key MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 696 of 909

M–66

ELECTRONIC 4WD CONTROL SYSTEM

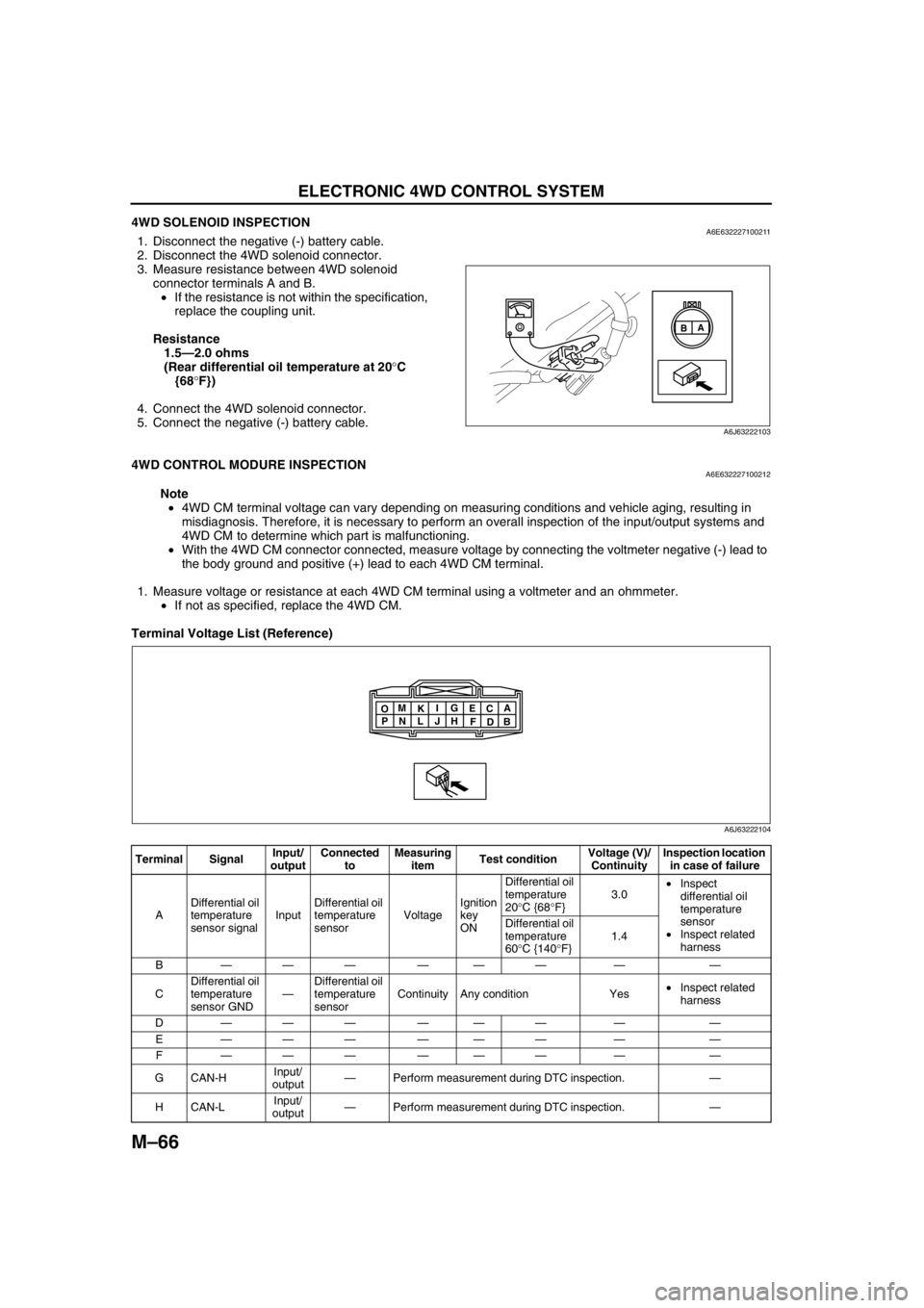

4WD SOLENOID INSPECTIONA6E6322271002111. Disconnect the negative (-) battery cable.

2. Disconnect the 4WD solenoid connector.

3. Measure resistance between 4WD solenoid

connector terminals A and B.

•If the resistance is not within the specification,

replace the coupling unit.

Resistance

1.5—2.0 ohms

(Rear differential oil temperature at 20°C

{68°F})

4. Connect the 4WD solenoid connector.

5. Connect the negative (-) battery cable.

End Of Sie

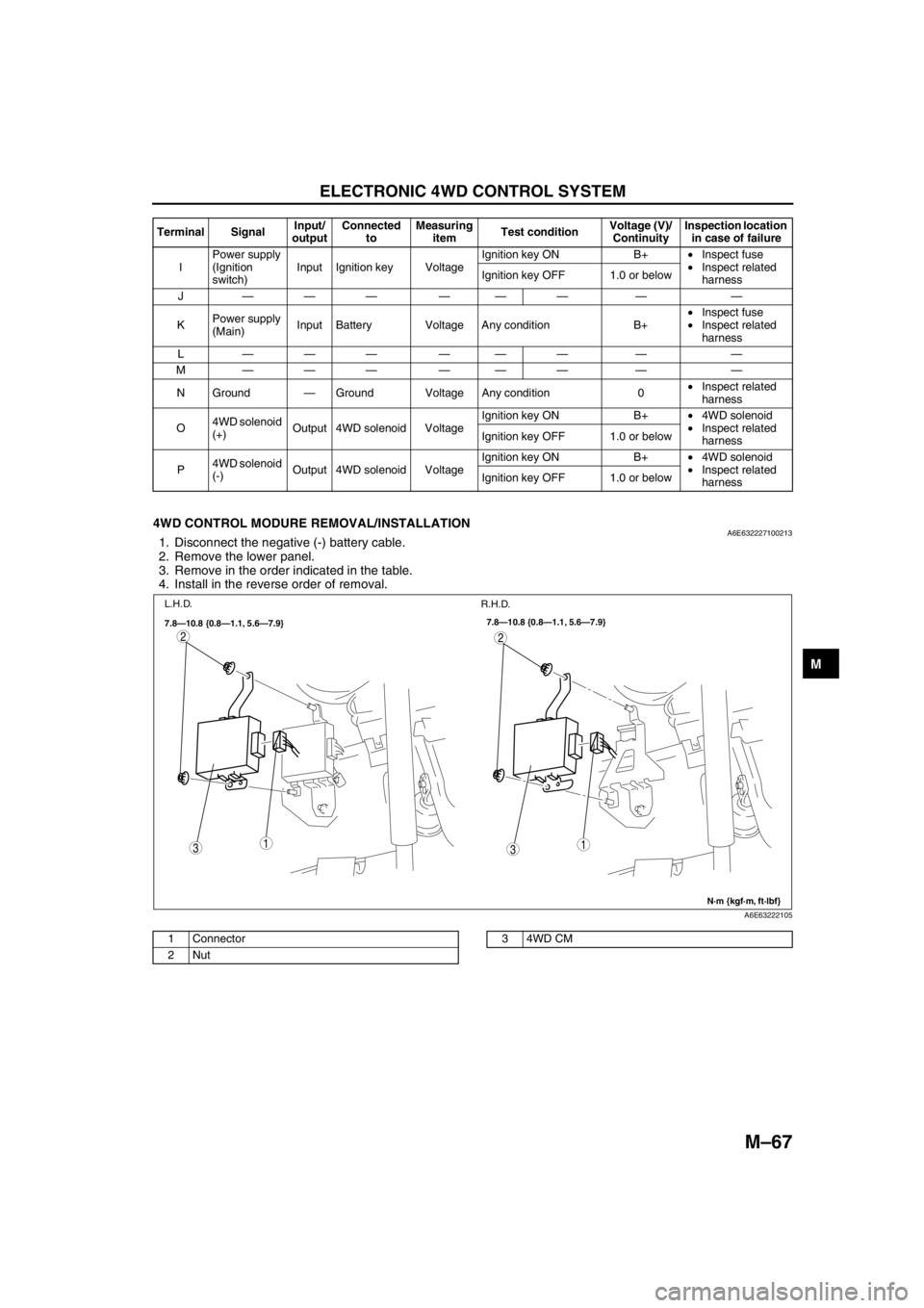

4WD CONTROL MODURE INSPECTIONA6E632227100212

Note

•4WD CM terminal voltage can vary depending on measuring conditions and vehicle aging, resulting in

misdiagnosis. Therefore, it is necessary to perform an overall inspection of the input/output systems and

4WD CM to determine which part is malfunctioning.

•With the 4WD CM connector connected, measure voltage by connecting the voltmeter negative (-) lead to

the body ground and positive (+) lead to each 4WD CM terminal.

1. Measure voltage or resistance at each 4WD CM terminal using a voltmeter and an ohmmeter.

•If not as specified, replace the 4WD CM.

Terminal Voltage List (Reference)

A

B

A6J63222103

Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

ADifferential oil

temperature

sensor signalInputDifferential oil

temperature

sensorVoltageIgnition

key

ONDifferential oil

temperature

20°C {68°F}3.0•Inspect

differential oil

temperature

sensor

•Inspect related

harness Differential oil

temperature

60°C {140°F}1.4

B——— ——— — —

CDifferential oil

temperature

sensor GND—Differential oil

temperature

sensorContinuity Any condition Yes•Inspect related

harness

D——— ——— — —

E——— ——— — —

F——— ——— — —

GCAN-HInput/

output—Perform measurement during DTC inspection.—

HCAN-LInput/

output—Perform measurement during DTC inspection.—

A

B C

D E

F G

H I

J K

L M

N O

P

A6J63222104

Page 697 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–67

M

End Of Sie

4WD CONTROL MODURE REMOVAL/INSTALLATIONA6E6322271002131. Disconnect the negative (-) battery cable.

2. Remove the lower panel.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

IPower supply

(Ignition

switch)Input Ignition key VoltageIgnition key ON B+•Inspect fuse

•Inspect related

harness Ignition key OFF 1.0 or below

J——— ——— — —

KPower supply

(Main)Input Battery Voltage Any condition B+•Inspect fuse

•Inspect related

harness

L——— ——— — —

M——— ——— — —

N Ground—Ground Voltage Any condition 0•Inspect related

harness

O4WD solenoid

(+)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below

P4WD solenoid

(-)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

31

2

31

2

7.8—10.8 {0.8—1.1, 5.6—7.9}

N·m {kgf·m, ft·lbf} 7.8—10.8 {0.8—1.1, 5.6—7.9}

L.H.D.

R.H.D.

A6E63222105

1 Connector

2Nut34WD CM

Page 706 of 909

M–76

ON-BOARD DIAGNOSTIC

ELECTRONIC 4WD CONTROL SYSTEM ON-BOARD DIAGNOSISA6E637027100202Reading DTCs Procedure

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Retrieve DTC by WDS or equivalent.

•If a DTC is displayed, proceed with inspection

steps for that DTC.

3. After repair, clear DTCs stored in the 4WD CM by

referring to the Clearing DTCs Procedure.

Clearing DTCs Procedures

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Clear DTCs by WDS or equivalent.

3. Turn the ignition key to OFF.

4. Perform the DTC inspection again, and verify that

no DTC appears.

5. Disconnect the WDS or equivalent.

DTC Table

End Of Sie

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DTC

Diagnosis system component Page

WDS or equivalent

P1887 System wiring (See M–77 DTC P1887)

P1888 Differential oil temperature sensor (See M–79 DTC P1888)

U0100 PCM communication (See M–80 DTC U0100)

U0101 TCM communication (See M–80 DTC U0101)

U0121 ABS/DSC communication (See M–80 DTC U0121)

Page 707 of 909

ON-BOARD DIAGNOSTIC

M–77

M

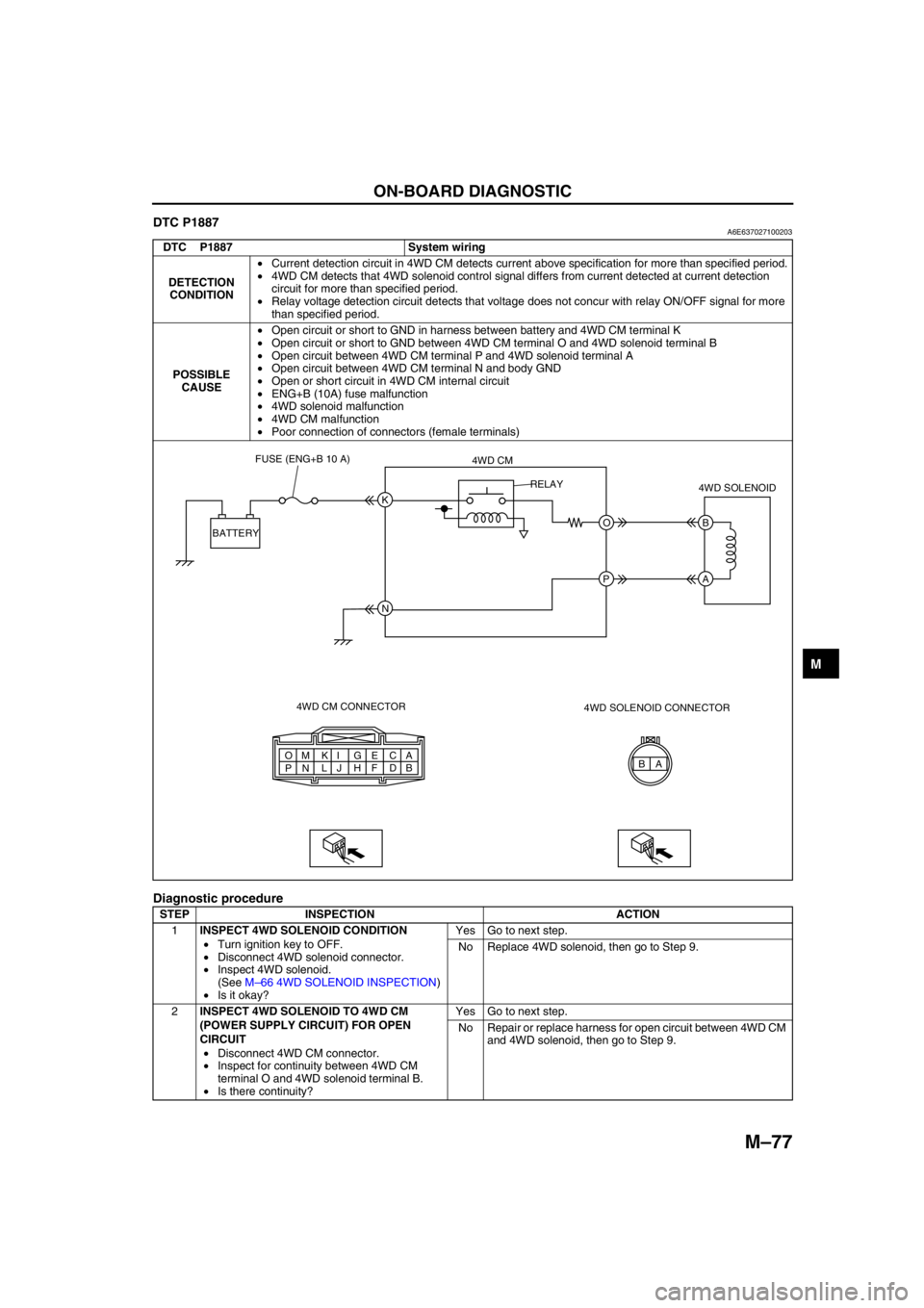

DTC P1887A6E637027100203

Diagnostic procedure

DTC P1887 System wiring

DETECTION

CONDITION•Current detection circuit in 4WD CM detects current above specification for more than specified period.

•4WD CM detects that 4WD solenoid control signal differs from current detected at current detection

circuit for more than specified period.

•Relay voltage detection circuit detects that voltage does not concur with relay ON/OFF signal for more

than specified period.

POSSIBLE

CAUSE•Open circuit or short to GND in harness between battery and 4WD CM terminal K

•Open circuit or short to GND between 4WD CM terminal O and 4WD solenoid terminal B

•Open circuit between 4WD CM terminal P and 4WD solenoid terminal A

•Open circuit between 4WD CM terminal N and body GND

•Open or short circuit in 4WD CM internal circuit

•ENG+B (10A) fuse malfunction

•4WD solenoid malfunction

•4WD CM malfunction

•Poor connection of connectors (female terminals)

STEP INSPECTION ACTION

1INSPECT 4WD SOLENOID CONDITION

•Turn ignition key to OFF.

•Disconnect 4WD solenoid connector.

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is it okay?Yes Go to next step.

No Replace 4WD solenoid, then go to Step 9.

2INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector.

•Inspect for continuity between 4WD CM

terminal O and 4WD solenoid terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

A A

B C

D E

F G

H I

J K

L M

N O

PB K

O B

A

N P BATTERYFUSE (ENG+B 10 A)

4WD CM

4WD CM CONNECTOR4WD SOLENOID

4WD SOLENOID CONNECTOR RELAY

Page 708 of 909

M–78

ON-BOARD DIAGNOSTIC

End Of Sie

3INSPECT 4WD SOLENOID TO 4WD CM

(POWER SUPPLY CIRCUIT) FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal O and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and 4WD solenoid, then go to Step 9.

No Go to next step.

4INSPECT 4WD SOLENOID TO 4WD CM

(GROUND CIRCUIT) FOR OPEN CIRCUIT

•Inspect for continuity between 4WD CM

terminal P and 4WD solenoid terminal A.

•Is there continuity?Yes Replace 4WD CM, then go to next step.

No Repair or replace harness for open circuit between 4WD CM

and 4WD solenoid, then go to Step 9.

5INSPECT 4WD CM POWER SUPPLY CIRCUIT

FOR OPEN CIRCUIT

•Measure voltage between 4WD CM terminal

K and ground.

•Is voltage B+?Yes Replace 4WD CM, then go to Step 9.

No Go to next step.

6INSPECT 4WD CM TO BATTERY FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector and battery

positive terminal.

•Inspect for continuity between 4WD CM

terminal K and battery positive terminal.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and battery positive terminal, then go to Step 9.

7INSPECT 4WD CM TO BATTERY FOR SHORT

TO GROUND

•Inspect for continuity between 4WD CM

terminal K and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and battery positive terminal, then go to Step 9.

No Replace 4WD CM, then go to step 9.

8INSPECT FUSE CONDITION

•Turn ignition key to OFF.

•Is ENG+B fuse (10A) okay?Yes Go to next step.

No Replace fuse, then go to Step 9.

9VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

10VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 709 of 909

ON-BOARD DIAGNOSTIC

M–79

M

DTC P1888A6E637027100204

Diagnostic procedure

DTC P1888 Differential oil temperature sensor

DETECTION

CONDITION•Differential oil temperature sensor voltage monitor circuit detects abnormal input voltage.

POSSIBLE

CAUSE•Open circuit, or short to battery or GND between 4WD CM terminal A and differential oil temperature

sensor terminal A

•Open circuit or short to battery between 4WD CM terminal C and differential oil temperature sensor

terminal B

•Differential oil temperature sensor malfunction

•4WD CM malfunction

•Poor connection of connectors (female terminals)

STEP INSPECTION ACTION

1INSPECT DIFFERENTIAL OIL

TEMPERATURE SENSOR CONDITION

•Turn ignition key to OFF.

•Disconnect differential oil temperature

sensor connector.

•Is it okay?Yes Go to next step.

No Replace differential oil temperature sensor, then go to Step

7.

2INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR OPEN

CIRCUIT

•Disconnect 4WD CM connector.

•Inspect for continuity between 4WD CM

terminal A and differential oil temperature

sensor terminal A.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and differential oil temperature sensor, then go to Step 7.

3INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

POWER

•Inspect voltage between 4WD CM terminal A

and ground.

•Is voltage B+?Yes Repair or replace harness for short to power between 4WD

CM and differential oil temperature sensor, then go to Step

7.

No Go to next step.

A B A

B C

D E

F G

H I

J K

L M

N O

PA

C A

B

4WD CM CONNECTOR4WD CM

DIFFERENTIAL OIL

TEMPERATURE SENSOR

DIFFERENTIAL OIL TEMPERATURE

SENSOR CONNECTOR

Page 713 of 909

TROUBLESHOOTING

M–83

M

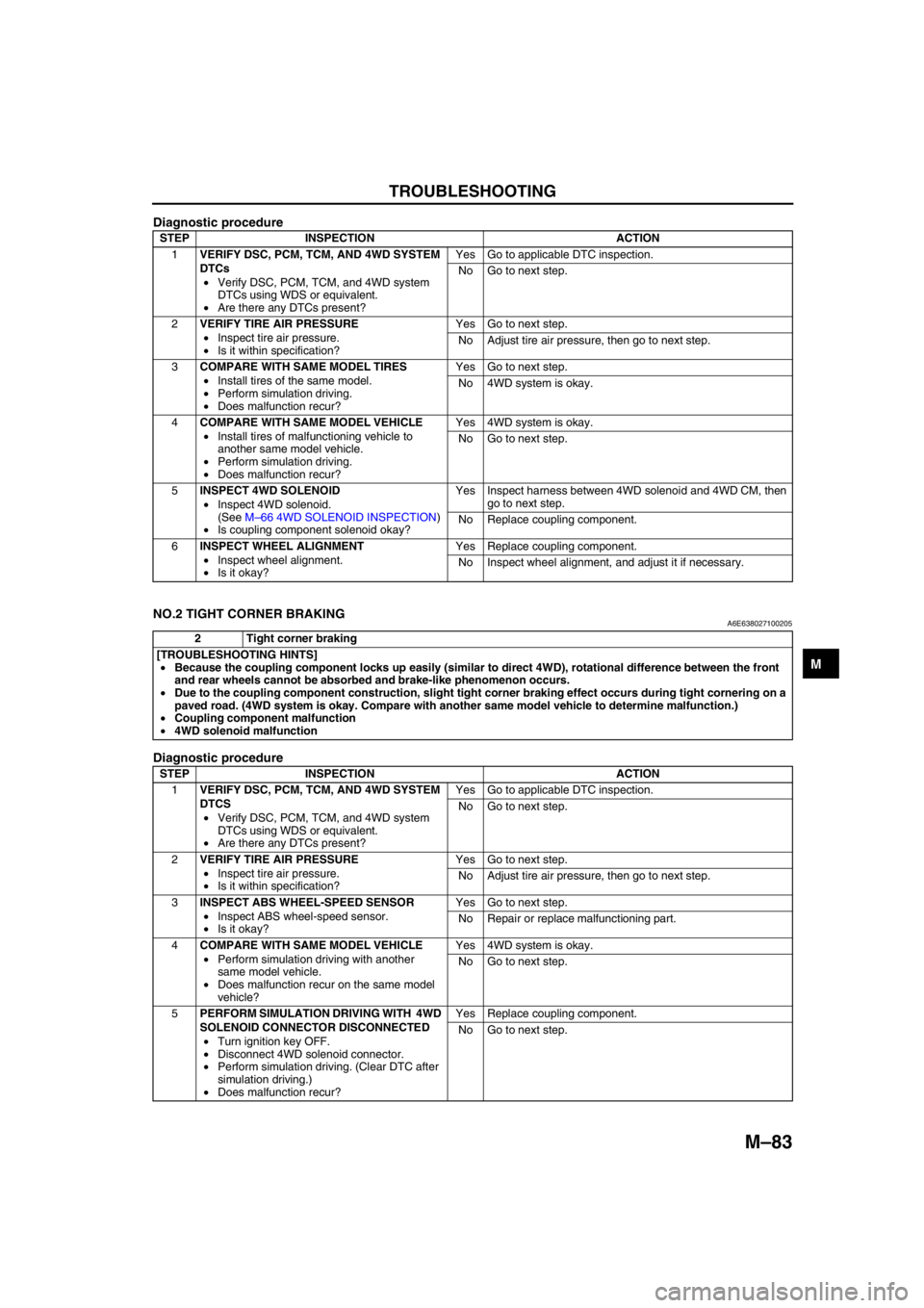

Diagnostic procedure

End Of Sie

NO.2 TIGHT CORNER BRAKINGA6E638027100205

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCs

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3COMPARE WITH SAME MODEL TIRES

•Install tires of the same model.

•Perform simulation driving.

•Does malfunction recur?Yes Go to next step.

No 4WD system is okay.

4COMPARE WITH SAME MODEL VEHICLE

•Install tires of malfunctioning vehicle to

another same model vehicle.

•Perform simulation driving.

•Does malfunction recur?Yes 4WD system is okay.

No Go to next step.

5INSPECT 4WD SOLENOID

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is coupling component solenoid okay?Yes Inspect harness between 4WD solenoid and 4WD CM, then

go to next step.

No Replace coupling component.

6INSPECT WHEEL ALIGNMENT

•Inspect wheel alignment.

•Is it okay?Yes Replace coupling component.

No Inspect wheel alignment, and adjust it if necessary.

2 Tight corner braking

[TROUBLESHOOTING HINTS]

•Because the coupling component locks up easily (similar to direct 4WD), rotational difference between the front

and rear wheels cannot be absorbed and brake-like phenomenon occurs.

•Due to the coupling component construction, slight tight corner braking effect occurs during tight cornering on a

paved road. (4WD system is okay. Compare with another same model vehicle to determine malfunction.)

•Coupling component malfunction

•4WD solenoid malfunction

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCS

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3INSPECT ABS WHEEL-SPEED SENSOR

•Inspect ABS wheel-speed sensor.

•Is it okay?Yes Go to next step.

No Repair or replace malfunctioning part.

4COMPARE WITH SAME MODEL VEHICLE

•Perform simulation driving with another

same model vehicle.

•Does malfunction recur on the same model

vehicle?Yes 4WD system is okay.

No Go to next step.

5PERFORM SIMULATION DRIVING WITH 4WD

SOLENOID CONNECTOR DISCONNECTED

•Turn ignition key OFF.

•Disconnect 4WD solenoid connector.

•Perform simulation driving. (Clear DTC after

simulation driving.)

•Does malfunction recur?Yes Replace coupling component.

No Go to next step.

Page 758 of 909

ON-BOARD DIAGNOSTIC

P–25

P

End Of Sie

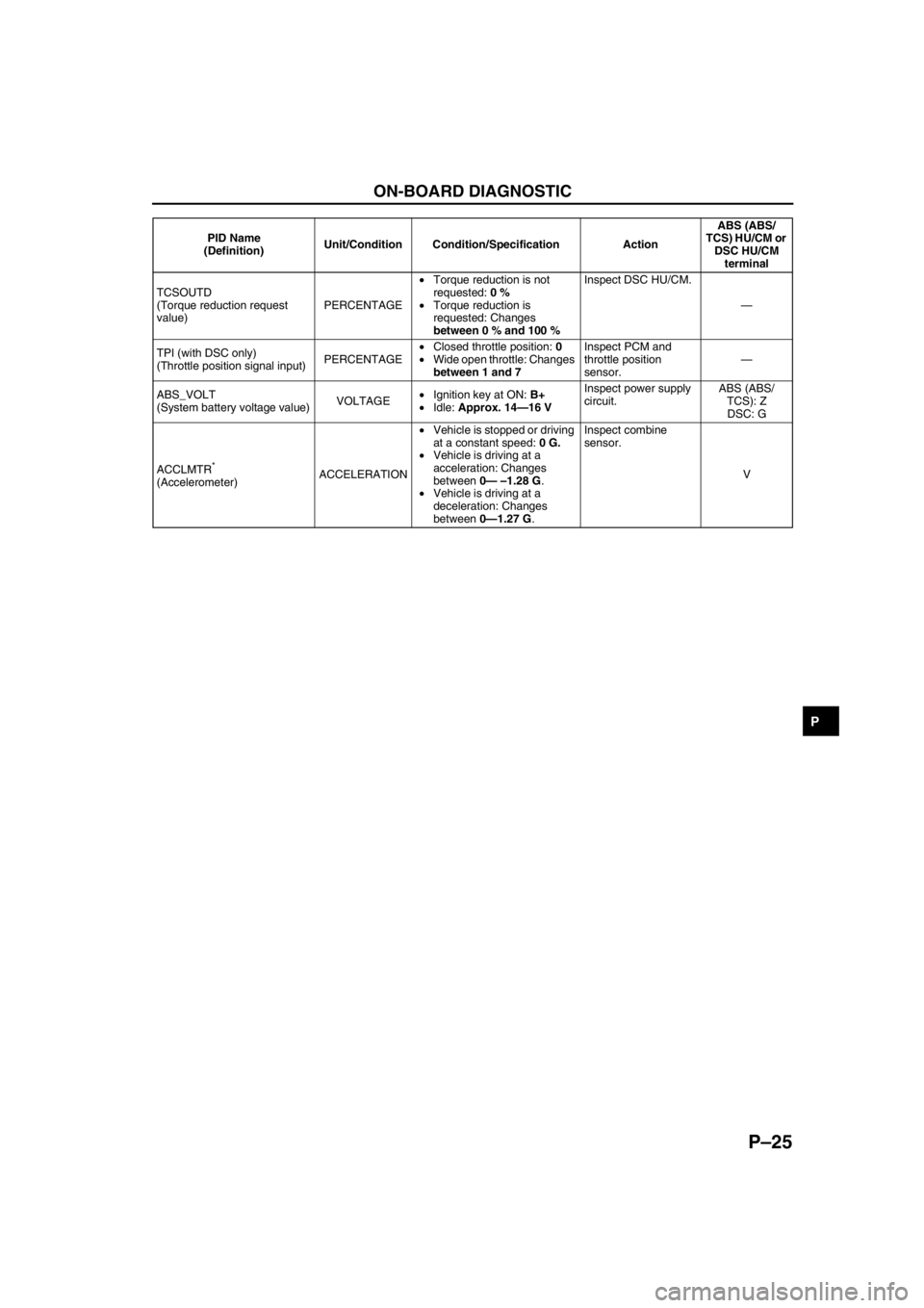

TCSOUTD

(Torque reduction request

value)PERCENTAGE•Torque reduction is not

requested: 0 %

•Torque reduction is

requested: Changes

between 0 % and 100 %Inspect DSC HU/CM.

—

TPI (with DSC only)

(Throttle position signal input)PERCENTAGE•Closed throttle position: 0

•Wide open throttle: Changes

between 1 and 7Inspect PCM and

throttle position

sensor.—

ABS_VOLT

(System battery voltage value)VOLTAGE•Ignition key at ON: B+

•Idle: Approx. 14—16 VInspect power supply

circuit.ABS (ABS/

TCS): Z

DSC: G

ACCLMTR

*

(Accelerometer)ACCELERATION•Vehicle is stopped or driving

at a constant speed: 0 G.

•Vehicle is driving at a

acceleration: Changes

between 0— –1.28 G.

•Vehicle is driving at a

deceleration: Changes

between 0—1.27 G.Inspect combine

sensor.

V PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 760 of 909

ON-BOARD DIAGNOSTIC

P–27

P

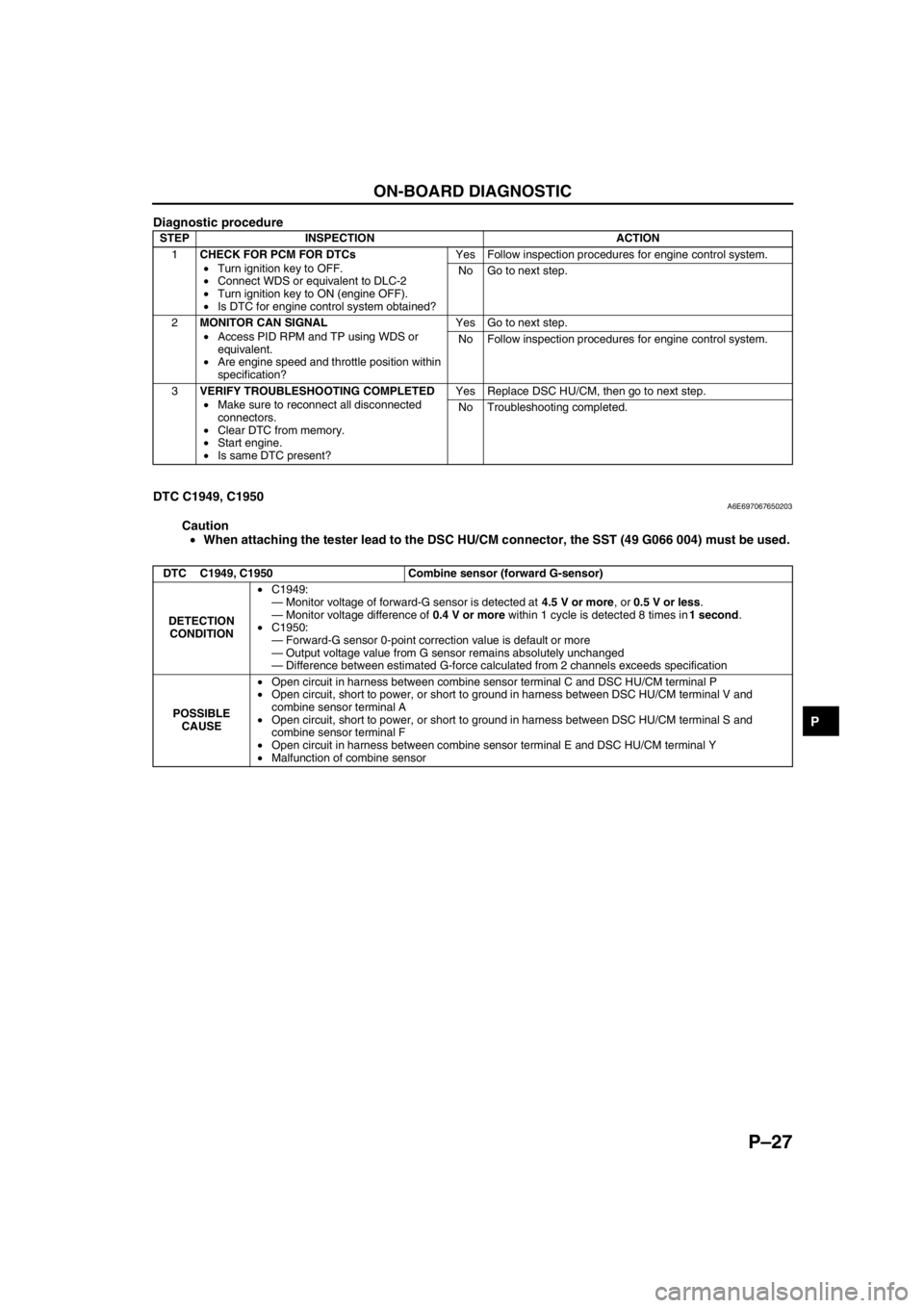

Diagnostic procedure

End Of Sie

DTC C1949, C1950A6E697067650203

Caution

•When attaching the tester lead to the DSC HU/CM connector, the SST (49 G066 004) must be used.

STEP INSPECTION ACTION

1CHECK FOR PCM FOR DTCs

•Turn ignition key to OFF.

•Connect WDS or equivalent to DLC-2

•Turn ignition key to ON (engine OFF).

•Is DTC for engine control system obtained?Yes Follow inspection procedures for engine control system.

No Go to next step.

2MONITOR CAN SIGNAL

•Access PID RPM and TP using WDS or

equivalent.

•Are engine speed and throttle position within

specification?Yes Go to next step.

No Follow inspection procedures for engine control system.

3VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

•Start engine.

•Is same DTC present?Yes Replace DSC HU/CM, then go to next step.

No Troubleshooting completed.

DTC C1949, C1950 Combine sensor (forward G-sensor)

DETECTION

CONDITION•C1949:

—Monitor voltage of forward-G sensor is detected at 4.5 V or more, or 0.5 V or less.

—Monitor voltage difference of 0.4 V or more within 1 cycle is detected 8 times in 1 second.

•C1950:

—Forward-G sensor 0-point correction value is default or more

—Output voltage value from G sensor remains absolutely unchanged

—Difference between estimated G-force calculated from 2 channels exceeds specification

POSSIBLE

CAUSE•Open circuit in harness between combine sensor terminal C and DSC HU/CM terminal P

•Open circuit, short to power, or short to ground in harness between DSC HU/CM terminal V and

combine sensor terminal A

•Open circuit, short to power, or short to ground in harness between DSC HU/CM terminal S and

combine sensor terminal F

•Open circuit in harness between combine sensor terminal E and DSC HU/CM terminal Y

•Malfunction of combine sensor

Page 761 of 909

P–28

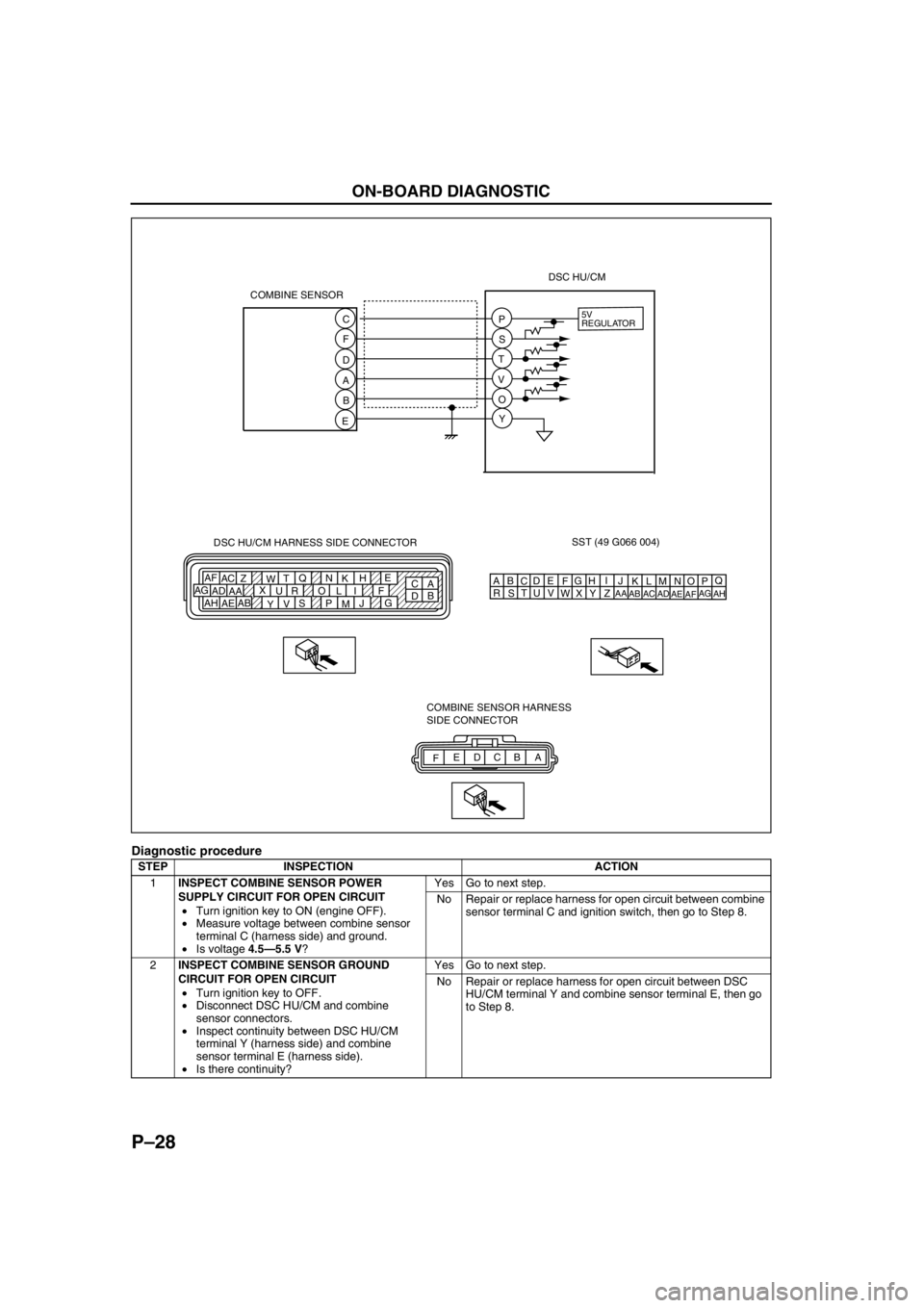

ON-BOARD DIAGNOSTIC

Diagnostic procedure

STEP INSPECTION ACTION

1INSPECT COMBINE SENSOR POWER

SUPPLY CIRCUIT FOR OPEN CIRCUIT

•Turn ignition key to ON (engine OFF).

•Measure voltage between combine sensor

terminal C (harness side) and ground.

•Is voltage 4.5—5.5 V?Yes Go to next step.

No Repair or replace harness for open circuit between combine

sensor terminal C and ignition switch, then go to Step 8.

2INSPECT COMBINE SENSOR GROUND

CIRCUIT FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Disconnect DSC HU/CM and combine

sensor connectors.

•Inspect continuity between DSC HU/CM

terminal Y (harness side) and combine

sensor terminal E (harness side).

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between DSC

HU/CM terminal Y and combine sensor terminal E, then go

to Step 8.

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB

AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH 5V

REGULATOR

COMBINE SENSOR

FA B C D E COMBINE SENSOR HARNESS

SIDE CONNECTOR C

F

D

A

B

EP

S

T

V

O

YDSC HU/CM