ignition MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1675 of 1865

15 CLUSTER SWITCH

86U15X-020

86U15X-021

A itt

TTTT h f

from f IG SW

from 9

def. relay

•>o-15 min. timer _To ground

86U15X-022

INSPECTION OF FOUR SWITCH TYPE

Hazard switch

1. Check for continuity between terminals of the

switch.

Position a b

C

d

OFF O— —0

ON

pi Pi Pl

ON

u

O O:

Indicates continuity

2. If continuity is not as specified, replace the switch.

Defroster switch

1. Turn the ignition switch ON.

2. Check the light for lighting.

3. If the light doesn't light, replace the light.

4. Check that the switch goes off after 15 min from

switch on.

5. Check the voltage between each terminal and a

body ground.

Position Terminal voltage

(V)

Position

f g h

OFF

12 12 0

ON

12 0 0

6. If the voltage of terminal "g" is 12V with switch off

but not OV with switch on, replace the defroster

switch

If the voltage of terminal "g" is not 12V with switch

off, trouble is in defroster relay or harness.

If the voltage of terminal "f" and "h" is not cor-

rect, the trouble is in the other parts or harness.

Rear wiper and washer switch

1. Check for continuity between the terminals in each

position with an ohmmeter.

1———___Terminal Position

"——

a b d f h

Rear wiper switch OFF CK -0

—O Rear wiper switch ON

o--0

O-—O

Rear washer switch OFF Rear washer switch ON

o-

-O O-

—o

86U15X-023

O O:

Indicates continuity

2. If continuity is not as specified, replace the switch.

15—20

Page 1682 of 1865

![MAZDA 626 1987 Workshop Manual

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable ran MAZDA 626 1987 Workshop Manual

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable ran](/img/28/57059/w960_57059-1681.png)

METER 15

86U15X-033

86U15X-034

104.1t! 21

2330 16.10

a £] U \JEMP j n

JJ

86U15X-035

Standard indication

(km/h)

Allowable range

(km/h)

60 60-63

Standard indication

(mph)

Allowable range

(mph)

60 60-63

86U15X-036

3. Set the SST to the resistance values shown in the

figure.

4. Turn the ignition switch ON, and check that the

needle indicator displays the correct values.

If the needle displays correctly, check the gauge

unit. If not, replace the fuel gauge in the meter or

repair the wiring harness.

Caution

a) Continue the above checks for at least two

minutes each to correctly judge the con-

dition.

b)The allowable indication error is twice the

width of the needle.

Water Temperature Gauge

1. Disconnect the connector from the water thermo

sensor.

2. Connect the red lead of the SST to the connec-

tor, and the black lead to a body ground.

3. Set the SST to the resistance values shown in the

figure.

4. Turn the ignition switch ON, and check that the

needle indicator displays the correct values.

If the needle displays the correct values, the trou-

ble is in the gauge unit; if not, the trouble is in the

meter or the wiring harness.

Caution

a) Continue the above checks for at least two

minutes each to correctly judge the con-

dition.

b)The allowable indication error is twice the

width of the needle.

INSPECTION OF DIGITAL METER

Speedometer

1. Using a speedometer tester, check the speedom-

eter for allowable indication error, and check the

operation of the odometer. Replace the meter as-

sembly if necessary.

2. Check the speedometer for fluctuation and/or ab-

normal noise.

Caution

a) If significant fluctuation occurs or the

speedometer does not move at all, remove

the speedometer cable. If normal, replace

the digital meter assembly.

b)Tire wear and improper inflation will in-

crease speedometer error.

15—27

Page 1683 of 1865

15 METER

Standard Indication

(rpm)

Allowable range

(rpm)

1000

900—

950

2000 1900-1950

3000 2900—2950

4000 3900-3950

5000 4900—4950

6000 5900-5950

86U15X-037

86U15X-038

86U15X-039

Standard display Expanded display

E ©FUEL F E © FUEL F

"io — •

QJ1QOOODDOOOD

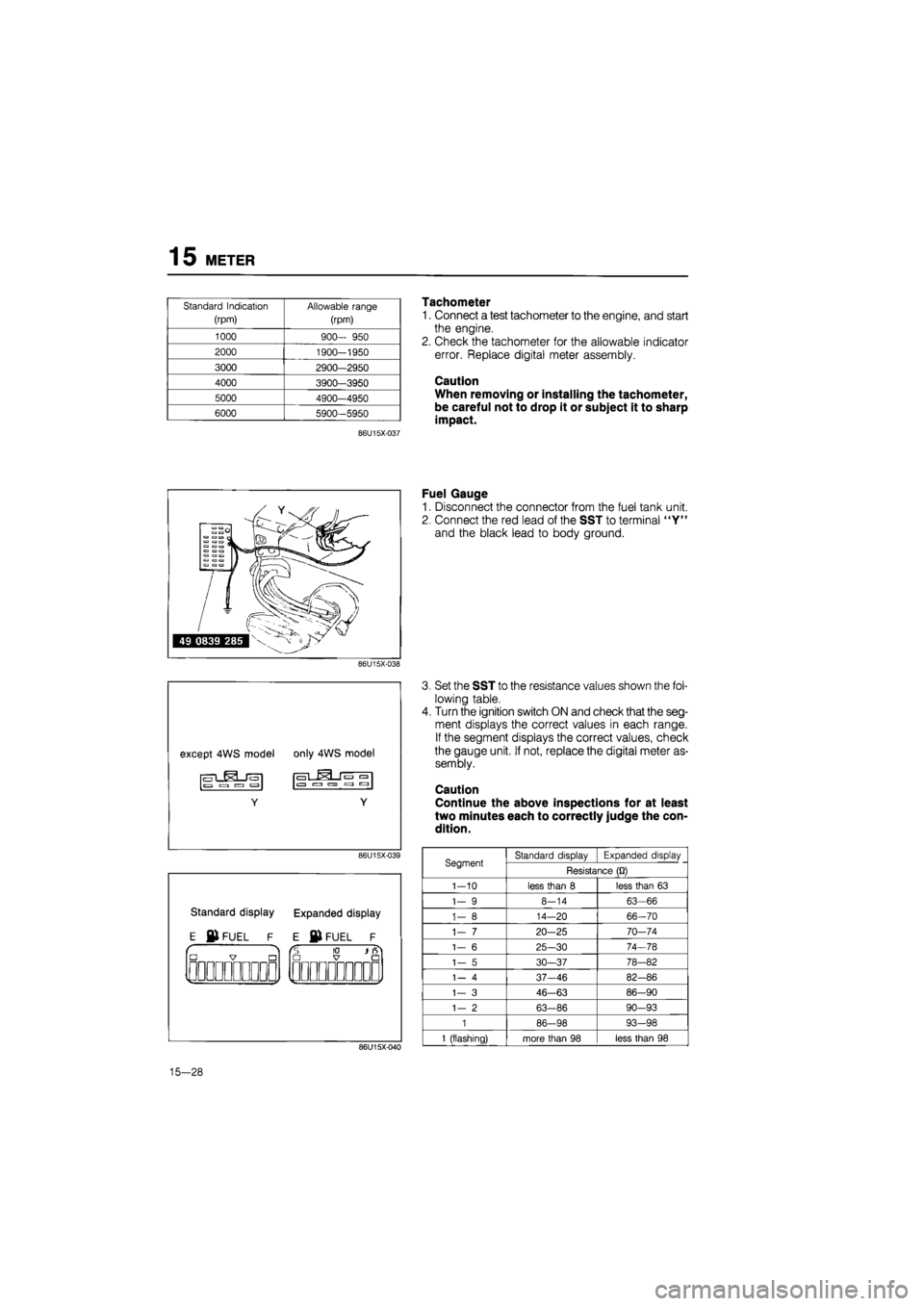

Tachometer

1. Connect a test tachometer to the engine, and start

the engine.

2. Check the tachometer for the allowable indicator

error. Replace digital meter assembly.

Caution

When removing or installing the tachometer,

be careful not to drop it or subject it to sharp

impact.

Fuel Gauge

1. Disconnect the connector from the fuel tank unit.

2. Connect the red lead of the SST to terminal "Y"

and the black lead to body ground.

86U15X-040

Set the SST to the resistance values shown the fol-

lowing table.

Turn the ignition switch ON and check that the seg-

ment displays the correct values in each range.

If the segment displays the correct values, check

the gauge unit. If not, replace the digital meter as-

sembly.

Caution

Continue the above inspections for at least

two minutes each to correctly judge the con-

dition.

Segment Standard display Expanded display Segment Resistance

(Q)

1-10

less than

8

less than

63

1-

9

8-14

63-66

1-

8

14—20 66-70

1-

7

20-25 70-74

1-

6

25-30 74-78

1-

5

30—37 78-82

1-

4

37-46 82-86

1—

3

46-63 86-90

1-

2

63-86 90-93

1

86-98 93-98

1

(flashing) more than

98

less than

98

15-28

Page 1684 of 1865

METER 15

Water Temperature Gauge

1. Remove the connector from the water thermo

sensor.

2. Connect the red lead of the SST to the connec-

tor, and the black lead to a body ground.

86U15X-041

C -&TEMP H

r

•

|

7 •

V i y

86U15X-042

3. Set the SST to the resistance values shown in the

following table.

4. Turn the ignition switch ON and check that the seg-

ment displays the correct values. If the segment

displays the correct values, check the gauge unit.

If not, replace the digital meter assembly or repair

wiring harness.

Caution

Continue the above checks for at least two

minutes each to correctly judge the condition.

Segment Resistance

(Q)

Segment Resistance

(Q)

1-10

less than

17

1-5

33-89

1-

9

17—20

1-4

89-120

1—

8

20—26

1-3

120-145

1—

7

26-28

1-2

145-177

1-

6

28-33

1

more than

177

INSPECTION OF METER SENDER

Fuel tank unit (except 4WS model)

1. Disconnect the connector from the fuel tank unit.

2. Remove the fuel tank unit from the tank.

3. Connect an ohmmeter to terminal "b" of con-

nector.

4. Move the unit arm slowly from point (F) to point

(E), and read the resistance values. If not as speci-

fied, replace the unit.

86U15X-043

15—29

Page 1693 of 1865

1 5 WARNING AND SENDER

Shift Indicator Light

All shift indicator lights do not Illuminate when ignition switch on. (other warning light are all right.)

Check the voltage

at BY

terminal

of

the inhibitor switch connector with ignition switch

on.

Terminal Voltage

BY 12V

NG

Repair the harness (Fuse box

to

inhibitor switch).

OK

Check the inhibitor switch. Refer

to

page 7B—65

NG

Replace the inhibitor switch. Check the inhibitor switch. Refer

to

page 7B—65 Replace the inhibitor switch.

OK

NG

Check the bulbs

of

the shift indicator lights.

NG

Replace the bulb.

OK

Turn the ignition switch on, and check the voltage

at

each terminal

of

the meter connector with each con-dition.

Terminal Selector lever Voltage

YL (2J) P 12V

RG (1L) R 12V

YR (2L) N 12V

Y(1V) D 12V

YB (1S) 2 12V

YW (1M) 1 12V

NG

Repair the harness (Inhibitor switch

to

meter).

76G15X-087

O/D OFF Indicator Light

OK

Repair the harness (O/D OFF switch

to

ground).

76G15X092

15-38

Page 1698 of 1865

CENTRAL PROCESSING UNIT (CPU) 1 5

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the CPU connectors.

3. Release the lock and remove the CPU from the

joint box.

4. Install in the reverse order of removal.

ON-VEHICLE INSPECTION

Note: Check the voltage between "a through

I" terminal and ground.

Check the continuity between "m,

n" terminal and ground.

86U15X-075

Terminal Connecting

to

Measurement condition Measurement value

a Interior light and courtesy lights Any time Approx.

12V

b Batterv Anv time Approx.

12V

c No used

— —

d Ground Anv time OV

e Seat belt warning light Ignition switch

ON

Approx.

12V

f Enaine control unit Enaine runnina Approx.

12V

g Key cylinder illumination light Any time Approx.

12V

i Key reminder switch Insert the key into the cylinder

Pull out the key from the cylinder

Approx.

12V

OV

j Ignition switch (ON) Ignition switch

ON

Ignition switch OFF

or

ACC

Approx.

12V

OV

k Ignition switch (ACC) Ignition switch

ON or

ACC

Ignition switch OFF

Approx.

12V

OV

I Light switch (In the combination switch) Turn the light switch ACC and

ON

Light switch OFF

Approx.

12V

OV

m Seat belt switch Seat belt fastened

Seat belt unfastered

OQ

OO

n Door switch Door closed

Door open

OO

on

76G15X-009

15—43

Page 1720 of 1865

POWER WINDOW 1 5

Power windows (except for driver's side) cannot be operated by main switch

Turn ignition switch

ON Note

Use only the main switch during the checking operation.

Check

for

12V

at

terminal

of

power window switch connector while operating main switch (driver's side)

Door Operation Wire

Passenger

side

Up "GW" Passenger

side Down "RW"

Rear left side

(except Coupe)

Up "LW" Rear left side

(except Coupe) Down "YW"

Rear right side

(except Coupe)

Up "GY" Rear right side

(except Coupe) Down "WR"

NG

Check power window switch (driver's side). Refer

to

page 15—66,

67.

OK

Check

for

12V

at

terminal

to

each door power win-dow switch connector

(5

pin) while operating main switch (driver's side)

Door Operation Wire

Passenger Up "GW"

side Down "RW"

Rear left side Up "LW"

(except Coupe) Down "YW"

Rear right side Up "GY"

(except Coupe) Down "WR"

Repair harness (Main switch—Switch

on

each door)

OK

Check

for

12V

at

"R" terminal and

"G"

terminal

of

each door switch connector

(5

pin) while operating main switch (driver's side)

•

Up: "R"

terminal

• Down:

"G"

terminal

NG

Check

for

12V

at

"R" terminal and

"G"

terminal

of

each door switch connector

(5

pin) while operating main switch (driver's side)

•

Up: "R"

terminal

• Down:

"G"

terminal

NG

Check switch

on

each door. Refer

to

page 15—67.

Check

for

12V

at

"R" terminal and

"G"

terminal

of

each door switch connector

(5

pin) while operating main switch (driver's side)

•

Up: "R"

terminal

• Down:

"G"

terminal

OK

76G15X-015

15—65

Page 1725 of 1865

15 REMOTE CONTROL MIRROR

TROUBLESHOOTING

Terminal Voltage

G (LW) 12V

H(B) OV

OK

Check the remote control mirror switch. Refer

to

fol-lowing inspection.

OK

Check for continuity between each terminals

of

the remote control mirror motor.

Terminal

Br

O

Lg

-O-

BrY

-O

O—O: indicate continuity

Remote control mirrors do not operate.

Check the voltage between each terminal

of

the

re-

mote control mirror switch connector and

a

body ground with ignition switch

in

ACC.

NG

Replace RADIO 15A fuse

or

repair the harness (Fuse box

to

switch, switch

to

body ground)

NG

Replace the switch.

NG

Replace the motor.

OK

Repair the harness. (Switch

to

Motor)

86U15X-124

86U15X-125

INSPECTION

Remote Control Mirror Switch

1. Remove the negative battery cable.

2. Remove the remote control mirror switch.

3. Check for continuity between the terminals using

an ohmmeter.

Position

Left

Right

Operation

Up

Down

Left

Right

Up

Down

Left

Right

9

O

o-

o

o

o

o-

o-

o

O-O—o

o-

o-

o~o

o

o-

o

o-

o-o

•o -o

•o

f

•o

-o

-O

o

-o

-o

o

o

o-o

-o-o

-o

o

•o

o

O—O: Indicates continuity

4. If continuity is not as specified, replace the remote

control mirror switch.

15—70

Page 1739 of 1865

1 5 CRUISE CONTROL SYSTEM

ON-VEHICLE INSPECTION (USING ACC CHECKER 49 9200 010)

76G15X-072

Note:

When checking the actuator on '88 models with EC-AT using this checker, the checker

should be modified as shown below in order to avoid damage of the EC-AT control unit.

Modification Procedure

1. Cut the wire at terminal no.6 indicated on ACC

checker connector.

2. Tape exposed end of wire cut in step 1 as shown.

This modification does not affect the usage of the ACC

checker except when used on the '81 RX-7 and 626

models. When the modified ACC checker is used on

these models, use a jumper wire and jump across

terminal no.6 to 3 indicated on ACC checker connec-

tor as shown.

Function of the ACC CHECKER

A. Check lights

Each item is verified by a check light, as described below.

Check light Check items

MAIN SW.

Ignition switch, fuse, main switch and associated wiring harness terminals and con-

nectors.

ACTUATOR—VAC

VAC coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 2

VENT

2

coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 1

VENT

1

coil continuity

in

the actuator and associated harness.

CLUTCH/BRAKE SW.

Clutch switch (M/T vehicles only), brake switch and associated harness

COMBINATION/INH. SW.

"SET", "COAST" and "RESUME" positions

in

the combination switch, inhibitor

switch (A/T vehicles only), and associated harness.

GENERATOR

Speed sensor output and associated harness.

76U15X-193

15-84

Page 1740 of 1865

CRUISE CONTROL SYSTEM 1 5

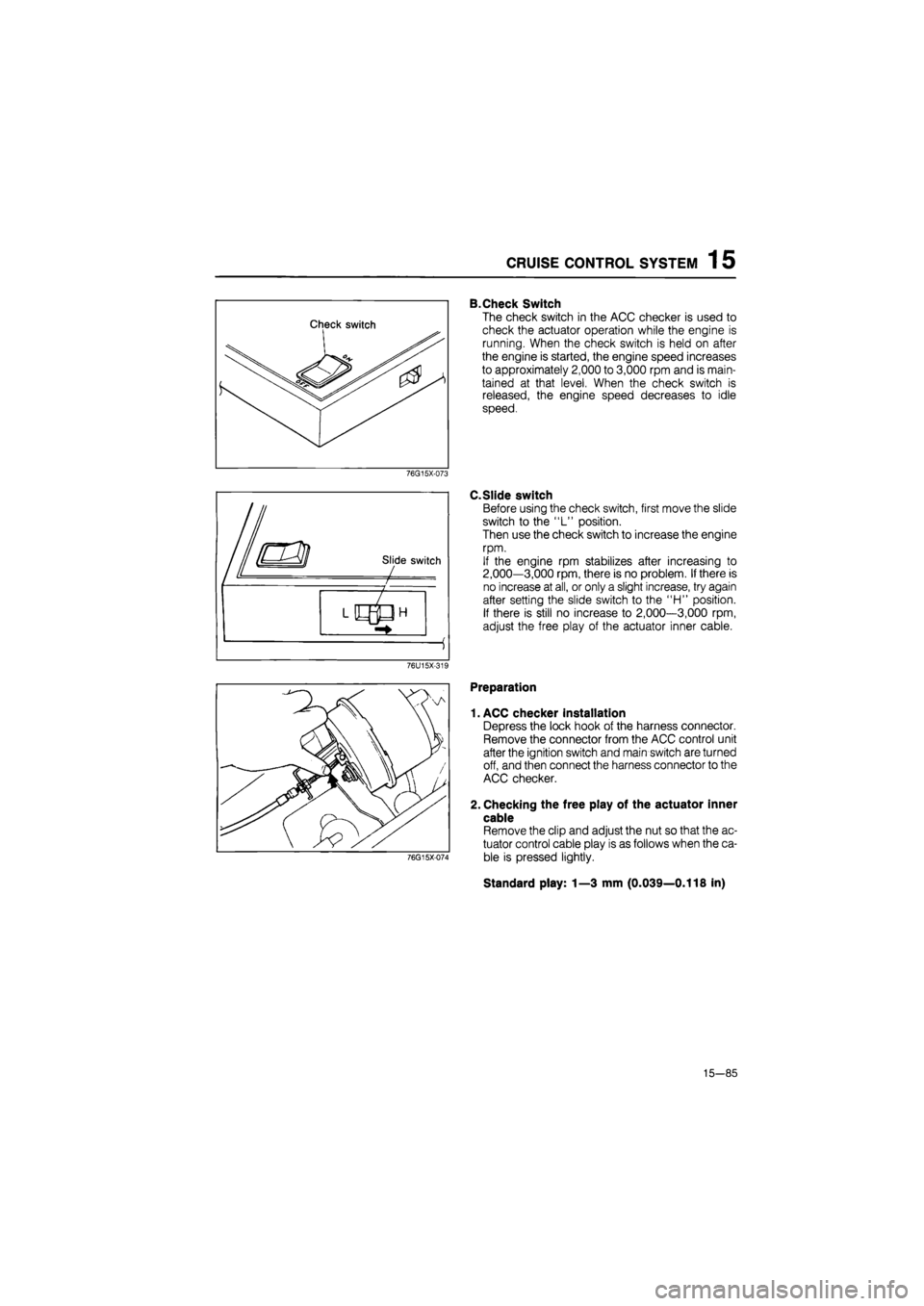

B.Check Switch

The check switch in the ACC checker is used to

check the actuator operation while the engine is

running. When the check switch is held on after

the engine is started, the engine speed increases

to approximately 2,000 to 3,000 rpm and is main-

tained at that level. When the check switch is

released, the engine speed decreases to idle

speed.

76G15X-073

C.Slide switch

Before using the check switch, first move the slide

switch to the "L" position.

Then use the check switch to increase the engine

rpm.

If the engine rpm stabilizes after increasing to

2,000—3,000 rpm, there is no problem. If there is

no increase at all, or only a slight increase, try again

after setting the slide switch to the "H" position.

If there is still no increase to 2,000—3,000 rpm,

adjust the free play of the actuator inner cable.

76U15X-319

76G15X-074

Preparation

1. ACC checker installation

Depress the lock hook of the harness connector.

Remove the connector from the ACC control unit

after the ignition switch and main switch are turned

off, and then connect the harness connector to the

ACC checker.

2. Checking the free play of the actuator inner

cable

Remove the clip and adjust the nut so that the ac-

tuator control cable play is as follows when the ca-

ble is pressed lightly.

Standard play: 1—3 mm (0.039—0.118 in)

15—85