fuel cap MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 90 of 909

F1–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E390218881201•The fuel and emission control systems are essentially carried over from the current Mazda6 (GG), except for

the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E390218881202System simplification

•Controller area network has been adopted with TCM communication (4WD).

TCM adoption

•DTC for CAN (TCM communication) has been adopted.

Modifications to match the vehicle characteristics

•The idle speed has been modified.

•Fuel pump (transfer) has been adopted.

End Of Sie

SPECIFICATIONSA6E390218881203

*1: Without the BARO sensor

*2: With the BARO sensor

Bold frames: New specifications

End Of Sie

OUTLINE

Item 2WD 4WD

Air cleaner element Type Paper element (oil permeated)

IAC valve Type Duty control

Fuel injectorType Hi-ohmic

Type of fuel delivery Top-feed

Type of drive Voltage

Pressure regulatorRegulating pressure

(kPa {kgf/cm

2, psi})440 {4.5, 64}

Fuel tankCapacity

(L {US qt, lmp qt})64 {68, 56} 62 {65, 54}

Fuel SpecificationUnleaded

(RON 90*

1/95*2 or above)Unleaded (RON 95 or above)

Catalyst Type TWC (monolythic)

EGR control Type Stepping motor type

Evaporative emission control

systemType Canister type

PCV system Type Closed type

Page 97 of 909

FUEL SYSTEM

F1–9

F1

End Of Sie

OUTLINEA6E391201006201•The fuel system is essentially carried over from that of the current Mazda6 (GG), except for the following. (See

Mazda6 Training Manual 3359-1*-02C.)

—A saddle type fuel tank has been adopted.

—A fuel pump (transfer) for fuel transmission has been added.

End Of Sie

STRUCTURAL VIEWA6E391201006202

.

End Of Sie

FUEL SYSTEM

7

5

4

3

6

1

2

A6E39122001

1 Fuel gauge sender sub-unit

2 Quick release connector (fuel tank side, transfer

hose part)

3 Non-return valve4 Quick release connector (fuel tank side, main fuel

pipe part)

5 Fuel tank

6 Fuel pump unit

7 Filler cap

Page 98 of 909

F1–10

FUEL SYSTEM

SYSTEM DIAGRAMA6E391201006203

.

End Of Sie

FUEL PUMP (TRANSFER)A6E391213350201Function

•The fuel tank for 4WD is saddle type. Fuel in the fuel gauge sender sub-unit side (right side) is pumped to the

left side of the fuel tank using the fuel pump (transfer).

Structure

•The fuel pump (transfer) is integrated into the fuel pump unit and it cannot be separately disassembled.

•The fuel pump (transfer) is composed of a relief valve and fuel jet pump.

87

5

4

3

6

1

2

:

9

10

A6E39122002

1 Filler cap

2 Pressure regulator

3 Fuel pump (transfer)

4 Fuel filter (high-pressure)

5Fuel pump6 Fuel filter (low-pressure)

7 Fuel pump unit

8 Pulsation damper

9 Fuel injector

10 Fuel flow

Page 112 of 909

F1–24

FUEL SYSTEM

10. Remove in the order indicated in the table.

11. Install in the reverse order of removal.

12. Complete the “AFTER REPAIR PROCEDURE”.

.

44—60

{4.5—6.1, 33—44}

7

5

4

3

2

1

6

A

N·m {kgf·m, ft·lbf} 44—60

{4.5—6.1, 33—44}

44—60

{4.5—6.1, 33—44}8.9—12.7 N·m

{91—120 kgf·cm, 79—110 in·lbf}

8.9—12.7 N·m

{91—120 kgf·cm, 79—110 in·lbf}

A6E39122008

1 Joint hose

(See F1–25 Joint Hose Installation Note)

2 Breather hose

(See F1–25 Breather Hose Installation Note)

3 Evaporative hose

(See F1–25 Evaporative Hose Installation Note)4 Fuel tank

5 Fuel-filler pipe

6 C-ring

7 Filler cap

Page 114 of 909

F1–26

FUEL SYSTEM

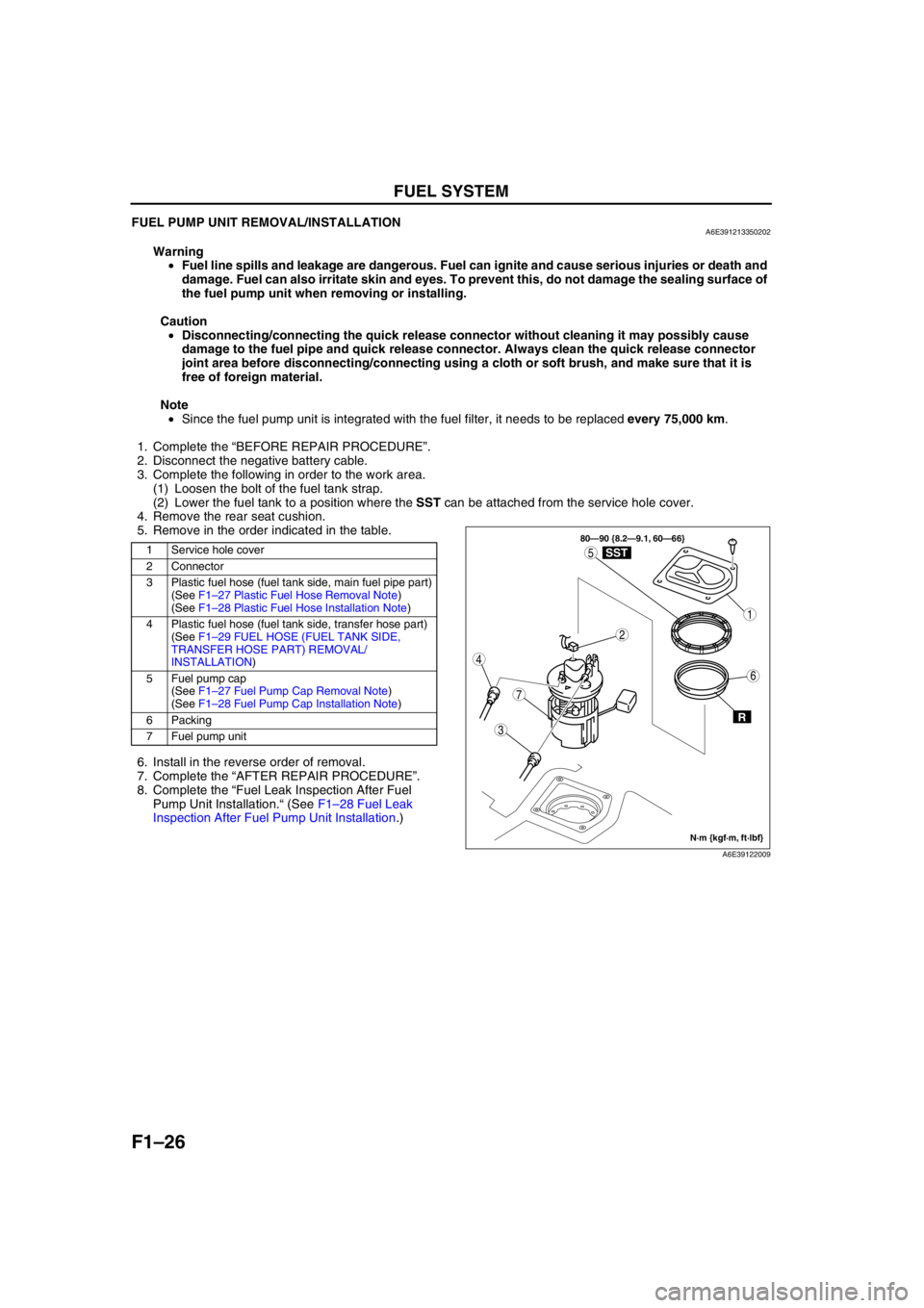

FUEL PUMP UNIT REMOVAL/INSTALLATIONA6E391213350202

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

•Since the fuel pump unit is integrated with the fuel filter, it needs to be replaced every 75,000 km.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel Leak Inspection After Fuel

Pump Unit Installation.“ (See F1–28 Fuel Leak

Inspection After Fuel Pump Unit Installation.)

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, main fuel pipe part)

(See F1–27 Plastic Fuel Hose Removal Note)

(See F1–28 Plastic Fuel Hose Installation Note)

4 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

5Fuel pump cap

(See F1–27 Fuel Pump Cap Removal Note)

(See F1–28 Fuel Pump Cap Installation Note)

6 Packing

7 Fuel pump unit

3

7

1

4

5

2

6

80—90 {8.2—9.1, 60—66}

R

SST

N·m {kgf·m, ft·lbf}

A6E39122009

Page 115 of 909

FUEL SYSTEM

F1–27

F1

Plastic Fuel Hose Removal Note

Caution

•The quick release connector may be damaged if the tab is bent excessively. Do not expand the tab

over the stopper.

1. Disconnect the quick release connector.

(1) Push the tab on the locking coupler 90

degrees until it stops.

(2) Pull the fuel hose straight back.

Note

•The stopper may be removed from the quick

connector. Take care not to lose it.

Reinstall it to the quick release connector

before reconnecting the fuel line.

•The locking coupler has two internal locking

tabs which retain the fuel pipe. Be sure that

the tab on the locking coupler is rotated until

it stops to release two internal locking tabs.

2. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Fuel Pump Cap Removal Note

1. Using the SST, remove the fuel pump cap.

FUEL PIPE

STOPPER TAB

A6E3912W001

LOCKING TAB

A6E3912W002

A6E39122015

49 T042 001A

A6E39122012

Page 116 of 909

F1–28

FUEL SYSTEM

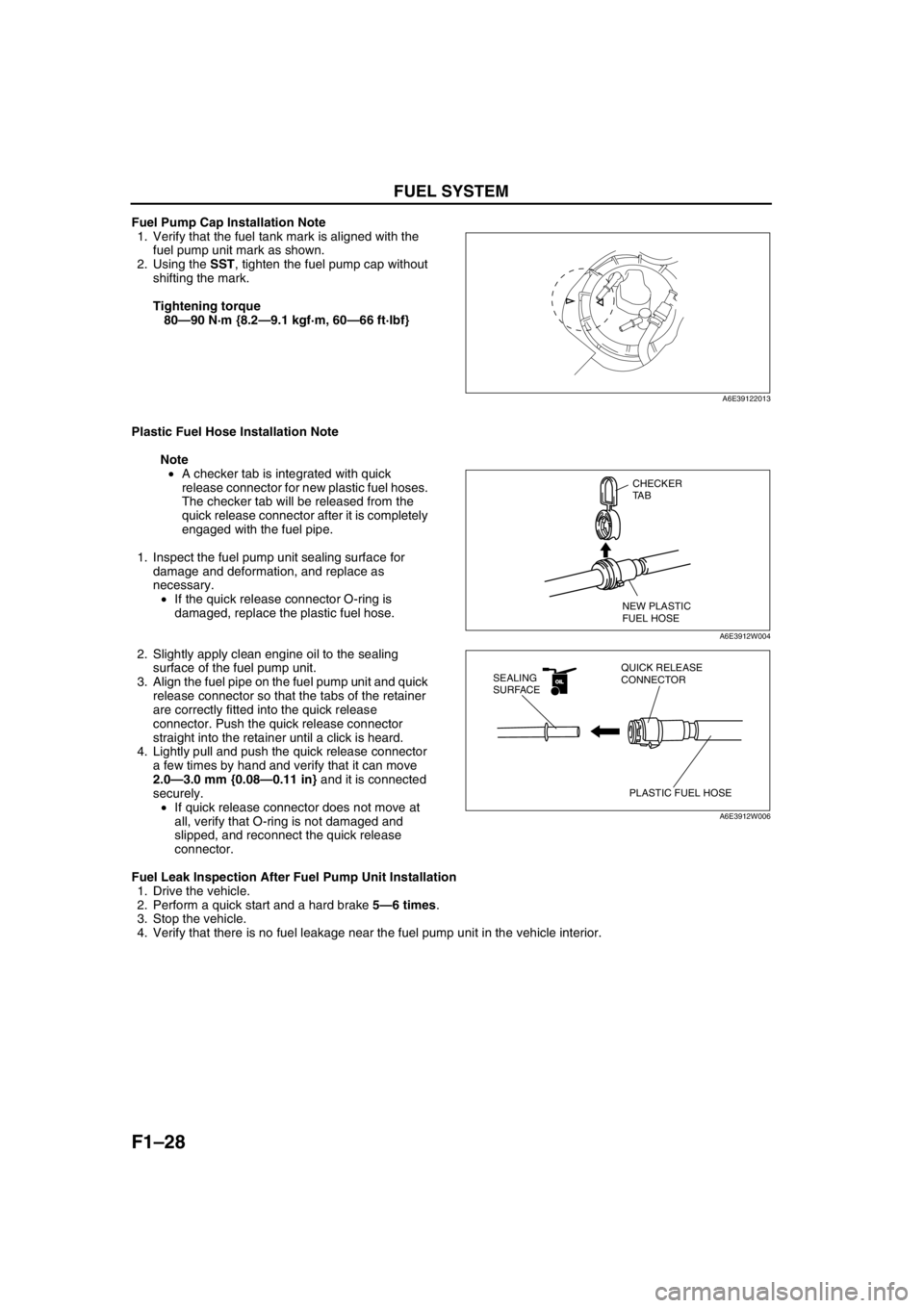

Fuel Pump Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump unit mark as shown.

2. Using the SST, tighten the fuel pump cap without

shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

2. Slightly apply clean engine oil to the sealing

surface of the fuel pump unit.

3. Align the fuel pipe on the fuel pump unit and quick

release connector so that the tabs of the retainer

are correctly fitted into the quick release

connector. Push the quick release connector

straight into the retainer until a click is heard.

4. Lightly pull and push the quick release connector

a few times by hand and verify that it can move

2.0—3.0 mm {0.08—0.11 in} and it is connected

securely.

•If quick release connector does not move at

all, verify that O-ring is not damaged and

slipped, and reconnect the quick release

connector.

Fuel Leak Inspection After Fuel Pump Unit Installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

A6E39122013

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

Page 155 of 909

OUTLINE

F2–3

F2

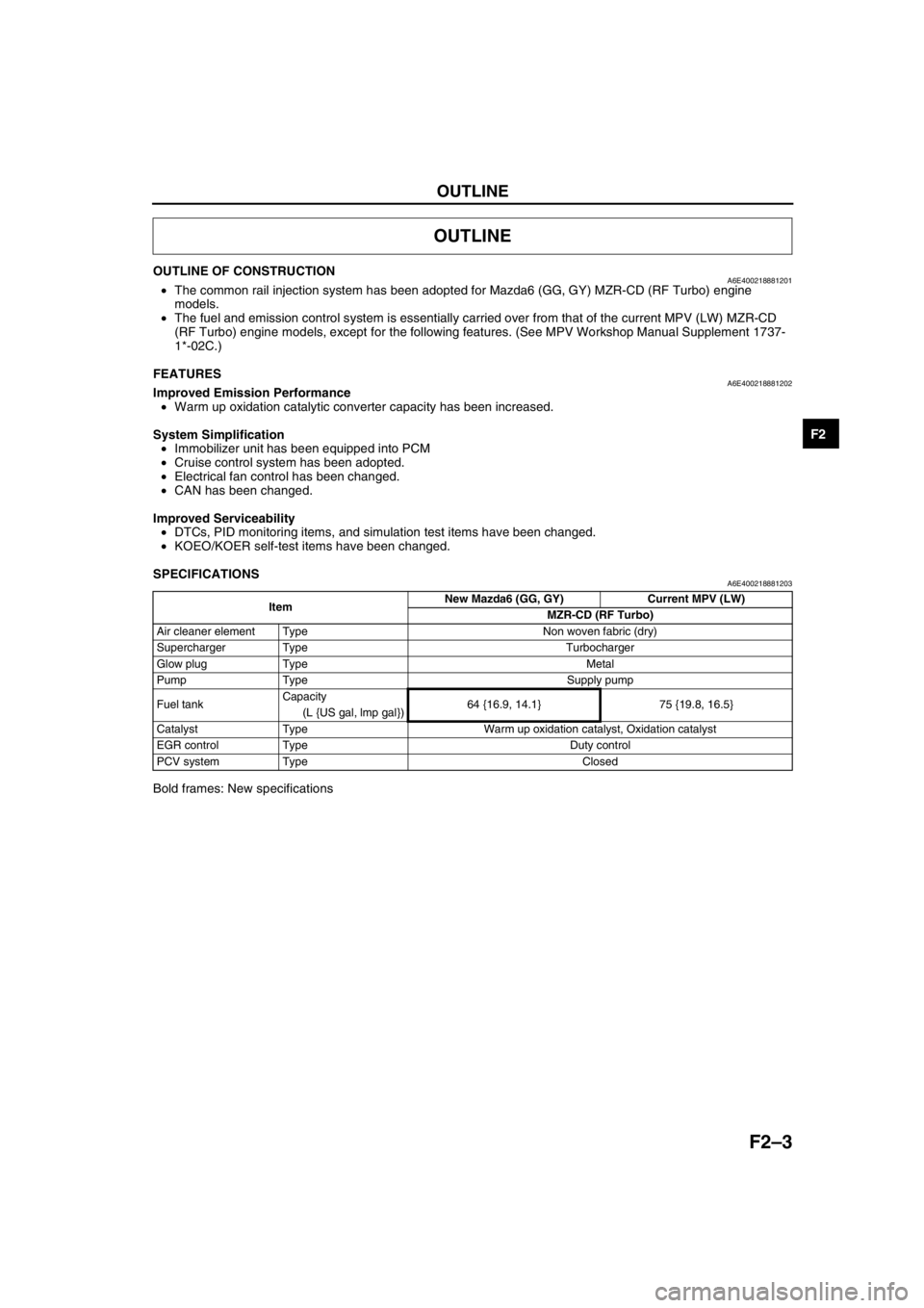

OUTLINE OF CONSTRUCTIONA6E400218881201•The common rail injection system has been adopted for Mazda6 (GG, GY) MZR-CD (RF Turbo) engine

models.

•The fuel and emission control system is essentially carried over from that of the current MPV (LW) MZR-CD

(RF Turbo) engine models, except for the following features. (See MPV Workshop Manual Supplement 1737-

1*-02C.)

End Of Sie

FEATURESA6E400218881202Improved Emission Performance

•Warm up oxidation catalytic converter capacity has been increased.

System Simplification

•Immobilizer unit has been equipped into PCM

•Cruise control system has been adopted.

•Electrical fan control has been changed.

•CAN has been changed.

Improved Serviceability

•DTCs, PID monitoring items, and simulation test items have been changed.

•KOEO/KOER self-test items have been changed.

End Of Sie

SPECIFICATIONSA6E400218881203

Bold frames: New specifications

End Of Sie

OUTLINE

ItemNew Mazda6 (GG, GY) Current MPV (LW)

MZR-CD (RF Turbo)

Air cleaner element Type Non woven fabric (dry)

Supercharger Type Turbocharger

Glow plug Type Metal

Pump Type Supply pump

Fuel tankCapacity

64 {16.9, 14.1} 75 {19.8, 16.5}

(L {US gal, lmp gal})

Catalyst Type Warm up oxidation catalyst, Oxidation catalyst

EGR control Type Duty control

PCV system Type Closed

Page 164 of 909

F2–12

FUEL SYSTEM

Fuel tank side

.

End Of Sie

4

31

2

A6E40122032

1 Fuel tank

2Fuel pump3 Nonreturn valve

4 Fuel filler cap

Page 168 of 909

F2–16

EMISSION SYSTEM, CONTROL SYSTEM

End Of SieWARM UP OXIDATION CATALYTIC CONVERTER DESCRIPTIONA6E401601007203•The warm up oxidation catalytic converter capacity has been increased to 1,920 ml {1,920 cc, 117 cu in} in

order to improve emission performance.

End Of Sie

OUTLINEA6E404018881201•The control system is essentially carried over from that of the current MPV (LW) MZR-CD (RF Turbo) engine

models. (See MPV Workshop Manual Supplement 1737-1*-02C.)

Input Device

×:Applicable –: Not applicable

CONTROL SYSTEM

ItemMazda6

(GG, GY)Current

MPV (LW)

Remark for new model

MZR-CD (RF Turbo)

Battery×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Starter (starter signal)×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Starter relay×–Newly adopted

Clutch switch×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Neutral switch×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Brake switch×Same function as Mazda6 (GG) L series engine model

Idle switch×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

A/C switch×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Refrigerant pressure switch×Same function as 626 (GF, GW) RF Turbo engine model

Cruise control switch×Same function as Mazda6 (GG) L series engine model

Accelerator position sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

MAF/IAT sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

IAT sensor No.2×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

ECT sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Fuel temperature sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

BARO sensor (integrated in PCM)×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Boost sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Fuel pressure sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

CMP sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

CKP sensor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

VSS×Vehicle speed signal is received by CAN

Calibration resistor×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Immobilizer unit (integrated in

PCM)×Immobilizer unit equipped into PCM