brakes MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 10 of 1865

G TOWING

76GOGX-OQ2

i-^C.

y -

- r^jfftj&H

r —I

76UQGX-003

86U0GX-004

G—8

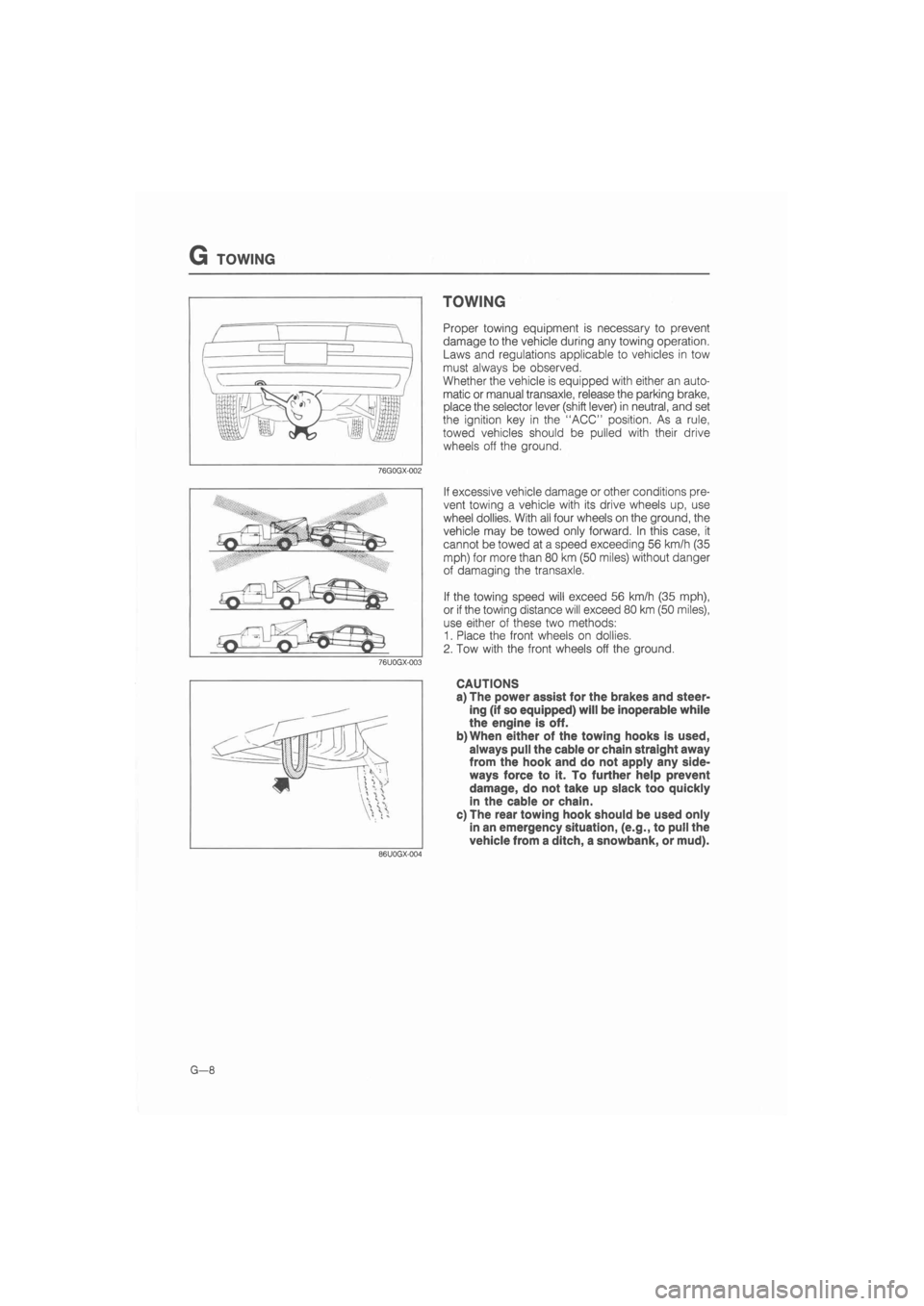

TOWING

Proper towing equipment is necessary to prevent

damage to the vehicle during any towing operation.

Laws and regulations applicable to vehicles in tow

must always be observed.

Whether the vehicle is equipped with either an auto-

matic or manual transaxle, release the parking brake,

place the selector lever (shift lever) in neutral, and set

the ignition key in the "ACC" position. As a rule,

towed vehicles should be pulled with their drive

wheels off the ground.

If excessive vehicle damage or other conditions pre-

vent towing a vehicle with its drive wheels up, use

wheel dollies. With all four wheels on the ground, the

vehicle may be towed only forward. In this case, it

cannot be towed at a speed exceeding 56 km/h (35

mph) for more than 80 km (50 miles) without danger

of damaging the transaxle.

If the towing speed will exceed 56 km/h (35 mph),

or if the towing distance will exceed 80 km (50 miles),

use either of these two methods:

1. Place the front wheels on dollies.

2. Tow with the front wheels off the ground.

CAUTIONS

a) The power assist for the brakes and steer-

ing (if so equipped) will be inoperable while

the engine is off.

b)When either of the towing hooks is used,

always pull the cable or chain straight away

from the hook and do not apply any side-

ways force to it. To further help prevent

damage, do not take up slack too quickly

in the cable or chain.

c) The rear towing hook should be used only

in an emergency situation, (e.g., to pull the

vehicle from a ditch, a snowbank, or mud).

Page 15 of 1865

For ECE Leaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust : Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

F8 engine with carbretor, MTX, ATX

FE engine with carbretor, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operatie under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

>

Z H m >

o m

H >

CD r-m

o m

m O m

(D o> Q. ® a

(Q 0) <0 o

m a

o m

c/> o x m a

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation.

It is strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

m a

m z >

z o m

G)

Page 19 of 1865

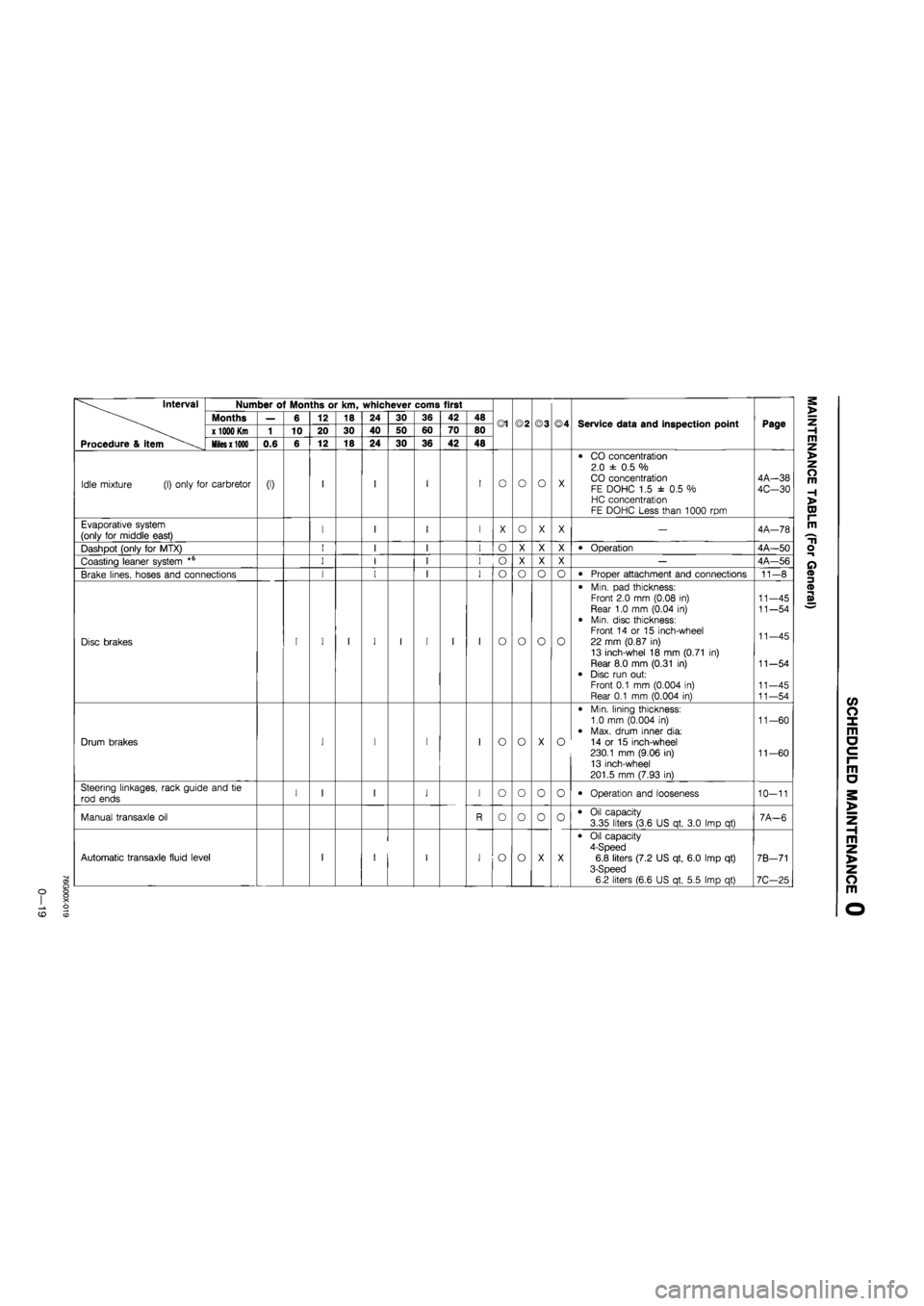

Interval

Procedure & item

Number of Months or km, whichever corns first

©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

Months — 6 12 18 24 30 36 42 48 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

x 1000 Km 1 10 20 30 40 50 60 70 80 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item Miles x 1000 0.6 6 12 18 24 30 36 42 48

©1 ©2 ©3 ©4 Service data and inspection point Page

Idle-up solenoid valve I I I I O MTX o X X — 4A—56

All electrical system *4 I I I I I I I I o o o o • Check the all electrical system Section 15

Head light aligment A A A A o o o o • Check the head light aiming 14-31

Steering and front suspension I I I I o o o 0 • Damage 10—28

Front and rear power steering system

and hoses (For 4WS) I I X X o X • Operation and looseness • Fluid leakage or oozing 10—44 10—14

4-Wheel steering system operation

and linkage (For 4WS) I I X X o X • Operation and looseness

• Fluid leakage or oozing

10—33 10—14

Rear wheel steering steering angle

(For 4WS) I I X X o X • Steering wheel angle: Inner 5°00' ± 45' Outer 5°00' ± 45'

13-54

Solenoid valve oil filter (For 4WS) R R X X o X — 10-41

Rear suspension outer ball joints

(For 4WS) I I X X o X • Damage, looseness and grease

leakage 13—37

Manual transaxle oil A R o o o 0 • Oil capacity 3.35 liters (3.6 US qt, 3.0 Imp qt) 7A-6

Automatic transaxle fluid level A A o o X X • Oil capacity 4-Speed 6.8 liters (7.2 US qt, 6.0 Imp qt) 3-Speed 6.2 liters (6.6 US qt, 5.5 Imp qt)

7B-2

Bolts and nuts on chasis and body T T T T T o o o o — —

Disk brakes/Drum brakes I I I I o o o o

• Min. pad thickness: Front 2.0 mm (0.08 in) Rear 1.0 mm (0.04 in) • Min. disc thickness: Front 14 or 15 inch-wheel

22 mm (0.87 in) 13 inch-wheel 18 mm (0.71 in) Rear 8.0 mm (0.31 in)

• Disc run out:

Front 0.1 mm (0.004 in) Rear 0.1 mm (0.004 in)

• Min. lining thickness: 1.0 mm (0.04 in) • Max, drum inner dia: 230.1 mm (9.06 in)

11—45

11—54

11—45

11—54

11-45 11—54

11-60

11—60

Page 21 of 1865

r

For ECE Unleaded gasoline

Chart symbols:

I

A

R

T

O

X

Inspect: Visual examination or functional measurement of a system's operation (performance)

Adjust: Examination resulting in adjustment or replacement

Replace or change

Tighten

Applicable

Not applicable

FE engine with fuel injection, MTX, ATX

FE DOHC engine with fuel injection, 4WS, MTX

FE engine with carburetor, MTX, ATX

RF-CX, RF-N engine with MTX

REMARKS:

Major service interval at 12 months/20,000 km (12,000 Miles), Lubrication service based on distance only 10,000 km (6,000 Miles) not time

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1 Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*2 If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regulary.

*3. If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4. This is a full function check of all electrical systems, i.e., all lights, washers (including condition of blades) electrical windows, sunroof, horn, etc....

*5. Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the brake fluid

should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It is

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

>

Z H m z >

o m

H >

DJ r~ m

m o m

c 3

(/> O X m o c i-m

o

m z >

z o m

CD

Page 27 of 1865

For General

Chart symbols:

I : Inspect: Visual examination and/or functional measurement of a system's operation or performance.

A : Adjust: Examination resuiting in adjustment or replacement.

R : Replace or change

T : Tighten

O : Applicable

X : Not applicable

© 1 : F6, F8 engine with carburetor, MTX, ATX

© 2 : FE engine with carbretor, MTX, ATX

©3 : FE DOHC engine with fuel injection, MTX

® 4 : RF-N engine with MTX

NOTE:

As the result of visual examination or functional measurement of a system's operation(performance), correct, clean or replace as required.

REMARKS:

After 80,000 km (48,000 Miles) or 48 months, continue to follow the described maintenance items and intervals periodically.

As for * marked items in this maintenance chart, please pay attention to the following points.

*1. If the vehicle is operated under the following conditions, it is suggested that the engine oil and oil filter be changed more often than at usual recommended

intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged period in cold temperatures or driving only short distances regularly.

"2. Replacement of the timing belt is required at every 100,000 km (60,000 Miles). Failure to repace the timing belt may result in damage to the engine.

*3 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often than at usual recommended intervals.

*4 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt, vacuum pump belt, super charger belt if equipped.

*5 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the vehicle is operated in extremely humid climates, the

brake fluid should be changed annually.

*6. Only F6 carbretor for Singapore (MTX Model)

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It i

strongly recommended that all servicing related to these systems be done by your Authorized Mazda Dealer.

o CJ1

Page 31 of 1865

CD

o> O o o X o

Interval

Procedure & item

Number of Months or km, whichever corns first

©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

Months — 6 12 18 24 30 36 42 48 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

x 1000 Km

1 10 20 30 40 50 60 70 80 ©1 ©2 ©3 ©4 Service data and inspection point Page

Interval

Procedure & item

Miles x 1000

0.6 6 12 18 24 30 36 42 48

©1 ©2 ©3 ©4 Service data and inspection point Page

Idle mixture (1) only for carbretor (I) I I I I O O o X

• CO concentration 2.0 ± 0.5 % CO concentration FE DOHC 1.5 ± 0.5 % HC concentration FE DOHC Less than 1000 rpm

4A-38

4C-30

Evaporative system

(only for middle east) I I I I X O X X — 4A—78

Dashpot (only for MTX) I I I I o X X X • Operation 4A—50

Coasting leaner system *6 t I I I

,

O X X X — 4A-56

Brake lines, hoses and connections I I I I o o o o • Proper attachment and connections 11-8

Disc brakes [ I I I I [ I I o o o o

• Min. pad thickness: Front 2.0 mm (0.08 in) Rear 1.0 mm (0.04 in)

• Min. disc thickness: Front 14 or 15 inch-wheel 22 mm (0.87 in)

13 inch-whel 18 mm (0.71 in) Rear 8.0 mm (0.31 in) • Disc run out: Front 0.1 mm (0.004 in) Rear 0.1 mm (0.004 in)

11—45 11—54

11—45

11—54

11—45

11—54

Drum brakes I I I I o o X o

• Min. lining thickness: 1.0 mm (0.004 in)

• Max. drum inner dia: 14 or 15 inch-wheel 230.1 mm (9.06 in) 13 inch-wheel 201.5 mm (7.93 in)

11-60

11—60

Steering linkages, rack guide and tie

rod ends I I I I I o o o o • Operation and looseness 10-11

Manual transaxle oil R o o 0 o • Oil capacity

3.35 liters (3.6 US qt, 3.0 Imp qt) 7A—6

Automatic transaxle fluid level I I I I o o X X

• Oil capacity 4-Speed 6.8 liters (7.2 US qt, 6.0 Imp qt) 3-Speed 6.2 liters (6.6 US qt, 5.5 Imp qt)

7B—71

7C-25

m z >

o m

H >

CO I-m

"ti o

a

Page 37 of 1865

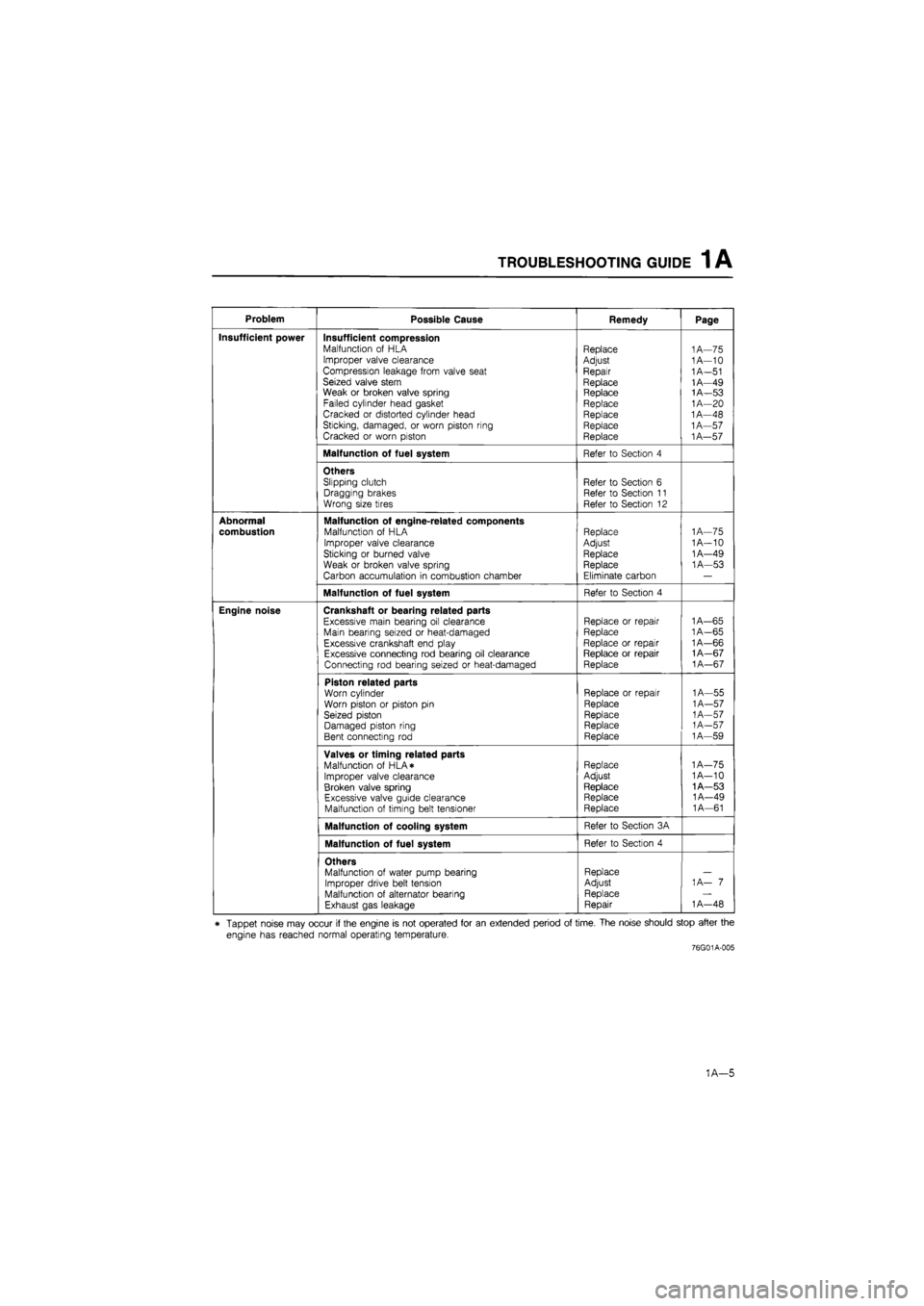

TROUBLESHOOTING GUIDE 1 A

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Improper valve clearance Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace

Adjust

Repair

Replace Replace Replace Replace Replace Replace

1A—75 1A—10

1

A—51 1A—49 1A—53

1

A—20 1A—48 1A—57

1

A—57

Malfunction of fuel system Refer to Section 4

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal

combustion

Malfunction of engine-related components Malfunction of HLA

Improper valve clearance Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Adjust Replace Replace

Eliminate carbon

1

A—75 1A—10 1A—49 1A—53

Malfunction of fuel system Refer to Section 4

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1A—65

1

A—65 1A—66 1A—67

1

A—67

Piston related parts Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1A—55

1

A—57

1

A—57

1

A—57 1A—59

Valves or timing related parts Malfunction of HLA* Improper valve clearance Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Adjust

Replace Replace Replace

1A—75 1A—10 1A—53 1A—49 1A—61

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1 A— 7

1

A—48

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the

engine has reached normal operating temperature.

76G01A-005

1A—5

Page 135 of 1865

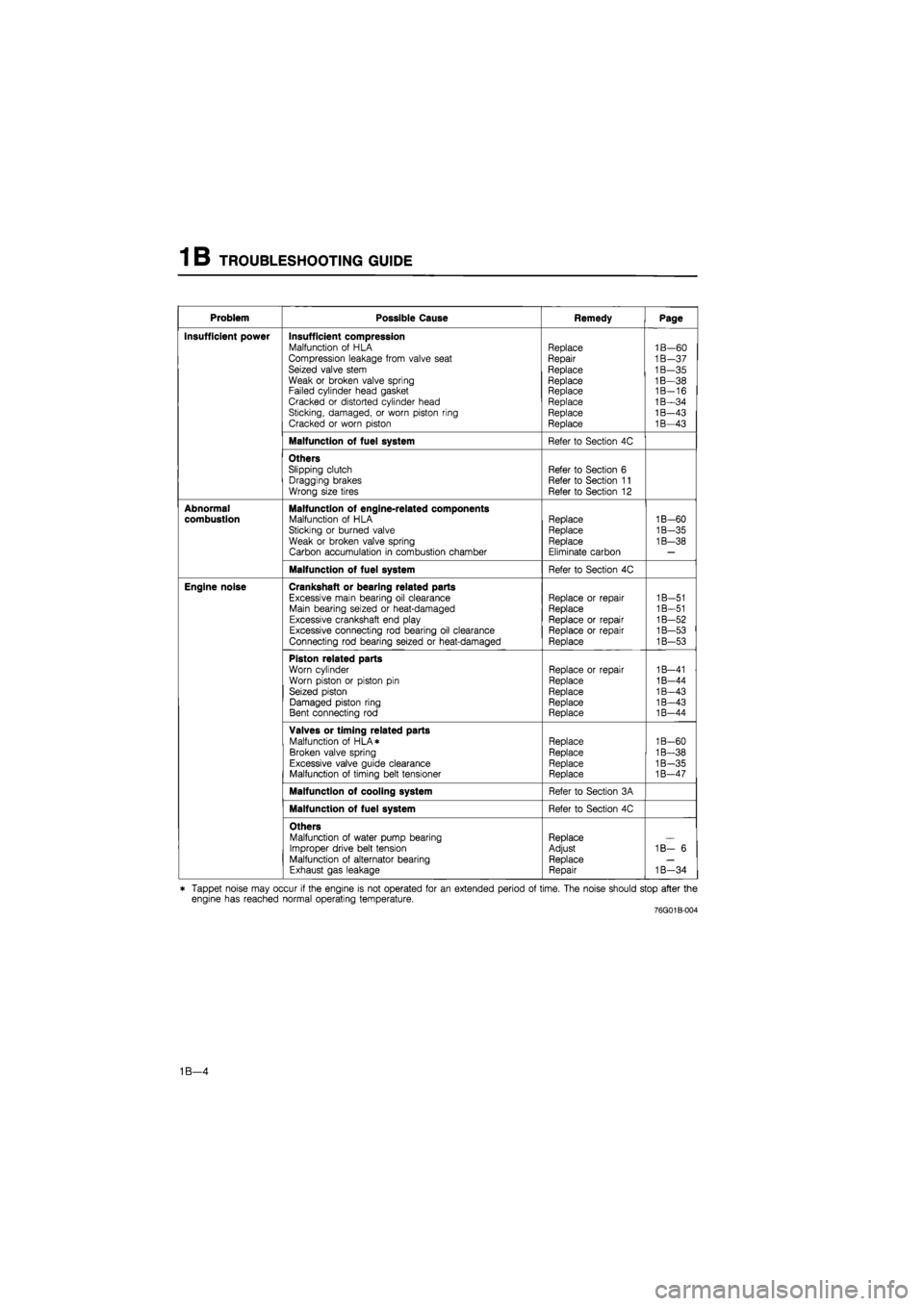

TROUBLESHOOTING GUIDE 1 B

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace Repair

Replace

Replace Replace Replace Replace Replace

1B—60 1B—37 1B—35 1B—38 1B-16 1B—34 1B—43 1B—43

Malfunction of fuel system Refer to Section 4C

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal combustion Malfunction of engine-related components Malfunction of HLA Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Replace Replace

Eliminate carbon

1B-60

1B-35

1B—38

Malfunction of fuel system Refer to Section 4C

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1B-51 1B—51 1B—52 1B—53 1B—53

Piston related parts

Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1B—41 1B-44 1B—43 1B—43 1B-44

Valves or timing related parts Malfunction of HLA* Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Replace Replace Replace

1B-60 1B—38 1B—35 1B—47

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4C

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1B— 6

1B—34

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the engine has reached normal operating temperature. 76G01B-004

1B—4

Page 216 of 1865

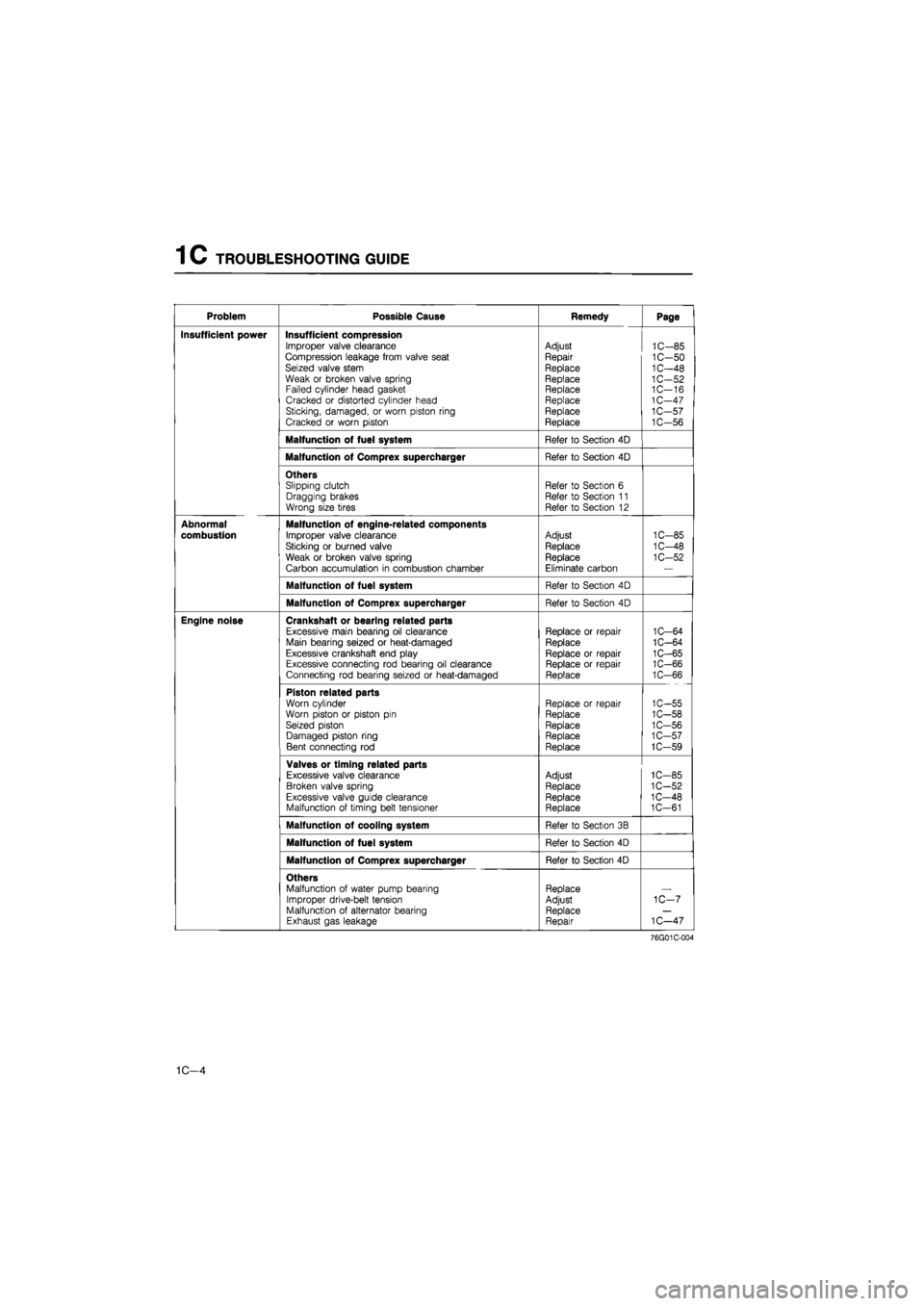

1 C TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Improper valve clearance Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Adjust

Repair

Replace Replace Replace Replace Replace Replace

1C-85 1C-50 1C-48 1C-52 1C—16 1C-47 1C-57 1C-56

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal

combustion

Malfunction of engine-related components

Improper valve clearance

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber

Adjust

Replace

Replace Eliminate carbon

1C-85

1C-48

1C-52

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Engine noise Crankshaft or bearing related parts Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1C-64 1C-64 1C-65 1C-66 1C-66

Piston related parts Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair Replace

Replace Replace Replace

1C-55 1C-58 1C-56 1C-57 1C-59

Valves or timing related parts Excessive valve clearance Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Adjust Replace Replace Replace

1C-85 1C-52 1C-48 1C-61

Malfunction of cooling system Refer to Section 3B

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Others Malfunction of water pump bearing Improper drive-belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1C-7

1C—47

76G01C-004

1C—4

Page 902 of 1865

7B TROUBLESHOOTING (G4A-EL)

Evaluation

Condition Possible Cause

No 1-2 up- or down-shift Stuck 1-2 shift solenoid valve

Stuck

1

-2 shift valve

No 2-3 up- or down-shift Stuck 2-3 shift solenoid valve Stuck 2-3 shift valve

No 3-OD up- or down-shift Stuck 3-4 shift solenoid valve Stuck 3-4 shift valve

No lock-up shift Stuck lock-up control solenoid valve Stuck lock-up control valve

Incorrect shift point Mis-adjusted throttle sensor Sticking shift valves

Excessive shift shock or slippage

Excessive shift shock Stuck accumulators Stuck or no one-way check orifice

Worn clutches, brakes, or one-way clutch

No engine braking effect Worn clutches or brakes

76G07B-035

Noise and vibration

Drive the vehicle in OD (lock-up), OD (no lock-up), 3rd (Hold) and check for abnormal noise or vibration.

Note

Abnormal noise and vibration can also be caused by the torque converter, drive shaft, or

differential. Therefore, checking of cause must be made with extreme care.

Kick-down

Drive the vehicle in OD, 3rd and 2nd gears and check that kick-down occurs for OD->3, OD->2, OD->1,

3->2, 3-+1, 2-> 1, and the shift points are as shown in the shift diagram.

S Range Test

Shift pattern

1. Shift the selector lever to S range and select the Economy mode.

2. Accelerate the vehicle and check that 1-2 and 2-3 up-shifts and down-shifts are obtained, and that

no overdrive and no lock-up are obtained.

Note

a) Inspections of shift shock and shift point are not necessary because these are the same

as those of the D Range Test.

b)ln S range, the shift patterns for Economy and Power modes are the same.

c) Shift points are the same as those of the D range (Power) shift diagram.

3. While driving in S range (Economy mode) and 3rd gear, select the Hold mode and check that 3rd

gear is held until the 3-2 down-shift point as shown in the S range (Hold) shift diagram is achieved.

4. Accelerate the vehicle with S range (Hold mode) and check that 2nd gear is held.

7B i—36