sensor MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1685 of 1865

15 METER

Fuel transfer unit (only 4WS model)

1. Remove the fuel transfer unit referring to section 4.

2. Remove the connector from the fuel transfer unit.

3. Connect an ohmmeter between "b" and "d" ter-

minal of the connector.

4. Move the unit arm slowly from point (F) to point

(E), and read the resistance values.

5. If not as specified, replace the unit.

86U15X-044

iel tank unit (only 4WS model)

Remove the fuel tank unit.

Remove the connector from the fuel tank unit.

Connect an ohmmeter between "d" terminal of the

connector and fuel tank unit cover.

Move the unit arm slowly from point (F) to point

(E) and read the resistance values.

If not as specified, replace the unit.

86U15X-045

Water Thermo Sensor

1. Remove the sensor.

2. Place the sensor in water along with a ther-

mometer.

3. Heat the water gradually, and check the resistance

of the sensor with an ohmmeter.

4. If the resistance is not as specified, replace the

sensor.

Resistance: 49.3—57.7 Q at 80°C (176°F)

76G15X-089

15-30

Page 1694 of 1865

WARNING AND SENDER 15

Coolant Level Warning Light

OK

Repair harness (Meter

to

coolant level sensor).

76G15X093

INSPECTION

Brake Fluid Level Sensor

1. Check for continuity of the sensor with an

ohmmeter.

Float level Continuity

Below

min

Yes

Above

min

No

2. If continuity is not as specified, replace the sensor.

86U15X-065

86U14X-066

Parking Brake Switch

1. Check for continuity between (R) terminal and a

body ground with an ohmmeter.

Lever Continuity

Pulled one notch Yes

Released No

2. If continuity is not as specified, adjust the switch

or replace the switch.

15—39

Page 1695 of 1865

15 WARNING AND SENDER

86U15X-068

86U15X069

86U15X-070

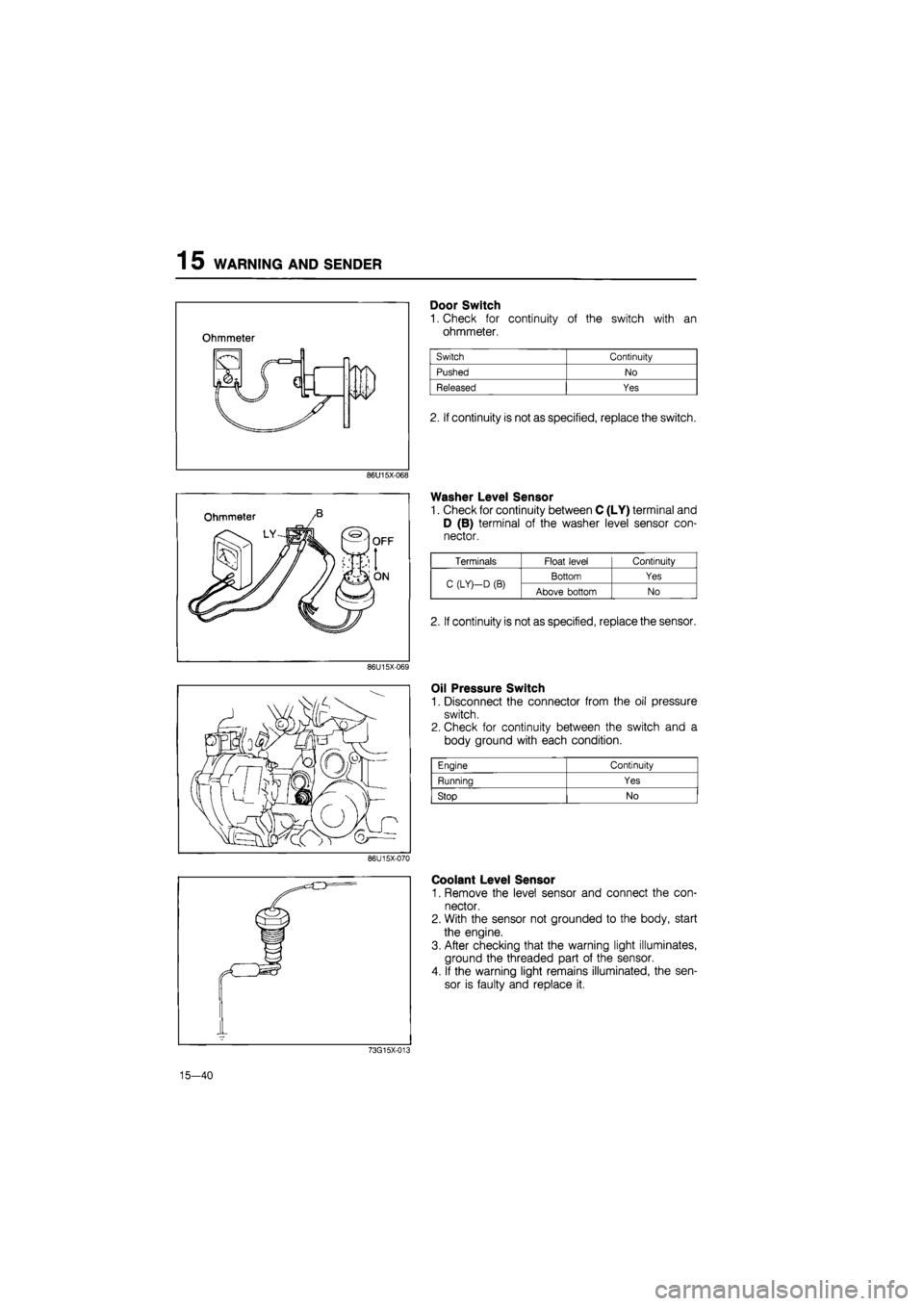

Door Switch

1. Check for continuity of the switch with an

ohmmeter.

2. If continuity is not as specified, replace the switch.

Washer Level Sensor

1. Check for continuity between C (LY) terminal and

D (B) terminal of the washer level sensor con-

nector.

Oil Pressure Switch

1. Disconnect the connector from the oil pressure

switch.

2. Check for continuity between the switch and a

body ground with each condition.

Coolant Level Sensor

1. Remove the level sensor and connect the con-

nector.

2. With the sensor not grounded to the body, start

the engine.

3. After checking that the warning light illuminates,

ground the threaded part of the sensor.

4. If the warning light remains illuminated, the sen-

sor is faulty and replace it.

73G15X-013

15—40

Engine Continuity

Running Yes

Stop No

Terminals Float level Continuity

C (LY)—D

(B)

Bottom Yes C (LY)—D

(B)

Above bottom No

2. If continuity is not as specified, replace the sensor.

Page 1739 of 1865

1 5 CRUISE CONTROL SYSTEM

ON-VEHICLE INSPECTION (USING ACC CHECKER 49 9200 010)

76G15X-072

Note:

When checking the actuator on '88 models with EC-AT using this checker, the checker

should be modified as shown below in order to avoid damage of the EC-AT control unit.

Modification Procedure

1. Cut the wire at terminal no.6 indicated on ACC

checker connector.

2. Tape exposed end of wire cut in step 1 as shown.

This modification does not affect the usage of the ACC

checker except when used on the '81 RX-7 and 626

models. When the modified ACC checker is used on

these models, use a jumper wire and jump across

terminal no.6 to 3 indicated on ACC checker connec-

tor as shown.

Function of the ACC CHECKER

A. Check lights

Each item is verified by a check light, as described below.

Check light Check items

MAIN SW.

Ignition switch, fuse, main switch and associated wiring harness terminals and con-

nectors.

ACTUATOR—VAC

VAC coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 2

VENT

2

coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 1

VENT

1

coil continuity

in

the actuator and associated harness.

CLUTCH/BRAKE SW.

Clutch switch (M/T vehicles only), brake switch and associated harness

COMBINATION/INH. SW.

"SET", "COAST" and "RESUME" positions

in

the combination switch, inhibitor

switch (A/T vehicles only), and associated harness.

GENERATOR

Speed sensor output and associated harness.

76U15X-193

15-84

Page 1742 of 1865

CRUISE CONTROL SYSTEM 1 5

CHECK LIGHTS (correct response)

ACTUATOR £

5 (O

W X

CHECK ITEMS AND CONDITIONS £ <0 z

VAC

CM I-1-z

Ul * < IE ffl X o V-

z o F < z ta

DC O 1-< DC Ui

TROUBLESHOOTING

(INCORRECT RESPONSE)

< S VAC UJ > < > -1 o o o UJ O

8. START THE ENGINE

• Shift lever to "N" position (A/T) O O O o X

A/T

O M/T X

O or X —

9. ACTUATOR OPERATION: (EGI model only) • After engine is started, set the slide switch "L" or "H". Then turn on check switch (keep in "D" position) Note: Engine speed should in-crease to 2,000—3,000 rpm. If over 4,000 rpm release the switch immediately.

o

X

1

o

X X X

A/T O M/T X

O or X

If engine speed does not come up to and remain

in

the

2,000

to

3,000

rpm. range, check the actuator and as-sociated harness.

10. SPEED SENSOR OUTPUT

Keeping idling condition, drive ve-

hicle slowly. o o 0 o X X 0 1 X

If GENERATOR LIGHT does not flash, trouble may be with speed sensor and associated harness.

76U15X-199

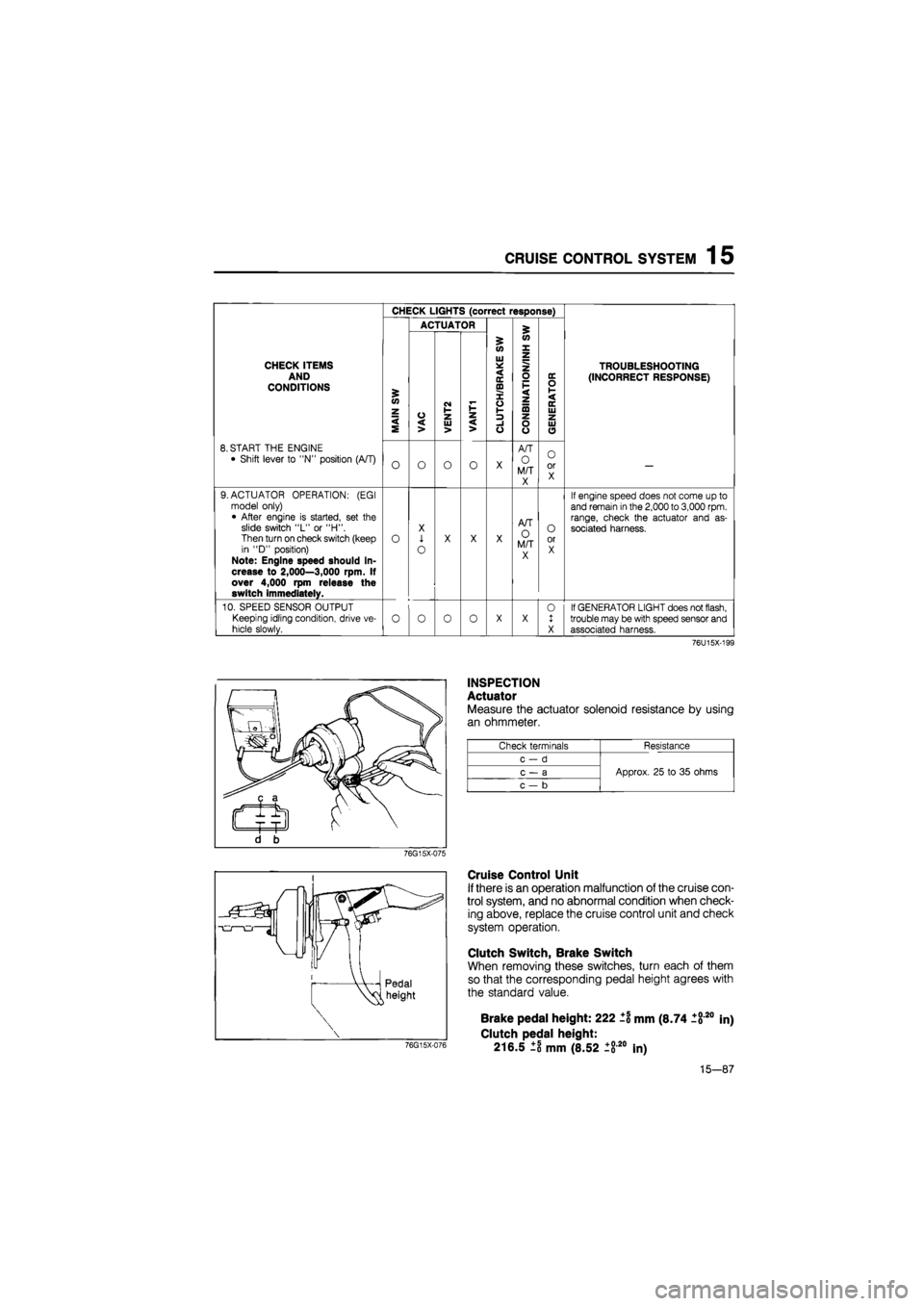

INSPECTION

Actuator

Measure the actuator solenoid resistance by using

an ohmmeter.

Check terminals Resistance

c-d

Approx. 25 to 35 ohms c — a Approx. 25 to 35 ohms

c — b

Approx. 25 to 35 ohms

76G15X-075

Cruise Control Unit

If there is an operation malfunction of the cruise con-

trol system, and no abnormal condition when check-

ing above, replace the cruise control unit and check

system operation.

Clutch Switch, Brake Switch

When removing these switches, turn each of them

so that the corresponding pedal height agrees with

the standard value.

76G15X-076

Brake pedal height: 222 ±1 mm (8.74 1820

Clutch pedal height:

216.5 ±8 mm (8.52 ±820 In)

in)

15-87

Page 1743 of 1865

1 5 CRUISE CONTROL SYSTEM

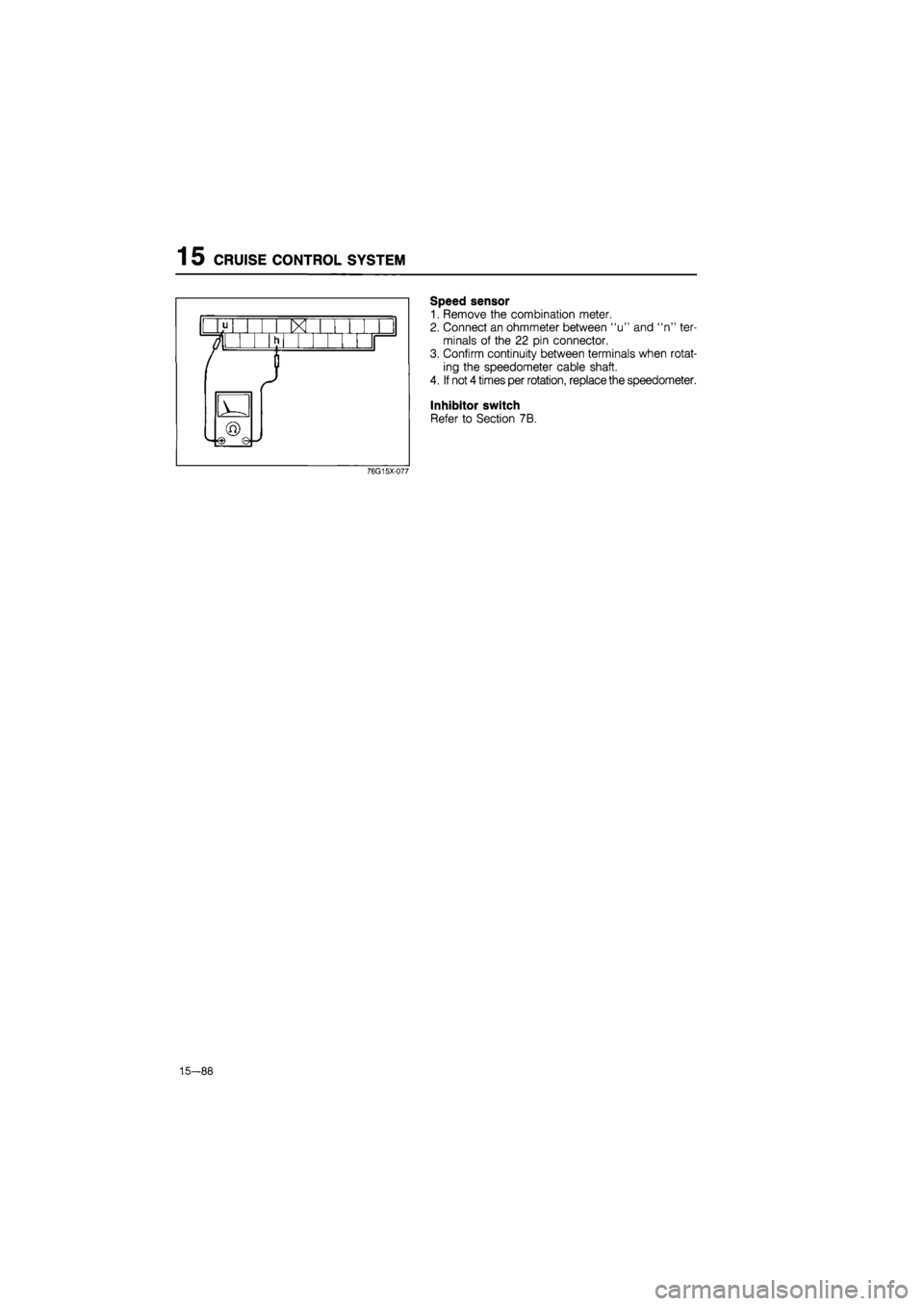

Speed sensor

1. Remove the combination meter.

2. Connect an ohmmeter between "u" and "n" ter-

minals of the 22 pin connector.

3. Confirm continuity between terminals when rotat-

ing the speedometer cable shaft.

4. If not 4 times per rotation, replace the speedometer.

Inhibitor switch

Refer to Section 7B.

76G15X-077

—88

Page 1749 of 1865

1 5 AUTO ADJUSTING SUSPENSION (AAS)

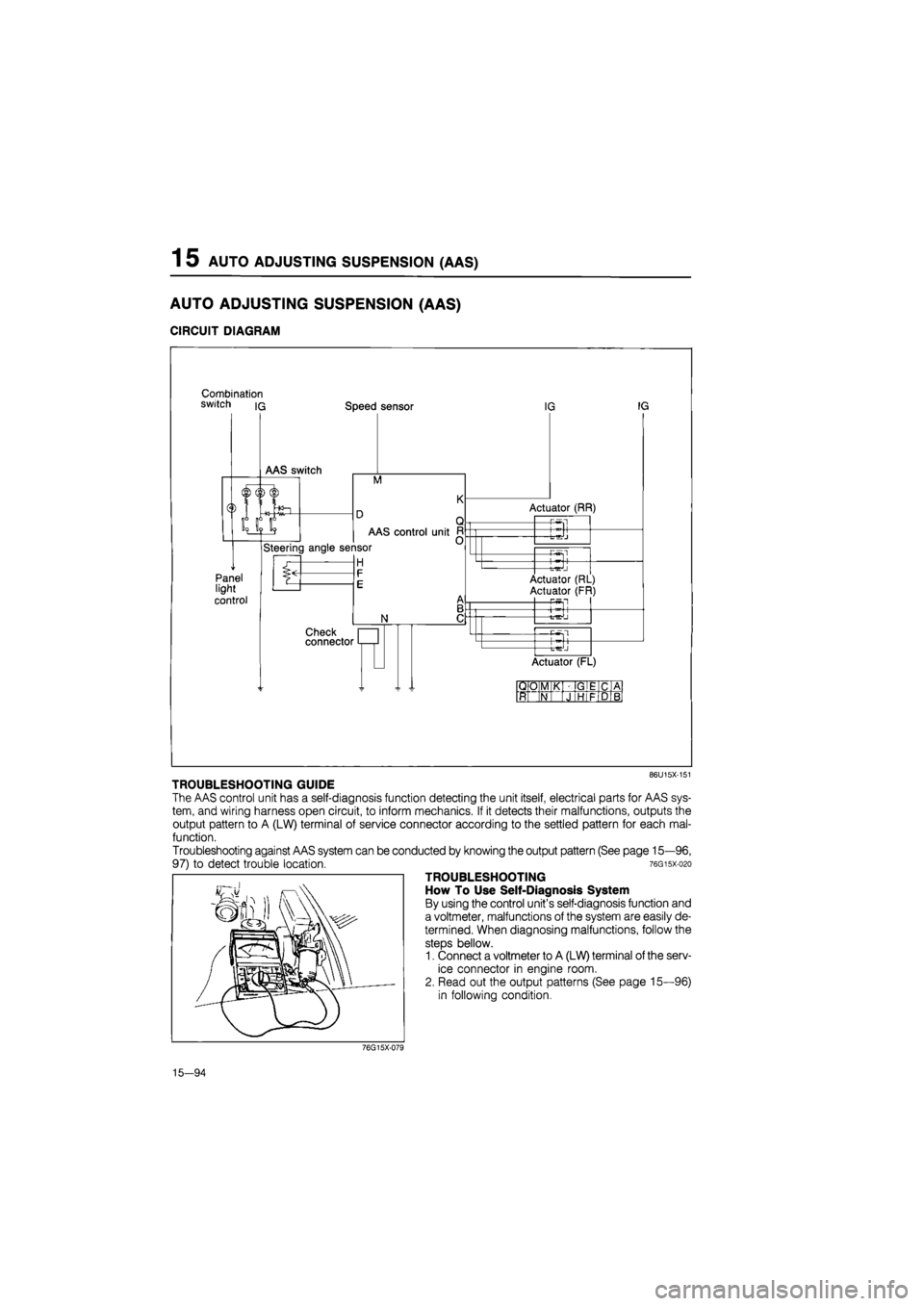

AUTO ADJUSTING SUSPENSION (AAS)

CIRCUIT DIAGRAM

Combination switch iq Speed sensor

M

Panel light

control

AAS control unit

Steering angle sensor

H

N

Check connector

IG IG

Actuator (RR)

-P-Sl

-t-^J

—Pwsl

Actuator (RL)

Actuator (FR) P5fl

+

Actuator (FL)

QO M K GIE C A

ft N J HI F D B

86U15X-151

TROUBLESHOOTING GUIDE

The AAS control unit has a self-diagnosis function detecting the unit itself, electrical parts for AAS sys-

tem, and wiring harness open circuit, to inform mechanics. If it detects their malfunctions, outputs the

output pattern to A (LW) terminal of service connector according to the settled pattern for each mal-

function.

Troubleshooting against AAS system can be conducted by knowing the output pattern (See page 15—96,

97) to detect trouble location. 76gisx-o2o

TROUBLESHOOTING

How To Use Self-Diagnosis System

By using the control unit's self-diagnosis function and

a voltmeter, malfunctions of the system are easily de-

termined. When diagnosing malfunctions, follow the

steps bellow.

1. Connect a voltmeter to A (LW) terminal of the serv-

ice connector in engine room.

2. Read out the output patterns (See page 15—96)

in following condition.

76G15X-079

15—94

Page 1751 of 1865

1 5 AUTO ADJUSTING SUSPENSION (AAS)

Condition Output pattern Malfunction Flow chart

No.

A

Set steering wheel

in

straight ahead position

0.5 sec

4.4V

n\/

2 sec

Vehicle speed sensor

or

wiring harness (Meter

—

Control unit)

AAS-1

Refer

to

page

15—98

A

Set steering wheel

in

straight ahead position

Vehicle speed sensor

or

wiring harness (Meter

—

Control unit)

AAS-1

Refer

to

page

15—98

A

Set steering wheel

in

straight ahead position

0.5 secO.!

4.4V

nv

i sec

2

sec

— <—i i— -

Steering wheel angle sen-

sor

or

wiring harness (An-

gle sensor

—

Control unit)

AAS-2

Refer

to

page

15-98

A

Set steering wheel

in

straight ahead position

-

Steering wheel angle sen-

sor

or

wiring harness (An-

gle sensor

—

Control unit)

AAS-2

Refer

to

page

15-98

A

Set steering wheel

in

straight ahead position

nv

Normal operation or wiring

harness (Fuse box

—

Con-

trol unit, control unit

—

Body ground)

AAS-3

Refer

to

page

15-99

A

Set steering wheel

in

straight ahead position

Normal operation or wiring

harness (Fuse box

—

Con-

trol unit, control unit

—

Body ground)

AAS-3

Refer

to

page

15-99

B

Turn the steering wheel

right and left

0.5 sec

4.4V

n\/

2 sec

—

Vehicle speed sensor

or

wiring harness (Meter

—

Control unit)

AAS-1

Refer

to

page

15-98

B

Turn the steering wheel

right and left

Vehicle speed sensor

or

wiring harness (Meter

—

Control unit)

AAS-1

Refer

to

page

15-98

B

Turn the steering wheel

right and left

0.5 sec 0

4.4V""-

.5 se c 2 se

-

Normal operation

—

B

Turn the steering wheel

right and left Normal operation

—

B

Turn the steering wheel

right and left

ov

Wiring harness (Fuse box

— Control unit, Control unit

— Body ground) See page

AAS-4

Refer

to

page

15—99

B

Turn the steering wheel

right and left

Wiring harness (Fuse box

— Control unit, Control unit

— Body ground) See page

AAS-4

Refer

to

page

15—99

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

0.5 sec

4.4V-""

_

n

Normal operation

—

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

Normal operation

—

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

0.5 sec 0

4.4V

nv

.5 se c

—

2 se

C

i—1 i—i

Front actuators

or

wiring

harness (Control unit

—

Front right

or

left actuator

AAS-5

Refer

to

page

15-100

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

Front actuators

or

wiring

harness (Control unit

—

Front right

or

left actuator

AAS-5

Refer

to

page

15-100

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

0.5 sec 0

4.4V*-

n\/

.5 se c

— r— —

2 sec

—1

Rear actuators

or

wiring

harness (Control unit

—

Rear right

or

left actuator

AAS-6

Refer

to

page

15-101

C

Change the switch from

NORMAL to SPORT

or

from SPORT

to

NORMAL

Rear actuators

or

wiring

harness (Control unit

—

Rear right

or

left actuator

AAS-6

Refer

to

page

15-101

15-96

Page 1752 of 1865

AUTO ADJUSTING SUSPENSION (AAS) 1 5

C

(Cont'd)

Operate

the

vehicle

at

above

15 km/h (9.3

mph) on

a

chassis roller

OV-

4.4V

0V-

4.4V

OV-

OV

AAS switch

or

wiring har-

ness (Fuse box

—

Control

box and AAS switch, AAS

switch

—

Control box and

Body ground)

Normal operation

Speed sensor

or

Steering

wheel angle sensor

or

wir-

ing harness (Control unit

—

Meter, Control unit

—

An-

gle sensor)

Speed sensor

or

Wiring

harness (Control unit

—

Meter, Fuse box

—

Control

unit, Control unit

—

Body

ground)

76G15X-080

15-97

Page 1753 of 1865

1 5 AUTO ADJUSTING SUSPENSION

Inspection of circuit

OK

Check

for

continuity between

1U

(GR) terminal

of

the meter connector and

M

(GR) terminal

of

the control unit connector.

Repair the wiring harness (Control unit

to

Meter).

OK

Replace the control unit.

76G15X-081

AAS-2

Failure

of

steering wheel angle sensor

or wiring harness (Angle sensor

—

Control unit)

I

Disconnect the control unit connector, and check

the

resistance between the terminals with

an

ohmmeter

when steering wheel

in

straight ahead position.

Terminal Resistance

A(G)

-

D(GW) ADDrox.

25 kfi

A(G)

-

C(GY) Approx.

50 kfl

C(GY^

-

D(G\M ADorox.

25 kfi

OK

Replace the control unit.

76G15X-082

15-98