engine oil capacity MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 713 of 1865

TROUBLESHOOTING GUIDE 5

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Starter does not turn at all, or Its turning speed Is too slow to start the engine.

Battery and related parts Poor contact of battery terminals Poor grounding of negative cable Voltage drop caused by discharged battery Insufficient voltage caused by battery malfunction

Clean and tighten Clean and repair Recharge Replace

5- 8

5- 8 5- 8

Ignition switch and related parts Poor contact of ignition switch Loose ignition switch wiring or connector Broken wire between ignition switch and magnetic switch

Replace Repair Repair or replace 5-38,45,56,66

Magnetic switch and related parts Loose wiring and/or connectors Burnt magnetic switch contact plate or improper contact Broken wire in magnetic switch pull-in coil Broken wire magnetic switch holding coil

Repair Replace

Replace Replace

5-38,45,56,66 5-43,54,64,74

5-43,54,64,74 5-43,54.64,74

Starter Poor contact of brushes

Fatigued brush spring Poor grounding of field coil Poor soldering of field coil Commutator mulfunction Grounded armature Worn parts

Adjust contact or replace Replace Replace Repair Repair or Replace Replace Replace

5-43,54,64,74

Starting problem Gasoline engine Insufficient battery capacity Malfunction of spark plug (s)

Loose positive terminal Damaged distributor cap or rotor Ignition coil malfunction laniter malfunction

Recharge Clean, adjust or replace Tighten Replace Replace Renlane

5— 8 5— 9

5—16 5—10 5-16,20

Diesel engine Insufficient battery capacity QSS svstem malfunction Recharge ReDlace 5— 8 5-76

Starter turns but pinion gear does not mesh with ring gear

Starter Tip of overrunning clutch pinion is worn Weakened overrunning clutch drive spring Worn overrunning clutch Improper sliding of spline

Worn bushing Worn ring gear

Replace Replace Replace Adjust contact and repair, or replace Replace ReDlace

5-40,54,70

Starter turns continuously (does not stop) Magnetic switch Sticking contact place of magnetic switch Layer shorting coil of magnetic switch Ignition switch does not return

Replace Replace Rfinlanfi

5-43,54,64,74 5-43,54,64,74

Misfiring Dirty or damaged spark plug (s) Malfunction of wiring, or open circuit Damaged distributor cap

Clean or replace Repair or Replace Replace

5- 9 5—10 5—16

Discharging of battery Alternator Loose drive belt Grounded or broken stator coil Broken rotor coil Poor contact of brush and slip ring

Malfunction of rectifier Malfunction of IC regulator Battery and related parts Insufficient or unsuitable battery electrolyte Malfunction of battery electrode (internal short-circuit) Poor contact of battery terminal (s) Excessive electric load

Adjust Replace Replace Clean, repair or replace Replace Replace

Adjust Replace

Clean and tighten Check power consump-tion and short circuit

5-37 5-32 5-32 5-32

5-34

5— 8 5- 8

5— 8

Overcharging of battery IC regulator malfunction Operating in extremely high temperature Replace Reoair

Poor acceleration Mis-adjusted ignition timing Distributor malfunction Adjust Repair or replace 5—11 5—11

Knocking Mis-adjusted ignition timing | Distributor malfunction Adjust Repair or replace 5—11 5—11

76G05X-003

5-7

Page 810 of 1865

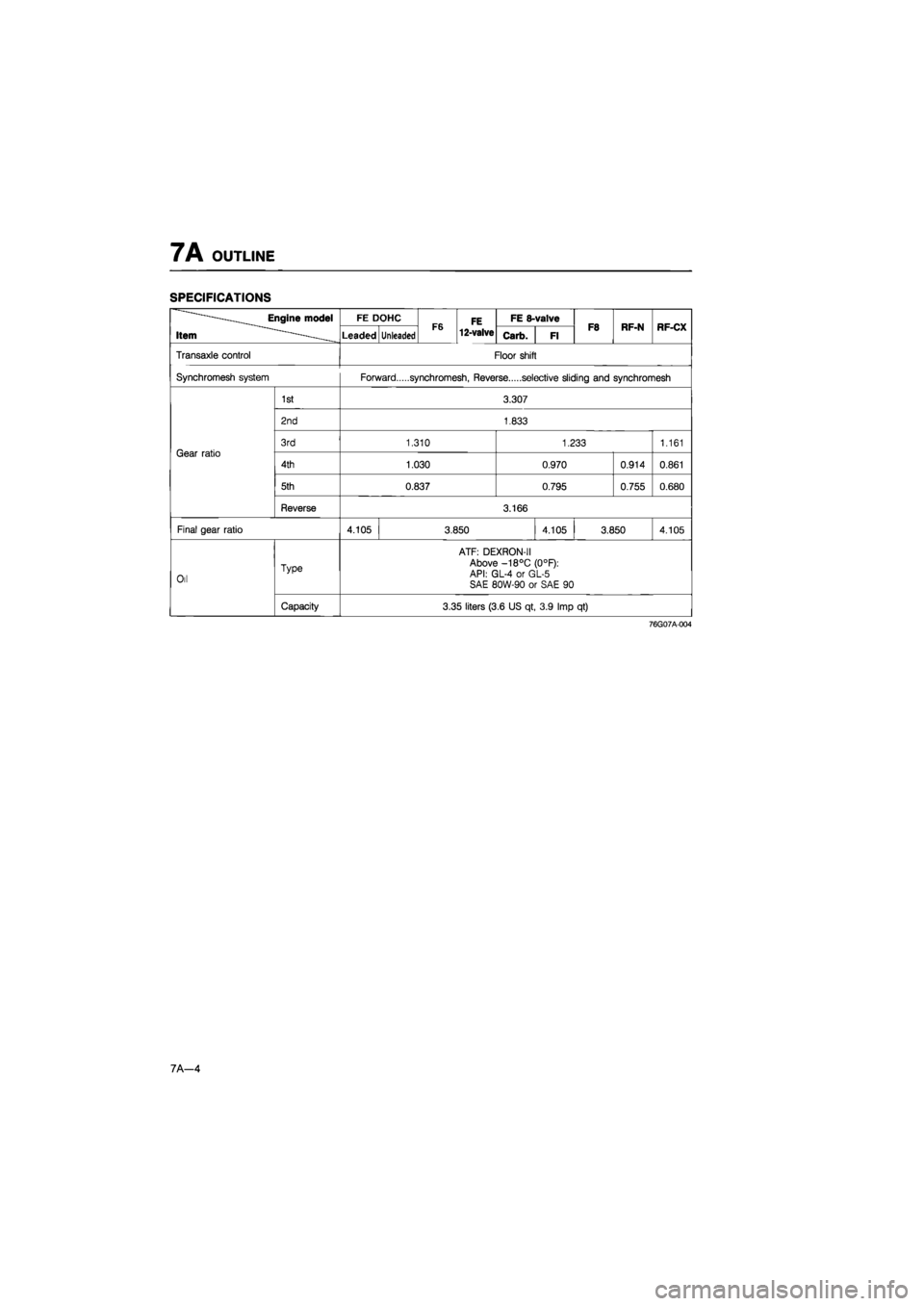

7A OUTLINE

SPECIFICATIONS

•Engine model

Item ——

FE DOHC F6 FE 12-valve

FE 8-valve F8 RF-N RF-CX •Engine model

Item —— Leaded Unleaded F6 FE 12-valve Carb. Fl F8 RF-N RF-CX

Transaxle control Floor shift

Synchromesh system Forward synchromesh, Reverse selective sliding and synchromesh

Gear ratio

1st 3.307

Gear ratio

2nd 1.833

Gear ratio 3rd 1.310 1.233 1.161 Gear ratio

4th 1.030 0.970 0.914 0.861

Gear ratio

5th 0.837 0.795 0.755 0.680

Gear ratio

Reverse 3.166

Final gear ratio 4.105 3.850 4.105 3.850 4.105

Oil Type

ATF: DEXRON-II Above -18°C (0°F): API: GL-4 or GL-5 SAE 80W-90 or SAE 90 Oil

Capacity 3.35 liters (3.6 US qt, 3.9 Imp qt)

76G07A-004

7A—4

Page 907 of 1865

TROUBLESHOOTING (G4A-HL) 7B

TROUBLESHOOTING (G4A-HL)

GENERAL NOTE

In the event of a problem with the automatic transaxle, the cause may be in the engine, power train,

hydraulic control system, or electrical control system.

When troubleshooting, therefore, it is recommended to begin from those points that can be judged

quickly and easily. The recommended troubleshooting sequence is described below.

STEP 4: TIME LAG TEST

Check time lag of oil pressure supply

STEP 6: OIL PRESSURE TEST Check line, throttle, and governor pressures

This step checks conditions surrounding the automatic

transaxle.

This step checks the electrical control system.

• Function of the electrical control system

• Components

This step checks the power train. • Friction element slipping • Torque converter capacity

This step checks operation of the hydraulic control system. • Accumulators • Friction elements slipping • Regulating valves

This step checks functions of the electric control system and

hydraulic control system.

This step checks major points of the hydraulic control system.

• Oil pump • Line pressure control • Throttle pressure control

• Governer pressure control

STEP 5: ROAD TEST Check items on road test

• Shift point • Shift schedule

• Kick-down • Shift shock • Lock-up and overdrive inhibition

By following the above 6 steps, the cause of the problem should be located.

As another guide to faster location of the causes of problems, the Quick Diagnosis Chart is included

at pages 7B—42, 43.

In this chart, a circle is used to indicate the components that might be the cause of trouble for 20

types of problems. It is only necessary to check those components indicated by circles, at each step

of the troubleshooting process, in order to quickly locate the cause of the problem.

76G07B-040

7B—41

Page 1027 of 1865

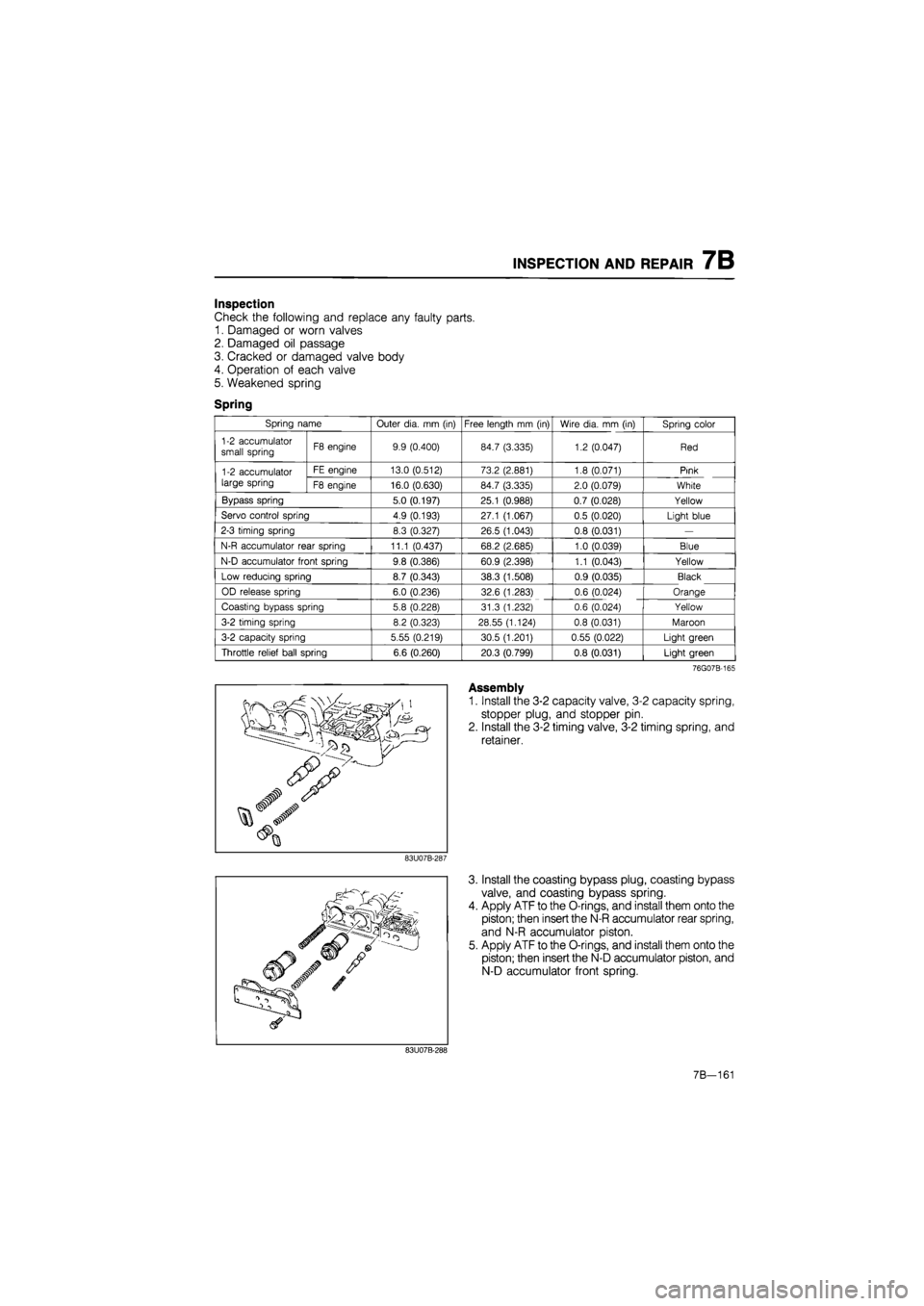

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm (in)

Wire dia.

mm

(in) Spring color

1-2 accumulator small spring F8 engine 9.9 (0.400) 84.7 (3.335) 1.2 (0.047) Red

1-2 accumulator large spring

FE engine 13.0 (0.512) 73.2 (2.881) 1.8 (0.071) Pink 1-2 accumulator large spring F8 engine 16.0 (0.630) 84.7 (3.335) 2.0 (0.079) White

Bypass spring 5.0 (0.197) 25.1 (0.988) 0.7 (0.028) Yellow

Servo control spring 4.9 (0.193) 27.1 (1.067) 0.5 (0.020) Light blue

2-3 timing spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

N-R accumulator rear spring 11.1 (0.437) 68.2 (2.685) 1.0 (0.039) Blue

N-D accumulator front spring 9.8 (0.386) 60.9 (2.398) 1.1 (0.043) Yellow

Low reducing spring 8.7 (0.343) 38.3 (1.508) 0.9 (0.035) Black

OD release spring 6.0 (0.236) 32.6 (1.283) 0.6 (0.024) Orange

Coasting bypass spring 5.8 (0.228) 31.3 (1.232) 0.6 (0.024) Yellow

3-2 timing spring 8.2 (0.323) 28.55 (1.124) 0.8 (0.031) Maroon

3-2 capacity spring 5.55 (0.219) 30.5 (1.201) 0.55 (0.022) Light green

Throttle relief ball spring 6.6 (0.260) 20.3 (0.799) 0.8 (0.031) Light green

76G07B-165

Assembly

1. Install the 3-2 capacity valve, 3-2 capacity spring,

stopper plug, and stopper pin.

2. Install the 3-2 timing valve, 3-2 timing spring, and

retainer.

83U07B-287

3. Install the coasting bypass plug, coasting bypass

valve, and coasting bypass spring.

4. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-R accumulator rear spring,

and N-R accumulator piston.

5. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-D accumulator piston, and

N-D accumulator front spring.

83U07B-288

7B—161

Page 1122 of 1865

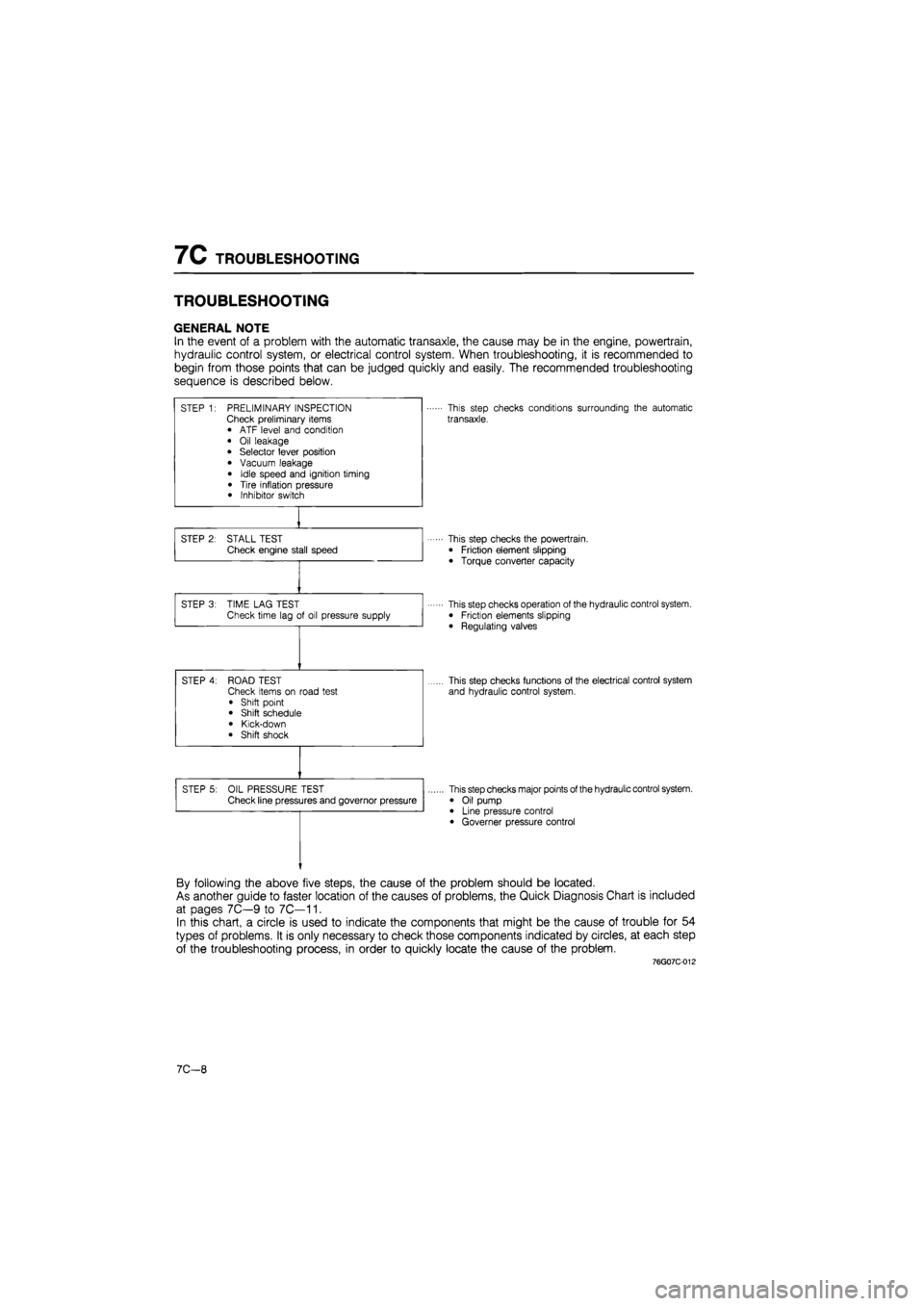

7C TROUBLESHOOTING

TROUBLESHOOTING

GENERAL NOTE

In the event of a problem with the automatic transaxle, the cause may be in the engine, powertrain,

hydraulic control system, or electrical control system. When troubleshooting, it is recommended to

begin from those points that can be judged quickly and easily. The recommended troubleshooting

sequence is described below.

STEP 1: PRELIMINARY INSPECTION Check preliminary items • ATF level and condition

• Oil leakage • Selector lever position

• Vacuum leakage

• Idle speed and ignition timing

• Tire inflation pressure • Inhibitor switch

This step checks conditions surrounding the automatic

transaxle.

STEP 2: STALL TEST Check engine stall speed This step checks the powertrain.

• Friction element slipping

• Torque converter capacity

STEP 3: TIME LAG TEST Check time lag of oil pressure supply This step checks operation of the hydraulic control system. • Friction elements slipping

• Regulating valves

STEP 4: ROAD TEST Check items on road test

• Shift point • Shift schedule

• Kick-down • Shift shock

This step checks functions of the electrical control system

and hydraulic control system.

STEP 5: OIL PRESSURE TEST Check line pressures and governor pressure This step checks major points of the hydraulic control system.

• Oil pump • Line pressure control • Governer pressure control

By following the above five steps, the cause of the problem should be located.

As another guide to faster location of the causes of problems, the Quick Diagnosis Chart is included

at pages 7C—9 to 7C—11.

In this chart, a circle is used to indicate the components that might be the cause of trouble for 54

types of problems. It is only necessary to check those components indicated by circles, at each step

of the troubleshooting process, in order to quickly locate the cause of the problem.

76G07C-012

7C—8

Page 1828 of 1865

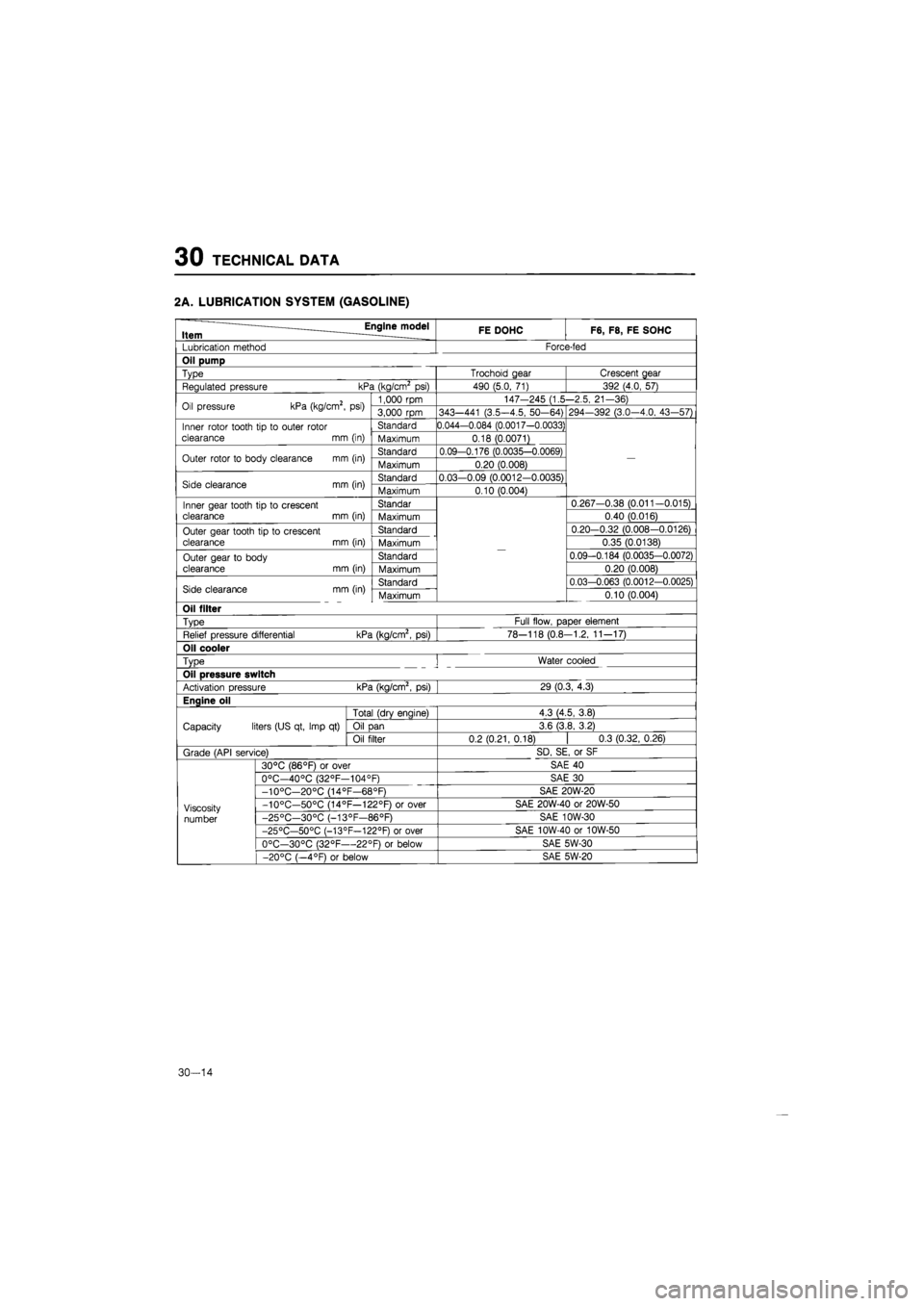

30 TECHNICAL DATA

2A. LUBRICATION SYSTEM (GASOLINE)

Engine model Item ____ FE DOHC F6, F8, FE SOHC

Lubrication method Force-fed

Oil pump

Type Trochoid gear Crescent gear

Regulated pressure kPa (kg/cm2

psi)

490 (5.0,

71)

392 (4.0, 57)

Oil pressure kPa (kg/cm2,

psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pressure kPa (kg/cm2,

psi)

3,000

rpm

343—441 (3.5-4.5, 50-64) 294—392 (3.0—4.0, 43-57)

Inner rotor tooth

tip to

outer rotor

clearance

mm

(in)

Standard 0.044-0.084 (0.0017-0.0033)

—

Inner rotor tooth

tip to

outer rotor

clearance

mm

(in) Maximum 0.18 (0.0071)

—

Outer rotor

to

body clearance

mm

(in) Standard 0.09-0.176 (0.0035-0.0069)

—

Outer rotor

to

body clearance

mm

(in) Maximum 0.20 (0.008)

—

Side clearance

mm

(in) Standard 0.03-0.09 (0.0012-0.0035)

—

Side clearance

mm

(in) Maximum 0.10 (0.004)

—

Inner gear tooth tip

to

crescent clearance

mm

(in)

Standar

—

0.267-0.38 (0.011-0.015) Inner gear tooth tip

to

crescent clearance

mm

(in) Maximum

—

0.40 (0.016)

Outer gear tooth tip

to

crescent clearance

mm

(in)

Standard

—

0.20-0.32 (0.008-0.0126) Outer gear tooth tip

to

crescent clearance

mm

(in) Maximum

—

0.35 (0.0138)

Outer gear

to

body

clearance

mm

(in)

Standard

—

0.09-0.184 (0.0035-0.0072) Outer gear

to

body

clearance

mm

(in) Maximum

—

0.20 (0.008)

Side clearance mm (in) Standard

—

0.03-0.063 (0.0012-0.0025) Side clearance mm (in) Maximum

—

0.10 (0.004)

Oil filter

Type Full flow, paper element

Relief pressure differential kPa (kg/cm2,

psi)

78-118 (0.8-1.2, 11-17)

Oil cooler

Type

!

Water cooled

Oil pressure switch

Activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Enaine oil

Capacity liters (US qt, Imp

qt)

Total (drv enaine) 4.3 (4.5, 3.8)

Capacity liters (US qt, Imp

qt)

Oil

Dan

3.6 (3.8, 3.2) Capacity liters (US qt, Imp

qt)

Oil filter 0.2(0.21,0.18)

|

0.3 (0.32,0.26)

Grade (API service) SD, SE,

or

SF

Viscosity

number

30°C (86°F)

or

over SAE

40

Viscosity

number

0°C—40°C (32°F—104°F) SAE

30

Viscosity

number

-10°C—20°C (14°F—68°F) SAE 20W-20

Viscosity

number

-10°C—50°C (14°F—122°F)

or

over SAE 20W-40

or

20W-50 Viscosity

number -25°C—30°C (-13°F—86°F) SAE 10W-30 Viscosity

number

-25°C—50°C (-13°F—122°F)

or

over SAE 10W-40

or

10W-50

Viscosity

number

0°C—30°C (32°F—22°F)

or

below SAE 5W-30

Viscosity

number

-20°C (—4°F)

or

below SAE 5W-20

30-14

Page 1829 of 1865

TECHNICAL DATA 30

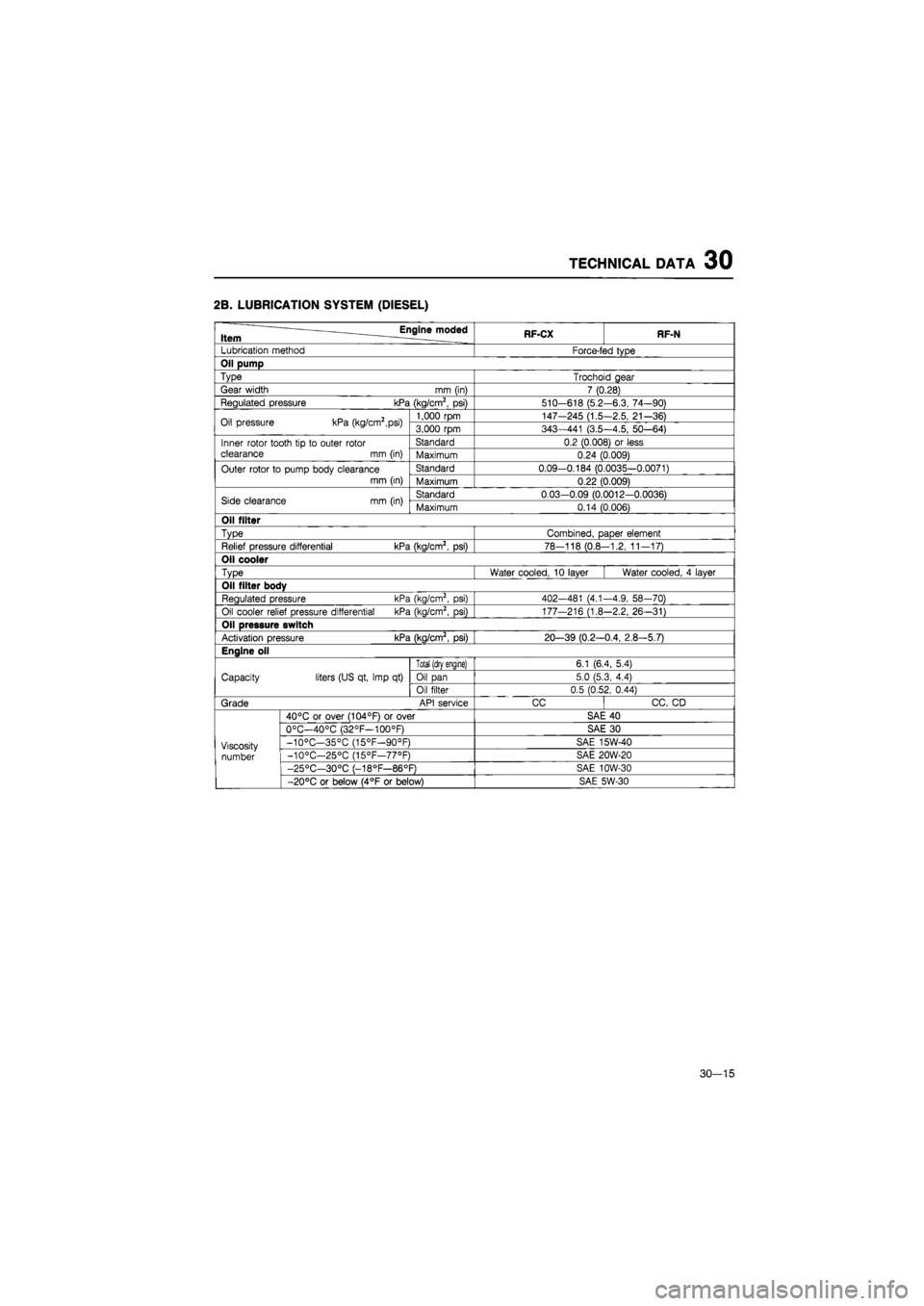

2B. LUBRICATION SYSTEM (DIESEL)

Engine moded Item RF-CX RF-N

Lubrication method Force-fed type

Oil pump

Type Trochoid gear

Gear width

mm

(in) 7 (0.28)

Regulated pressure kPa (kg/cm2,

psi)

510-618 (5.2-6.3, 74-90)

Oil pressure kPa (kg/cm2,psi) 1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pressure kPa (kg/cm2,psi) 3,000 rpm 343—441 (3.5—4.5, 50—64)

Inner rotor tooth

tip to

outer rotor clearance

mm

(in)

Standard 0.2 (0.008)

or

less Inner rotor tooth

tip to

outer rotor clearance

mm

(in) Maximum 0.24 (0.009)

Outer rotor

to

pump body clearance

mm (in)

Standard 0.09-0.184 (0.0035-0.0071) Outer rotor

to

pump body clearance

mm (in) Maximum 0.22 (0.009)

Side clearance

mm

(in) Standard 0.03-0.09 (0.0012-0.0036) Side clearance

mm

(in) Maximum 0.14 (0.006)

Oil filter

Type Combined, paper element

Relief pressure differential kPa (kg/cm2,

psi)

78-118 (0.8-1.2, 11-17)

Oil cooler

Type Water cooled,

10

layer Water cooled,

4

layer

Oil filter body

Regulated pressure kPa (kg/cm2,

psi)

402-481 (4.1-4.9, 58—70)

Oil cooler relief pressure differential kPa (kg/cm2,

psi)

177-216 (1.8-2.2, 26-31)

Oil pressure switch

Activation pressure kPa (kg/cm2,

psi)

20-39 (0.2—0.4, 2.8-5.7)

Engine oil

Capacity liters (US qt, Imp

qt)

Total (drv enaine) 6.1 (6.4, 5.4)

Capacity liters (US qt, Imp

qt)

Oil pan 5.0 (5.3, 4.4) Capacity liters (US qt, Imp

qt)

Oil filter 0.5 (0.52, 0.44)

Grade API service CC CC,

CD

Viscosity number

40°C

or

over (104°F)

or

over SAE

40

Viscosity number

0°C—40°C (32°F—100°F) SAE

30

Viscosity number

-10°C—35°C (15°F—90°F) SAE 15W-40 Viscosity number -10°C—25°C (15°F—77°F) SAE 20W-20 Viscosity number

-25°C—30°C (-18°F—86°F) SAE 10W-30

Viscosity number

-20°C

or

below (4°F

or

below) SAE 5W-30

30—15

Page 1832 of 1865

30 TECHNICAL DATA

4A. FUEL AND EMISSION CONTROL SYSTEM (CARBURETOR)

F6 and F8 Engine

Engine F6 F8

Spec. General Singapore General

ECE, Hong

Kong, &

Singapore

Idle speed rpm MTX 800

+ 50

0 Idle speed rpm ATX (in

N

range)

—

950 +58 900

+ 50

0

CO concentration °/o 2.0

± 0.5

Carburetor

Type Down draft two barrel

Throat diameter mm (in) Primary 30 (1.18) Throat diameter mm (in) Secondary 34 (1.34)

Venturi diameter mm (in) Primary 23.5 (0.93) Venturi diameter mm (in) Secondary 29.0 (1.14)

Main nozzle mm (in) Primary 2.6 (0.10) Main nozzle mm (in) Secondary 2.8 (0.11)

Primary MTX 1.10 1.09 (0.0429) 1.14 (0.045)

Main

jet

mm (in) Primary ATX (0.0433) 1.08 (0.0425) 1.12 (0.044)

Secondary 1.50 (0.059)

Primary MTX 0.60 0.60 (0.024) 0.55 (0.022)

Main

air

bleed mm (in) Primary ATX (0.024) 0.80 (0.031) 0.60 (0.024)

Secondary 0.50 (0.020)

Slow

jet

mm (in) Primary 0.48 (0.019) 0.46 (0.018) Slow

jet

mm (in) Secondary 1.00 (0.039) 1.10 (0.043)

Primary No.

1

0.80 (0.031)

Slow

air

bleed Primary No.

2

1.90 (0.075)

mm (in) Secondary No.

1

1.00 (0.039) 0.80 (0.031) Secondary No.

2

0.50 (0.020)

Power

jet

mm (in) 0.50 (0.020)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore 1.40-1.76(0.055-0.069) MTX: 0.48-0.64 (0.019-0 025) ATX: 0.56-0.72 (0.022-0.028)

Max. fuel flow

"L"

44 (17.3)

Float level adjustment Clearance between float and

air

horn without gasket

mm (in) Fuel stop

"H •

12.5 (0.49)

Clearance between float and

air

horn/without gasket; float lowered

by

own weight

Choke breaker diaphragm Start 180-240 (7.1-9.5) 100—160 (3.9-6.3)

mmHg

(in Hg)

Stop 290—350 (11.4-13.8) 220-280 (8.7-11.0)

Choke opener Start

—

35-65 (1.4-2.6)

—

35-65 (1.4-2.6)

mmHg

(in Hg)

Stop

—

130-190 (5.1-7.5)

—

130-190

(5,1-7.5)

Accelerator linkage

Free plav

of

cable

at

carburetor mm (in) 1-3 (0.039—0.118)

Fuel tank

Capacity Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel pump

Type Mechanical pump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8-3.8)

Feedina capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switching Manual Diaphragm type

Element

tvDe

Oil permeated paper

Fuel specification Leaded regular

30-18

Page 1833 of 1865

TECHNICAL DATA 30

FE Engine

Engine 8 Valve 12 Valve 8 Valve

Spec. General Middle

East

ECE,

Hong Kong, &

Singapore

Unleaded

Fuel

(West Germany)

Idle speed rpm MTX 800

+5§

850 Idle speed rpm ATX 900 +5S

(ir

N range)

CO concentration

%

2.0

± 0,5

Carburetor

Type Down draft, two barrel

Throat diameter mm (in) Primary 30 (1.18) Throat diameter mm (in) Secondary 34 (1.34)

Venturi diameter mm (in) Primary 23.5 (0.93) Venturi diameter mm (in) Secondary 29.0 (1.14)

Main nozzle mm (in) Primary 2.6 (0.10) Main nozzle mm (in) Secondary 2.8 (0.11)

Primary MTX 1.14 (0.045) 1.09 (0.0429) 1.14 (0.045) 1.09 (0.0429) Main

jet

mm (in) Primary ATX 1.12 (0.044) 1.08 (0.0425) 1.12 (0.044) 1.09 (0.0429)

Secondary 1.55 (0.061) 1.50 (0.059) 1.55 (0.061) 1.50 (0.059)

Primary MTX 0.50 (0.020) 0.60 (0.024) 0.50 (0.020) 0.50 (0.020) Main

air

bleed mm (in) Primary ATX 0.55 (0.022) 0.80 (0.031) 0.55 (0.022) 0.50 (0.020)

Secondary 0.50 (0.020)

Primary 0.46 (0.018)

Slow jet mm (in) Secondary MTX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 0.90 (0.035) Secondary ATX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 1.00 (0.031)

Primary No.

1

0.80 (0.031)

Slow

air

bleed Primary No.

2

1.90 (0.075)

mm (in) Secondary No.

1

0.80 (0.031) 1.00 (0.039) 0.80 (0.031) 1.00 (0.039) Secondary No.

2

0.50 (0.020)

Power jet mm (in) MTX 0.50 (0.020) 0.50 (0.020) Power jet mm (in) ATX 0.50 (0.020) 0.40 (0.016)

Fast idle adjustment mm (in) MTX 0.48-0.64 (0.019-0.025) 1 40—1

76

0.48-0.64 (0.019-0.025) 1

40

1

76

Clearance between primary throttle valve and bore ATX 0.56-0.72

(0.022-0.028) (0.055-0.069) 0.56-0.72 (0.022-0.028) (0.055-0.069)

Max. fuel flow

"L"

44 (17.3)

Float level adjustment Clearance between float and

air

horn without aasket

mm (in) Fuel stop

"H •

12.5 (0.49)

Clearance between float and

air

horn without aasket float lowered

bv

own weiaht

Choke breaker diaphragm Start

100-160 (3,9-6.3) 180-240 (7.1-94) 100-160 (39-6.3) 180-240 (7.1-9,4)

mmHg

(in Hg)

Stop

220-280 (8.7-11,0) 290-350 (11,4-13.8) 220-280 (8.7-11.0) 290-350 (11.4-13.8)

Choke opener mmHg (in

Hg)

Start

—

80-120 (3.1-8.7) 30-70 (1.2-2.8)

—

Choke opener mmHg (in

Hg)

Stop

—

220-280 (87-11.0) 130-190 (5.1-7.5)

—

Accelerator llnkaae

Free play

of

cable

at

carburetor mm (in) 1-3 (0.039-0.118)

Fuel tank

Capacity Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel pump

TvDe

Mechanical pump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8-3.8)

20-29 (0.20-030, 2.8-4.3) 20-26

(020-0.27, 28-38)

Feeding capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

TvDe

Paoer element with maanet

Air cleaner

Fresh-Hot switchina Diaohraam Manual Diaohraam Bimetal

Element tvoe Oil oermeated oaoer

Fuel specification Leaded super Unleaded super Leaded regular Leaded super Unleaded super Unleaded regular

30-19

Page 1840 of 1865

30 TECHNICAL DATA

7A. MANUAL TRANSAXLE

Engine model FE DOHC Ffl FE FE

B

valve F8 Item —— Leaded UriBsded Ffl 12 valve Carb. Fl F8 RF-N RF-CX

Transmission

Shift

lever

position Floor shift

Gear ratio

First 3.307

Second 1.833

Third 1.310

Fourth 1.030

Fifth 0.837

1,233

0.970

0.795

0.914

1.161

0.861

0.755 0.680

Reverse 3.166

Oil capacity liters US qt, Imp

qt)

3.35 (3.6, 3.0)

Fluid type

ATF: DEXRON-II

Above 0°F: API GL-4

or

GL-5

SAE80W—90

or

SAE90

Clearance

Clearance

of

lever and reverse idle

gear

mm (in)

Standard 0.1—0.32 (0.004-0.013) Clearance

of

lever and reverse idle

gear

mm (in)

Wear limit 0.5 (0.020)

Clearance

of

shift fork and clutch hub sleeve

mm (in)

Standard 0.2—0.4 (0.008-0.016) Clearance

of

shift fork and clutch hub sleeve

mm (in)

Wear limit 0.5 (0.020)

Clearance

of

synchronizer ring

and

gear

mm

(in)

Standard 1.5 (0.059) Clearance

of

synchronizer ring

and

gear

mm

(in) Wear limit 0.8 (0.021)

Gear thrust clearance

mm (in)

First Standard 0.05—0.28 (0.002-0.011)

Gear thrust clearance

mm (in)

First Limit 0.3 (0.020)

Gear thrust clearance

mm (in)

Second Standard 0.18—0.46 (0.007-0.018)

Gear thrust clearance

mm (in)

Second Limit 0.5 (0.02) Gear thrust clearance

mm (in) Third Standard 0.05-0.20 (0.002-0.008)

Gear thrust clearance

mm (in) Third Limit 0.25 (0.010)

Gear thrust clearance

mm (in)

Fourth Standard 0.17—0.37 (0.0064—0.014)

Gear thrust clearance

mm (in)

Fourth Limit 0.4 (0.016)

Bearing preload

of

primary shaft gear

Primary shaft

0.1-0.25 N-m (1.0-2.5 cm-kg, 0.86-2.18 in-lb) Secondary shaft 0.2-0.4 N-m (2.0—4.0 cm-kg, 1.7-3.4 in-lb)

Bearing preload adjust shim mm (in) 0.25 (0.010), 0.30 (0.012), 0.35 (0.014), 0.40 (0.016), 0.45 (0.018), 0.50 (0.020), 0.55 (0.022), 0.60 (0.024), 0.65 (0.026), 0.70 (0.028), 0.75 (0.030), 0.80 (0.031)

Drive and differential

Final gear

TvDe

Reduction ratio

Side

bearina Dreload

Helical aear

4.1051 3.850 4.1051 3.850

4.150

1.4-2.0 N

m

(14—20 cm-kg, 12-17 in-lb)

Bearing preload adjust shim mm (in)

0.10 (0.004), 0.15 (0.006), 0.20 (0.008), 0.25 (0.010), 0.30 (0.012), 0.35 (0.014), 0.40 (0.016), 0.45 (0.018), 0.50 (0.020), 0.55 (0.022), 0.60 (0.024), 0.65 (0.026), 0.70 (0.028), 0.75 (0.030), 0.80 (0.031), 0.85 (0.033), 0.90 (0.035), 0.95 (0.037), 1.00 (0.039), 1.05 (0.041), 1.10 (0.043), 1.15 (0.045), 1.20 (0.047)

Backlash

of

side aear and

Dinion

aear mm (in) 0-0.1 (0-0.004)

30—26