wheel MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1449 of 1865

REAR DRUM BRAKE 1 1

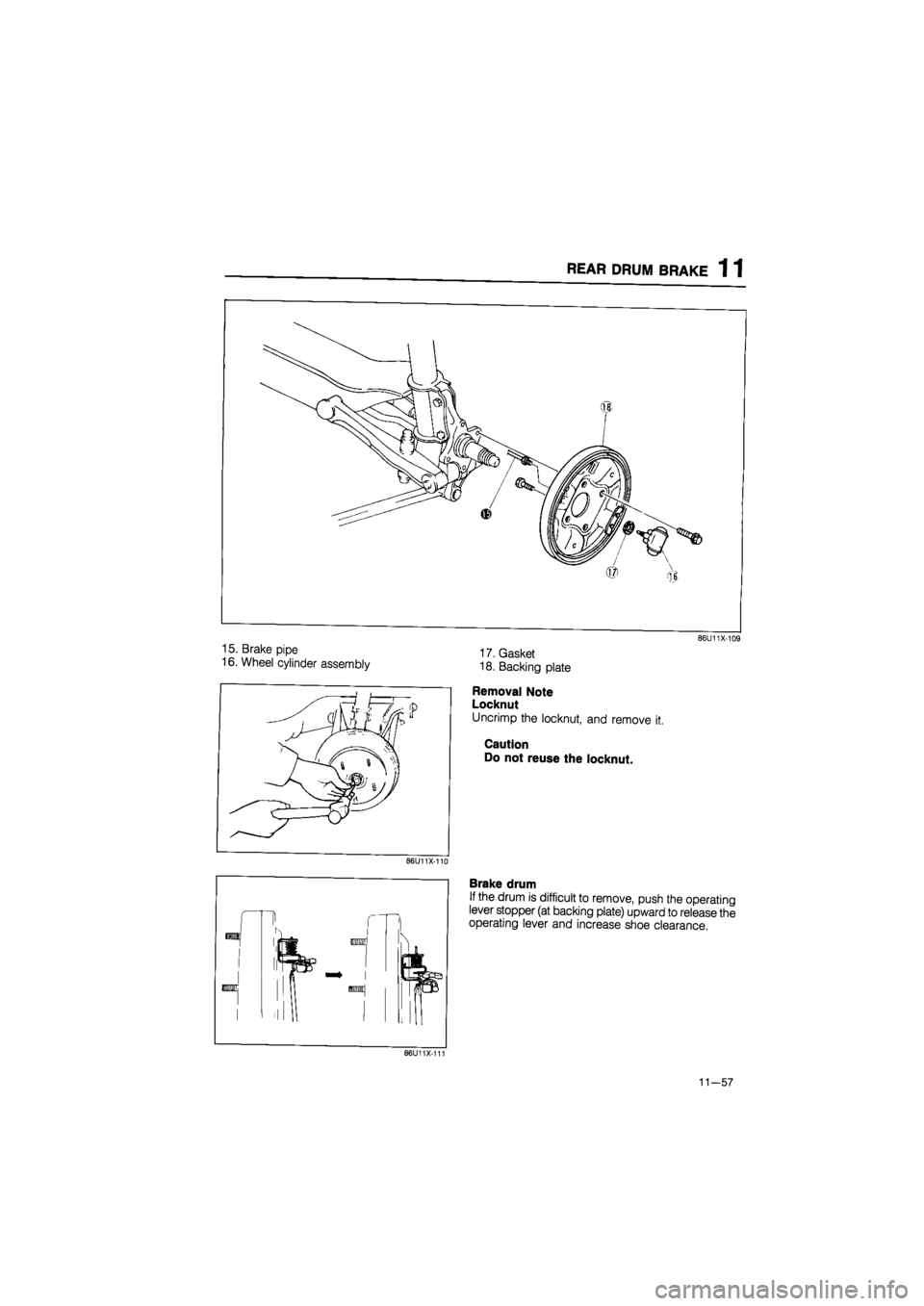

15. Brake pipe

16. Wheel cylinder assembly

86U11X-109

17. Gasket

18. Backing plate

Removal Note

Locknut

Uncrimp the locknut, and remove it.

Caution Do not reuse the locknut.

86U11X-110

Brake drum

If the drum is difficult to remove, push the operating

lever stopper (at backing plate) upward to release the

operating lever and increase shoe clearance.

86U11X-111

11-57

Page 1451 of 1865

REAR DRUM BRAKE 1 1

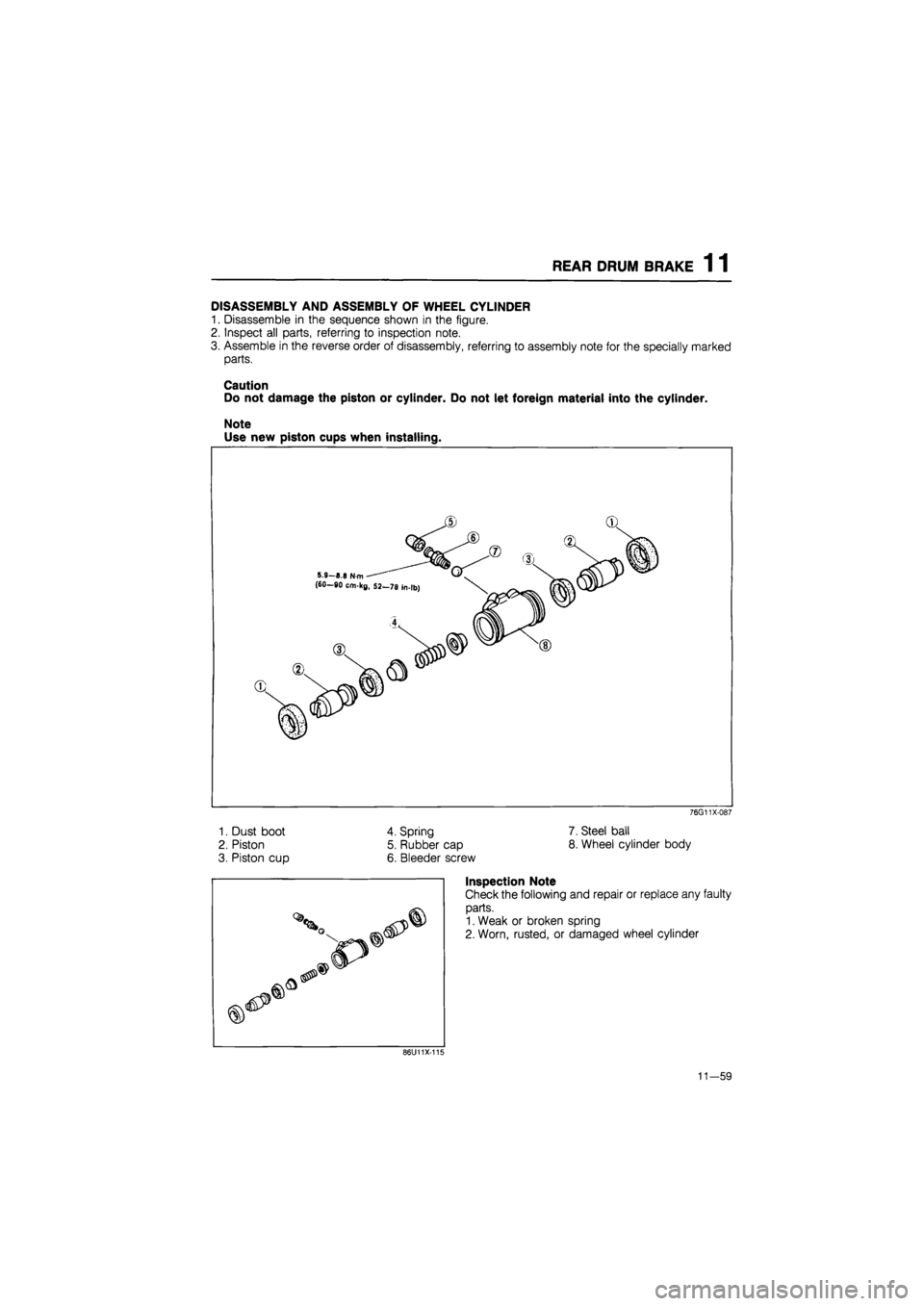

DISASSEMBLY AND ASSEMBLY OF WHEEL CYLINDER

1. Disassemble in the sequence shown in the figure.

2. Inspect all parts, referring to inspection note.

3. Assemble in the reverse order of disassembly, referring to assembly note for the specially marked

parts.

Caution

Do not damage the piston or cylinder. Do not let foreign material into the cylinder.

Note Use new piston cups when installing.

76G11X-087

1. Dust boot

2. Piston

3. Piston cup

4. Spring

5. Rubber cap

6. Bleeder screw

7. Steel ball

8. Wheel cylinder body

V ^

Inspection Note

Check the following and repair or replace any faulty

parts.

1. Weak or broken spring

2. Worn, rusted, or damaged wheel cylinder

86U11X-115

11—59

Page 1452 of 1865

1 1 REAR DRUM BRAKE

86U11X-116

86U11X-117

76G11X-049

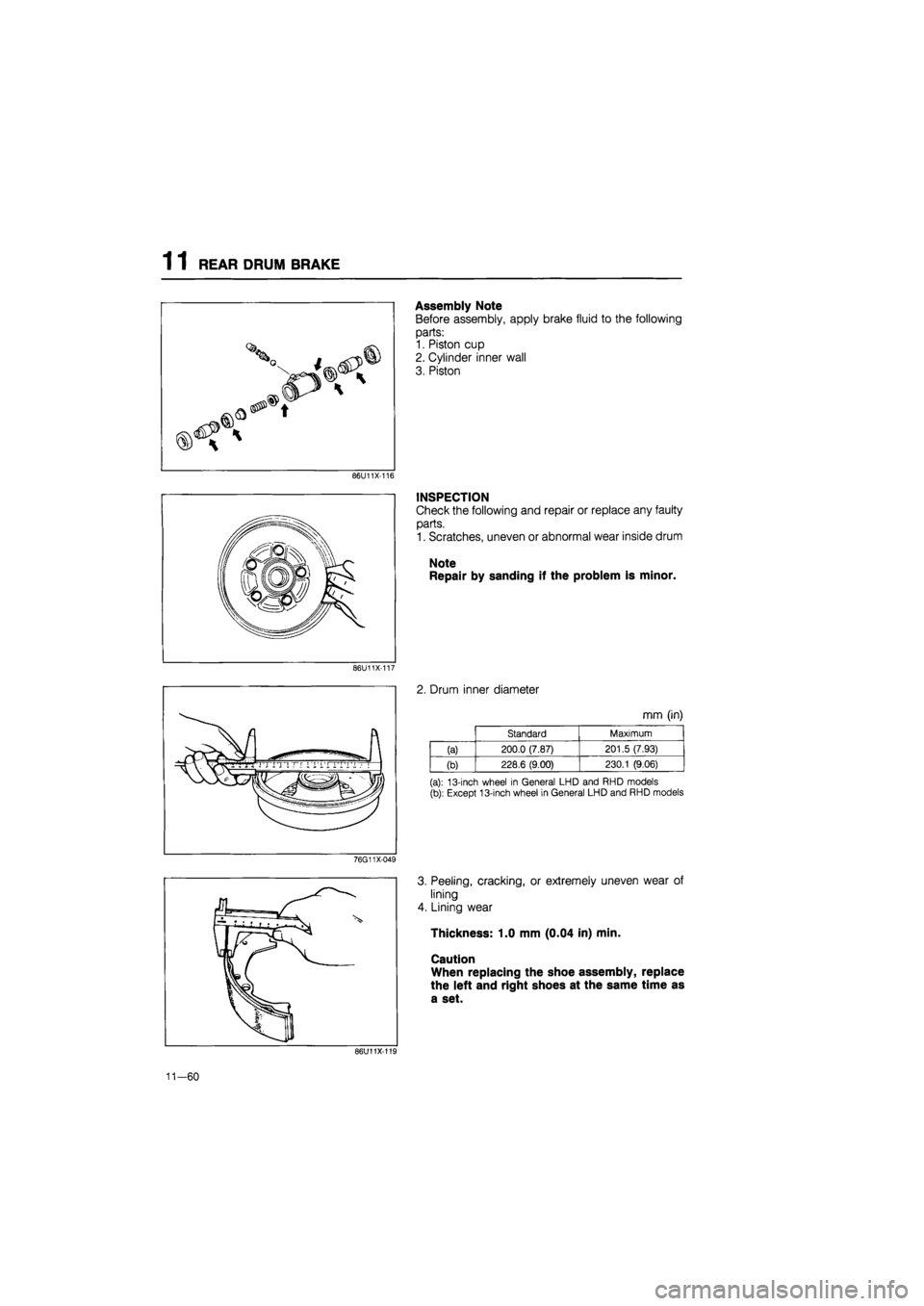

Assembly Note

Before assembly, apply brake fluid to the following

parts:

1. Piston cup

2. Cylinder inner wall

3. Piston

INSPECTION

Check the following and repair or replace any faulty

parts.

1. Scratches, uneven or abnormal wear inside drum

Note Repair by sanding if the problem is minor.

2. Drum inner diameter

mm (in)

Standard Maximum

(a) 200.0 (7.87) 201.5 (7.93)

(b) 228.6 (9.00) 230.1 (9.06)

(a): 13-inch wheel

in

General LHD and RHD models (b): Except 13-inch wheel

in

General LHD and RHD models

3. Peeling, cracking, or extremely uneven wear of

lining

4. Lining wear

Thickness: 1.0 mm (0.04 in) min.

Caution

When replacing the shoe assembly, replace

the left and right shoes at the same time as

a set.

86U11X-119

11-60

Page 1453 of 1865

REAR DRUM BRAKE 1 1

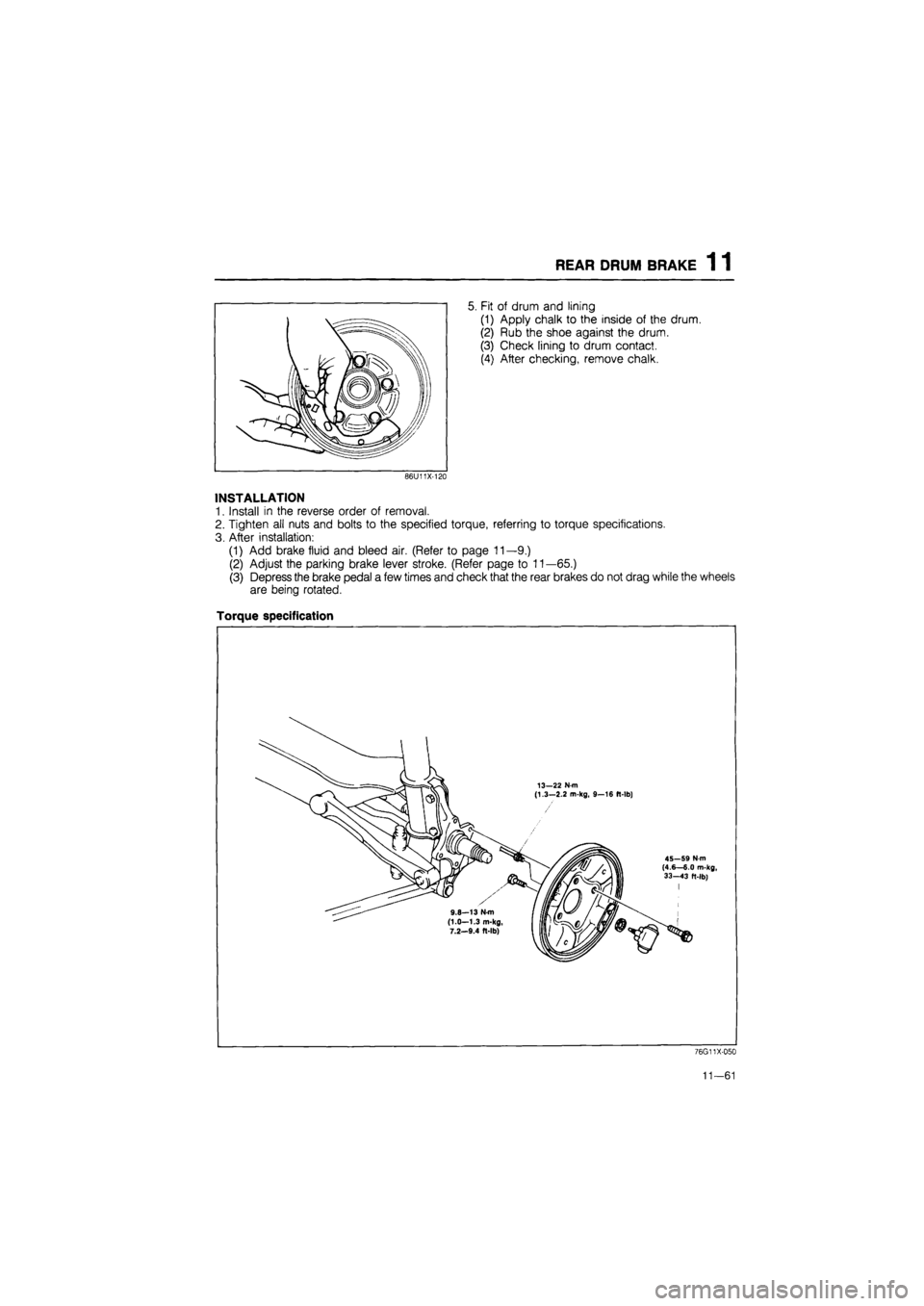

5. Fit of drum and lining

(1) Apply chalk to the inside of the drum.

(2) Rub the shoe against the drum.

(3) Check lining to drum contact.

(4) After checking, remove chalk.

2. Tighten all nuts and bolts to the specified torque, referring to torque specifications.

3. After installation:

(1) Add brake fluid and bleed air. (Refer to page 11—9.)

(2) Adjust the parking brake lever stroke. (Refer page to 11—65.)

(3) Depress the brake pedal a few times and check that the rear brakes do not drag while the wheels

are being rotated.

Torque specification

86U11X-120

INSTALLATION

1. Install in the reverse order of removal.

76G11X-050

11—61

Page 1455 of 1865

REAR DRUM BRAKE 1 1

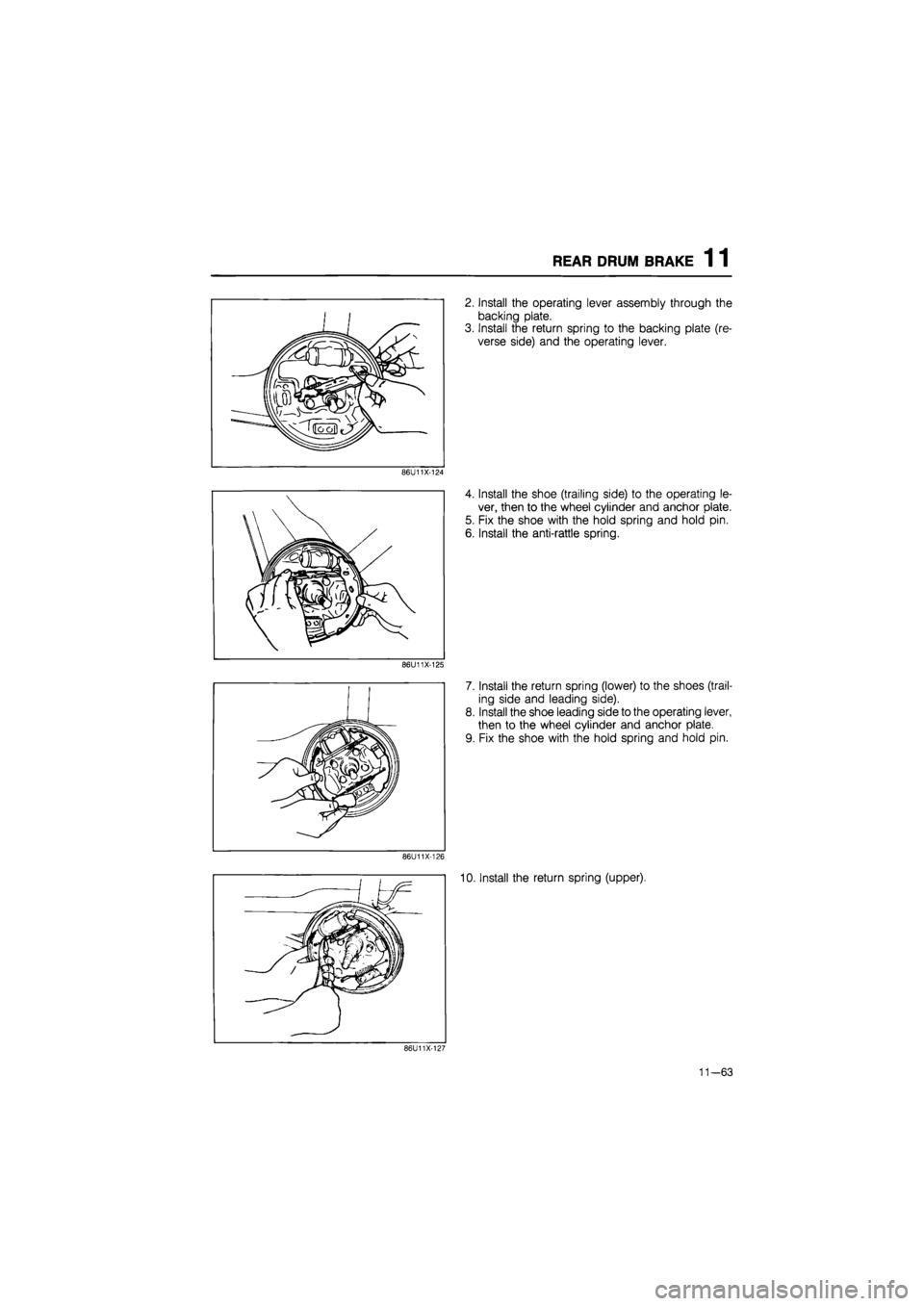

2. Install the operating lever assembly through the

backing plate.

3. Install the return spring to the backing plate (re-

verse side) and the operating lever.

86U11X-124

4. Install the shoe (trailing side) to the operating le-

ver, then to the wheel cylinder and anchor plate.

5. Fix the shoe with the hold spring and hold pin.

6. Install the anti-rattle spring.

86U11X-125

7. Install the return spring (lower) to the shoes (trail-

ing side and leading side).

8. Install the shoe leading side to the operating lever,

then to the wheel cylinder and anchor plate.

9. Fix the shoe with the hold spring and hold pin.

86U11X-126

—c^Uf5

>5

—/ / wr >-"W jtnc ^sy

10. Install the return spring (upper).

86U11X-127

11-63

Page 1458 of 1865

1 1 PARKING BRAKE

REMOVAL AND INSTALLATION OF PARKING BRAKE LEVER

1. Block the wheels firmly.

2. Release the parking brakes.

3. Remove in the sequence shown in the figure.

4. Inspect all parts, referring to inspection note.

5. Install in the reverse order of removal, referring to installation note for specially marked parts.

6. After installation:

Adjust the parking lever stroke. (Refer to page 11—65.)

(1.8—2.5 m-kg, 13-18 ft-lb)

76G11X-051

1. Rear console 4. Adjust nut 7. Button

2. Parking brake switch 5. Parking brake lever 8. Spring

3. Clip 6. Cover

11-66

Page 1460 of 1865

1 1 PARKING BRAKE

REMOVAL OF PARKING BRAKE CABLE

1. Block the wheels firmly.

2. Remove the rear console. (Refer to page 11—66.)

3. Release the parking brake and remove the adjust nut of the parking brake lever. (Refer to page

11—66.)

4. Jack up the vehicle and support it with safety stands.

5. Remove the parking brake cable in the sequence shown in the figure.

76G11X-052

1. Front parking cable 3. Parking brake cable (left)

2. Spring 4. Parking brake cable (right)

11-68

Page 1461 of 1865

PARKING BRAKE 1 1

INSTALLATION OF PARKING BRAKE CABLE

1. Install in the reverse order of removal, referring to installation note for specially marked parts.

2. Tighten all nuts and bolts to the specified torque, referring to torque specifications.

3. After installation:

(1) Adjust the parking brake lever stroke. (Refer to page 11—65.)

(2) Depress the brake pedal a few times and check that the rear brakes do not drag while the wheels

are being rotated.

Torque specifications

Rear drum brake

76G11X-053

11-69

Page 1463 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

ANTI-LOCK BRAKE SYSTEM (ABS)

STRUCTURAL VIEW

1. Hydraulic unit 4. Sensor rotor (front) 7. Wheel speed sensor (rear)

2. Relay box 5. Wheel speed sensor (front) 8. Sensor rotor (rear)

3. Control unit 6. Check connector

11—71

Page 1465 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

TROUBLESHOOTING

Precaution

Conditions that are not malfunctions

1. It may happen that vibration is felt in the steering wheel, body, and/or brake pedal when the ABS

is functioning; such vibration is simply an indication that the system is functioning.

2. Sound of the pump motor operating, accumulator pressure being released, or the relay operating

may be heard from the engine compartment when the engine is started as the system is being auto-

matically checked.

3. The ABS pump motor may be automatically activated even though the ABS is not operating.

4. The ABS warning light may illuminate under any of the following conditions:

• When the vehicle is traveling on snow or ice with the parking brake activated or a brake dragging

at one wheel.

• When different-sized tires are used.

• When tires of different gripping performance are used.

• When (while the vehicle is jacked up or stuck) only the front wheels are spun for 20 seconds or more.

• When there is insufficient battery voltage.

Note

Under the above conditions, the warning light will not illuminate a second time when the

ignition is switched OFF then back ON, and there will be no memory entry to the control

unit of a problem.

Troubleshooting notes

The ABS is composed of electrical components, mechanical components (hydraulic unit), and the com-

ponents of the standard brake system.

Fundamentally, malfunction of the ABS electrical or mechanical components is judged by the self-

diagnosis function within the ABS control unit. And malfunctions are indicated by the warning light

in the instrument panel.

The location

of

a malfunction is indicated by the technician switching the system to the diagnosis-indication

mode.

The self-diagnosis and indication functions must be used when malfunctions of the ABS are being

diagnosed.

76G11X-091

11—73