engine coolant MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 490 of 909

AUTOMATIC TRANSAXLE

K2–75

K2

Time Lag Test

1. Perform mechanical system test preparation. (See K2–72 Mechanical System Test Preparation.)

2. Start the engine.

3. Warm up the engine until the ATF temperature reaches 60—70°C {140—158°F}. Shift the selector lever from N

position to D range.

4. Use a stopwatch to measure the time it takes from shifting until engagement is felt. Take three measurements

for each test and average the results using the following formula.

Formula

Average time lag = (Time 1 + Time 2 + Time 3) / 3

5. Perform the test for the following shifts in the same manner.

•N position → P position

Time lag

N → D range ... approx. 0.5—1.0 second

N → R position ... approx. 0.6— 1.0 second

Evaluation of time lag test

End Of SieROAD TESTA6E571401030210Road Test Preparation

1. Inspect the engine coolant. (See Section E.)

2. Inspect the engine oil. (See D–8 ENGINE OIL INSPECTION.)

3. Inspect the ATF levels. (See K2–78 AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION.)

4. Inspect the idle speed and ignition timing in P position. (See F1–22 IDLE SPEED INSPECTION (4WD).)

5. Bring up the engine and transaxle to normal operating temperature.

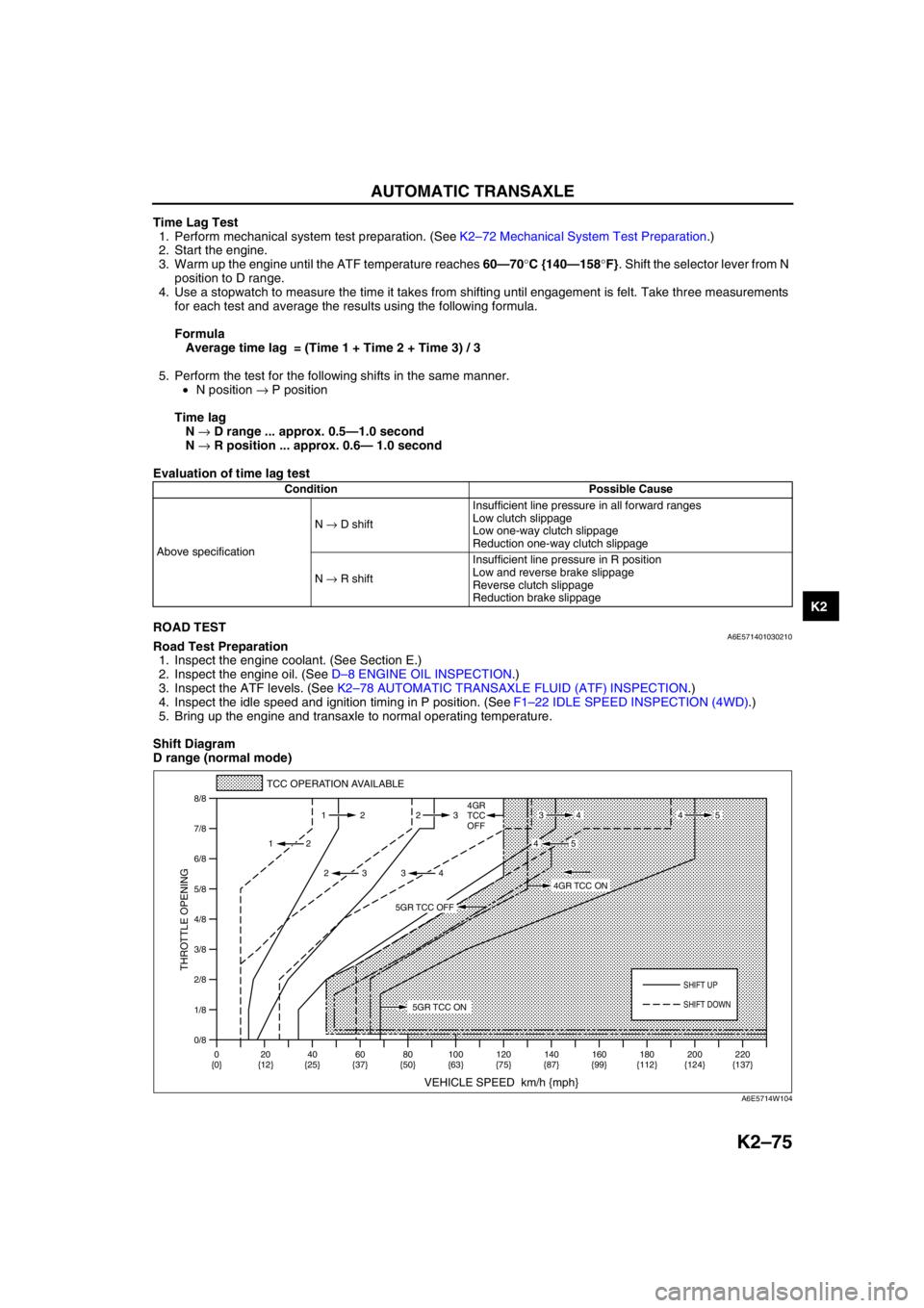

Shift Diagram

D range (normal mode)

Condition Possible Cause

Above specificationN → D shiftInsufficient line pressure in all forward ranges

Low clutch slippage

Low one-way clutch slippage

Reduction one-way clutch slippage

N → R shiftInsufficient line pressure in R position

Low and reverse brake slippage

Reverse clutch slippage

Reduction brake slippage

0/8 1/8

2/8

3/8

4/8

5/8

6/8

7/8

8/8

TCC OPERATION AVAILABLE

VEHICLE SPEED km/h {mph}

THROTTLE OPENING

SHIFT UP

4GR

TCC

OFF

SHIFT DOWN

0

{0}20

{12}40

{25}60

{37}80

{50}100

{63}120

{75}140

{87}160

{99}180

{112}220

{137} 200

{124} 112 23

2

2 232

34

4534

45

5GR TCC ON

4GR TCC ON

5GR TCC OFF

A6E5714W104

Page 527 of 909

K2–112

AUTOMATIC TRANSAXLE

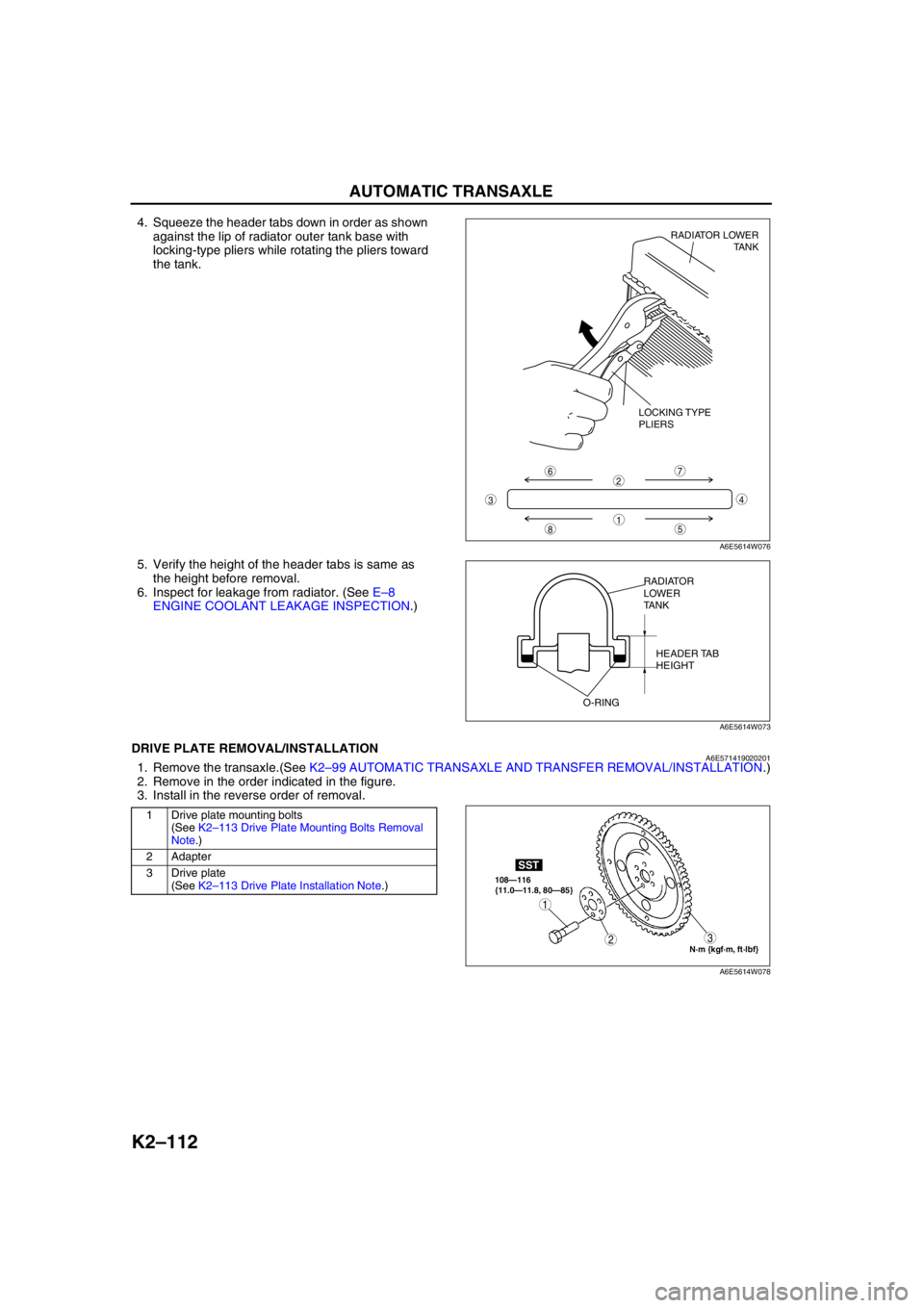

4. Squeeze the header tabs down in order as shown

against the lip of radiator outer tank base with

locking-type pliers while rotating the pliers toward

the tank.

5. Verify the height of the header tabs is same as

the height before removal.

6. Inspect for leakage from radiator. (See E–8

ENGINE COOLANT LEAKAGE INSPECTION.)

End Of SieDRIVE PLATE REMOVAL/INSTALLATIONA6E5714190202011. Remove the transaxle.(See K2–99 AUTOMATIC TRANSAXLE AND TRANSFER REMOVAL/INSTALLATION.)

2. Remove in the order indicated in the figure.

3. Install in the reverse order of removal.

.

8

7

5

43

6

1

2

LOCKING TYPE

PLIERSRADIATOR LOWER

TANK

A6E5614W076

RADIATOR

LOWER

TANK

HEADER TAB

HEIGHT

O-RING

A6E5614W073

1 Drive plate mounting bolts

(See K2–113 Drive Plate Mounting Bolts Removal

Note.)

2 Adapter

3 Drive plate

(See K2–113 Drive Plate Installation Note.)

N·m {kgf·m, ft·lbf} 108—116

{11.0—11.8, 80—85}

SST

3

1

2

A6E5614W078

Page 614 of 909

TROUBLESHOOTING

K2–199

K2

End Of SieNO.23 TRANSAXLE OVERHEATSA6E578001030226

Diagnostic procedure

End Of SieNO.24 ENGINE STALLS WHEN SHIFTED TO D RANGE, OR IN R POSITIONA6E578001030227

2•Do following symptoms concurrently occur?

—Engine flares up or slips during

acceleration

—Engine flares up or slips when shiftingYes Go to symptom troubleshooting No.14 “Engine flares up or

slips when upshifting or downshifting” or No.15 “Engine

flares up or slips when accelerating vehicle”.

No Go to next step.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM. STEP INSPECTION ACTION

23 Transaxle Overheat

DESCRIPTION•Burnt smell emitted from transaxle.

•Smoke emitted from transaxle.

POSSIBLE

CAUSE•Malfunction is restricted to hindrance of coolant at oil cooler. In addition, overheating of transaxle may

be caused by a malfunction of TFT sensor.

—Line pressure low

•ATF level low

•Incorrect throttle position signal

•Misadjustment of throttle cable

—Oil cooler malfunction (Foreign material mixed in with ATF)

—TFT sensor malfunction

—Excessive amount of ATF

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Is line pressure okay?

(See K2–72 Line Pressure Test.)Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Is stall speed okay?

(See K2–74 Stall Speed Test.)Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

3•Inspect TFT sensor and related harness:

vibration, intermittent open/short circuit

•Is it okay?Yes Go to next step.

No Repair or replace part if necessary.

4•Inspect pressure control solenoid circuit.

•Is it okay?Yes Go to next step.

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

5•Inspect for bend, damage, corrosion or kinks

of oil cooler pipes.

•Are oil cooler pipes okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace any defective parts.

6•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

24 Engine stalls when shifted to D range, or in R position

DESCRIPTION•Engine stalls when shifting from N or P position to D range or R position at idle.

POSSIBLE

CAUSE•Malfunction is on the engine control side (e.g. IAC system). Otherwise, malfunction is in input/turbine

speed sensor (engine sometimes starts) or TCC piston circuit (engine always stalls).

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic and

Automatic Transaxle Basic Inspection are conducted.

Page 651 of 909

GENERAL PROCEDURES

M–21

M

PRECAUTION (FRONT AND REAR AXLE)A6E631001018201Wheel and Tire Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}

Brake Line Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid gets on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

2. If any brake line has been disconnected any time during the procedure, add brake fluid, bleed the brakes, and

inspect for leakage after the procedure has been completed.

Suspension Arm Removal/Installation

1. Tighten any part of the suspension that uses rubber bushings only after vehicle has been lowered and

unloaded.

Note

•Unloaded: Fuel tank is full. Engine coolant and engine oil are at specified level. Spare tire, jack, and tools

are in designated position.

Connector Disconnection

1. Disconnect the negative (-) battery cable before disconnecting connectors.

Electronic Control 4WD System Parts

1. After servicing the electronic control 4WD system parts, verify that no DTC has been stored. Clear any DTCs

remaining in the memory.

End Of Sie

GENERAL PROCEDURES

Page 765 of 909

OUTLINE

R–3

R

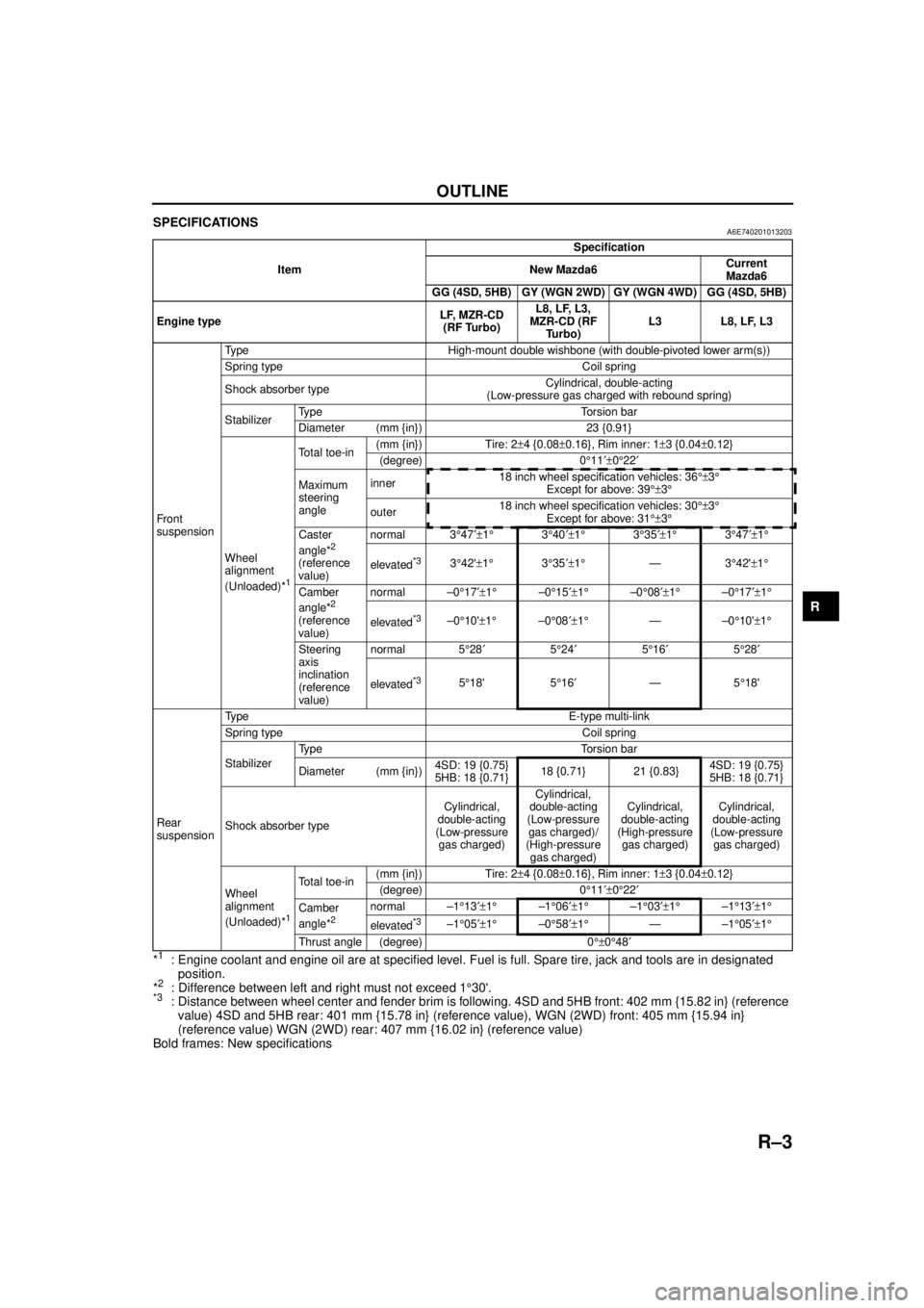

SPECIFICATIONSA6E740201013203

*1: Engine coolant and engine oil are at specified level. Fuel is full. Spare tire, jack and tools are in designated position.

*

2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is following. 4SD and 5HB front: 402 mm {15.82 in} (reference

value) 4SD and 5HB rear: 401 mm {15.78 in} (reference value), WGN (2WD) front: 405 mm {15.94 in}

(reference value) WGN (2WD) rear: 407 mm {16.02 in} (reference value)

Bold frames: New specifications

End Of Sie

Item Specification

New Mazda6 Current

Mazda6

GG (4SD, 5HB) GY (WGN 2WD) GY (WGN 4WD) GG (4SD, 5HB)

Engine type LF, MZR-CD

(RF Turbo) L8, LF, L3,

MZR-CD (RF Turbo) L3 L8, LF, L3

Fr o nt

suspension Type High-mount double wishbone (with double-pivoted lower arm(s))

Spring type Coil spring

Shock absorber type

Cylindrical, double-acting

(Low-pressure gas charged with rebound spring)

Stabilizer Type Torsion bar

Diameter (mm {in}) 23 {0.91}

Wheel

alignment

(Unloaded)*

1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Maximum

steering

angle inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Caster

angle*

2

(reference

value) normal 3

°47 ′±1° 3°40 ′±1° 3°35 ′±1° 3°47 ′±1°

elevated*33 °42' ±1° 3°35 ′±1° —3 °42' ±1 °

Camber

angle*

2

(reference

value) normal –0

°17 ′±1° –0°15 ′±1° –0°08 ′±1° –0°17 ′±1°

elevated*3–0 °10' ±1° –0°08 ′±1° —–0 °10' ±1°

Steering

axis

inclination

(reference

value) normal 5

°28 ′ 5°24 ′ 5°16 ′ 5°28 ′

elevated

*35 °18' 5 °16 ′ —5 °18'

Rear

suspension Type E-type multi-link

Spring type Coil spring

Stabilizer

Type Torsion bar

Diameter (mm {in})

4SD: 19 {0.75}

5HB: 18 {0.71}18 {0.71} 21 {0.83}

4SD: 19 {0.75}

5HB: 18 {0.71}

Shock absorber type Cylindrical,

double-acting

(Low-pressure gas charged) Cylindrical,

double-acting

(Low-pressure gas charged)/

(High-pressure

gas charged) Cylindrical,

double-acting

(High-pressure gas charged) Cylindrical,

double-acting

(Low-pressure gas charged)

Wheel

alignment

(Unloaded)*

1

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Camber

angle*

2

normal –1 °13 ′±1° –1°06 ′±1° –1°03 ′±1° –1°13 ′±1°

elevated

*3–1 °05 ′±1° –0°58 ′±1° —–1 °05 ′±1°

Thrust angle (degree) 0 °±0°48 ′

Page 767 of 909

REAR SUSPENSION

R–5

R

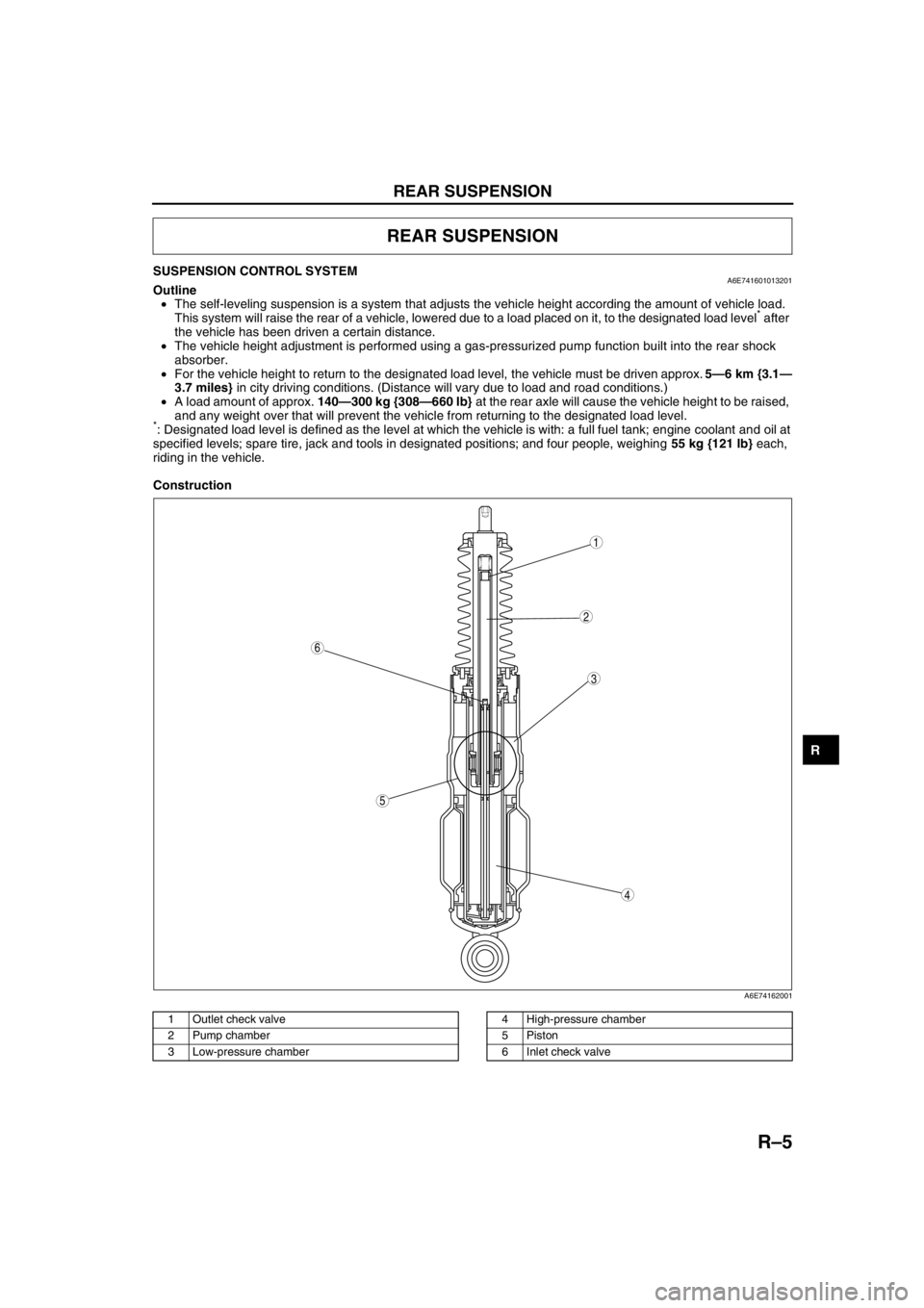

SUSPENSION CONTROL SYSTEMA6E741601013201Outline

•The self-leveling suspension is a system that adjusts the vehicle height according the amount of vehicle load.

This system will raise the rear of a vehicle, lowered due to a load placed on it, to the designated load level

* after

the vehicle has been driven a certain distance.

•The vehicle height adjustment is performed using a gas-pressurized pump function built into the rear shock

absorber.

•For the vehicle height to return to the designated load level, the vehicle must be driven approx. 5—6 km {3.1—

3.7 miles} in city driving conditions. (Distance will vary due to load and road conditions.)

•A load amount of approx. 140—300 kg {308—660 lb} at the rear axle will cause the vehicle height to be raised,

and any weight over that will prevent the vehicle from returning to the designated load level.

*: Designated load level is defined as the level at which the vehicle is with: a full fuel tank; engine coolant and oil at

specified levels; spare tire, jack and tools in designated positions; and four people, weighing 55 kg {121 lb} each,

riding in the vehicle.

Construction

.

REAR SUSPENSION

5

4

3

6

1

2

A6E74162001

1 Outlet check valve

2 Pump chamber

3 Low-pressure chamber4 High-pressure chamber

5Piston

6 Inlet check valve

Page 770 of 909

R–8

WHEEL ALIGNMENT

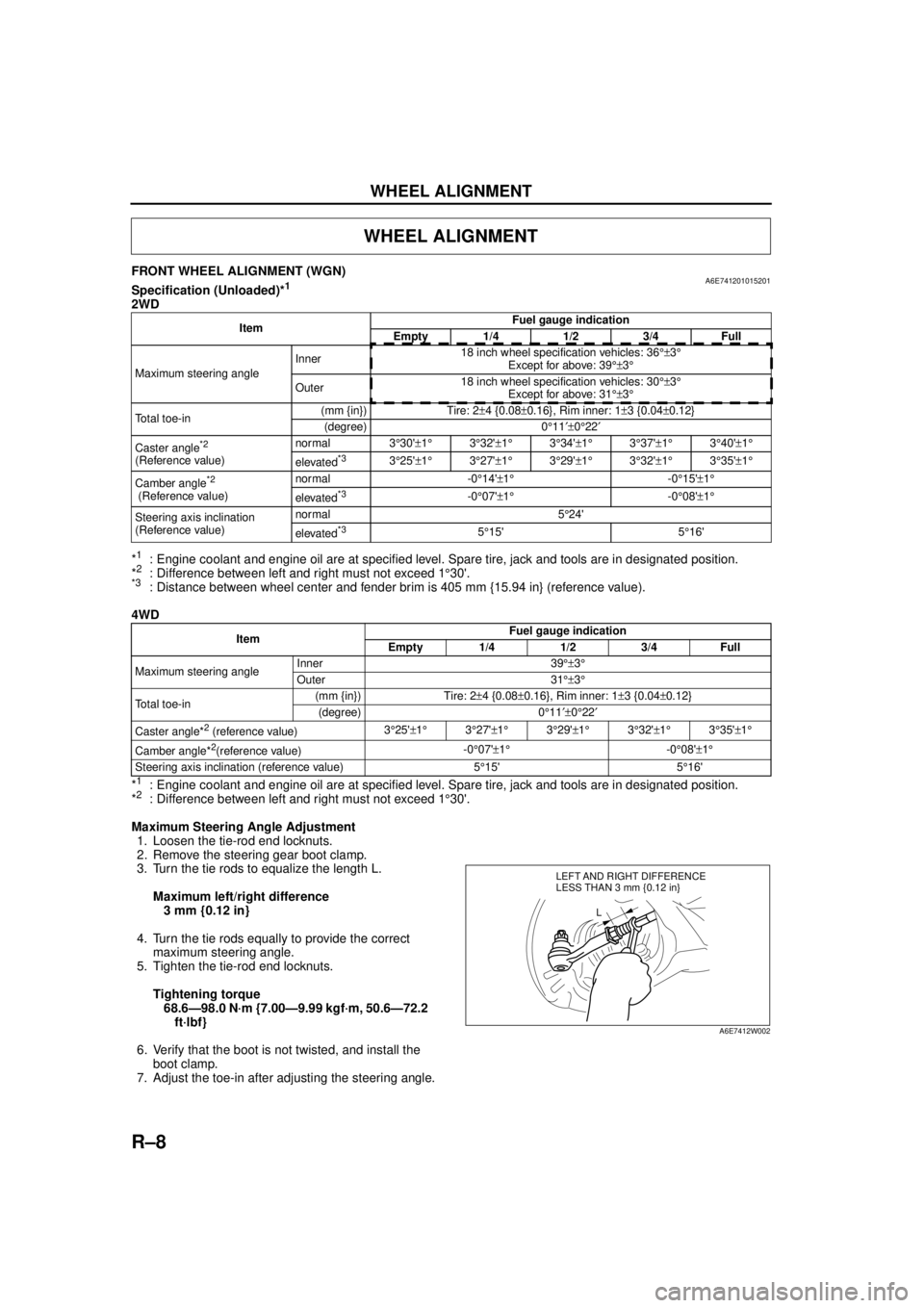

FRONT WHEEL ALIGNMENT (WGN)A6E741201015201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is 405 mm {15.94 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.

Maximum Steering Angle Adjustment 1. Loosen the tie-rod end locknuts.

2. Remove the steering gear boot clamp.

3. Turn the tie rods to equalize the length L.

Maximum left/right difference3 mm {0.12 in}

4. Turn the tie rods equally to provide the correct maximum steering angle.

5. Tighten the tie-rod end locknuts.

Tightening torque68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

6. Verify that the boot is not twisted, and install the boot clamp.

7. Adjust the toe-in after adjusting the steering angle.

WHEEL ALIGNMENT

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1° 3°37' ±1° 3°40' ±1 °

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1° 3°32' ±1° 3°35' ±1 °

Camber angle

*2

(Reference value) normal -0

°14' ±1 ° -0°15' ±1°

elevated*3-0 °07' ±1 ° -0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle*

2 (reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1 °

Camber angle*

2(reference value) -0

°07' ±1 ° -0°08' ±1°

Steering axis inclination (reference value) 5 °15' 5 °16'

LEFT AND RIGHT DIFFERENCE

L

LESS THAN 3 mm {0.12 in}

A6E7412W002

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

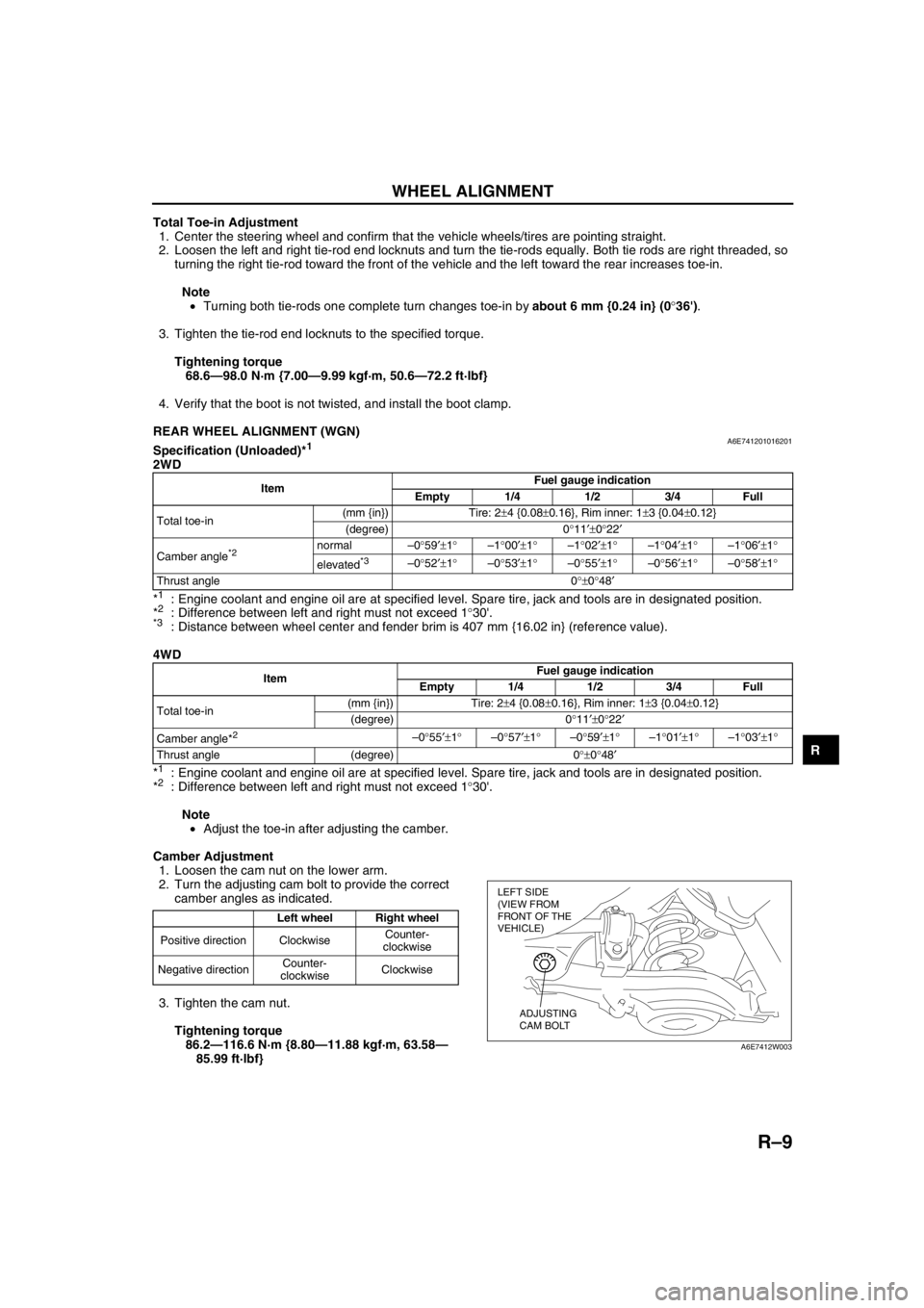

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 869 of 909

U–6

CONTROL SYSTEM

WATER HEATER SYSTEMA6E854000169201Outline

•The function, structure and operation of the water heater system is essentially carried over from that of the

current MPV (LW) model, except for following:

—Full/half switching temperature has been changed.

Structural View

.

Operation

Full/half switching

•Depending on the engine coolant temperature, the CPU sets the flame to either full or half strength settings.

.

End Of Sie

CONTROL SYSTEM

1

2

A6E85402002

1 Water heater unit2 Fuel pump (water heater system)

3

1

2

68

{154}74

{165}75

{167}78

{172}˚C

{˚F}

A6E85402003

1 Full mode

2 Half mode3 Idle mode

Page 873 of 909

U–10

BASIC SYSTEM

A/C UNIT REMOVAL/INSTALLATIONA6E8516611302011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Drain the engine coolant.

4. Remove the dashboard.

5. Remove the theft-deterrent control module.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug open fittings after removing any refrigeration

cycle parts to keep moisture or foreign material out of the cycle.

6. Remove in the order indicated in the table. Do not allow compressor oil to spill.

.

BASIC SYSTEM

1

L.H.D.R.H.D.

3

2

R

R

N·m {kgf·cm, in·lbf} 6.86—9.80

{70.0—99.9,

60.8—86.7}

R

R

3

2

1

4

A6E85162001

1 Heater hose

2 Cooler pipe No.4 (L.H.D.) or cooler pipe No.5

(R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION) (R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)3 Cooler pipe No.3

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION) (R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

4A/C unit

(See U–11 A/C Unit Installation Note)