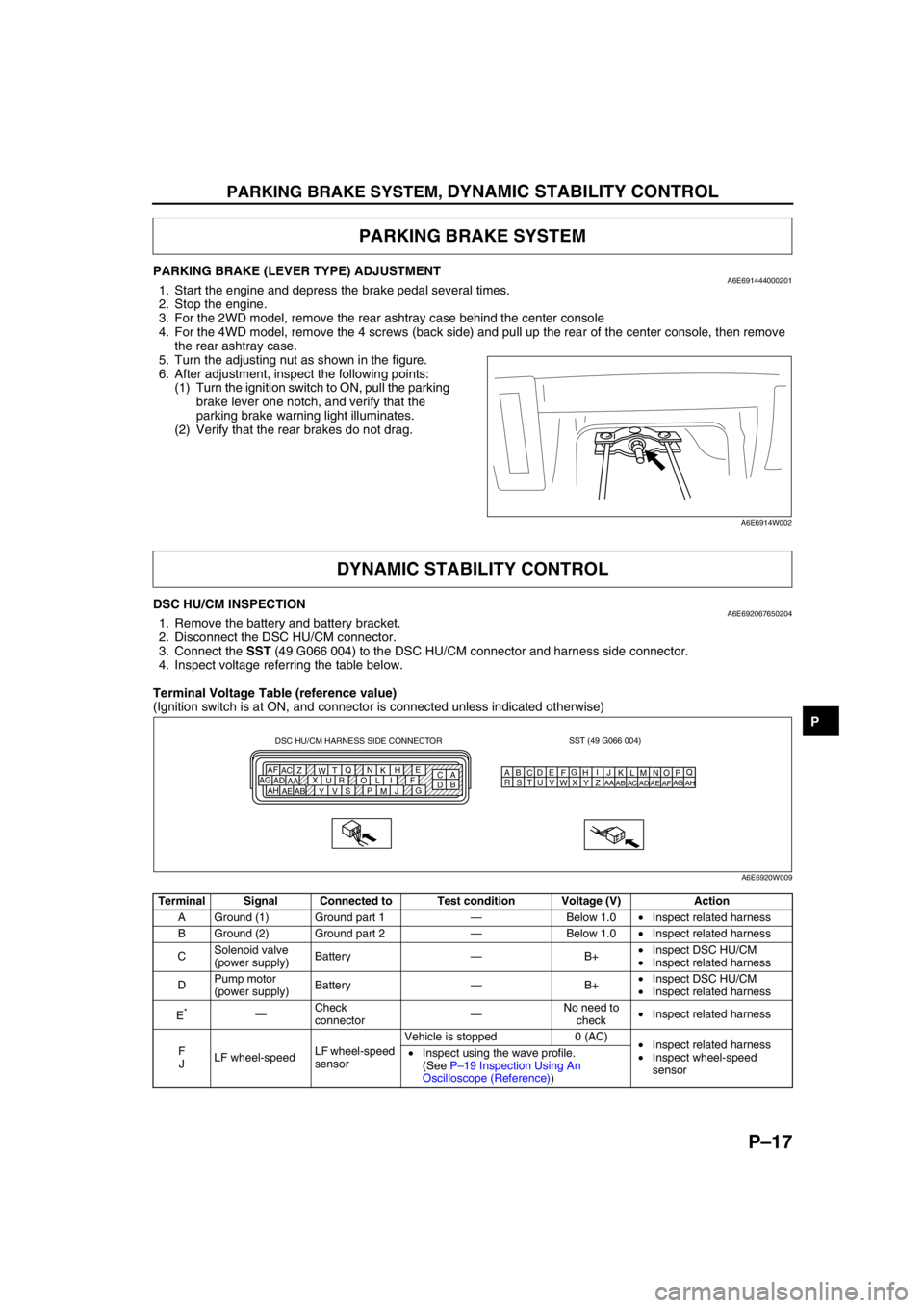

Page 750 of 909

PARKING BRAKE SYSTEM, DYNAMIC STABILITY CONTROL

P–17

P

PARKING BRAKE (LEVER TYPE) ADJUSTMENTA6E6914440002011. Start the engine and depress the brake pedal several times.

2. Stop the engine.

3. For the 2WD model, remove the rear ashtray case behind the center console

4. For the 4WD model, remove the 4 screws (back side) and pull up the rear of the center console, then remove

the rear ashtray case.

5. Turn the adjusting nut as shown in the figure.

6. After adjustment, inspect the following points:

(1) Turn the ignition switch to ON, pull the parking

brake lever one notch, and verify that the

parking brake warning light illuminates.

(2) Verify that the rear brakes do not drag.

End Of Sie

DSC HU/CM INSPECTIONA6E6920676502041. Remove the battery and battery bracket.

2. Disconnect the DSC HU/CM connector.

3. Connect the SST (49 G066 004) to the DSC HU/CM connector and harness side connector.

4. Inspect voltage referring the table below.

Terminal Voltage Table (reference value)

(Ignition switch is at ON, and connector is connected unless indicated otherwise)

PARKING BRAKE SYSTEM

A6E6914W002

DYNAMIC STABILITY CONTROL

Terminal Signal Connected to Test condition Voltage (V) Action

A Ground (1) Ground part 1—Below 1.0•Inspect related harness

B Ground (2) Ground part 2—Below 1.0•Inspect related harness

CSolenoid valve

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

DPump motor

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

E

*—Check

connector—No need to

check•Inspect related harness

F

JLF wheel-speedLF wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

A6E6920W009