key MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 762 of 909

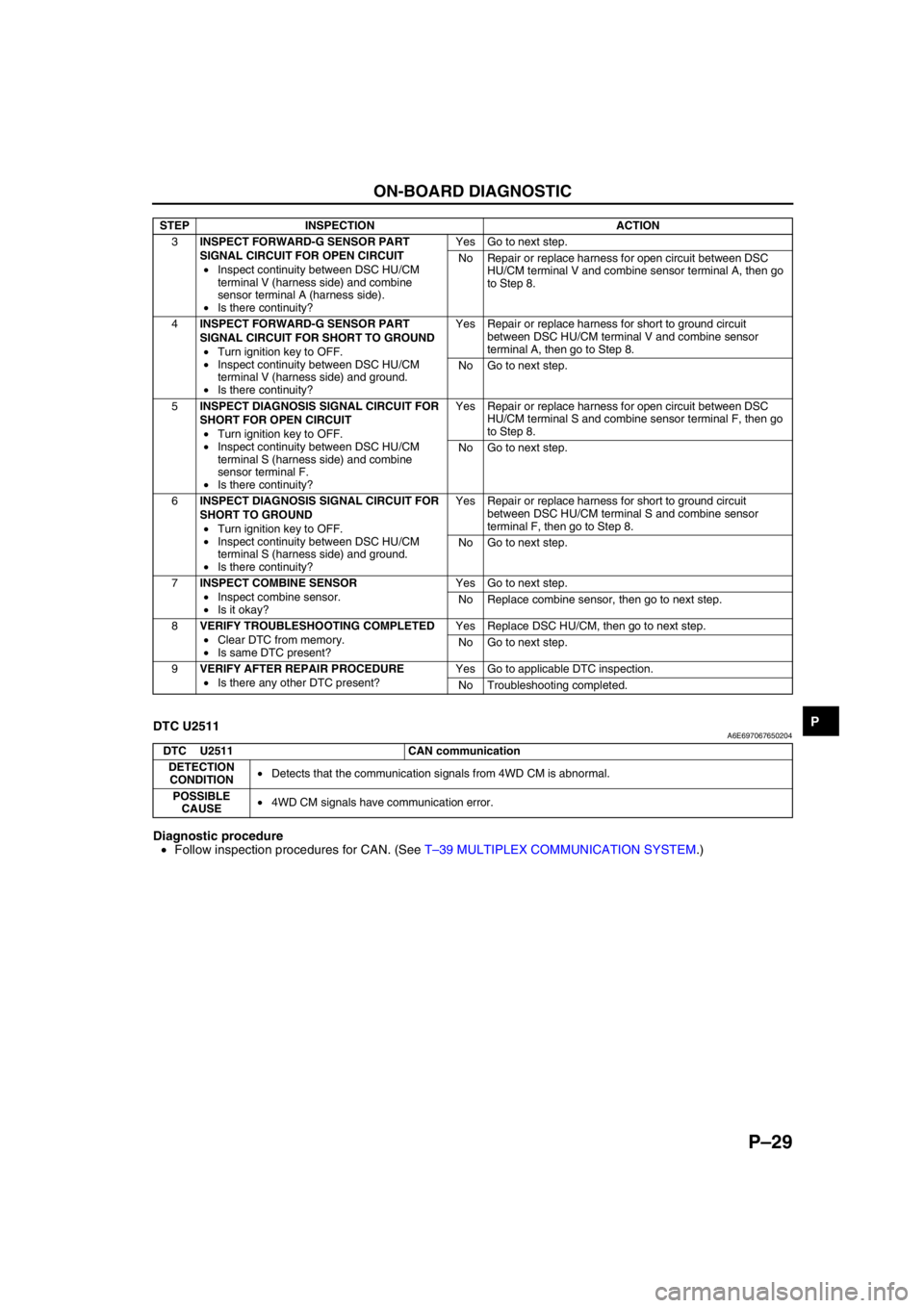

ON-BOARD DIAGNOSTIC

P–29

PEnd Of Sie

DTC U2511A6E697067650204

Diagnostic procedure

•Follow inspection procedures for CAN. (See T–39 MULTIPLEX COMMUNICATION SYSTEM.)

End Of Sie

3INSPECT FORWARD-G SENSOR PART

SIGNAL CIRCUIT FOR OPEN CIRCUIT

•Inspect continuity between DSC HU/CM

terminal V (harness side) and combine

sensor terminal A (harness side).

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between DSC

HU/CM terminal V and combine sensor terminal A, then go

to Step 8.

4INSPECT FORWARD-G SENSOR PART

SIGNAL CIRCUIT FOR SHORT TO GROUND

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal V (harness side) and ground.

•Is there continuity?Yes Repair or replace harness for short to ground circuit

between DSC HU/CM terminal V and combine sensor

terminal A, then go to Step 8.

No Go to next step.

5INSPECT DIAGNOSIS SIGNAL CIRCUIT FOR

SHORT FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal S (harness side) and combine

sensor terminal F.

•Is there continuity?Yes Repair or replace harness for open circuit between DSC

HU/CM terminal S and combine sensor terminal F, then go

to Step 8.

No Go to next step.

6INSPECT DIAGNOSIS SIGNAL CIRCUIT FOR

SHORT TO GROUND

•Turn ignition key to OFF.

•Inspect continuity between DSC HU/CM

terminal S (harness side) and ground.

•Is there continuity?Yes Repair or replace harness for short to ground circuit

between DSC HU/CM terminal S and combine sensor

terminal F, then go to Step 8.

No Go to next step.

7INSPECT COMBINE SENSOR

•Inspect combine sensor.

•Is it okay?Yes Go to next step.

No Replace combine sensor, then go to next step.

8VERIFY TROUBLESHOOTING COMPLETED

•Clear DTC from memory.

•Is same DTC present?Yes Replace DSC HU/CM, then go to next step.

No Go to next step.

9VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC U2511 CAN communication

DETECTION

CONDITION•Detects that the communication signals from 4WD CM is abnormal.

POSSIBLE

CAUSE•4WD CM signals have communication error.

Page 790 of 909

LIFTGATE

S–9

S

9. To remove the stay damper, remove the bolt B.

10. Install in the reverse order of removal.

End Of Sie

LIFTGATE DISASSEMBLY/ASSEMBLYA6E772262010202WGN

1. Disconnect the negative battery cable.

2. Remove the liftgate lower trim.

3. To remove the liftgate outer handle and liftgate key cylinder, remove the rear finisher.

4. To remove the stud ball, separate the stud ball and the stay damper.

5. Disassemble in the order indicated in the table.

6. Assemble in the reverse order of disassembly.

.

BOLT B

HINGE

STAY DAMPER

BOLT A

NUT

LIFTGATE

N·m {kgf·cm, in·lbf} 8.8—12.7

{90—130,

78—112}

32.4—48.5 N·m

{3.3—4.9 kgf·m,

24—35 ft·lbf} 7.8—10.8

{80—110, 70—95}

A6E77221102

A

2

N·m {kgf·cm, in·lbf}

A

31

B

6.90—9.80

{70—100,

60.8—86.7}

4.0—5.8

{39.8—60.1,

34.6—52.2}

4

B

16—23 N·m

{1.6—2.4 kgf·m,

12—17 ft·lbf}3.9—5.9

{39.8—60.1,

34.6—52.2}

5

7

6

A6A7722W103

1 Liftgate latch and lock actuator

2 Liftgate outer handle

3 Liftgate key cylinder

4Clip5Stud ball

6 Liftgate

7 Stopper

Page 896 of 909

TD–4

TECHNICAL DATA

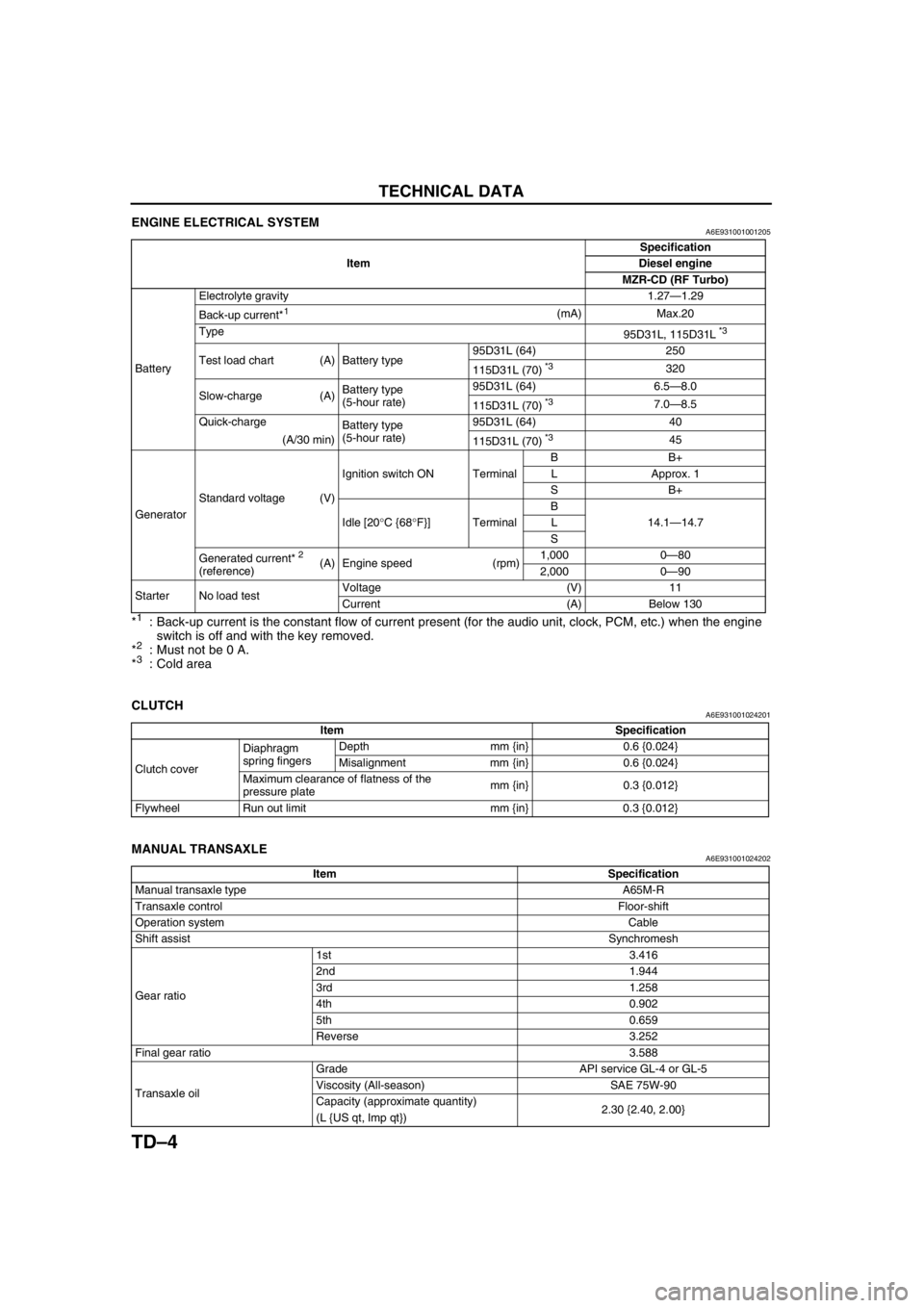

ENGINE ELECTRICAL SYSTEMA6E931001001205

*1: Back-up current is the constant flow of current present (for the audio unit, clock, PCM, etc.) when the engine

switch is off and with the key removed.

*

2: Must not be 0 A.

*3: Cold area

End Of Sie

CLUTCHA6E931001024201

End Of Sie

MANUAL TRANSAXLEA6E931001024202

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

BatteryElectrolyte gravity 1.27—1.29

Back-up current*

1(mA) Max.20

Type

95D31L, 115D31L

*3

Test load chart (A) Battery type95D31L (64) 250

115D31L (70) *3320

Slow-charge (A)Battery type

(5-hour rate)95D31L (64) 6.5—8.0

115D31L (70)

*37.0—8.5

Quick-charge

Battery type

(5-hour rate)95D31L (64) 40

(A/30 min)

115D31L (70)

*345

GeneratorStandard voltage (V)Ignition switch ON TerminalBB+

L Approx. 1

SB+

Idle [20°C {68°F}] TerminalB

14.1—14.7 L

S

Generated current*

2

(reference) (A) Engine speed (rpm)1,000 0—80

2,000 0—90

Starter No load testVoltage (V) 11

Current (A) Below 130

Item Specification

Clutch coverDiaphragm

spring fingersDepth mm {in} 0.6 {0.024}

Misalignment mm {in} 0.6 {0.024}

Maximum clearance of flatness of the

pressure platemm {in} 0.3 {0.012}

Flywheel Run out limit mm {in} 0.3 {0.012}

Item Specification

Manual transaxle typeA65M-R

Transaxle controlFloor-shift

Operation systemCable

Shift assistSynchromesh

Gear ratio1st 3.416

2nd 1.944

3rd 1.258

4th 0.902

5th 0.659

Reverse 3.252

Final gear ratio3.588

Transaxle oilGrade API service GL-4 or GL-5

Viscosity (All-season) SAE 75W-90

Capacity (approximate quantity)

2.30 {2.40, 2.00}

(L {US qt, Imp qt})