brakes MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1132 of 1865

7C TROUBLESHOOTING

STEP 4 (ROAD TEST)

This step is performed to check for problems in the various ranges. If these tests show any problems,

adjust or replace by referring to the QUICK DIAGNOSIS CHART and mechanical sections.

Caution

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

Gearshift Function Check Items

1. Shift shock must be minimal, and shifting must be smooth.

2. Engine speed must not run away, and the shifting must not be delayed.

3. Transaxle must shift through Di D2 -»• D3 in D range.

4. Transaxle must shift from 3rd in D range to 2nd gear when 2 range is selected.

5. Transaxle must shift from 2nd to 1st when 1 range is selected from 3rd gear in D range.

6. Transaxle must not upshift in 1 range.

7. Transaxle must remain in 2nd gear in 2 range.

8. Transaxle must positively lock in P range.

The transaxle must positively lock when P range is selected while moving at a speed below 4 km/h

(2.5 mph) on level ground. The transaxle must positively lock when set in P range with the vehicle

on a gentle slope and the brakes disengaged.

Shift Speed

Throttle condition

(manifold vacuum) Hange Shift Vehicle speed km/h (mph) Throttle condition

(manifold vacuum) Hange Shift FE engine F6 engine

Fully opened 0—100 mmHg (0-3.94 inHg)

D

1st - 2nd 47—57 (29—35) 44-54 (27-33)

Fully opened 0—100 mmHg (0-3.94 inHg)

D 2nd - 3rd 106-119 (66—74) 95-108 (59-67) Fully opened 0—100 mmHg (0-3.94 inHg)

D 3rd - 2nd 95-103 (59-64) 86-94 (53-58)

Fully opened 0—100 mmHg (0-3.94 inHg)

D

2nd - 1st 35-39 (22-24) 34-38 (21-24)

Half-throttle 130 mmHg (5.12 inHg) D 1st - 2nd 18-31 (11-19) 18-31 (11-19) Half-throttle 130 mmHg (5.12 inHg) D 2nd -»• 3rd 39-68 (24—42) 44-73 (27-45)

Fully closed D 2nd - 1st 10-15 (6-9) 10-15 (6-9) Fully closed 1 2nd - 1st 32—39 (20-24) 33-40 (20-25)

1. Full-throttle: The throttle opening during kick-down when the manifold vacuum is between 0—100

mmHg (0—3.94 inHg)

2. Half-throttle: The throttle opening at manifold vacuum of 130 mmHg (5.12 inHg) 76G07C-028

7C-18

Page 1278 of 1865

DRIVESHAFT 9

REMOVAL

Remove in the sequence shown in the figure referring to the removal note for the specially marked parts.

0

B6U09X-U53

6. Hub cap

7. Lock nut

8. Driveshaft

9. Joint shaft

10. Transaxle

Removal Note

Lock nut

Applying the brakes. Raise the lock nut tab and loos-

en it. Do not remove it.

1. Wheel

2. Tie-rod end

3. Stabilizer

4. Lower arm

5. Splash shield

86U09X-054

9-29

Page 1396 of 1865

1 1 OUTLINE

SPECIFICATIONS

Item Specification

Brake pedal

Type Suspended

Brake pedal Pedal lever ratio 4.2 Brake pedal

Max. stroke mm (in) LHD: 136.5 (5.37) RHD: 135 (5.31)

Master cylinder Type Tandem (with level sensor) Master cylinder

Cylinder inner diameter mm (in) 22.22 (0.87)

Front disc brake

Type Mounting support, Ventilated disc

Front disc brake

Cylinder bore mm (in) 53.97 (2.12)

Front disc brake Pad dimensions (area x thickness) mm2 x mm (in2 x in) 4,800 x 10 (7.44 x 0.39) Front disc brake

Disc plate dimensions mm (in) (outer diameter x thickness) 13 inch-wheel: 242 x 20 (9.53 x 0.79) 14 or 15 inch-wheel: 264 x 24 (10.39 x 0.94)

Rear disc brake

(Turbo model)

Type Mounting support, Solid disc

Rear disc brake

(Turbo model)

Cylinder bore mm (in) 30.2 (1.19)

Rear disc brake

(Turbo model) Pad dimensions (area x thickness) mm2 x mm (in2 x in) 2,900 x 8 (4.5 x 0.31)

Rear disc brake

(Turbo model)

Disc plate dimensions mm (in) (outer diameter x thickness) 259 x 10 (10.2 x 0.39)

Rear drum brake

(Non-Turbo model)

Type Leading-trailing

Rear drum brake

(Non-Turbo model)

Wheel cylinder inner diameter mm (in) 17.46 (0.69)

Rear drum brake

(Non-Turbo model) Lining dimensions mm (in)

(width x length x thickness) (a): 25 x 191.9 x 5 (0.98 x 7.56 x 0.20)

(b): 30 x 219.3 x 5 (1.18 x 8.63 x 0.20)

Rear drum brake

(Non-Turbo model)

Drum inner diameter mm (in) (a): 200.0 (7.87) (b): 228.6 (9.0)

Rear drum brake

(Non-Turbo model)

Shoe clearance adjustment Automatic adjuster

Power brake unit Type Vacuum multiplier Power brake unit

Diameter mm (in) 238 (9.37)

Braking force control device Type Dual proportioning valve or ABS (if equipped)

Brake fluid DOT-3 or DOT-4, or SAE J1703

Parking brake Type Center lever (Mechanical two rear brakes)

(a)...13-inch wheel in General LHD and RHD models

(b)...Except 13-inch wheel in General LHD and RHD models

11-4

Page 1397 of 1865

TROUBLESHOOTING GUIDE 1 1

TROUBLESHOOTING GUIDE

The table below covers the normal braking system. Refer to page 11—73 for ABS system.

Problem Possible cause Remedy Page

Poor braking Leakage of brake fluid Air in system Worn pad or lining

Brake fluid, grease, oil, or water on pad or lining Hardening of pad or lining surface or poor contact Malfunction of disc brake piston Malfunction of master cylinder or wheel cylinder Malfunction of power brake unit

Malfunction of check valve (vacuum hose)

Damaged vacuum hose Deterioration of flexible hose Malfunction of dual proportioning valve

Repair Air bleed Replace

Clean or replace Grind or replace Replace Repair or replace Repair or replace Repair or replace Replace Replace Replace

11-9 11-40,47,56 11-40,47,56 11-40,47,56 11—43,50 11-14,57 11-29 11-29 11-29

11-39

Brakes pull to one

side

Worn pad or lining

Brake fluid, grease, oil, or water on pad or lining Hardening of pad or lining surface or poor contact Abnormal wear or distortion of disc, drum, pad, or lining Malfunction of automatic adjuster Looseness of backing plate mounting bolts Malfunction of wheel cylinder

Improper adjustment of wheel bearing preload, or wear Improper adjustment of wheel alignment Unequal tire air pressures

Replace Clean or replace Grind or replace Repair or replace Repair or replace Tighten

Repair or replace Refer to Section 9 Refer to Section 10 Refer to Section 12

11-40,47,56 11-40,47,56 11-40,47,56 11-40,47,56 11-56 11-61 11-57

Brakes do not

release

No brake pedal play

Improper adjustment of push rod clearance

Clogged master cylinder return port Shoe does not return properly Wheel cylinder does not return properly Improper return due to malfunction of piston seal of disc brake Excessive runout of disc plate Improper return of parking brake cable or improper ad-justment

Improper adjustment of wheel bearing preload

Adjust

Adjust

Clean

Adjust Clean or replace Replace

Replace Repair or adjust

Refer to Section 9

11-11

11—23,24

11-57 11—43,50

11-65

Pedal goes too far (too much pedal stroke)

Air in system due to insufficient brake fluid

Improper adjustment of pedal play Worn pad or lining Air in system

Add fluid and bleed air

Adjust Replace Air bleed

11—9

11—11 11-40,47,56 11-9

Abnormal noise or

vibration during

braking

Worn pad or lining Deterioration of pad or lining Brakes do not release

Foreign material or scratches on disc plate or drum con-tact surface

Looseness of backing plate or caliper mounting bolts Damage or deviation of disc or drum contact surface Poor contact of pad or lining Insufficient grease on sliding parts

Replace

Grind or replace

Repair

Clean

Tighten Replace Repair or replace Apply grease

11-40,47,56 11-40,47,56

11-61 11-56 11-40,47,56

Parking brake

does not hold well

Excessive lever stroke

Brake cable stuck or damaged

Brake fluid or oil on pad or lining Hardening of pad or lining surface or poor contact

Adjust

Repair or replace Clean or replace Grind or replace

11-65

11-68

11-40,47,56

11-40,47,56

76G11X-003

11—5

Page 1404 of 1865

1 1 BRAKE PEDAL

Pedal-to-floor clearance

76G11X-009

REMOVAL

Remove in the sequence shown in the figure.

Pedal-to-Floor Clearance

Inspection

Check that the distance from the floor panel to the

center of the upper surface of the pedal pad is as

specified when the pedal is depressed with a force

of 589 N (60 kg, 132.3 lb).

Pedal-to-floor clearance:

LHD and RHD

95 mm (3.7 in) min.

If the distance is less than specified, check for the

following problems.

1. Air in brake system

2. Malfunction of automatic adjuster (rear drum

brakes)

3. Worn shoes or pads

86U11X-020

1. Clevis pin

2. Brake pedal

3. Return spring

4. Guide pipe

5. Bushing

6. Brake pad

11—12

Page 1433 of 1865

FRONT DISC BRAKE 11

13. Lower the caliper assembly onto the mounting

support.

14. Tighten the mounting bolt to the specified torque.

Tightening torque:

31—41 N-m (3.2—4.2 m-kg, 23—30 ft-lb)

76G11X-076

15. Mount the wheels.

16. Apply the brakes a few times; then turn the wheels

and check that the brakes do not drag excessively.

17. Lower the vehicle.

18. Tighten the wheel lug nuts.

Tightening torque:

88—118 N-m (9.0—12.0 m-kg, 65—87 ft-lb)

76G11X-077

11—41

Page 1438 of 1865

1 1 FRONT DISC BRAKE

INSTALLATION

1. Install in the reverse order of removal.

2. Tighten all nuts and bolts to the specified torque, referring to torque specifications.

3. After installation:

(1) Add brake fluid and bleed air. (Refer to page 11—9.)

(2) Depress the brake pedal a few times and check that the front brakes do not drag excessively

while the wheels are being rotated.

Note

Refer to page 11—40 for pad installation.

Torque specifications

76G11X-047

11—46

Page 1439 of 1865

REAR DISC BRAKE 1 1

REAR DISC BRAKE

SIMPLE INSPECTION OF DISC PAD WEAR

1. Loosen the rear wheel lug nuts.

2. Jack up the rear of the vehicle and support it with

safety stands.

3. Remove the wheels.

4. Look through the caliper inspection hole and check

that the remaining thickness of the pad is 1 mm

(0.04 in) min.

76G11X-082

86U11X-084

REPLACEMENT OF DISC PAD

Caution

Replace the left and right pads at the same

time.

1. Loosen the wheel lug nuts.

2. Release the parking brakes.

3. Jack up the rear of the vehicle and support it with

safety stands.

4. Remove the wheels.

5. Remove the parking brake cable from the cable

bracket and the operating lever.

6. Remove the upper mounting bolt; then pivot the

caliper.

7. Remove the V-springs.

8. Remove the pads and shims.

Warning

Asbestos dust is a health hazard. Do not blow

away brake dust with compressed air.

86U11X-085

86U11X-086

9. Apply the grease supplied in the pad attachment

set to the new shims; then attach them to the new

pads.

10. Turn the piston fully inward by rotating the SST

clockwise. Align the piston groove as shown in the

illustration.

Note

The piston groove and inner pad alignment pin

must be aligned when the inner pad is in-

stalled.

11. Install the pads and shims to the mounting support.

12. Install the pad clip.

11—47

Page 1440 of 1865

1 1 REAR DISC BRAKE

86U11X-087

86U11X-088

13. Lift the caliper assembly onto the mounting

support.

14. Tighten the mounting bolt to the specified torque.

Tightening torque:

16—24 Nm (1.6—2.4 m-kg, 12—17 ft-lb)

15. Connect the parking cable end to the operating

lever; then tighten the locknut.

Tightening torque:

20—28 N-m (2.0—2.9 m-kg, 14—21 ft-lb)

Caution

There must be no clearance between the ca-

ble end and the operating lever.

16. Mount the wheels.

17. Apply the brakes a few times; then check that the

brakes do not drag excessively while the wheels

are being rotated.

18. Lower the vehicles.

19. Tighten the wheel lug nuts.

Tightening torque:

88—118

N

m (9—12 m-kg, 65—87 ft-lb)

76G11X-083

11-48

Page 1441 of 1865

REAR DISC BRAKE 1 1

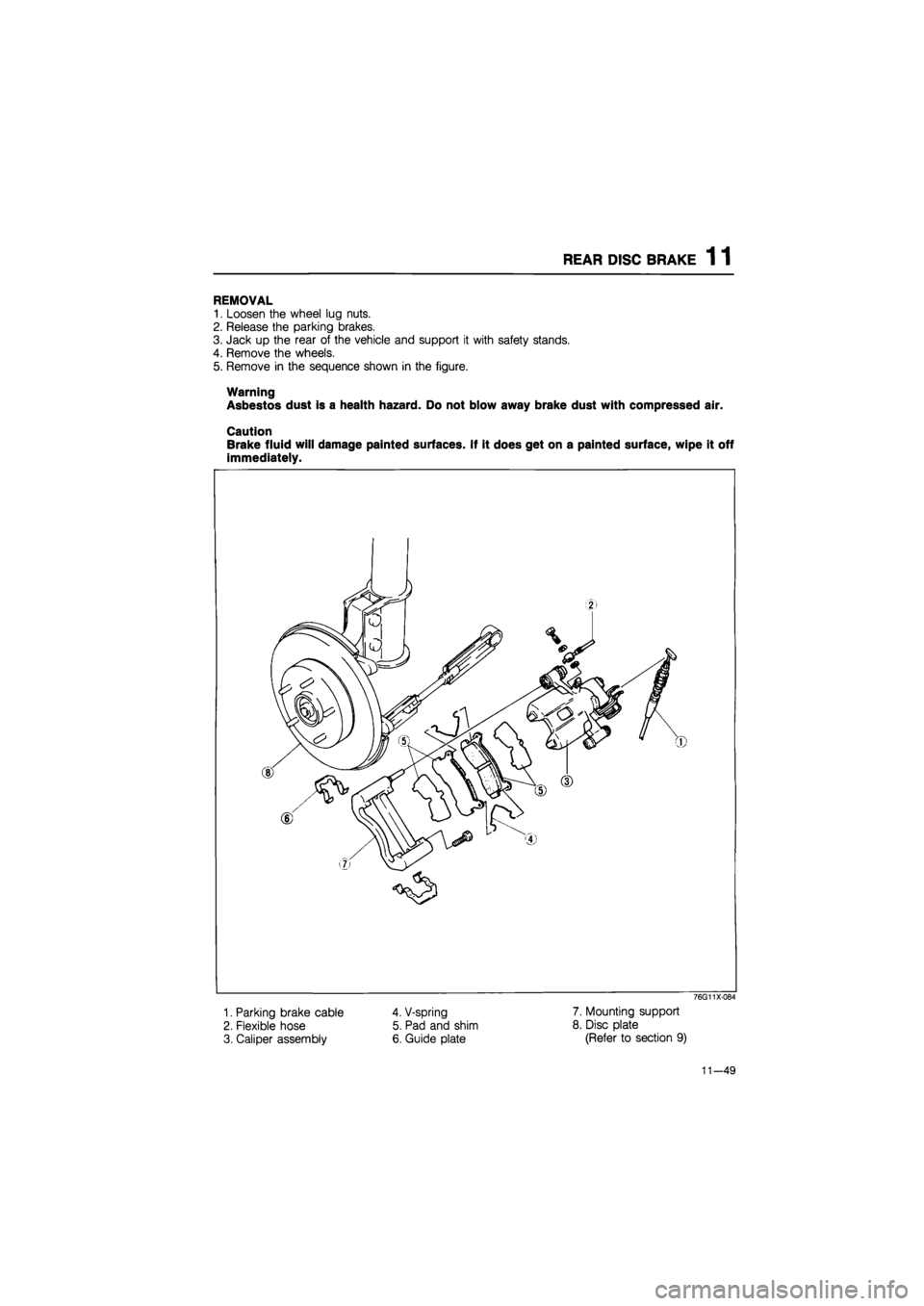

REMOVAL

1. Loosen the wheel lug nuts.

2. Release the parking brakes.

3. Jack up the rear of the vehicle and support it with safety stands.

4. Remove the wheels.

5. Remove in the sequence shown in the figure.

Warning Asbestos dust is a health hazard. Do not blow away brake dust with compressed air.

Caution

Brake fluid will damage painted surfaces. If it does get on a painted surface, wipe it off

immediately.

76G11X-084

1. Parking brake cable

2. Flexible hose

3. Caliper assembly

4. V-spring

5. Pad and shim

6. Guide plate

7. Mounting support

8. Disc plate

(Refer to section 9)

11—49