check oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1008 of 1865

7B INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

1-2 accumulator small spring 11.0 (0.433) 88.1 (3.348) 1.4 (0.055) Gray

1-2 accumulator large spring 16.0 (0.630) 78.0 (3.071) 2.0 (0.079) Blue

Bypass, Servo control spring 5.0 (0.197) 33.4 (1.315) 0.55 (0.022) Maroon

2-3 timing spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

N-R accumulator rear spring 11.1 (0.437) 62.0 (2.441) 1.2 (0.047) Light green

N-D accumulator front spring 9.8 (0.386) 52.9 (2.083) 1.0 (0.039) Brown

Coasting bypass spring 5.8 (0.228) 37.7 (1.484) 0.6 (0.024) Dark blue

3-2 timing spring 8.2 (0.323) 28.6 (1.126) 0.8 (0.031) Red

3-2 capacity spring 5.4 (0.213) 30.6 (1.205) 0.5 (0.020) White

Throttle relief ball spring 6.6 (0.260) 21.6 (0.850) 0.8 (0.031)

—

76G07B-151

Assembly

1. Install the 3-2 capacity valve, 3-2 capacity spring,

and stopper plug; then install the stopper pin.

2. Install the 3-2 timing valve, the 3-2 timing spring,

and retainer.

86U07B-280

3. Install the coasting bypass plug, coasting bypass

valve and coasting bypass spring.

4. Apply ATF to the O-rings, and install them to the

piston; then insert the N-R accumulator rear spring

and N-R accumulator piston.

5. Apply ATF to the O-rings, and install them to the

piston; then insert the N-D accumulator piston and

N-D accumulator front spring.

76G07B-152

7B—142

Page 1011 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm (in)

Wire dia.

mm

(in) Spring color

Pressure modifier spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

Low reducing spring 8.7 (0.343) 38.3 (1.508) 0.9 (0.035) Black

1-2 shift spring 8.7 (0.343) 41.3 (1.626) 1.0 (0.039) Yellow

2-3, 3-4 shift spring 7.4 (0.291) 36.6 (1.441) 0.8 (0.031) Gray

Throttle backup spring 9.65 (0.380) 26.9 (1.059) 0.55 (0.022) Red

Throttle modulator spring 6.3 (0.248) 47.9 (1.886) 0.8 (0.031)

—

Throttle assist spring 5.15 (0.203) 32.3 (1.272) 0.55 (0.022) Dark green

Throttle spring 5.4 (0.213) 47.2 (1.858) 0.8 (0.031) Pink

Converter relief ball spring 6.9 (0.272) 24.1 (0.949) 0.9 (0.035) Maroon

Orifice check valve spring 5.0 (0.197) 12.5 (0.492) 0.23 (0.009)

—

76G07B-219

]

Assembly

1. Install the throttle adjust plug, throttle assist spring,

throttle valve, and throttle plug assembly.

86U07B-288

Caution

Install the throttle plug assembly with the

groove aligned with the bolt hole.

86U07B-289

7B-145

Page 1014 of 1865

7B INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

Pressure regulator spring 11.5 (0.453) 26.5 (1.043) 1.0 (0.039) Maroon

Lock-up control spring 5.0 (0.197) 35.2 (1.386) 0.6 (0.024) Purple

86U07B-295

Assembly

1. Install the lock-up control spring, lock-up control

valve, stopper plug, and stopper pin.

86U07B-296

Install the pressure regulator valve, pressure regu-

lator spring, pressure regulator spring seat, pres-

sure regulator plug, pressure regulator plug sleeve,

pressure regulator backup plug, stopper plug, and

stopper pin.

Note

Install the stopper plug larger end first.

86U07B-297

3. Install the manual valve.

86U07B-298

7B-148

Page 1025 of 1865

INSPECTION AND REPAIR 7B

13. Remove the orifice check valves (01.5 mm, 0.059

in) and springs, oil strainer, and rubber ball from

the main control body.

76G07B-164

7B-159

Page 1027 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm (in)

Wire dia.

mm

(in) Spring color

1-2 accumulator small spring F8 engine 9.9 (0.400) 84.7 (3.335) 1.2 (0.047) Red

1-2 accumulator large spring

FE engine 13.0 (0.512) 73.2 (2.881) 1.8 (0.071) Pink 1-2 accumulator large spring F8 engine 16.0 (0.630) 84.7 (3.335) 2.0 (0.079) White

Bypass spring 5.0 (0.197) 25.1 (0.988) 0.7 (0.028) Yellow

Servo control spring 4.9 (0.193) 27.1 (1.067) 0.5 (0.020) Light blue

2-3 timing spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

N-R accumulator rear spring 11.1 (0.437) 68.2 (2.685) 1.0 (0.039) Blue

N-D accumulator front spring 9.8 (0.386) 60.9 (2.398) 1.1 (0.043) Yellow

Low reducing spring 8.7 (0.343) 38.3 (1.508) 0.9 (0.035) Black

OD release spring 6.0 (0.236) 32.6 (1.283) 0.6 (0.024) Orange

Coasting bypass spring 5.8 (0.228) 31.3 (1.232) 0.6 (0.024) Yellow

3-2 timing spring 8.2 (0.323) 28.55 (1.124) 0.8 (0.031) Maroon

3-2 capacity spring 5.55 (0.219) 30.5 (1.201) 0.55 (0.022) Light green

Throttle relief ball spring 6.6 (0.260) 20.3 (0.799) 0.8 (0.031) Light green

76G07B-165

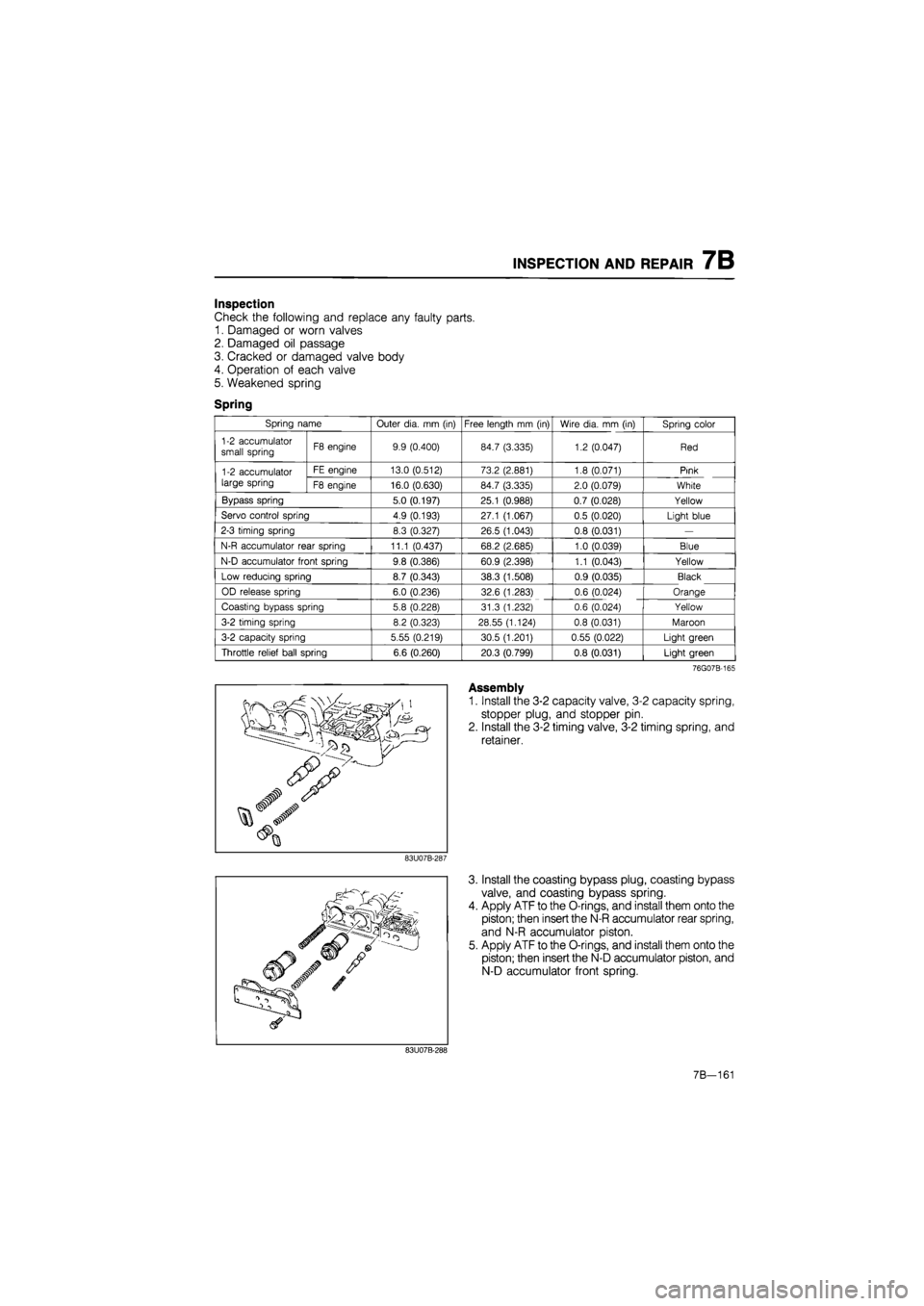

Assembly

1. Install the 3-2 capacity valve, 3-2 capacity spring,

stopper plug, and stopper pin.

2. Install the 3-2 timing valve, 3-2 timing spring, and

retainer.

83U07B-287

3. Install the coasting bypass plug, coasting bypass

valve, and coasting bypass spring.

4. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-R accumulator rear spring,

and N-R accumulator piston.

5. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-D accumulator piston, and

N-D accumulator front spring.

83U07B-288

7B—161

Page 1031 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

1-2 shift control spring 5.5 (0.217) 46.0 (1.811) 0.5 (0.020) Light green

1-2 shift spring 5.0 (0.197) 24.9 (0.980) 0.5 (0.020) Gray

2-3 shift spring 6.1 (0.240) 39.7 (1.563) 0.65 (0.026) Pink

3-4 shift spring 6.4 (0.252) 37.0 (1.457) 0.6 (0.024)

—

Throttle backup spring 6.4 (0.252) 33.5 (1.319) 0.6 (0.024) Pink

Throttle modulator front spring 5.0 (0.197) 27.8 (1.094) 0.6 (0.024) Red

Throttle modulator rear spring 7.15 (0.281) 30.8 (1.213) 0.85 (0.033) Red

1 rang control spring 6.15 (0.242) 39.2 (1.543) 0.65 (0.026) White

2 rang control spring 3.95 (0.156) 32.1 (1.264) 0.45 (0.018)

—

Kick-down spring 5.4 (0.213) 38.1 (1.500) 0.8 (0.031)

—

Throttle assist spring 5.15 (0.203) 32.3 (1.272) 0,55 (0.022) Dark green

Throttle spring 5.4 (0.213) 48.3 (1.902) 0.8 (0.031)

—

Converter relief ball spring 6.9 (0.272) 24.1 (0.949) 0.9 (0.035) Maroon

Orifice check valve spring 5.0 (0.197) 12.5 (0.492) 0.23 (0.009)

-

76G07B-220

Assembly

1. Install the throttle adjust plug, throttle assist spring,

throttle valve, throttle spring, and throttle plug as-

sembly.

83U07B-296

Caution

Install the throttle plug assembly with the

groove aligned with the bolt hole.

83U07B-297

7B—165

Page 1035 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm (in)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

Wire dia.

mm (in)

Spring color

Blue

Yellow

Red"

Pressure regulator spring 9.5 (0.374)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

Lock-up control spring 7,3 (0 287)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

Lock-up support spring 7.0 (0.276)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red" OD lock-up spring 7.1 (0.280) 66.5 (2.618)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

76G07B-166

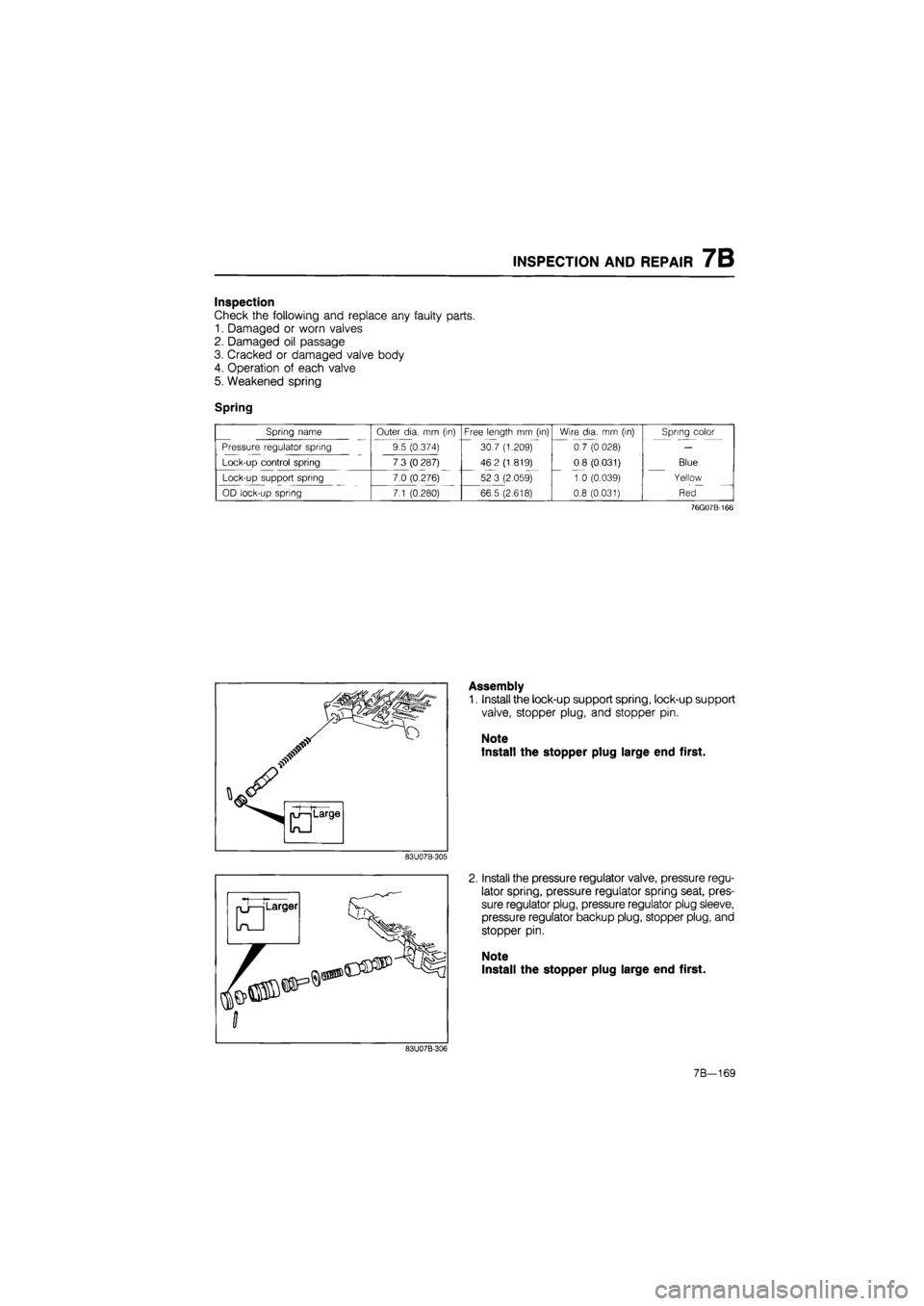

Assembly

1. Install the lock-up support spring, lock-up support

valve, stopper plug, and stopper pin.

Note

Install the stopper plug large end first.

83U07B-305

2. Install the pressure regulator valve, pressure regu-

lator spring, pressure regulator spring seat, pres-

sure regulator plug, pressure regulator plug sleeve,

pressure regulator backup plug, stopper plug, and

stopper pin.

Note

Install the stopper plug large end first.

83U07B-306

7B—169

Page 1038 of 1865

7B INSPECTION AND REPAIR

Oil strainer micuiici /^j in Orifice

5 mm (0.059 in)

Orifice 01.5 mm (0.059 in)

Rubber ball

3. Install the orifice check valves (01.5 mm, 0.059 in)

and springs, oil strainer, and rubber ball in the main

control body as shown.

76GQ7B-167

4. Install the rear control body to the main control

body.

83U07B-315

5. Loosely tighten the bolts.

Note

Match the bolt head letter as shown.

83U07B-316

Rubber ball

6. Turn the assembly over and install the rubber balls

in the main contrcl body as shown.

83U07B-317

7B-172

Page 1051 of 1865

INSPECTION AND REPAIR 7B

BEARING COVER ASSEMBLY

Disassembly

Disassemble in the sequence shown in the figure referring to the disassembly note for the specially

marked parts.

1. Oil seal

2. Bearing outer

race

3. O-ring

4. Bearing cover

86U07B-347

Disassembly note

Bearing outer race

Remove the bearing outer race with a pin punch and

hammer as shown.

Inspection

Check the following and replace any faulty parts.

1. Damaged bearing cover

2. Damaged or worn bushing

86U07B-348

Assembly

1. Press the bearing outer race into the cover.

2. Press the oil seal into the cover with the SST.

86U07B-349

7B—185

Page 1053 of 1865

ASSEMBLY 7B

ASSEMBLY

PRECAUTION

(1) The automatic transaxle consists of high-precision-finished parts, necessitating careful inspection

before assembly because even a small nick could cause fluid leakage or affect performance.

(2) Clean out oil holes and oil passages with compressed air, and check that there are no obstructions.

(3) Before assembly, apply ATF to each O-ring, seal ring, rotating part, and friction part.

(4) If the brake band or drive plates are replaced with new ones, first soak them in ATF for at least

2 hours before installing.

(5) Each seal gasket and O-ring must be replaced with a new one.

(6) Be sure to install all thrust bearings and races in the correct direction and position.

ASSEMBLY—STEP 1

Torque Specifications

83U07B-365

11—14 N-m (110—140 cm-kg, 95—122 in-lb) 6-9 N-m (60—90 cm-kg, 52—78 in-lb)

8—11 N-m (80—110 cm-kg, 69—95 In-lb)

19—26 N m (1.9—2.6 m-kg, 14—19 ft-lb)

83U07B-366

7B—187