change time MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 15 of 1865

For ECE Leaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust : Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

F8 engine with carbretor, MTX, ATX

FE engine with carbretor, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operatie under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

>

Z H m >

o m

H >

CD r-m

o m

m O m

(D o> Q. ® a

(Q 0) <0 o

m a

o m

c/> o x m a

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation.

It is strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

m a

m z >

z o m

G)

Page 21 of 1865

r

For ECE Unleaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust: Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

FE engine with fuel injection, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

FE engine with carburetor, MTX, ATX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the brake fluid

should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It is

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

>

Z H m z >

o m

H >

DJ r~ m

m o m

c 3

(/> O X m o c i-m

o

m z >

z o m

CD

Page 852 of 1865

7A ASSEMBLY

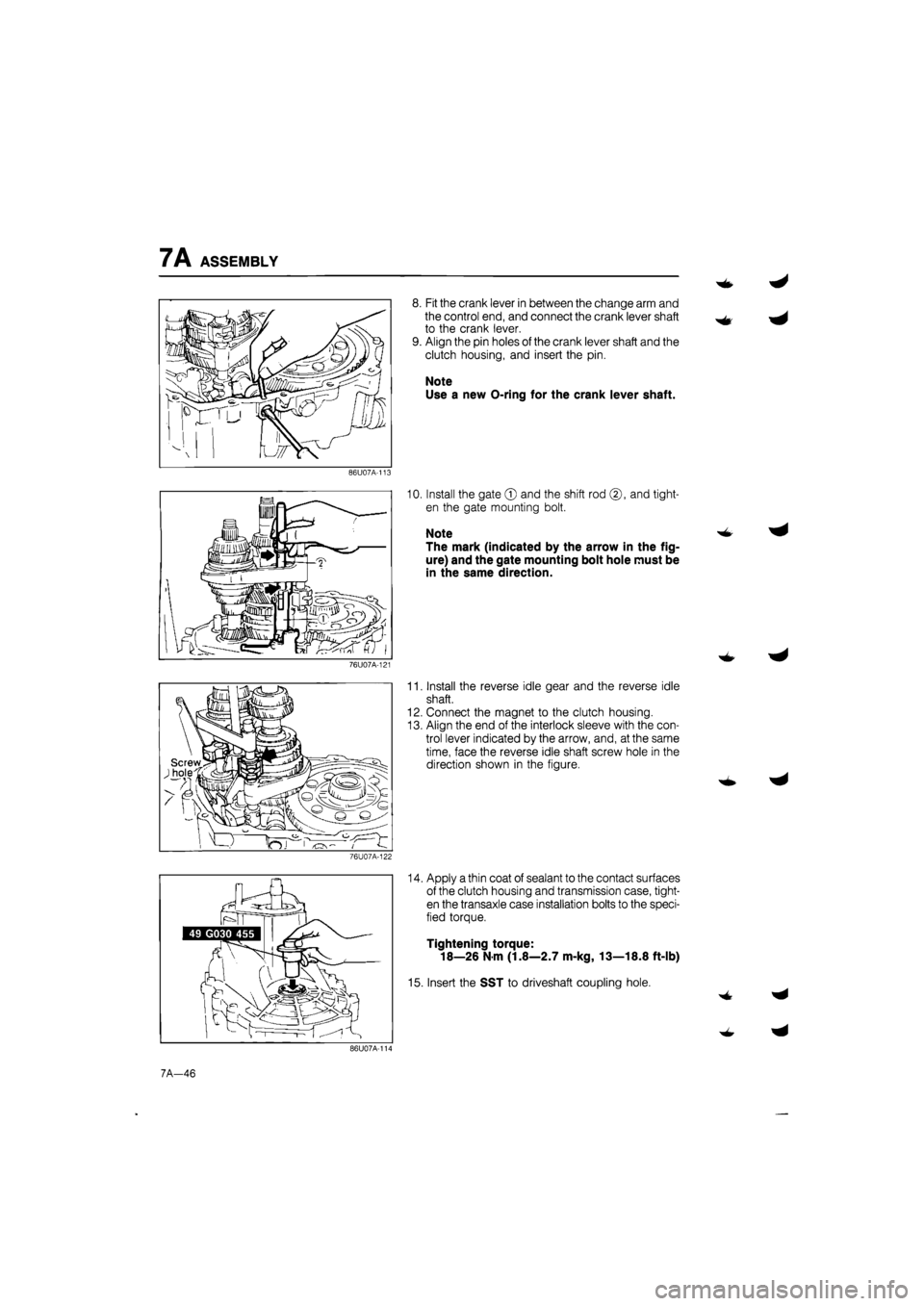

8. Fit the crank lever in between the change arm and

the control end, and connect the crank lever shaft

to the crank lever.

9. Align the pin holes of the crank lever shaft and the

clutch housing, and insert the pin.

Note

Use a new O-ring for the crank lever shaft.

86U07A-113

10. Install the gate © and the shift rod ©, and tight-

en the gate mounting bolt.

Note

The mark (indicated by the arrow in the fig-

ure) and the gate mounting bolt hole must be

in the same direction.

76U07A-121

11. Install the reverse idle gear and the reverse idle

shaft.

12. Connect the magnet to the clutch housing.

13. Align the end of the interlock sleeve with the con-

trol lever indicated by the arrow, and, at the same

time, face the reverse idle shaft screw hole in the

direction shown in the figure.

76U07A-122

14. Apply a thin coat of sealant to the contact surfaces

of the clutch housing and transmission case, tight-

en the transaxle case installation bolts to the speci-

fied torque.

Tightening torque:

18—26 N m (1.8—2.7 m-kg, 13—18.8 ft-lb)

15. Insert the SST to driveshaft coupling hole.

7A-46

Page 1419 of 1865

POWER BRAKE UNIT 1 1

86U11X-038

0

o

X

\ V^ Third

Second

^ First

86U11X-039

O X

fiSy

V

86U11X-040

Pedal-depression Pre!tur!9au9e

force gauge

^Intake manifold

86U11X-041

POWER BRAKE UNIT

FUNCTION CHECK

Simple Method

First step

1. With the engine stopped, depress the pedal a few

times.

2. With the pedal depressed, start the engine

3. If immediately after the engine starts the pedal

moves down slightly, the unit is operating.

Second step

1. Start the engine.

2. Stop the engine after it has run for

1

or 2 minutes.

3. Depress the pedal with the usual force.

4.

If

the first pedal stroke is long and becomes short-

er with subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the

check valve or vacuum hose, and examine the in-

stallation condition. Repair if necessary, and inspect

it once again.

Third step

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal still depressed.

4. Hold the pedal down for about 30 seconds.

5. If the pedal height does not change, the unit is

operating.

6. If there is a problem, check for damage to the

check valve or vacuum hose, and check the con-

nection. Repair if necessary, and check once

again.

If the nature of the problem is still not clear after fol-

lowing the 3 steps above, follow the more detailed

check described in "Method using tester".

Method Using Tester

Connect a pressure gauge, vacuum gauge, and ped-

al depression force gauge as shown in the figure. Af-

ter bleeding the air from the pressure gauge, conduct

the test as described in the 3 steps below.

Note

Use commercially available gauges and ped-

al depression force gauge.

11—27