ABS MAZDA 6 2002 Suplement Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 769 of 909

REAR SUSPENSION, OUTLINE

R–7

R

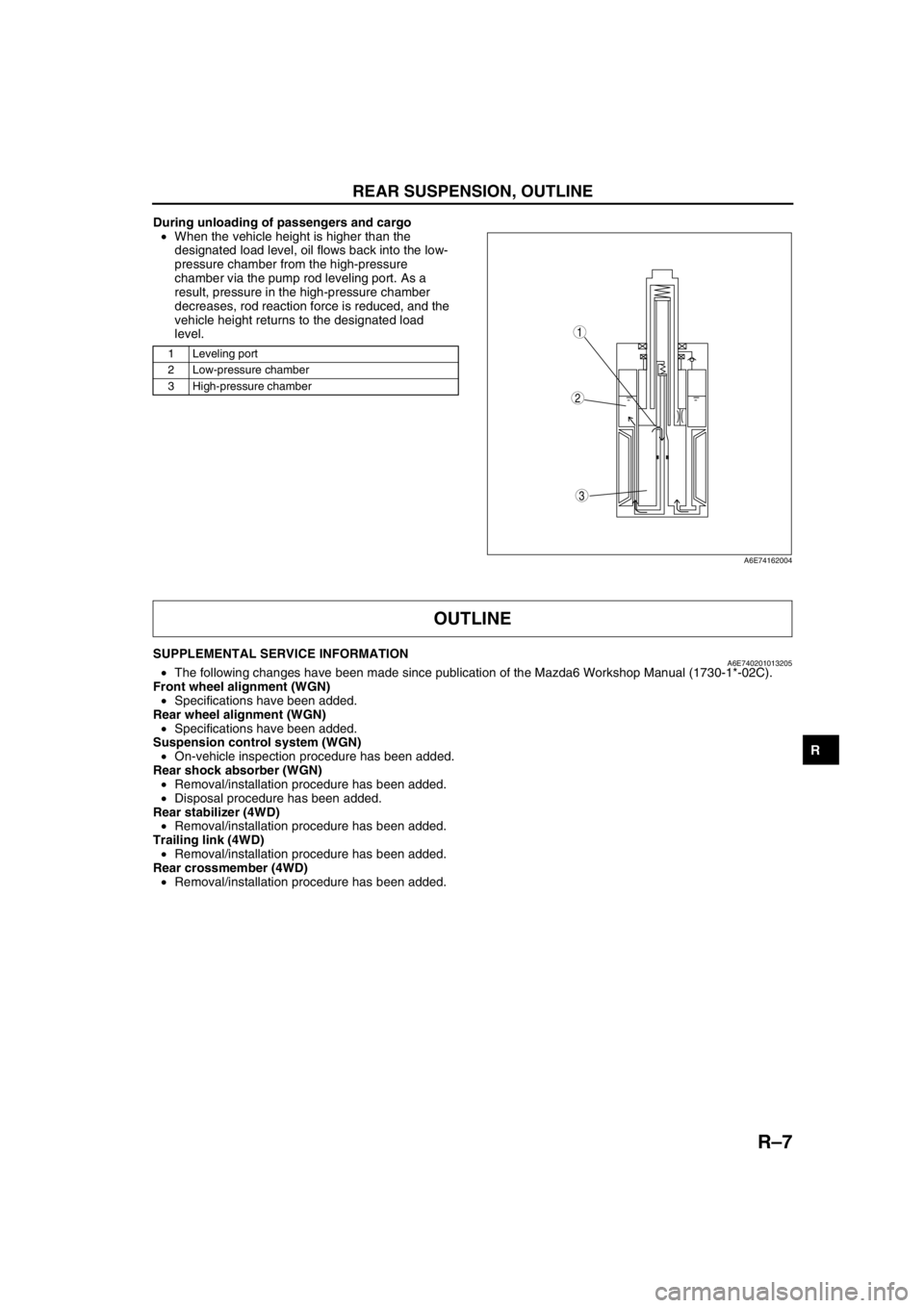

During unloading of passengers and cargo

•When the vehicle height is higher than the

designated load level, oil flows back into the low-

pressure chamber from the high-pressure

chamber via the pump rod leveling port. As a

result, pressure in the high-pressure chamber

decreases, rod reaction force is reduced, and the

vehicle height returns to the designated load

level.

.

End Of Sie

SUPPLEMENTAL SERVICE INFORMATIONA6E740201013205•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Front wheel alignment (WGN)

•Specifications have been added.

Rear wheel alignment (WGN)

•Specifications have been added.

Suspension control system (WGN)

•On-vehicle inspection procedure has been added.

Rear shock absorber (WGN)

•Removal/installation procedure has been added.

•Disposal procedure has been added.

Rear stabilizer (4WD)

•Removal/installation procedure has been added.

Trailing link (4WD)

•Removal/installation procedure has been added.

Rear crossmember (4WD)

•Removal/installation procedure has been added.

End Of Sie

1 Leveling port

2 Low-pressure chamber

3 High-pressure chamber

3

1

2

A6E74162004

OUTLINE

Page 773 of 909

REAR SUSPENSION

R–11

R

SUSPENSION CONTROL SYSTEM ON-VEHICLE INSPECTION (WGN)A6E7416010132021. Pull up the dust boot and visually inspect the piston rod for oil leakage.

2. Remove all cargo and drive the vehicle, with only the driver aboard, for 1 km {0.62 miles} or more. After

driving, verify that the rear vehicle height (distance measured from the fender brim to the center of the wheel) is

360 mm {14.2 in} or more

*. If not as specified, replace the rear shock absorbers.

3. Place a load equivalent to five people riding in

order to make the rear vehicle height to be 330

mm {13.0 in} or less.

4. Immediately after driving the vehicle for 5 km {3.0

miles} or more, under the same load conditions,

verify that the rear vehicle height is 335 mm {13.2

in} or more. If not as specified replace the rear

shock absorbers.

*: Indicates rear vehicle height with fuel tank full.

Height will vary 6—8 mm {0.24—0.31 in} between a

full and empty fuel tank.

End Of SieREAR SHOCK ABSORBER REMOVAL/INSTALLATION (WGN)A6E741628700201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

REAR SUSPENSION

SECTION

A—AMEASURING POINT

A

A

A6E7412W001

1 Rear shock absorber and bracket

2Bracket

(See R–12 Bracket Installation Note)

3 Rear shock absorber

1

3

37.2—51.9

{3.80—5.29,

27.5—38.2}

286.2—116.6

{8.80—11.88,

63.58—85.99}

86.2—116.6

{8.80—11.88,

63.58—85.99}

N·m {kgf·m, ft·lbf}

A6E74162006

Page 774 of 909

R–12

REAR SUSPENSION

Bracket Installation Note

1. Install the bracket as shown in the figure.

End Of SieREAR SHOCK ABSORBER DISPOSAL (WGN)A6E7416287002021. Lay the shock absorber on a level, horizontal surface.

2. Using a 2—3 mm {0.08—0.12 in} drill bit, drill a

hole in the high-pressure side (area indicated by

A), and allow the gas to escape.

Warning

•The oil in the shock absorber is

pressurized and could spray out. Be sure

to drill slowly and carefully.

3. Using a 2—3 mm {0.08—0.12 in} drill bit, drill a

hole in the low-pressure side (area indicated by

B).

4. Place the shock absorber with the hole drilled in

Step 3 turned downwards. Move the piston rod up

and down several times to drain out the oil.

5. Cut the tube at the end of the shock absorber,

and completely drain the oil out.

6. Properly dispose of the waste oil according to

waste disposal laws.

End Of Sie

106.5—112.5°

A6J74162006

A

A6J74161003

B

A6J74161006

Page 776 of 909

R–14

REAR SUSPENSION

Bolt (Differential Front Side) Installation Note

1. Support the differential with a jack, and then

install the bolt.

2. Connect differential oil temperature sensor

connector and 4WD solenoid connector.

End Of SieTRAILING LINK REMOVAL/INSTALLATION (4WD)A6E741628200201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

3. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162011

Page 777 of 909

REAR SUSPENSION

R–15

R

.

1

2

93.2—131.4

{9.51—13.39, 68.75—96.91}

86.2—116.6

{8.80—11.88,

63.58—85.99}

7

5

C

C

A

A

B

B

D

D

E

E

4

6

3

18.6—25.5

{1.90—2.60,

13.8—18.8}

18.6—25.5

{1.90—2.60,

13.8—18.8}

86.2—116.6

{8.80—11.88,

63.58—85.99}86.2—116.6

{8.80—11.88,

63.58—85.99}

N·m {kgf·m, ft·lbf}

A6E74162008

1 ABS wheel-speed sensor

2 Parking brake cable

3 Bolt (shock absorber lower side)

4 Bolt (trailing link front side)

(See R–16 Bolt (Trailing Link Front Side) Removal

Note)

(See R–16 Bolt (Trailing Link Front Side) Installation

Note)5 Bolt (Lateral link outer side)

(See R–16 Bolt (Lateral Link Outer Side) Removal

Note)

(See R–16 Bolt (Lateral Link Outer Side) Installation

Note)

6 Toe link bracket

7 Trailing link

Page 778 of 909

R–16

REAR SUSPENSION

Bolt (Trailing Link Front Side) Removal Note

1. Support the trailing link with a jack.

Caution

•Removing the trailing link is dangerous.

The trailing link could fall and cause

serious injury or death. Verify that the

jack securely supports the trailing link.

2. Remove the bolts (trailing link front side).

Bolt (Lateral Link Outer Side) Removal Note

1. Loosen the bolt (lateral link inner side).

2. Remove the bolt (lateral link outer side).

Bolt (Lateral Link Outer Side) Installation Note

1. Tighten the bolt (lateral link outer side).

2. Tighten the bolt (lateral link inner side).

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—85.99 ft·lbf}

Bolt (Trailing Link Front Side) Installation Note

1. Support the trailing link with a jack.

2. Tighten the bolts (trailing link front side).

End Of SieREAR CROSSMEMBER REMOVAL/INSTALLATION (4WD)A6E741628400201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove the rear auto leveling sensor and harness.

(See T–20 REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATION.)

2. Remove the middle pipe.

(See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Adjust the headlight zeroset.

6. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162010

JACK

A6E74162010

Page 814 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–3

T

OUTLINEA6E811155430201•A TCM and a 4WD control module have been adopted for the CAN system-related module.

End Of Sie

STRUCTRURAL VIEWA6E811155430202

.

End Of Sie

MULTIPLEX COMMUNICATION SYSTEM

4

1

3

2

5

A6E81111101

1 ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

DSC HU/CM (with DSC)

2 Instrument cluster3TCM

4PCM

5 4WD control module

Page 815 of 909

T–4

MULTIPLEX COMMUNICATION SYSTEM

SYSTEM WIRING DIAGRAMA6E811155430203

.

End Of SieCAN SIGNAL-CHARTA6E811155430204

OUT: Output (sends signal)

IN: Input (receives signal)

1

2

67

3

8

4

5

ROAF AG

HG

2M2J2W

2X

9

10

CAN_L

CAN_H

A6E81111102

1PCM

2 DSC HU/CM (with DSC)

3 ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

4 Data link connector-2

5 Instrument cluster

6 TCM (JA5AX-EL)7 4WD control module (4WD)

8Twist pair

9 2R (except MZR-CD (RF Turbo))

39 (MZR-CD (RF Turbo))

10 2U (except MZR-CD (RF Turbo))

13 (MZR-CD (RF Turbo))

SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Accelerator pedal position

(MZR-CD (RF Turbo))OUT IN IN–IN

Air induction type OUT–IN––

ATF temperature IN OUT–––

AT warning light conditions

(JA5AX-EL)IN OUT––IN

Battery reconnection

(except MZR-CD (RF

Turbo))OUT IN–––

Brake system configuration

(EBD/ABS/TCS/DSC)IN–OUT–IN

Brake system

statusABS IN–OUT––

EBD/ABS/

TCS/DSC––OUT IN IN

Brake system warning light

conditions (brake fluid level

sensor)––IN–OUT

Country OUT–IN––

Coupling torque (with

DSC)––IN OUT–

Coupling torque request

(with DSC)––OUT IN–

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Page 817 of 909

T–6

MULTIPLEX COMMUNICATION SYSTEM

ON-BOARD DIAGNOSTIC FUNCTIONA6E811155430205Outline

•The on-board diagnostic function is incorporated into the PCM, TCM, ABS (ABS/TCS) HU/CM (with ABS (ABS/

TCS)), DSC HU/CM (with DSC), 4WD control module, and instrument cluster. This function can narrow down

CAN system malfunction locations.

•Due to the adoption of the TCM and the 4WD CM, some DTCs and PID/data monitor items have been added.

Other functions are the same as those of the current Mazda6 (GG) model.

Block Diagram

.

Fail-Safe Function

•When the failure detection function detemines that there is a malfunction, the fail-safe function illuminates a

warning light to advise the driver of the malfunction.

1

3

24

5

6

A6E81111103

1PCM

2 TCM (JA5AX-EL)

3 ABS (ABS/TCS) HU/CM or DSC HU/CM4 4WD control module (4WD)

5 Instrument cluster

6Twist pair

Module Fail-safe function

PCM•MIL illuminated

TCM•AT warning light illuminated

•ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

•DSC HU/CM (with DSC)•ABS (ABS/TCS) suspended (with ABS (ABS/TCS))

•DSC suspended (with DSC)

•ABS warning light illuminated

•DSC/TCS indicator light illuminated

•DSC OFF light illuminated

•TCS OFF light illuminated

4WD control module•4WD indicator light illuminated

Instrument cluster•Speedometer, tachometer, water temperature gauge: 0 displayed