oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 232 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

76G01C-037

Apply engine oil

/

Cylinder head bolt

below head length

76G01C-038

(8) (4; D (5)

® ®

76G01C-039

3m-kg

(21.7ft-lb

Installation

Cylinder head

1. Throughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt and grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

6. Apply engine oil to the threads and the seat face

of the cylinder head bolts.

7. Tighten the cylinder head bolts.

(1) Tighten the bolts to the specified torque, in the

order shown in the figure.

Tightening torque:

29 N-m (3.0 m-kg, 22 ft-lb)

(2) Make paint marks on the bolt heads, as shown

in the figure.

(3) With the paint marks as a reference point, turn

the cylinder head bolts another 90°

(90°—105°) in the tightening direction. Tight-

en them in the order.

(4) Then tighten them once again 90°

(90°—105°) in the tightening order.

Caution

Be absolutely sure that the bolts are tightened

in the proper order.

76G01C-044

1C—20

Page 234 of 1865

1 C ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

76G01C-045

Gasket

Head cover Apply sealant

J

76G01C-046

76G01C-047

Timing marks

Timing marks

Timing

marks-

Injection pump pulley

1. Install the injection pump pulley with the semicir-

cular (woodruff) key to the injection pump shaft.

2. Rotate the injection pump pulley until the timing

marks are aligned.

3. Affix the injection pump pulley to the bracket us-

ing two bolts (35—40 mm, 1.4—1.6 in).

4. Tighten the lock nut.

Tightening torque:

59—69 Nm (6.0—7.0 m-kg, 43—51 ft-lb)

Cylinder head cover

1. Apply sealant to the shaded areas.

2. Install the cylinder head cover.

Tightening torque:

7—10

N

m (70—100 cm-kg, 61—87 in-lb)

3. Install the PCV hose.

Timing belt

1. Return the crankshaft about 45° to the timing mark

on the oil pump housing.

2. Check that the timing marks of the camshaft pul-

ley and the injection pump pulley align with the tim-

ing marks on the seal plate.

3. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE)

76G01C-048

1C-22

Page 236 of 1865

1 C ON-VEHICLE MAINTENANCE (VALVE SEAL)

VALVE SEAL

Removal

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01C-052

76G01C-053

1. Cylinder head cover 7. Tappet and adjusting disc

2. Timing belt (Refer to page 1C—11) 8. Valve keeper

3. Camshaft pulley 9. Upper valve spring seat

4. Rear camshaft pulley 10. Valve spring

5. Camshaft cap 11. Lower valve spring seat

6. Camshaft and oil seal 12. Valve seal

1C—24

Page 238 of 1865

1 C ON-VEHICLE MAINTENANCE (VALVE SEAL)

Valve seal

1. Plug the oil drain hole with a rag to prevent the posi-

bility of the valve keepers from falling into the oil

pan.

2. Turn the crankshaft to position the piston of the

valve seal to be replaced at top dead center.

3. Remove the valve keepers with the SST.

76G01C-057

4. Remove the valve spring and spring seats.

5. Remove the valve seal with the SST.

Caution

Do not turn the crankshaft while the valve

spring is removed. Replace the valve seals at

every cylinders.

76G01C-058

1C—26

Page 239 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 C

Installation

Install in the reverse order of removal referring to the installation note.

Torque Specifications

20—26 N-m (2.0—2.7 m-kg, 14—20 ft-lb)

N-m (5.6—6.6 m-kg, ft-lb)

55—65 N m (5.6—6.6 m-kg, 41—48 ft-lb)

76G01C-243

Installation note

Valve seal

1. Apply engine oil to the inside of the new valve seal.

2. Push it on gently with the SST.

86U01X-049

1C—27

Page 240 of 1865

1 C ON-VEHICLE MEINTENANCE (VALVE SEAL)

3. Install the spring seat, valve springs and valve

keepers with the SST.

76G01C-059

Tappet and adjusting disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

76G01C-060

Camshaft and camshaft cap

1. Move the No.1 piston to TDC, and then rotate

the crankshaft approximately 45°

76G01C-061

' Apply sealant

2. Apply engine oil to the camshaft and the journals.

3. Apply a coat of sealant to the shaded areas as

shown in the figure.

76G01C-062

1C-28

Page 241 of 1865

ON-VEHICLE MAINTENANCE (VALVE SEAL) 1 C

4. Set the camshaft and camshaft cap so that the key

groove faces directly upward.

And tighten the cap nuts loosely.

5. Apply a coat of engine oil to the new oil seal lip

and insert it.

76G01C-063

6. Tighten the camshaft cap nuts gradually and in the

order shown in the figure.

Tightening torque:

20—26 N-m (2.0—2.7 m-kg, 14—20 ft-lb)

76G01C-064

Camshaft pulley and rear camshaft pulley

Hold the camshaft with a wrench (29 mm, 1.14 in),

tighten the camshaft pulley and rear camshaft pul-

ley lock bolts.

Tightening torque:

55—65 N-m (5.6—6.6 m-kg, 41—48 ft-lb)

76G01C-066

1C—29

Page 242 of 1865

1 C ON-VEHICLE MAINTENANCE (VALVE SEAL)

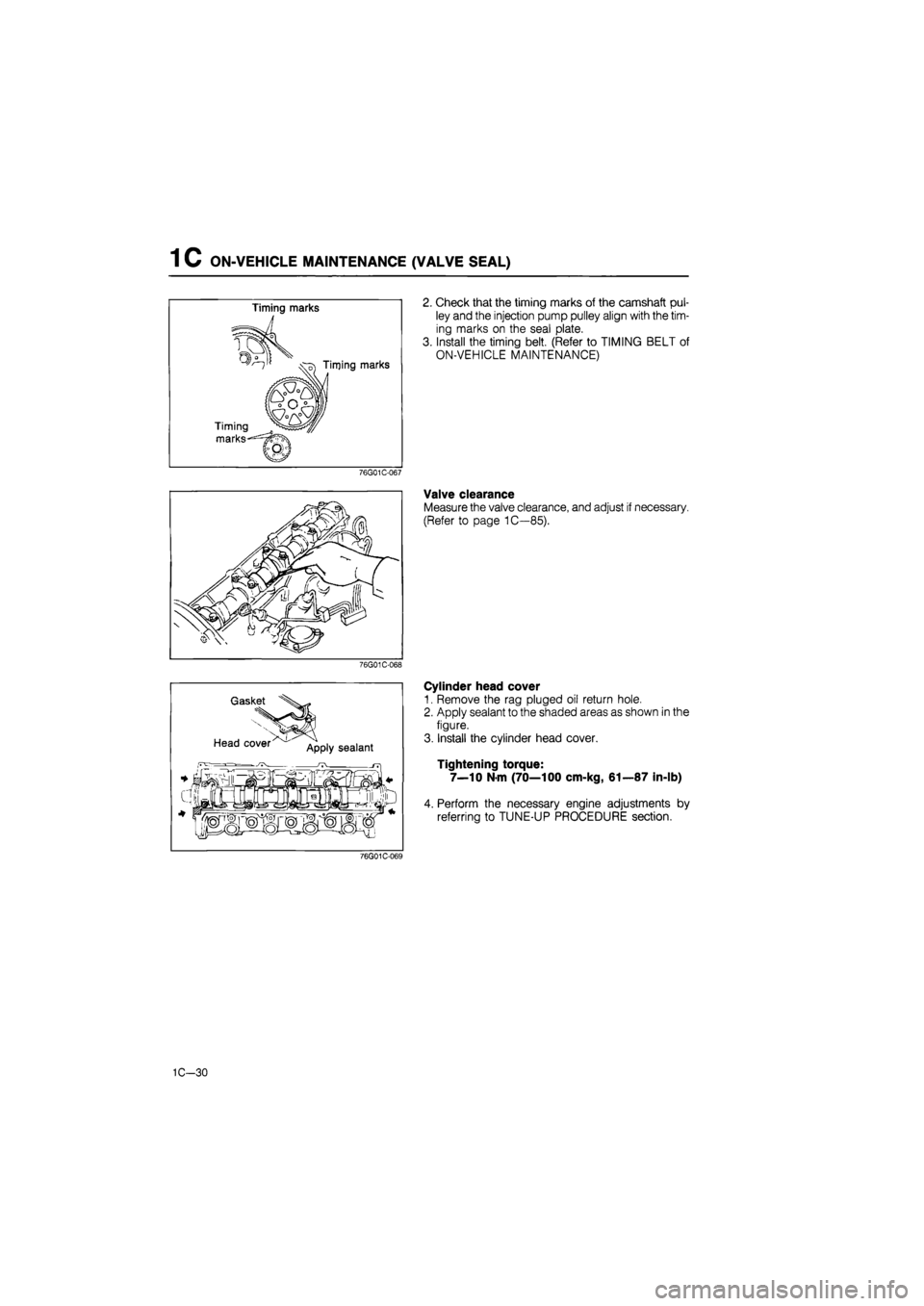

2. Check that the timing marks of the camshaft pul-

ley and the injection pump pulley align with the tim-

ing marks on the seal plate.

3. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE)

76G01C-067

Valve clearance

Measure the valve clearance, and adjust if necessary.

(Refer to page 1C—85).

76G01C-068

Gasket

Head cover App|y sealant

Cylinder head cover

1. Remove the rag pluged oil return hole.

2. Apply sealant to the shaded areas as shown in the

figure.

3. Install the cylinder head cover.

Tightening torque:

7—10 Nm (70—100 cm-kg, 61—87 in-lb)

4. Perform the necessary engine adjustments by

referring to TUNE-UP PROCEDURE section.

76G01C-069

1C-30

Page 243 of 1865

REMOVAL 1C

REMOVAL

1. Disconnect the negative battery cable.

2. Drain the engine oil and coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01C-071

1. Battery and battery carrier

2. Accelerator cable

3. Air cleaner assembly

4. Radiator harness

5. Radiator hose

6. Radiator and cooling fan

7. Brake vacuum hose

8. Intercooler pipe and hose*

9. Fuel hose

10. Drive belt cover

Note

11. P/S pump

12. No.4 engine mount

13. Clutch release cylinder

14. Speedometer cable

15. Transaxle harness

16. A/C compressor

17. Engine harness

18. Heater hose

19. Front wheel

20. Engine side cover

21. Tie-rod end

22. Stabilizer control rod

23. Lower arm bushing

24. Driveshaft

25. Change rod

26. Extension bar

27. Exhaust pipe and stay

28. Engine mount

29. Engine and transaxle

30. Transaxle

marked parts are equipped only for RF-CX.

1C-31

Page 247 of 1865

DISASSEMBLY (AUXILIARY PARTS) 1 C

1. A/C compressor bracket 9. Alternator and drive belt

2. Vacuum pump and drive belt 10. Oil filter

3. Air funnel assembly 11. Oil filter cover

4. Comprex supercharger insulator 12. Oil cooler assembly

5. Comprex supercharger and drive belt 13. Exhaust pipe bracket

6. Exhaust manifold insulator 14. Alternator bracket

7. Exhaust manifold 15. Blow-by chamber

8. Intake manifold

Blow-by chamber

76G01C-074

Disassembly Note

Engine hanger

1. Remove the CSD hose.

2. Loosen the vacuum pump oil pipe bolts.

76G01C-075

3. Install the engine on the SST.

76G01C-076

1C—35