reset MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 140 of 909

F1–52

ON-BOARD DIAGNOSTIC

End Of Sie

DTC (4WD)A6E397018881204•Detection logics and conditions are as shown below.

Controller Area Network (CAN)

PCM cannot receive any signals from TCM (U0101)

•PCM cannot receive any signals from TCM.

End Of Sie

OBD DRIVE MODEA6E397018881205•Performing the Drive Mode inspects the OBD system for proper operation. The Drive Mode must be performed

to ensure that no additional DTCs are present.

•During Drive Mode, the following systems are inspected:

—Oxygen sensor (HO2S)

—Oxygen sensor heater

—Catalytic converter (TWC)

Caution

•While performing the Drive Mode, always operate the vehicle in a safe and lawful manner.

•When the WDS or equivalent is used to observe monitor system condition while driving, be sure to

have another technician with you, or record the data in the WDS or equivalent using the PID/DATA

MONITOR AND RECORD function and inspect later.

Note

•Vehicle speed and engine speed detected by the PCM may differ from that indicated by the speedometer

and tachometer. Use the WDS or equivalent to monitor vehicle speed.

•If the OBD system inspection is not completed during the Drive Mode, the following causes are

considered:

1. The OBD system detects the malfunction.

2. The Drive Mode procedure is not completed correctly.

•Disconnecting the battery will reset the memory. Do not disconnect the battery during and after Drive

Mode.

PCM Adaptive Memory Procedure Drive Mode

Note

•The PCM adaptive memory condition can be confirmed with RFCFLAG PID.

•If RFCFLAG PID is “Learnt”, PCM Adaptive Memory Procedure Drive Mode is not necessary, because

PCM already has adaptive memory.

•If RFCFLAG PID is “Not Learnt”, PCM Adaptive Memory Procedure Drive should be performed before

HO2S Heater, HO2S, and TWC Repair Verification Drive Mode.

1. Start the engine and warm it up completely.

2. Verify all accessory loads (A/C, headlights, blower fan, rear window defroster) are off.

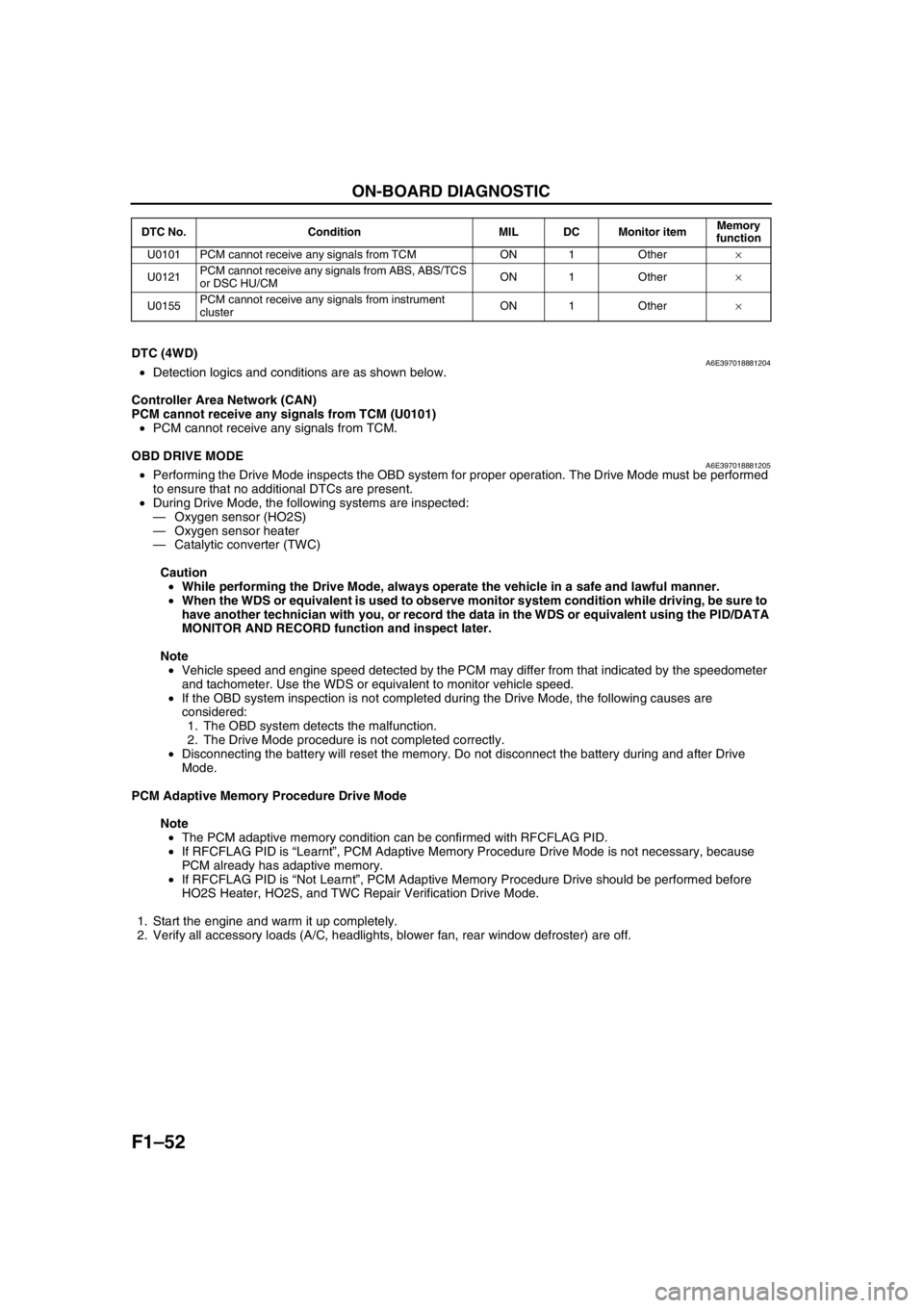

U0101 PCM cannot receive any signals from TCM ON 1 Other×

U0121PCM cannot receive any signals from ABS, ABS/TCS

or DSC HU/CMON 1 Other×

U0155PCM cannot receive any signals from instrument

clusterON 1 Other× DTC No. Condition MIL DC Monitor itemMemory

function

Page 479 of 909

K2–64

AUTOMATIC TRANSAXLE

ON-BOARD DIAGNOSTIC (OBD) SYSTEM DESCRIPTIONA6E571418901210•The OBD system has the following functions:

—Failure detection function: detects failure of the input/output devices and system components of the ATX.

—Memory function: stores the DTC when a failure is detected.

—Fail-safe function: fixes the output device function and input value of the sensors/switches to ensure

minimum vehicle drivability when a failure is detected.

—PID data monitoring function: monitors the input/output signal and calculated value of the TCM and sends

the monitoring data to the scan tool.

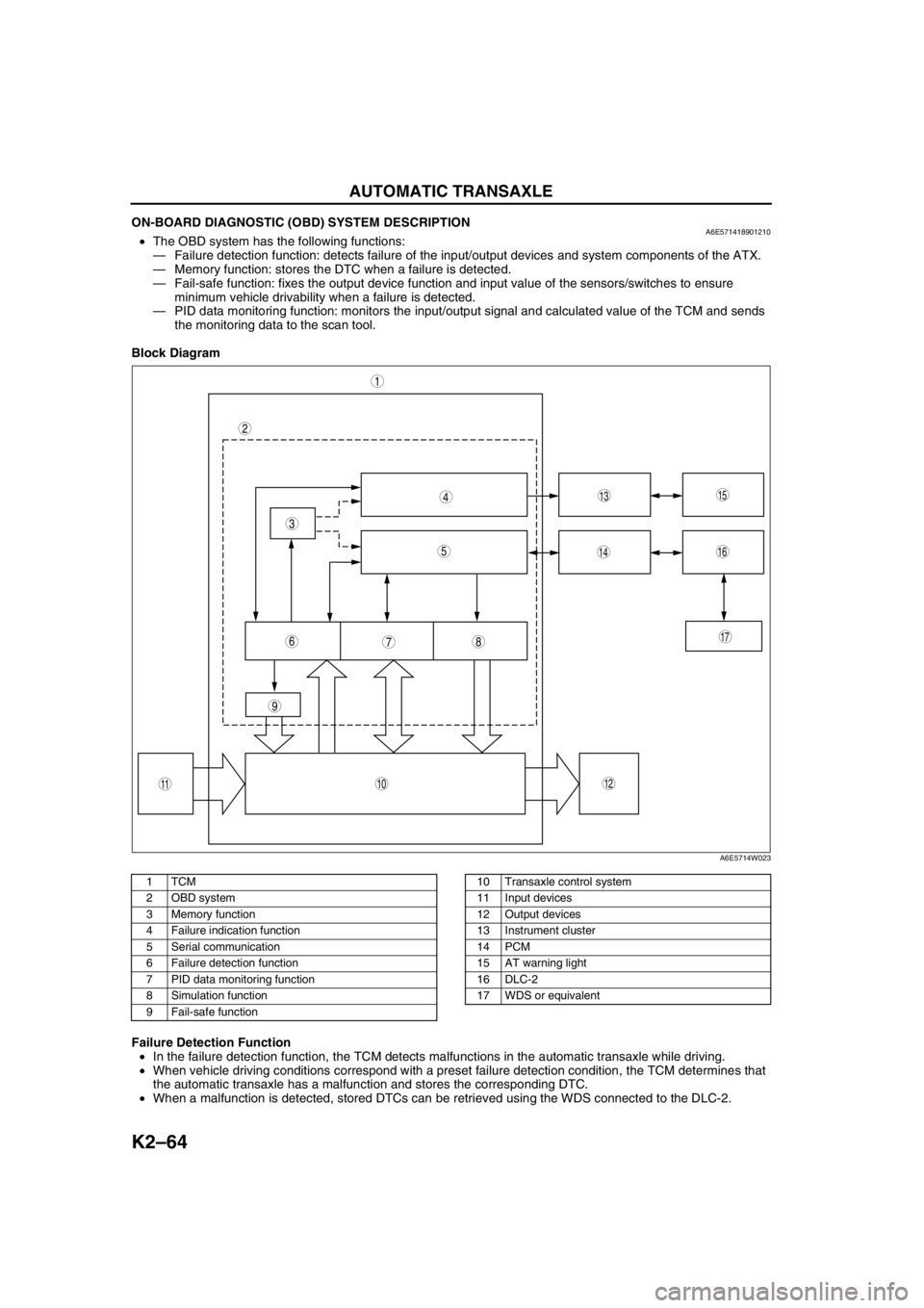

Block Diagram

.

Failure Detection Function

•In the failure detection function, the TCM detects malfunctions in the automatic transaxle while driving.

•When vehicle driving conditions correspond with a preset failure detection condition, the TCM determines that

the automatic transaxle has a malfunction and stores the corresponding DTC.

•When a malfunction is detected, stored DTCs can be retrieved using the WDS connected to the DLC-2.

9

87

5

4

3

1

2

10

17

15

1614

13

1112

6

A6E5714W023

1TCM

2 OBD system

3 Memory function

4 Failure indication function

5 Serial communication

6 Failure detection function

7 PID data monitoring function

8 Simulation function

9 Fail-safe function10 Transaxle control system

11 Input devices

12 Output devices

13 Instrument cluster

14 PCM

15 AT warning light

16 DLC-2

17 WDS or equivalent

Page 480 of 909

AUTOMATIC TRANSAXLE

K2–65

K2

Memory Function

•The memory function stores failure information detected in the failure detection function. Once failure

information is stored, the memory will not be cleared even when the ignition switch is turned off (LOCK

position) or the malfunction is repaired.

•The stored memory (failure information) can be cleared by using the WDS or disconnecting the negative

battery cable.

Failure Indication Function

•The failure indication function illuminates the AT warning lights when the failure detection function determines

there is a malfunction.

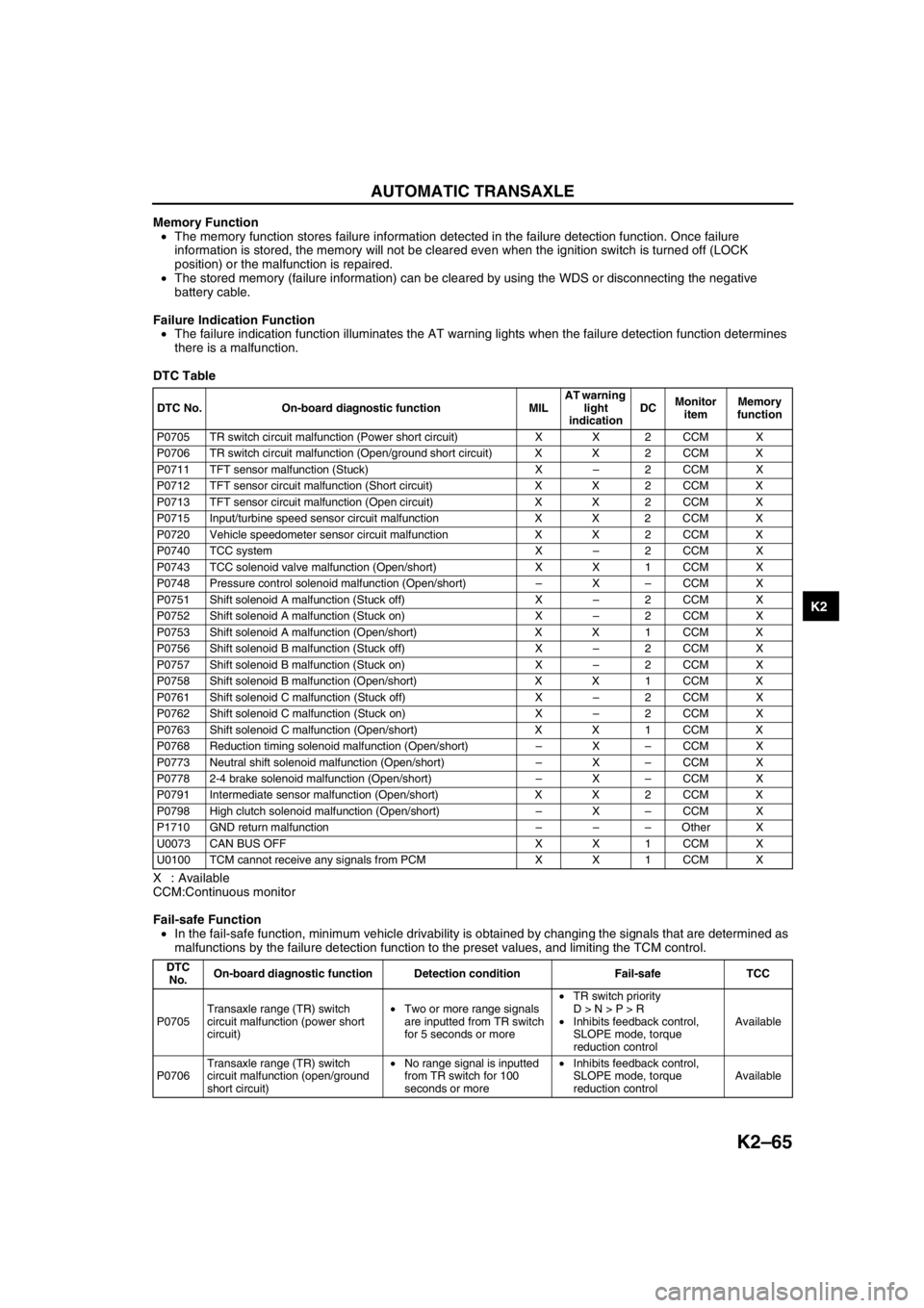

DTC Table

X : Available

CCM:Continuous monitor

Fail-safe Function

•In the fail-safe function, minimum vehicle drivability is obtained by changing the signals that are determined as

malfunctions by the failure detection function to the preset values, and limiting the TCM control.

DTC No. On-board diagnostic function MILAT warning

light

indicationDCMonitor

itemMemory

function

P0705 TR switch circuit malfunction (Power short circuit) X X 2 CCM X

P0706 TR switch circuit malfunction (Open/ground short circuit) X X 2 CCM X

P0711 TFT sensor malfunction (Stuck) X–2 CCM X

P0712 TFT sensor circuit malfunction (Short circuit) X X 2 CCM X

P0713 TFT sensor circuit malfunction (Open circuit) X X 2 CCM X

P0715 Input/turbine speed sensor circuit malfunction X X 2 CCM X

P0720 Vehicle speedometer sensor circuit malfunction X X 2 CCM X

P0740 TCC system X–2 CCM X

P0743 TCC solenoid valve malfunction (Open/short) X X 1 CCM X

P0748 Pressure control solenoid malfunction (Open/short)–X–CCM X

P0751 Shift solenoid A malfunction (Stuck off) X–2 CCM X

P0752 Shift solenoid A malfunction (Stuck on) X–2 CCM X

P0753 Shift solenoid A malfunction (Open/short) X X 1 CCM X

P0756 Shift solenoid B malfunction (Stuck off) X–2 CCM X

P0757 Shift solenoid B malfunction (Stuck on) X–2 CCM X

P0758 Shift solenoid B malfunction (Open/short) X X 1 CCM X

P0761 Shift solenoid C malfunction (Stuck off) X–2 CCM X

P0762 Shift solenoid C malfunction (Stuck on) X–2 CCM X

P0763 Shift solenoid C malfunction (Open/short) X X 1 CCM X

P0768 Reduction timing solenoid malfunction (Open/short)–X–CCM X

P0773 Neutral shift solenoid malfunction (Open/short)–X–CCM X

P0778 2-4 brake solenoid malfunction (Open/short)–X–CCM X

P0791 Intermediate sensor malfunction (Open/short) X X 2 CCM X

P0798 High clutch solenoid malfunction (Open/short)–X–CCM X

P1710 GND return malfunction–––Other X

U0073 CAN BUS OFF X X 1 CCM X

U0100 TCM cannot receive any signals from PCM X X 1 CCM X

DTC

No.On-board diagnostic function Detection condition Fail-safe TCC

P0705Transaxle range (TR) switch

circuit malfunction (power short

circuit)•Two or more range signals

are inputted from TR switch

for 5 seconds or more•TR switch priority

D > N > P > R

•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

P0706Transaxle range (TR) switch

circuit malfunction (open/ground

short circuit)•No range signal is inputted

from TR switch for 100

seconds or more•Inhibits feedback control,

SLOPE mode, torque

reduction controlAvailable

Page 886 of 909

ON-BOARD DIAGNOSTIC

U–22–1

U

U–22H EA TER AND A I R C O NDI T ION ER SYST EMS

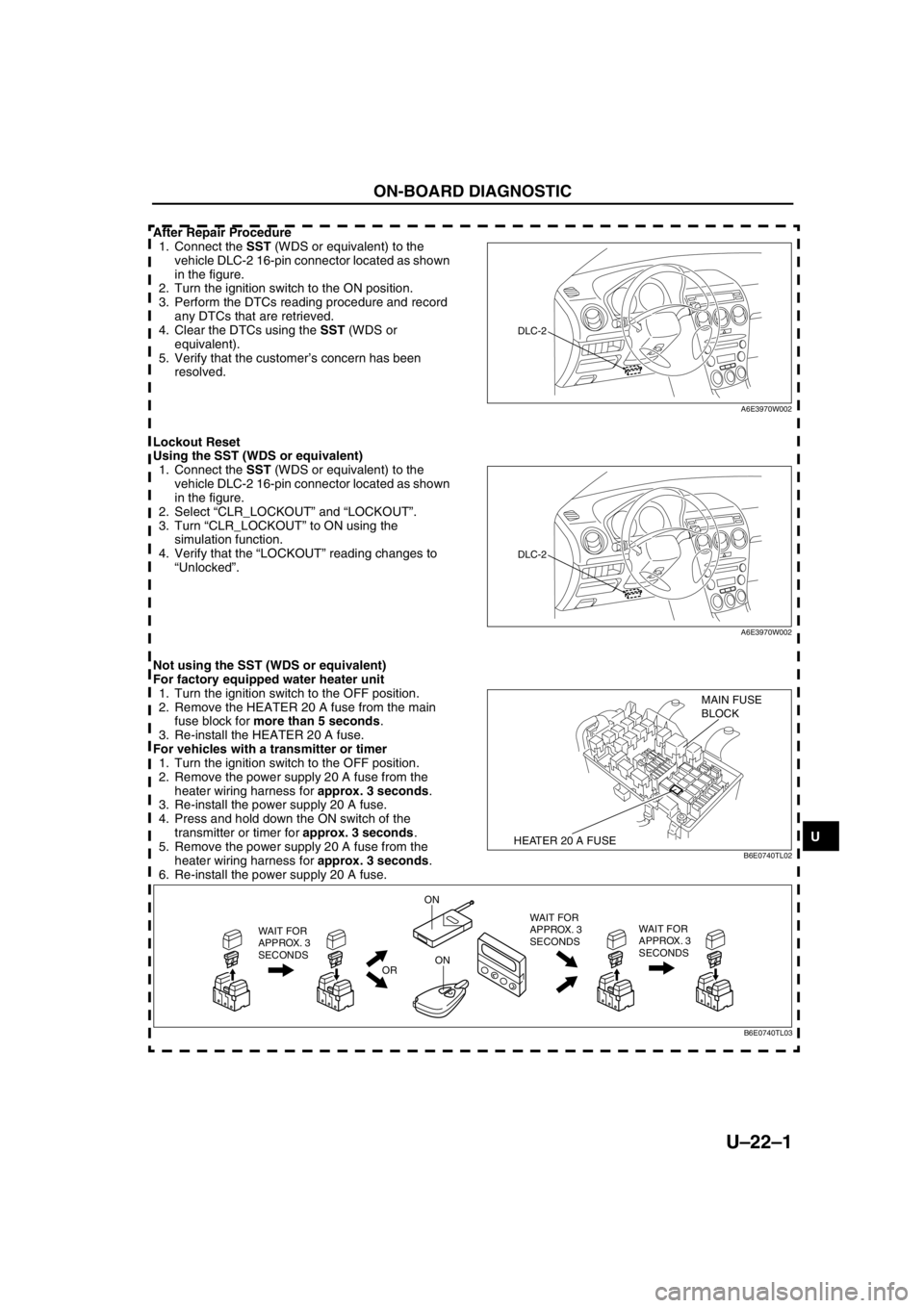

After Repair Procedure

1. Connect the SST (WDS or equivalent) to the

vehicle DLC-2 16-pin connector located as shown

in the figure.

2. Turn the ignition switch to the ON position.

3. Perform the DTCs reading procedure and record

any DTCs that are retrieved.

4. Clear the DTCs using the SST (WDS or

equivalent).

5. Verify that the customer’s concern has been

resolved.

Lockout Reset

Using the SST (WDS or equivalent)

1. Connect the SST (WDS or equivalent) to the

vehicle DLC-2 16-pin connector located as shown

in the figure.

2. Select “CLR_LOCKOUT” and “LOCKOUT”.

3. Turn “CLR_LOCKOUT” to ON using the

simulation function.

4. Verify that the “LOCKOUT” reading changes to

“Unlocked”.

Not using the SST (WDS or equivalent)

For factory equipped water heater unit

1. Turn the ignition switch to the OFF position.

2. Remove the HEATER 20 A fuse from the main

fuse block for more than 5 seconds.

3. Re-install the HEATER 20 A fuse.

For vehicles with a transmitter or timer

1. Turn the ignition switch to the OFF position.

2. Remove the power supply 20 A fuse from the

heater wiring harness for approx. 3 seconds.

3. Re-install the power supply 20 A fuse.

4. Press and hold down the ON switch of the

transmitter or timer for approx. 3 seconds.

5. Remove the power supply 20 A fuse from the

heater wiring harness for approx. 3 seconds.

6. Re-install the power supply 20 A fuse.

ON-BOARD DIAGNOSTIC

DLC-2

A6E3970W002

DLC-2

A6E3970W002

HEATER 20 A FUSE

MAIN FUSE

BLOCK

B6E0740TL02

WAIT FOR

APPROX. 3

SECONDS

OR

ON

ONWAIT FOR

APPROX. 3

SECONDS WAIT FOR

APPROX. 3

SECONDS

B6E0740TL03

Page 891 of 909

ON-BOARD DIAGNOSTIC

U–25

U

End Of Sie

DTC B2453, B2454A6E857001038208

Diagnostic procedure

End Of Sie

DTC B2548A6E857001038210

Diagnostic procedure

End Of Sie

4INSPECT WATER HEATER UNIT

•Clear the DTC.

•Perform the KOEO Self Test. (See U–22

KOEO Self Test/Combustion Test.)

•Is the same DTC present?Yes Replace the water heater unit.

(See U–15 WATER HEATER UNIT REMOVAL/

INSTALLATION)

No Go to the next step.

5VERIFY AFTER REPAIR PROCEDURE

•Perform after repair procedure. (See U–22–1

After Repair Procedure.)

•Are any DTCs present?Yes Go to the applicable DTC troubleshooting.

No Troubleshooting completed. STEP INSPECTION ACTION

DTCB2453 Blower fan circuit short to ground

B2454 Blower fan circuit open

DETECTION

CONDITION•CPU detects Malfunction in blower fan circuit

POSSIBLE

CAUSE•Water heater unit malfunction

ACTION

•Replace the water heater unit.

(See U–15 WATER HEATER UNIT REMOVAL/INSTALLATION)

DTC B2548 Water heater lockout mode

DETECTION

CONDITION•This DTC is stored if the water heater unit detects the same DTC three times and the water heater unit

then suspends system operation for safety reasons.

POSSIBLE

CAUSE•Water heater unit malfunction

•Fuel pump (water heater system) malfunction

•Generator malfunction

•Battery malfunction

•Open or short circuit in related harness

STEP INSPECTION ACTION

1INSPECT WATER HEATER UNIT

•Perform the lockout reset. (See U–22–1 Lockout

Reset.)

•Read DTCs using the SST (WDS or equivalent)

•Are any DTCs present?Yes Go to applicable DTC troubleshooting.

No Troubleshooting completed.