clock MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 825 of 1865

DISASSEMBLY 7 A

Disassembly Note

Transaxle

Mount the transaxle on the SST.

86U07A-037

Lock nut

1. Lock the primary shaft with the SST.

2. Shift to 1st or 2nd gear.

3. Remove the lock nut.

86U07A-038

Shift rod

rj 'ic^rv

Shift fork and shift rod assembly

1. Align the ends of the interlock sleeve and of the

control lever, then turn the shift rod counter-

clockwise.

2. While holding the 1st-2nd shift fork with one hand

and the 3rd-4th shift fork with the other, raise them

both at the same time and shift each of the clutch

hub sleeves.

86U07A-039

3. Lift the control end and remove the steel ball, and,

at the same time, remove the shift rod from the

clutch housing.

4. Separate the shift rod and shift fork assembly from

each of the clutch hub sleeves.

76U07A-227

7A-19

Page 933 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

Inspection of Continuity

1. Disconnect the brake light switch connector.

2. Check for continuity between the terminals while

depressing the brake pedal.

79G07C-114

76G07B-076

KICK-DOWN SWITCH (G4A-HL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage at terminal (V) with a voltmeter.

Depressing stroke Terminal voltage

7/8-8/8 (Full) Approx. 12V

0-7/8 Below 1,5V

3. If not correct, check the wiring harness, switch, or

adjust the switch position.

Inspection of Continuty

1. Disconnect the kick-down switch connector.

2. Check for continuity of the switch with an

ohmmeter.

Switch Continuity

Pushed Yes

Released No

3. If not correct, replace the kick-down switch.

76G07B-077

Adjustment

1. Loosen the kick-down switch locknuts.

2. Depress the accelerator pedal fully.

3. Turn the switch until the threaded case touches the

stopper.

4. Turn the switch counterclockwise by one half revo-

lution.

5. Secure the switch with the locknut.

76G07B-078

7B—67

Page 941 of 1865

ON-VEHICLE MAINTENANCE 7B

'mfm^i! kfOl iff t—

76G07B-093

76G07B-094

Main fuse block (G4A-EL)

Install the main fuse block.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

Battery carrier

Install the battery carrier.

Tightening torque:

31—40 Nm (3.2—4.1 m-kg, 23—30 ft-lb)

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks. (Refer to page

7 B—71)

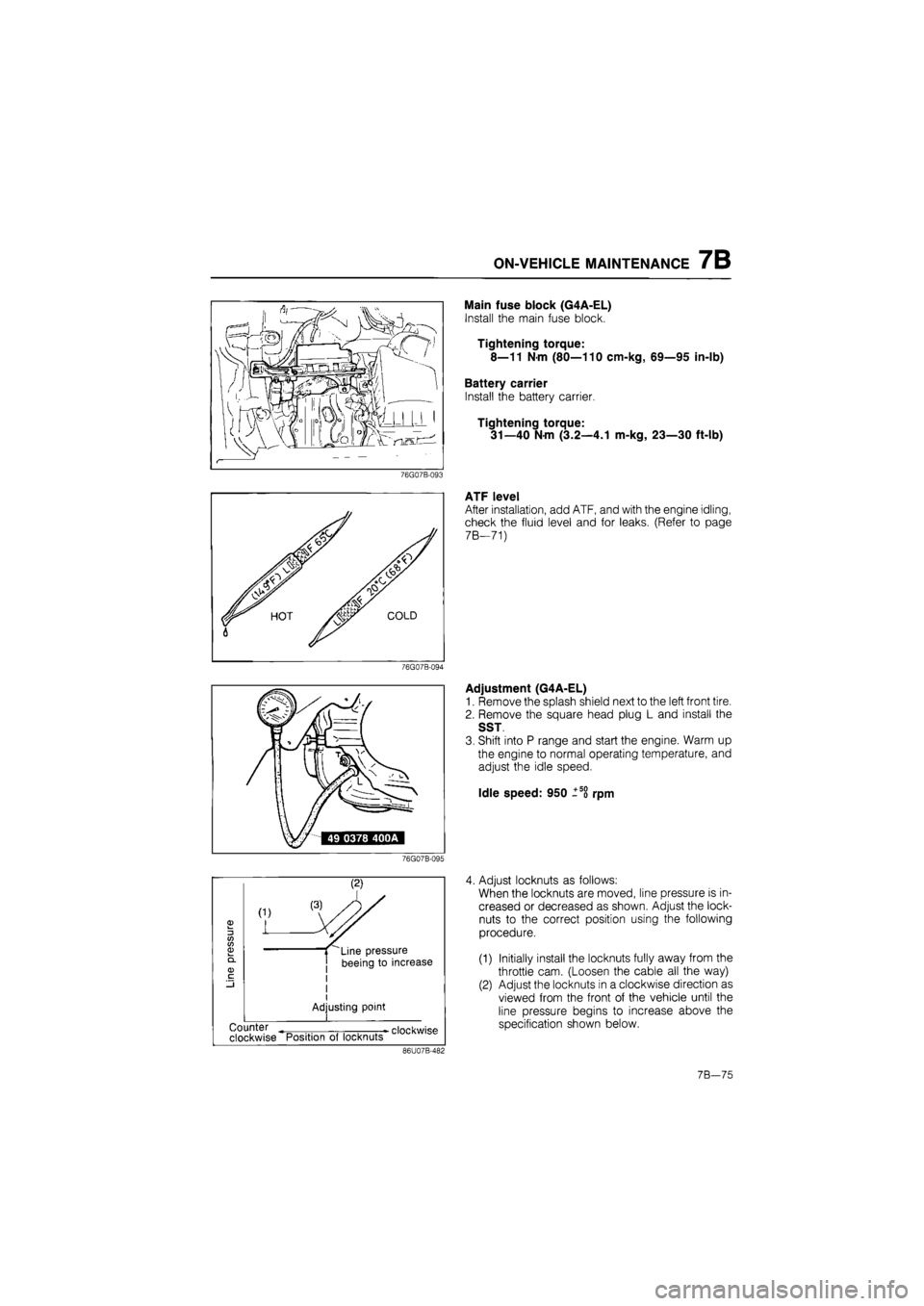

Adjustment (G4A-EL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug L and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 950 ±5o rpm

76G07B-095

3 CO CO 03

(1)

L

Line pressure

beeing to increase

I

Adjusting point

•

clockwise Counter

clockwise Position of locknuts

86U07B-482

4. Adjust locknuts as follows:

When the locknuts are moved, line pressure is in-

creased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

line pressure begins to increase above the

specification shown below.

7B—75

Page 942 of 1865

7B ON-VEHICLE MAINTENANCE

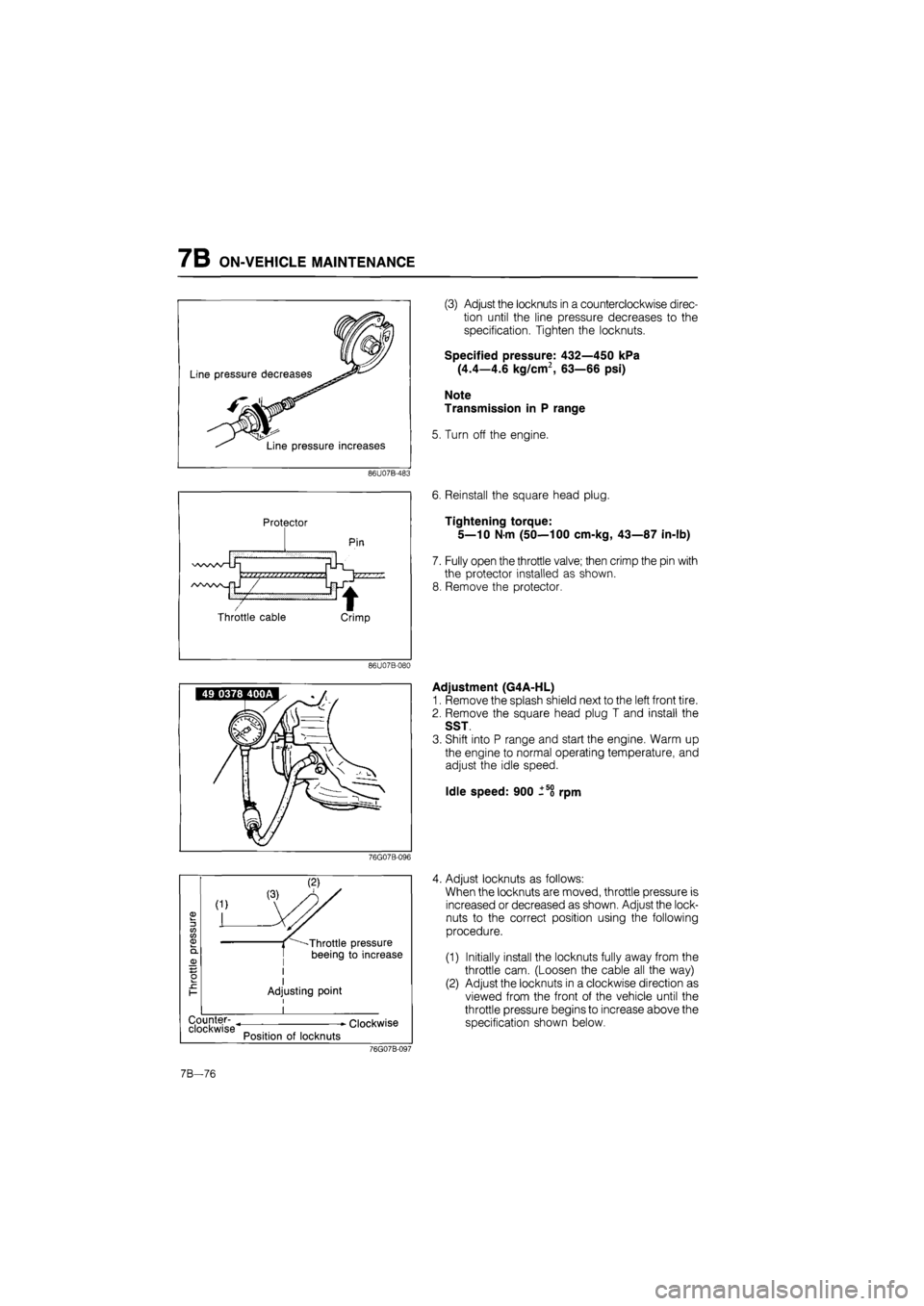

Line pressure decreases

Line pressure increases

86U07B-483

Protector

-7 / Throttle cable

86U07B-080

(3) Adjust the locknuts in a counterclockwise direc-

tion until the line pressure decreases to the

specification. Tighten the locknuts.

Specified pressure: 432—450 kPa

(4.4—4.6 kg/cm2, 63—66 psi)

Note

Transmission in P range

5. Turn off the engine.

6. Reinstall the square head plug.

Tightening torque:

5—10 N m (50—100 cm-kg, 43—87 in-lb)

7. Fully open the throttle valve; then crimp the pin with

the protector installed as shown.

8. Remove the protector.

Adjustment (G4A-HL)

1. Remove the splash shield next to the left front tire.

2. Remove the square head plug T and install the

SST

3. Shift into P range and start the engine. Warm up

the engine to normal operating temperature, and

adjust the idle speed.

Idle speed: 900 -5o rpm

76G07B-096

3 tn tn

L

Counter- ^ clockwise

Throttle pressure

beeing to increase

I Adjusting point

Position of locknuts

Clockwise

4. Adjust locknuts as follows:

When the locknuts are moved, throttle pressure is

increased or decreased as shown. Adjust the lock-

nuts to the correct position using the following

procedure.

(1) Initially install the locknuts fully away from the

throttle cam. (Loosen the cable all the way)

(2) Adjust the locknuts in a clockwise direction as

viewed from the front of the vehicle until the

throttle pressure begins to increase above the

specification shown below.

76G07B-097

7B—76

Page 943 of 1865

ON-VEHICLE MAINTENANCE 7B

Line pressure decreases

Line pressure increases

76G07B-098

Protector

NAAA/V^

/NA/w^nJ

Throttle cable Crimp

86U07B-080

(3) Adjust the locknuts in a counterclockwise direc-

tion until the throttle pressure decreases to the

specification. Tighten the locknuts.

Specified pressure: 88—108 kPa

(0.9—1.1 kg/cm2, 13—16 psi)

Note

Transmission in P range

5. Turn off the engine.

6. Reinstall the square head plug.

Tightening torque:

5—10 N m (50—100 cm-kg, 43—87 in-lb)

7. Fully open the throttle valve; then crimp the pin with

the protector installed as shown.

8. Remove the protector.

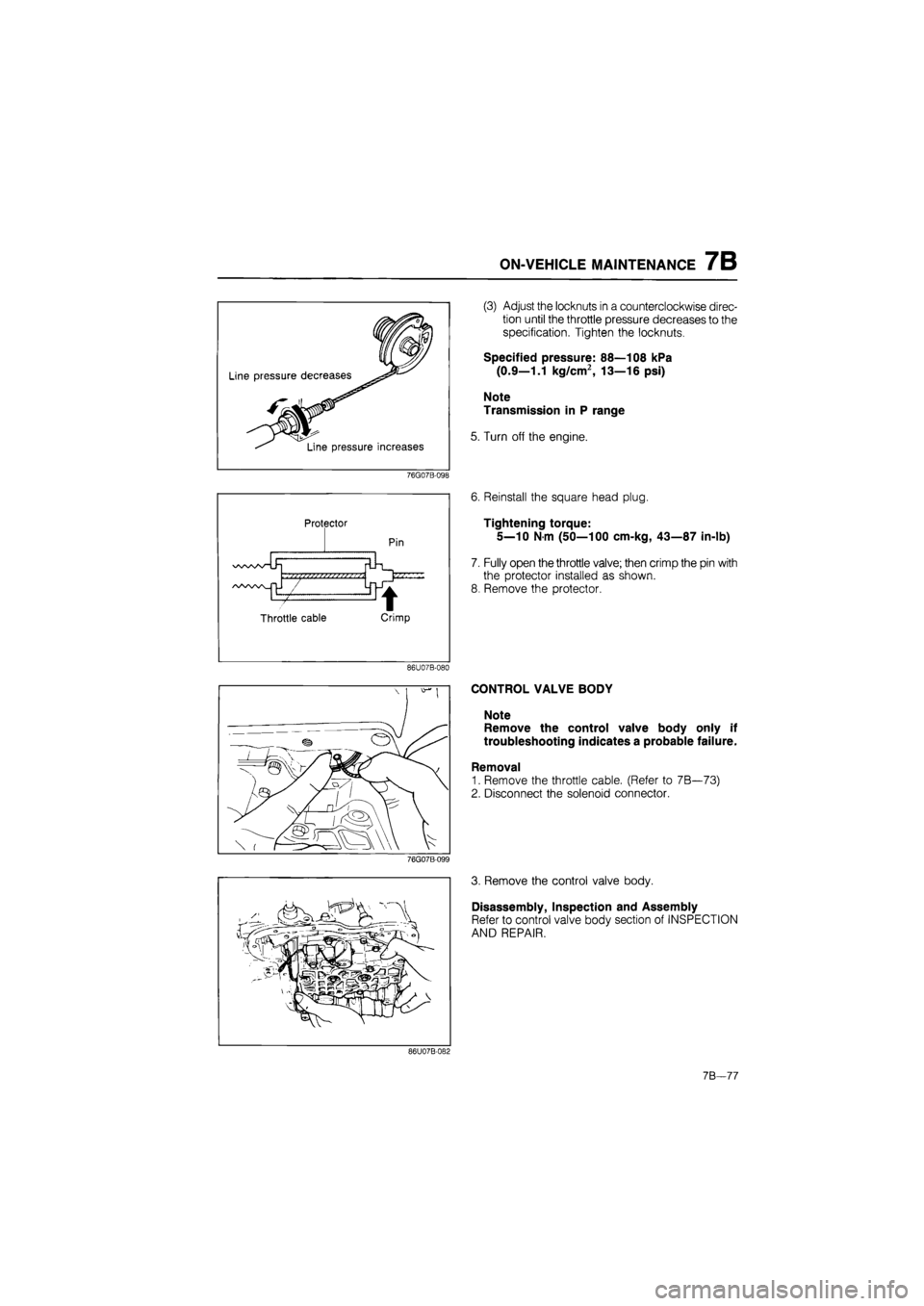

CONTROL VALVE BODY

Note

Remove the control valve body only if

troubleshooting indicates a probable failure.

Removal

1. Remove the throttle cable. (Refer to 7B—73)

2. Disconnect the solenoid connector.

76G07B-099

3. Remove the control valve body.

Disassembly, Inspection and Assembly

Refer to control valve body section of INSPECTION

AND REPAIR.

86U07B-082

7B—77

Page 988 of 1865

7B INSPECTION AND REPAIR

SMALL SUN GEAR AND ONE-WAY CLUTCH

Disassembly

Disassemble in the sequence shown in the figure.

1. Thrust bearing

2. Snap ring

3. One-way clutch

inner race

4. Thrust bearing

5. Snap ring

6. Small sun gear

7. Sun gear drum

8. Thrust bearing

9. One-way clutch

outer race

10. One-way clutch

86U07B-221

Inspection

Check the following and replace any faulty parts.

1. Sun gear drum and small sun gear for damage or

wear

2. Bushing for damage or wear

Specification:

Sun gear drum: 33.425 mm (1.316 in) max.

Small sun gear: 24.021 mm (0.946 in) max.

86U07B-222

3. Inner and outer race for damage or wear

4. Damaged or worn clutch hub

5. Damaged or worn gear

6. Damaged or worn thrust bearing

7. Broken or worn snap ring

8. One-way clutch operation

Hold the one-way clutch outer race. Check that the

inner race turns only counterclockwise.

86U07B-223

7B—122

Page 990 of 1865

7B INSPECTION AND REPAIR

86U07B-228

86U07B-229

86U07B-230

7. Install the one-way clutch inner race into the one-

way clutch outer race by turning inner race coun-

terclockwise.

8. Hold the one-way clutch outer race. Check that the

inner race turns only counterclockwise.

Assembly

1. Install the small sun gear into the sun gear drum.

2. Install the snap ring.

3. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it to the one-way clutch inner

race.

Thrust bearing outer diameter:

62.1 mm (2.44 in)

4. Install the one-way clutch inner and outer race to

the sun gear drum.

Note

Align the splines of the one-way clutch inner

race and small sun gear clutch hub.

86U07B-231

7B—124

Page 991 of 1865

INSPECTION AND REPAIR 7B

5. Install the snap ring.

86U07B-232

86U07B-233

6. Check that when the small sun gear is held, the

one-way clutch outer race turns smoothly and only

clockwise.

7. Apply petroleum jelly to the thrust bearing to se-

cure it; then install it to the sun gear drum.

Thrust bearing outer diameter:

72.0 mm (2.83 in)

86U07B-234

7B—125

Page 993 of 1865

INSPECTION AND REPAIR 7B

One-way clutch 6. Damaged or worn one-way clutch and operation

7. Detached roller

Note

Assemble the one-way clutch and the inner

race, then confirm that the one-way clutch ro-

tates only clockwise and smoothly.

86U07B-238

Assembly

1. Assemble the carrier hub assembly to the inner

race.

86U07B-239

2. Install th snap ring.

86U07B-240

3. Apply petroleum jelly to the bearing races to se-

cure them; then install them to both sides of the

one-way clutch and carrier hub assembly.

Bearing race outer diameter

Sun gear drum side: 72.0 mm (2.83 in)

3-4 clutch side: 57.0 mm (2.21 in)

Note

Install the tabs of the bearing race into the

alignment holes.

86U07B-241

7B—127

Page 1071 of 1865

ASSEMBLY 7B

11. Install the one-way clutch.

(1) Hold the one-way clutch horizontally.

(2) Install it by turning the carrier hub assembly

counterclockwise.

(3) Install the snap ring.

86U07B-406

49 G019 028

12. Install the servo to the transaxle case.

(1) Install the servo spring and servo.

(2) Compress the servo with the SST.

(3) Install the snap ring.

(4) Remove the SST.

(5) Install the piston stem.

86U07B-407

13. Install the anchor strut.

86U07B-408

14. Install the 2-4 brake band in the transaxle case so

that it is expanded fully.

Note

Interlock the 2-4 brake band and anchor strut

as shown.

86U07B-409

7B-205