check oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1190 of 1865

7C INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring 76go7c-2o2

Spring

Name Outer dia. mm (in) Free length mm (in) Wire dia. mm (in)

Throttle backup 7.3 (0.287) 36.0 (1.417) 0.8 (0.031)

Downshift 5.55 (0.219) 21.9 (0.862) 0.55 (0.022)

2-3 shift 6.9 (0.272) 41.0 (1.614) 0.7 (0.028)

1-2 shift 6.4 (0.252) 31.63 (1.245) 0.4 (0.016)

Second lock 5.55 (0.219) 33.5 (1.319) 0.55 (0.022)

Pressure regulator 11.7 (0.461) 43.0 (1.693) 1.2 (0.047)

Throttle relief 7.0 (0.276) 11.2 (0.441) 0.9 (0.035)

Orifice check 5.0 (0.197) 15.5 (0.610) 0.23 (0.009)

76G07C-203

Valve Location

63U07B-500

7C-76

Page 1192 of 1865

7C INSPECTION AND REPAIR

—® Orifice

76G07C-208

76G07C-209

76G07C-210

imru . ^P^l

o

o o o

13. Install the orifice check valve (<£2.0 mm (0.079 in))

in the upper body as shown.

14. Install the separator plate on the lower body, and

hold it with clips; then install them onto the upper

body.

15. Tighten the mounting bolts to the specified torque.

Tightening torque:

A: 2.5—3.4 N-m (25—35 cm-kg, 22—30 in-lb)

B: 5—7 N m (50—70 cm-kg, 43—61 in-lb)

16. Install the oil strainer.

Tightening torque:

3—4 Nm (30—40 cm-kg, 26—35 in-lb)

17. Turn the valve body assembly over, and install the

sub-body.

Tightening torque:

2.5—3.4 N-m (25—35 cm-kg, 22—30 in-lb)

18. Install the manual valve.

76G07C-211

7C-78

Page 1201 of 1865

INSPECTION AND REPAIR 7C

Disassembly note

Bearing outer race

Remove the bearing outer race with the SST.

Inspection

Check the following and replace any faulty parts.

1. Damaged bearing cover

2. Damaged or worn bushing

76G07C-223

Assembly

1. Press the bearing outer race into the cover.

2. Press the oil seal into the cover.

76G07C-224

BEARING HOUSING

Disassembly

Remove the bearing outer race with the SST.

Note

Install the bearing outer race during reassem-

bly of the transaxle to adjust the preload.

76G07C-225

Inspection

Check the following and replace any faulty parts.

1. Damaged bearing housing

2. Damaged bearing outer race

86U07B-351

7C-87

Page 1202 of 1865

7C INSPECTION AND REPAIR

SIDE BEARING HOUSING

Disassembly

Disassemble in the sequence shown in the figure, referring to the disassembly note for specially marked

part.

1. Oil seal

2. Bearing outer

race

3. Adjust shim

4. O-ring

5. Side bearing

housing cover

76G07C-226

76G07C-227

Disassembly note

Bearing outer race

Remove the bearing outer race with the SST.

Note

Install the bearing outer race during reassem-

bly of the transaxle to adjust the preload.

Inspection

Check the following and replace any faulty parts.

1. Damaged side bearing housing cover

2. Damaged or worn bushing

Assembly

1. Press the oil seal into the cover with the SST.

76G07C-228

7C-88

Page 1203 of 1865

ASSEMBLY 7C

ASSEMBLY

PRECAUTION

(1) The automatic transaxle consists of high-precision-finished parts, necessitating careful inspection

before assembly because even a small nick could cause fluid leakage or affect performance.

(2) Clean out oil holes and oil passages with compressed ajr, and check that there are no obstructions.

(3) Before assembly, apply ATF to each O-ring, seal ring, rotating part, and friction part.

(4) If the brake band or drive plates are replaced with new ones, soak them in ATF for at least 2 hours

before installing.

(5) Each seal gasket and O-ring must be replaced with a new one.

(6) Be sure to install all thrust bearings and races in the correct direction and position.

ASSEMBLY—STEP 1

Torque Specifications

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

76G07C-229

7C-89

Page 1226 of 1865

7C ASSEMBLY

7C-112

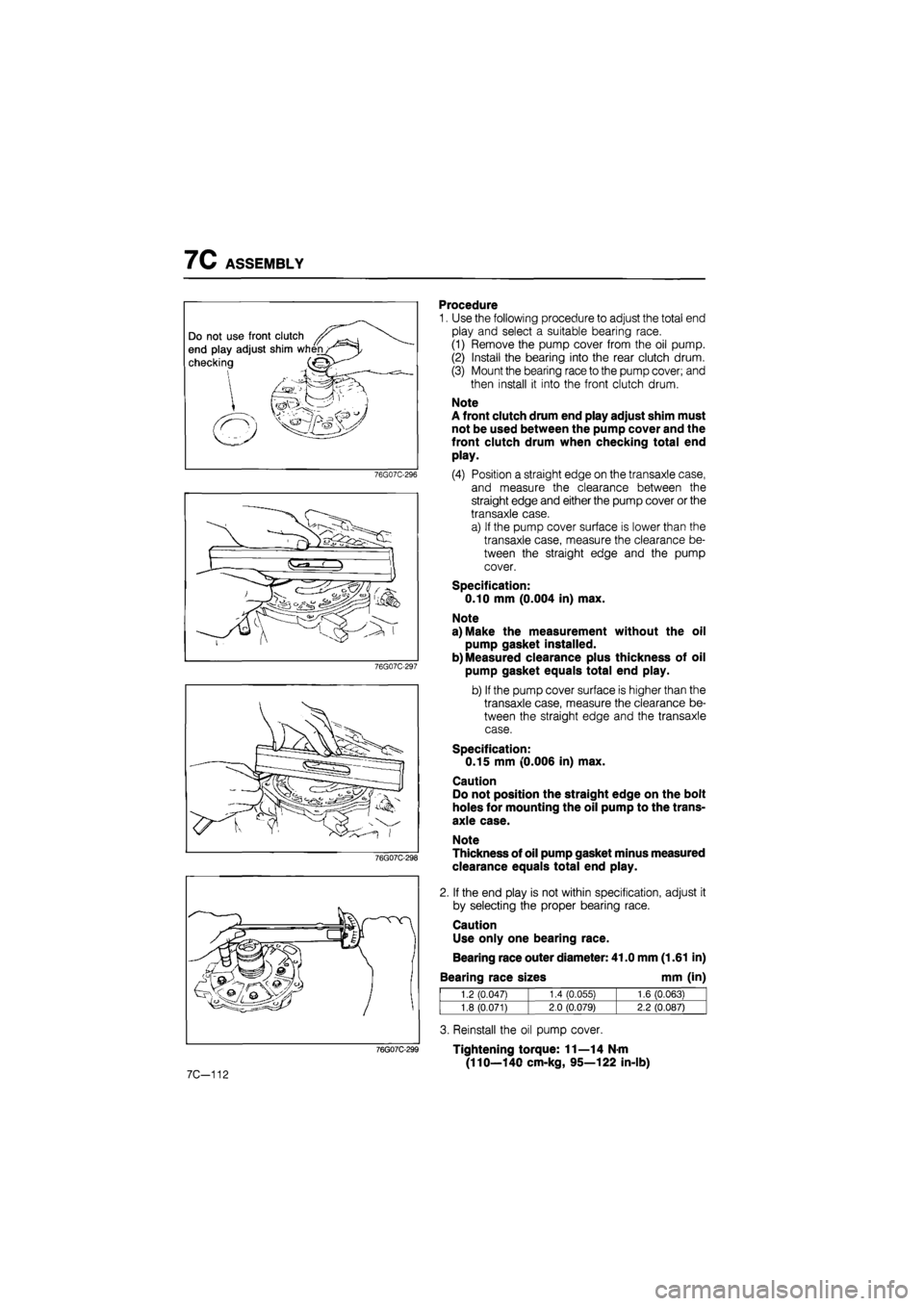

Procedure

1. Use the following procedure to adjust the total end

play and select a suitable bearing race.

(1) Remove the pump cover from the oil pump.

(2) Install the bearing into the rear clutch drum.

(3) Mount the bearing race to the pump cover; and

then install it into the front clutch drum.

Note

A front clutch drum end play adjust shim must

not be used between the pump cover and the

front clutch drum when checking total end

play.

(4) Position a straight edge on the transaxle case,

and measure the clearance between the

straight edge and either the pump cover or the

transaxle case.

a) If the pump cover surface is lower than the

transaxle case, measure the clearance be-

tween the straight edge and the pump

cover.

Specification:

0.10 mm (0.004 in) max.

Note

a) Make the measurement without the oil

pump gasket installed.

b) Measured clearance plus thickness of oil

pump gasket equals total end play.

b) If the pump cover surface is higher than the

transaxle case, measure the clearance be-

tween the straight edge and the transaxle

case.

Specification:

0.15 mm (0.006 in) max.

Caution

Do not position the straight edge on the bolt

holes for mounting the oil pump to the trans-

axle case.

Note

Thickness of oil pump gasket minus measured

clearance equals total end play.

2. If the end play is not within specification, adjust it

by selecting the proper bearing race.

Caution

Use only one bearing race.

Bearing race outer diameter: 41.0 mm (1.61 in)

Bearing race sizes mm (in)

1.2 (0.047) 1.4 CO.055) 1.6 (0.063)

1.8 (0.071) 2.0 (0.079) 2.2 (0.087)

3. Reinstall the oil pump cover.

Tightening torque: 11—14 N-m

(110—140 cm-kg, 95—122 in-lb)

Page 1228 of 1865

7C ASSEMBLY

76G07C-303

76G07C-304

76G07C-305

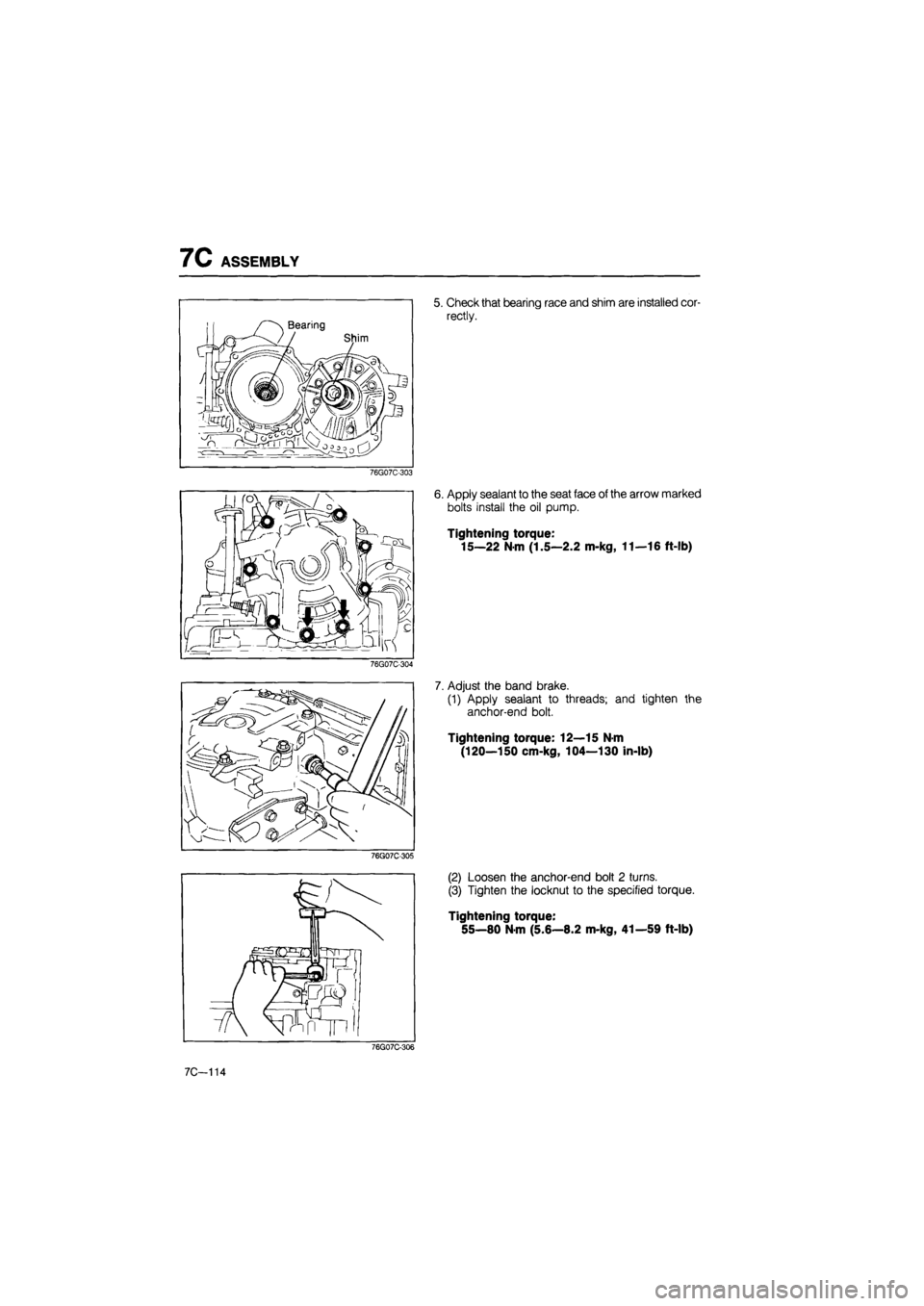

5. Check that bearing race and shim are installed cor-

rectly.

6. Apply sealant to the seat face of the arrow marked

bolts install the oil pump.

Tightening torque:

15—22 N m (1.5—2.2 m-kg, 11—16 ft-lb)

7. Adjust the band brake.

(1) Apply sealant to threads; and tighten the

anchor-end bolt.

Tightening torque: 12—15 N-m

(120—150 cm-kg, 104—130 in-lb)

(2) Loosen the anchor-end bolt 2 turns.

(3) Tighten the locknut to the specified torque.

Tightening torque:

55—80 N-m (5.6—8.2 m-kg, 41—59 ft-lb)

76G07C-306

7C-114

Page 1241 of 1865

HYDRAULIC CIRCUIT 7C

R RANGE

Band servo

Release side

Oil cooler

Low and reverse brake 1 pressure Vacuum diaphragm Kick-down solenoid Rear clutch pressure

Front clutch pressure

Downshift valve H Oil pump Vacuum throttle valve

Throttle backup valve

Orifice check valve

Modifier 15| valve

2-3 shift valve

Second lock valve

Orifice valve Pressure regulator valve

Line pressure t4s2

Operating line pressure

Governor pressure

Torque converter

Throttle pressure Secondary x governor valve Primary governor valve

76G07C-340

7C—127

Page 1242 of 1865

7C HYDRAULIC CIRCUIT

N RANGE

Oil cooler

Low and reverse brake •l pressure Vacuum diaphragm Kick-down solenoid

Rear clutch pressure

Front clutch pressure

Downshift valve 11 Oil pump Throttle backup valve

Vacuum throttle valve

x 18 Orifice YjI check valve H [ Throttle relief I valve

Modifier 15| valve Orifice check

I

valve

Orifice check valve 11 j! Pressure regulator valve

Line pressure

Governor pressure

Torque converter

Throttle pressure Primary governor valve Secondary x governor valve

76G07C-341

7C—128

Page 1243 of 1865

HYDRAULIC CIRCUIT 7C

D RANGE (1ST GEAR)

Band servo

Kick-down solenoid

Downshift valve Throttle backup valve

76G07C-342

Pressure regulator valve

Line pressure

Operating line pressure

Governor pressure

Torque converter

Throttle pressure

Orifice ch< valve

Secondary * Primary x governor valve governor valve

Vacuum | throttle valve

valve

Apply side

Release side

Low and reverse brake pressure

Rear clutch pressure

Vacuum diaphragm

Oil pump

Throttle relief valve

J Orifii check valve

Orifice check valve

Front clutch pressure

Modifier 1! valve

7C—129