engine MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 754 of 909

ON-BOARD DIAGNOSTIC

P–21

P

DSC ON-BOARD DIAGNOSISA6E697067650201DTC Table

Note

•There is no change except for the code marked with an asterisk *

ON-BOARD DIAGNOSTIC

DTC

Diagnosis system component

WDS or

equivalent

B1318 DSC power supply

B1342 DSC HU/CM

B1483 Stop switch signal (with DSC only)

B1484 Stop switch signal (with DSC only)

B1486 Stop switch signal (with DSC only)

B1627 Reverse signal (with DSC only)

B2477 Module configuration (with DSC only)

C1095 Motor relay, pump motor

C1096 Motor relay, pump motor

C1119* Engine control system

C1125 Brake fluid level sensor (with DSC only)

C1140 DSC HU (pump) (with DSC only)

C1145 Right front wheel-speed sensor

C1148 Right front wheel-speed sensor/sensor rotor

C1155 Left front wheel-speed sensor

C1158 Left front wheel-speed sensor/sensor rotor

C1165 Right rear wheel-speed sensor

C1168 Right rear wheel-speed sensor/sensor rotor

C1175 Left rear wheel-speed sensor

C1178 Left rear wheel-speed sensor/sensor rotor

C1186 Fail-safe relay

C1194 Left front pressure reduction solenoid valve

C1198 Left front pressure retention solenoid valve

C1210 Right front pressure reduction solenoid valve

C1214 Right front pressure retention solenoid valve

C1233 Left front wheel-speed sensor/sensor rotor

C1234 Right front wheel-speed sensor/sensor rotor

C1235 Right rear wheel-speed sensor/sensor rotor

C1236 Left rear wheel-speed sensor/sensor rotor

C1242 Left rear pressure reduction solenoid valve

C1246 Right rear pressure reduction solenoid valve

C1250 Left rear pressure retention solenoid valve

C1254 Right rear ABS pressure retention solenoid valve

C1266 Fail-safe relay

C1280 Combine sensor (with DSC only)

C1400 Right front traction switch solenoid valve (with DSC only)

C1410 Left front traction switch solenoid valve (with DSC only)

C1414 DSC HU/CM (with DSC only)

C1507 DSC control (with DSC only)

C1508 TCS control

C1510 Right front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1511 Left front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1512 Right rear solenoid valve, motor or wheel-speed sensor/sensor rotor

C1513 Left rear solenoid valve, motor or wheel-speed sensor/sensor rotor

Page 755 of 909

P–22

ON-BOARD DIAGNOSTIC

PID/DATA Monitor Table

Note

•There is no change except for the PID marked with an asterisk *

C1730 Combine sensor (with DSC only)

C1949* Combine sensor (with DSC only)

C1950* Combine sensor (with DSC only)

C1951 Combine sensor (with DSC only)

C1952 Combine sensor (with DSC only)

C1953 Brake fluid pressure sensor (with DSC only)

C1954 Brake fluid pressure sensor (with DSC only)

C1955 Steering angle sensor (with DSC only)

C1956 Steering angle sensor (with DSC only)

C1957 Right front DSC switch solenoid valve (with DSC only)

C1958 Left front DSC switch solenoid valve (with DSC only)

C1959 Combine sensor (with DSC only)

U1900 CAN communication

U2021 Invalid/fault data received

U2511* CAN communication

U2516 CAN communicationDTC

Diagnosis system component

WDS or

equivalent

PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

RPM

(Engine speed signal input)RPM•Engine is stopped: 0 RPM

•Engine is running: Indicates

engine speedInspect PCM.—

TRANSGR

*

(with DSC only)

(Transaxle gear position)FN4A-EL:

R/N/D/S/L

JA5AX-EL:

R/N/D•Selector lever position is

displayed

—R: R

—N: N

—D: D

—S: SInspect PCM, TR

switch, or DSC HU/

CM.

—

TRAC_SW

(TCS OFF switch input)ON/OFF•TCS (DSC) OFF switch is

depressed: ON

•TCS (DSC) OFF switch is

released: OFFInspect TCS (DSC)

OFF switch.

AA

TC LVAL (with DSC only)

(Traction switch solenoid valve

(LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

TC RVAL (with DSC only)

(Traction switch solenoid valve

(RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

L_DSC O (with DSC only)

(Stability control solenoid

valve (LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

R_DSC O (with DSC only)

(Stability control solenoid

valve (RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

CCNTABS

(Number of continuous codes)—DTC is detected: 1—255

DTC is not detected: 0Perform inspection

using appropriate

DTC.—

Page 759 of 909

P–26

ON-BOARD DIAGNOSTIC

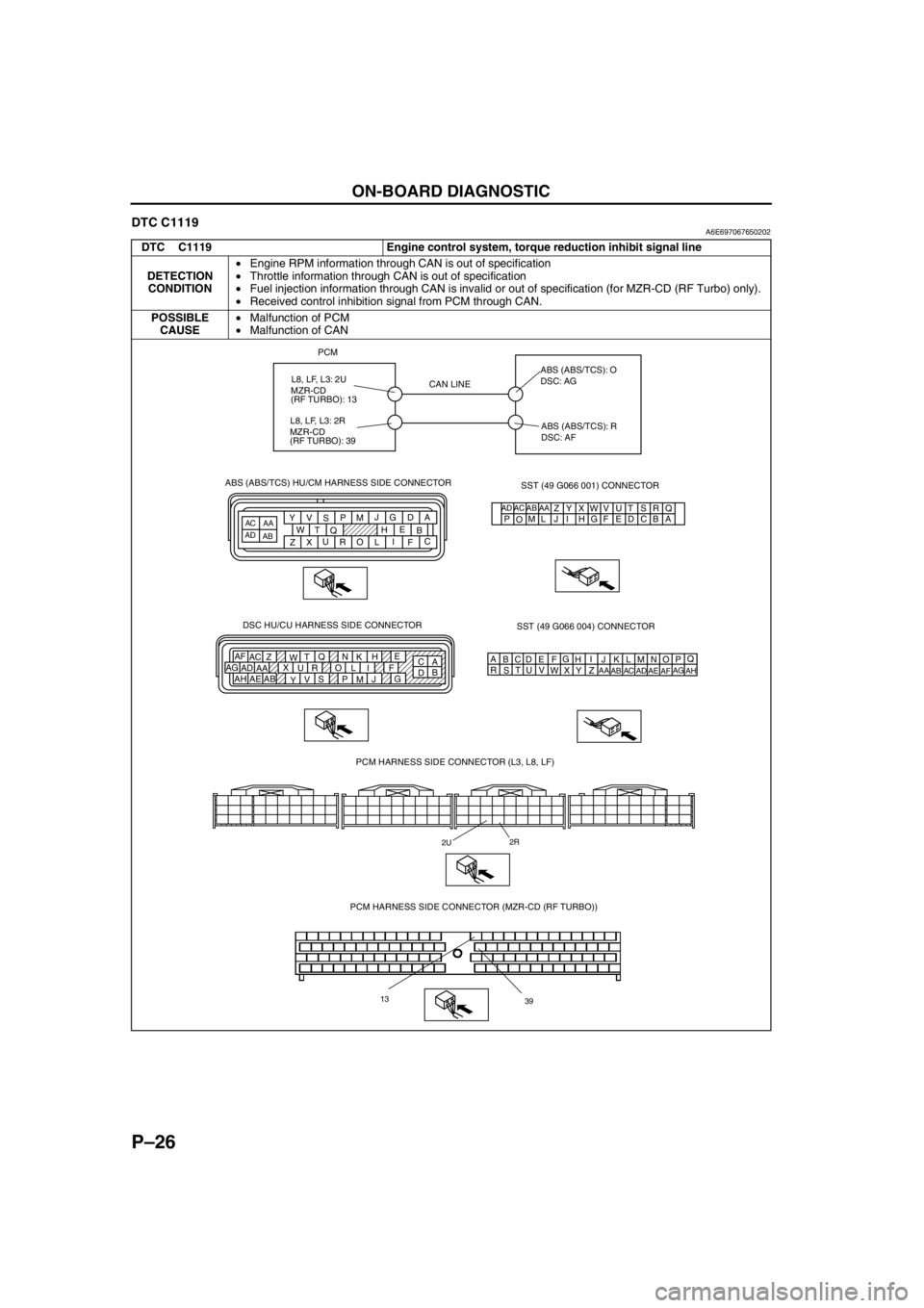

DTC C1119A6E697067650202

DTC C1119 Engine control system, torque reduction inhibit signal line

DETECTION

CONDITION•Engine RPM information through CAN is out of specification

•Throttle information through CAN is out of specification

•Fuel injection information through CAN is invalid or out of specification (for MZR-CD (RF Turbo) only).

•Received control inhibition signal from PCM through CAN.

POSSIBLE

CAUSE•Malfunction of PCM

•Malfunction of CAN

PCM

PCM HARNESS SIDE CONNECTOR (L3, L8, LF)

2U2R

CAN LINEABS (ABS/TCS): O

DSC: AG

ABS (ABS/TCS): R

DSC: AF

AQ

B

CDE

FG

HI

J DSC HU/CU HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB

AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

SST (49 G066 001) CONNECTOR

AD AC AB AAA Q

B R

C S

D T

E U

F V

G W

H X

I Y

J L M

O PZ ABS (ABS/TCS) HU/CM HARNESS SIDE CONNECTOR

ADAC

ABAA

A

B

C D

E

F G

H

I J

L M

O P

Q

R S

T

U V

W

X Y

Z

SST (49 G066 004) CONNECTOR

PCM HARNESS SIDE CONNECTOR (MZR-CD (RF TURBO))

13

39

L8, LF, L3: 2U

MZR-CD

(RF TURBO): 13

L8, LF, L3: 2R

MZR-CD

(RF TURBO): 39

Page 760 of 909

ON-BOARD DIAGNOSTIC

P–27

P

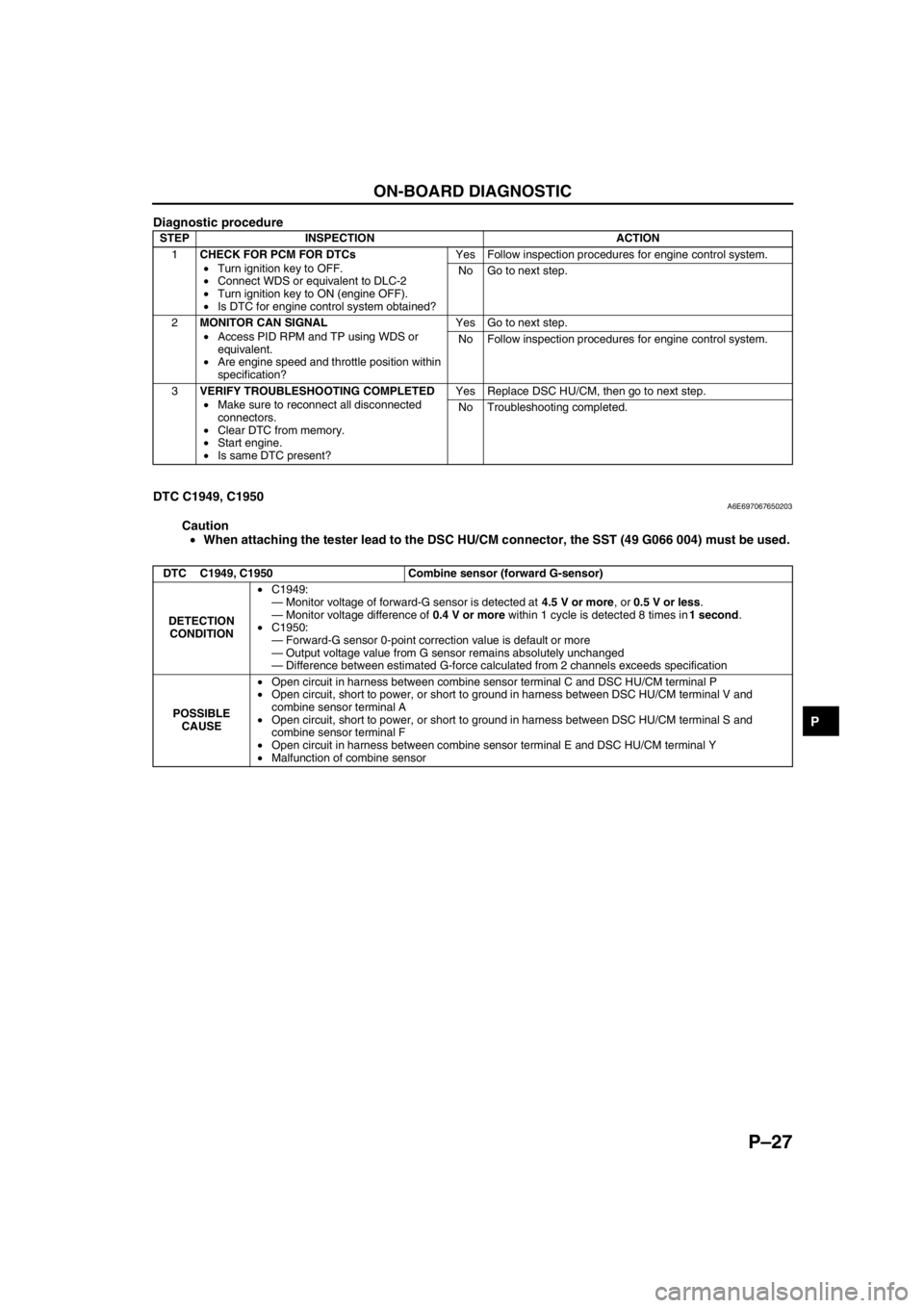

Diagnostic procedure

End Of Sie

DTC C1949, C1950A6E697067650203

Caution

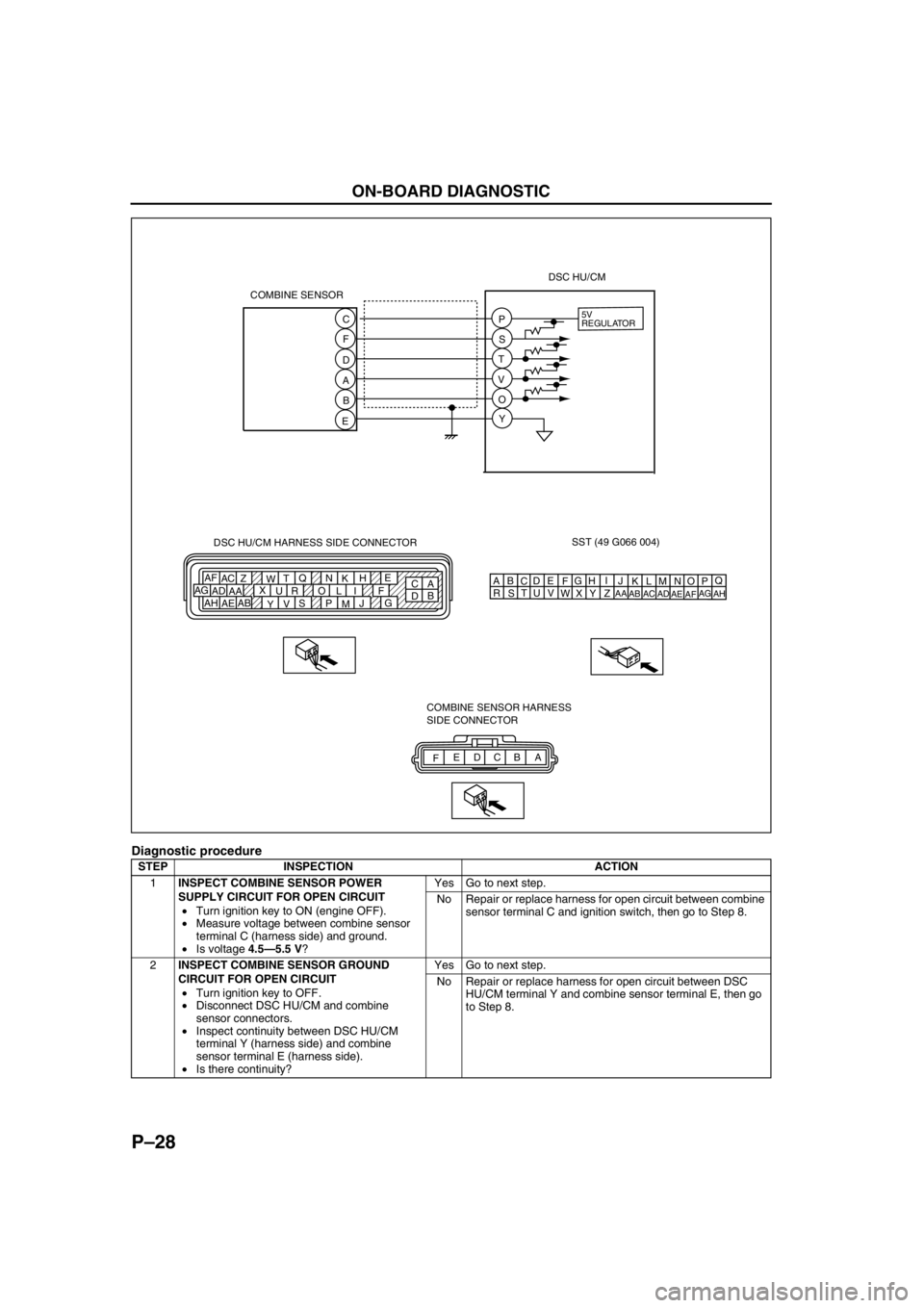

•When attaching the tester lead to the DSC HU/CM connector, the SST (49 G066 004) must be used.

STEP INSPECTION ACTION

1CHECK FOR PCM FOR DTCs

•Turn ignition key to OFF.

•Connect WDS or equivalent to DLC-2

•Turn ignition key to ON (engine OFF).

•Is DTC for engine control system obtained?Yes Follow inspection procedures for engine control system.

No Go to next step.

2MONITOR CAN SIGNAL

•Access PID RPM and TP using WDS or

equivalent.

•Are engine speed and throttle position within

specification?Yes Go to next step.

No Follow inspection procedures for engine control system.

3VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

•Start engine.

•Is same DTC present?Yes Replace DSC HU/CM, then go to next step.

No Troubleshooting completed.

DTC C1949, C1950 Combine sensor (forward G-sensor)

DETECTION

CONDITION•C1949:

—Monitor voltage of forward-G sensor is detected at 4.5 V or more, or 0.5 V or less.

—Monitor voltage difference of 0.4 V or more within 1 cycle is detected 8 times in 1 second.

•C1950:

—Forward-G sensor 0-point correction value is default or more

—Output voltage value from G sensor remains absolutely unchanged

—Difference between estimated G-force calculated from 2 channels exceeds specification

POSSIBLE

CAUSE•Open circuit in harness between combine sensor terminal C and DSC HU/CM terminal P

•Open circuit, short to power, or short to ground in harness between DSC HU/CM terminal V and

combine sensor terminal A

•Open circuit, short to power, or short to ground in harness between DSC HU/CM terminal S and

combine sensor terminal F

•Open circuit in harness between combine sensor terminal E and DSC HU/CM terminal Y

•Malfunction of combine sensor

Page 761 of 909

P–28

ON-BOARD DIAGNOSTIC

Diagnostic procedure

STEP INSPECTION ACTION

1INSPECT COMBINE SENSOR POWER

SUPPLY CIRCUIT FOR OPEN CIRCUIT

•Turn ignition key to ON (engine OFF).

•Measure voltage between combine sensor

terminal C (harness side) and ground.

•Is voltage 4.5—5.5 V?Yes Go to next step.

No Repair or replace harness for open circuit between combine

sensor terminal C and ignition switch, then go to Step 8.

2INSPECT COMBINE SENSOR GROUND

CIRCUIT FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Disconnect DSC HU/CM and combine

sensor connectors.

•Inspect continuity between DSC HU/CM

terminal Y (harness side) and combine

sensor terminal E (harness side).

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between DSC

HU/CM terminal Y and combine sensor terminal E, then go

to Step 8.

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB

AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH 5V

REGULATOR

COMBINE SENSOR

FA B C D E COMBINE SENSOR HARNESS

SIDE CONNECTOR C

F

D

A

B

EP

S

T

V

O

YDSC HU/CM

Page 765 of 909

OUTLINE

R–3

R

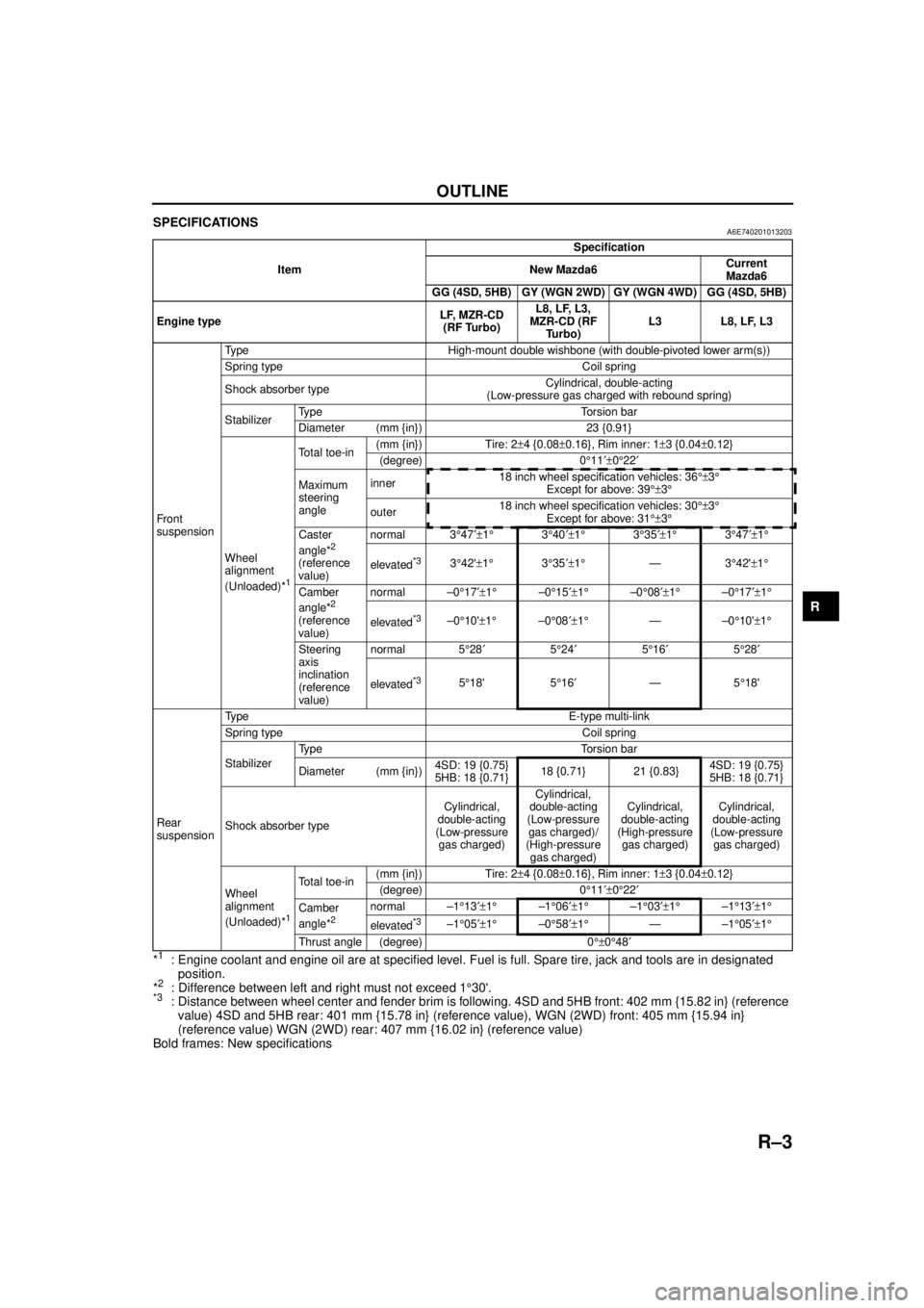

SPECIFICATIONSA6E740201013203

*1: Engine coolant and engine oil are at specified level. Fuel is full. Spare tire, jack and tools are in designated position.

*

2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is following. 4SD and 5HB front: 402 mm {15.82 in} (reference

value) 4SD and 5HB rear: 401 mm {15.78 in} (reference value), WGN (2WD) front: 405 mm {15.94 in}

(reference value) WGN (2WD) rear: 407 mm {16.02 in} (reference value)

Bold frames: New specifications

End Of Sie

Item Specification

New Mazda6 Current

Mazda6

GG (4SD, 5HB) GY (WGN 2WD) GY (WGN 4WD) GG (4SD, 5HB)

Engine type LF, MZR-CD

(RF Turbo) L8, LF, L3,

MZR-CD (RF Turbo) L3 L8, LF, L3

Fr o nt

suspension Type High-mount double wishbone (with double-pivoted lower arm(s))

Spring type Coil spring

Shock absorber type

Cylindrical, double-acting

(Low-pressure gas charged with rebound spring)

Stabilizer Type Torsion bar

Diameter (mm {in}) 23 {0.91}

Wheel

alignment

(Unloaded)*

1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Maximum

steering

angle inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Caster

angle*

2

(reference

value) normal 3

°47 ′±1° 3°40 ′±1° 3°35 ′±1° 3°47 ′±1°

elevated*33 °42' ±1° 3°35 ′±1° —3 °42' ±1 °

Camber

angle*

2

(reference

value) normal –0

°17 ′±1° –0°15 ′±1° –0°08 ′±1° –0°17 ′±1°

elevated*3–0 °10' ±1° –0°08 ′±1° —–0 °10' ±1°

Steering

axis

inclination

(reference

value) normal 5

°28 ′ 5°24 ′ 5°16 ′ 5°28 ′

elevated

*35 °18' 5 °16 ′ —5 °18'

Rear

suspension Type E-type multi-link

Spring type Coil spring

Stabilizer

Type Torsion bar

Diameter (mm {in})

4SD: 19 {0.75}

5HB: 18 {0.71}18 {0.71} 21 {0.83}

4SD: 19 {0.75}

5HB: 18 {0.71}

Shock absorber type Cylindrical,

double-acting

(Low-pressure gas charged) Cylindrical,

double-acting

(Low-pressure gas charged)/

(High-pressure

gas charged) Cylindrical,

double-acting

(High-pressure gas charged) Cylindrical,

double-acting

(Low-pressure gas charged)

Wheel

alignment

(Unloaded)*

1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Camber

angle*

2

normal –1 °13 ′±1° –1°06 ′±1° –1°03 ′±1° –1°13 ′±1°

elevated

*3–1 °05 ′±1° –0°58 ′±1° —–1 °05 ′±1°

Thrust angle (degree) 0 °±0°48 ′

Page 767 of 909

REAR SUSPENSION

R–5

R

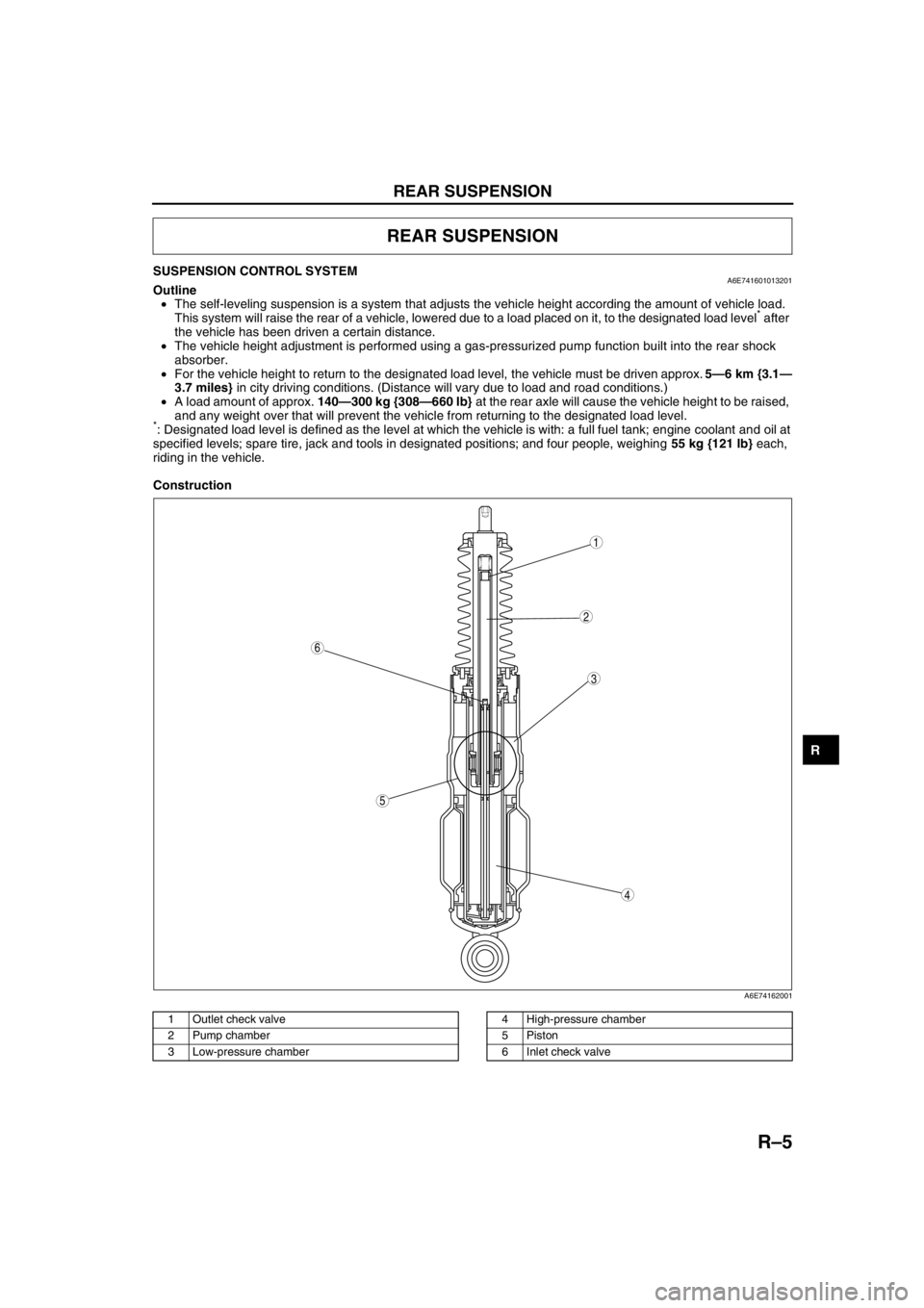

SUSPENSION CONTROL SYSTEMA6E741601013201Outline

•The self-leveling suspension is a system that adjusts the vehicle height according the amount of vehicle load.

This system will raise the rear of a vehicle, lowered due to a load placed on it, to the designated load level

* after

the vehicle has been driven a certain distance.

•The vehicle height adjustment is performed using a gas-pressurized pump function built into the rear shock

absorber.

•For the vehicle height to return to the designated load level, the vehicle must be driven approx. 5—6 km {3.1—

3.7 miles} in city driving conditions. (Distance will vary due to load and road conditions.)

•A load amount of approx. 140—300 kg {308—660 lb} at the rear axle will cause the vehicle height to be raised,

and any weight over that will prevent the vehicle from returning to the designated load level.

*: Designated load level is defined as the level at which the vehicle is with: a full fuel tank; engine coolant and oil at

specified levels; spare tire, jack and tools in designated positions; and four people, weighing 55 kg {121 lb} each,

riding in the vehicle.

Construction

.

REAR SUSPENSION

5

4

3

6

1

2

A6E74162001

1 Outlet check valve

2 Pump chamber

3 Low-pressure chamber4 High-pressure chamber

5Piston

6 Inlet check valve

Page 770 of 909

R–8

WHEEL ALIGNMENT

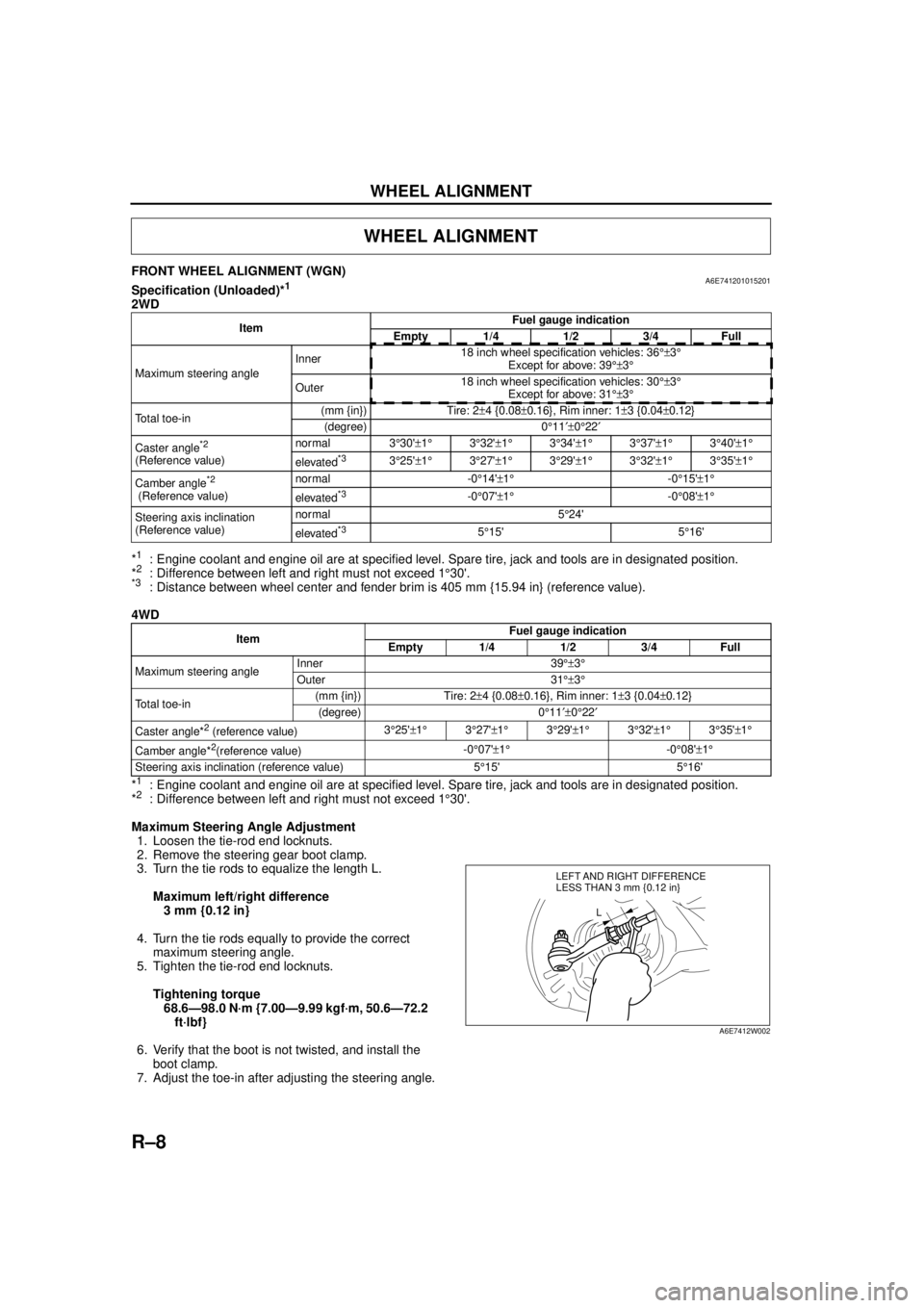

FRONT WHEEL ALIGNMENT (WGN)A6E741201015201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is 405 mm {15.94 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.

Maximum Steering Angle Adjustment 1. Loosen the tie-rod end locknuts.

2. Remove the steering gear boot clamp.

3. Turn the tie rods to equalize the length L.

Maximum left/right difference3 mm {0.12 in}

4. Turn the tie rods equally to provide the correct maximum steering angle.

5. Tighten the tie-rod end locknuts.

Tightening torque68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

6. Verify that the boot is not twisted, and install the boot clamp.

7. Adjust the toe-in after adjusting the steering angle.

WHEEL ALIGNMENT

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1° 3°37' ±1° 3°40' ±1 °

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1° 3°32' ±1° 3°35' ±1 °

Camber angle

*2

(Reference value) normal -0

°14' ±1 ° -0°15' ±1°

elevated*3-0 °07' ±1 ° -0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle*

2 (reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1 °

Camber angle*

2(reference value) -0

°07' ±1 ° -0°08' ±1°

Steering axis inclination (reference value) 5 °15' 5 °16'

LEFT AND RIGHT DIFFERENCE

L

LESS THAN 3 mm {0.12 in}

A6E7412W002

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

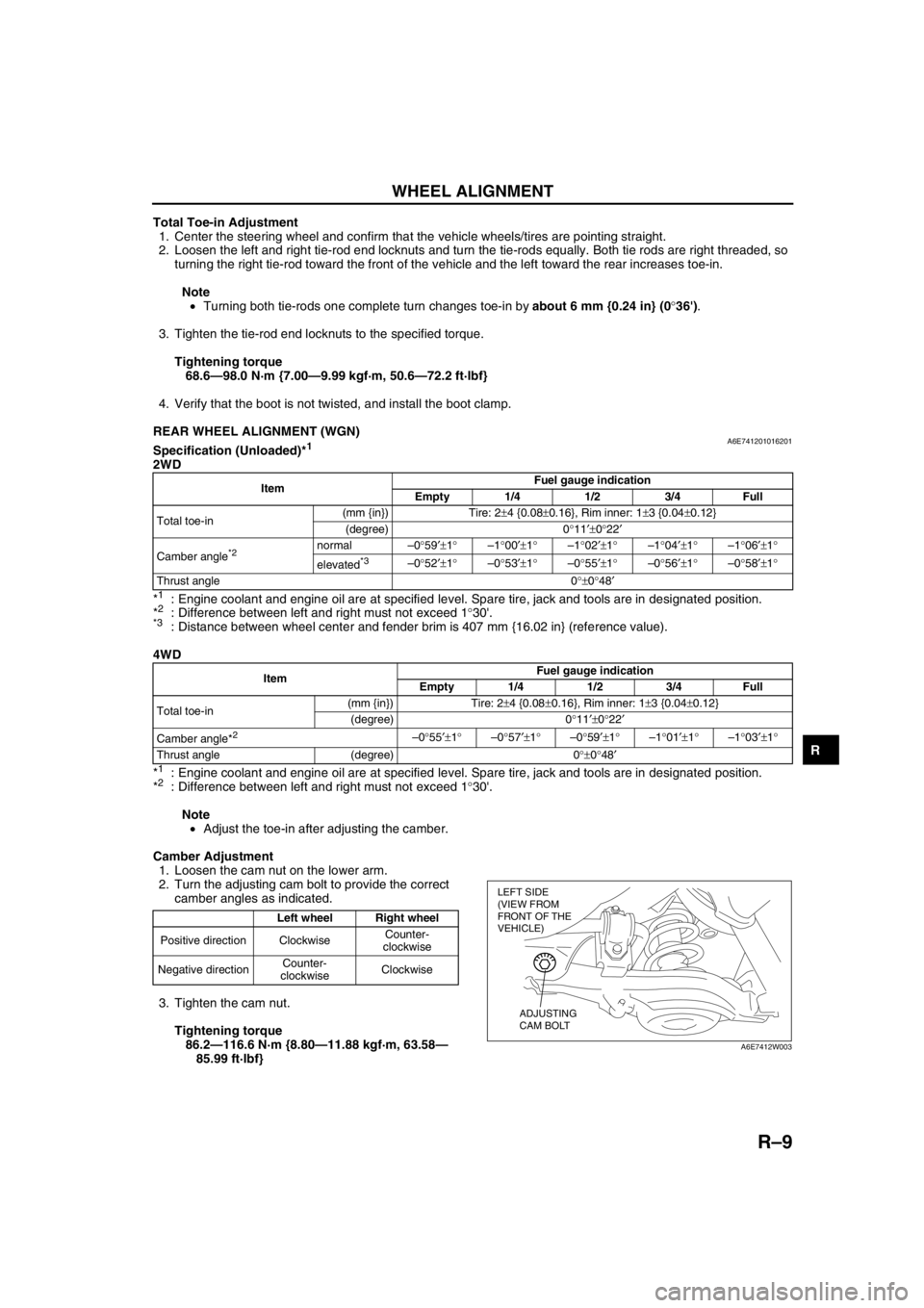

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster