oil change MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 327 of 1865

OUTLINE 2B

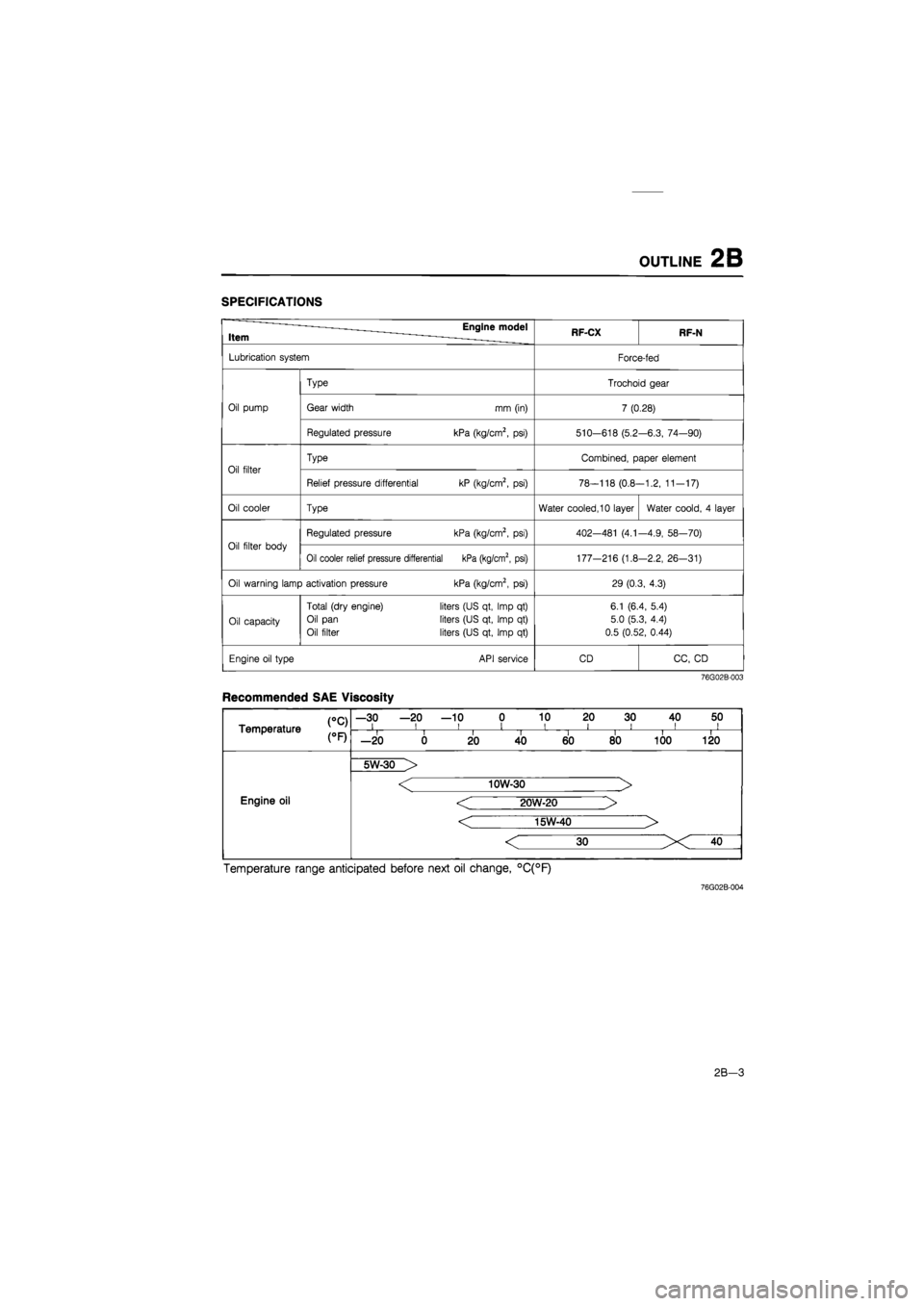

SPECIFICATIONS

Item Engine model RF-CX RF-N

Lubrication system Force-fed

Type Trochoid gear

Oil pump Gear width mm (in) 7 (0.28)

Regulated pressure kPa (kg/cm2,

psi)

510-618 (5.2 -6.3, 74—90)

Oil filter

Type Combined, paper element

Oil filter

Relief pressure differential kP (kg/cm2,

psi)

78-118 (0.8--1.2, 11-17)

Oil cooler Type Water cooled, 10 layer Water coold,

4

layer

Oil filter body

Regulated pressure kPa (kg/cm2,

psi)

402—481

(4.1

-4.9, 58—70)

Oil filter body

Oil cooler relief pressure differential kPa (kg/cm2, psi) 177-216 (1.8 -2.2, 26-31)

Oil warning lamp activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Oil capacity

Total (dry engine)

Oil pan

Oil filter

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

6.1 (6.4, 5.4)

5.0 (5.3, 4.4)

0.5 (0.52, 0.44)

Engine oil type API service CD CC,

CD

76G02B-003

Recommended SAE Viscosity

CC) Temperature

—30 —20 —10 0 10 20 30 40 50 i i i i i i i ii CC) Temperature i i II i i i i —20 0 20 40 60 80 100 120

Engine oil

5W-30 >

Engine oil

< 10W-30 >

< 20W-20 >

< 15W-40 >

Engine oil

Temperature range anticipated before next oil change, °C(°F)

76G02B-004

2B-3

Page 726 of 1865

5 IGNITER

(FE

DOHC)

76G05X-018

IGNITER

INSPECTION

1. Disconnect the center high tension lead from the

distributor cap.

2. Hold it with insulated pliers approx. 5—10 mm

(0.20—0.39 in) from a ground.

3. Turn th ignition switch ON.

4. Remove the rubber seal from the igniter connector.

5. Apply battery voltage to terminal A (LR) with a jum-

per wire.

6. Check that a strong blue spark is visible when the

wire is disconnected.

76G05X-019

If no spark is seen, connect a voltmeter between

terminal B (B) and terminal C (YL), and check for

battery voltage.

76G-05X-020

8. Repeat steps 5 and check

that

the voltage changes

to 2—3V.

9.

If

the voltage is not as specified, replace the igniter.

10.

If

the voltage is as specified, check the ignition coil

and high tension lead.

76G05X-021

5-20

Page 811 of 1865

TROUBLESHOOTING GUIDE 7A

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Change lever won't Seized change lever ball Replace 7A-58 shift smoothly, or is Seized change control rod joint Replace 7A-58

hard to shift Bent change control rod Replace 7A-58

Too much play in Worn change control rod bushing Replace 7A-58 change lever Weak spring of ball or change lever Replace 7A-58 Worn bushing of ball or change lever Replace 7A—58

Difficult to shift Bent change rod Replace 7A—58

No grease in transmission control Lubricate with grease 7A-58

Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace with oil of 7A-6 specified quality

Wear or play of shift fork or shift rod Replace 7 A—18

Wear of synchronizer ring Replace 7A-27

Wear of synchronizer cone of gear Replace 7A-27

Bed contact of synchronizer ring and cone of Replace 7A-27 gear

Excessive longitudinal play of gears Replace 7A-22

Wear of bearing Adjust or replace 7A—22

Wear of synchronizer key spring Replace 7A-27

Excessive shaft gear bearing preload Adjust 7A-37

Improperly adjusted change guide plate Adjust 7A-20

Won't stay in gear Bent change control rod Replace 7A-58

Worn change control rod bushing Replace 7A-58

Weak change lever ball spring Replace 7A-58

Improperly installed extension bar Tighten 7A-58

Wear of shift fork Replace 7A—22

Wear of clutch hub Replace 7A-27

Worn clutch hub sleeve Replace 7A-27

Worn gear sliding part of both shaft gears Replace 7A-26

Worn gear sliding part of each gear Replace 7A-26

Worn steel sliding groove of control end Replace 7 A—18

Weak spring pressing against steel ball Replace 7A-18

Excessive thrust clearance Replace 7A—33,35

Worn bearing Replace 7A—22

Improperly installed engine mount Tighten 7A—49

Abnormal noise Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace 7A-6

Worn bearing Adjust or replace 7A-22

Worn gear sliding surface of both shaft gears Replace 7A—26

Wear of sliding surfaces of gears Replace 7A-26

Excessive thrust clearance Replace 7A—33,35

Damaged gear teeth Replace with oil of 7A-26

specified quality Foreign material in gears Replace 7A-22

Damaged differential gear, or excessive backlash Adjust or replace 7A—30

76G07A-005

7A-5

Page 826 of 1865

7A DISASSEMBLY

STEP 2

Disassemble in the sequence shown in the figure referring to disassembly note for the specially marked

parts.

76G07A-018

76G07A-019

1. Bearing outer race 15. Selector 28. Roll pin

2. Oil seal 16. Oil seal 29. Reverse lever shaft

3. Bearing outer race 17. Bolt 30. Reverse lever

4. Funnel 18. Bleeder cover 31. Drain plug and washer

5. Bolts 19. Bleeder 32. Neutral switch and gasket

6. Guide plate 20. Bolt 33. Bearing outer race

7. Pipe 21. Speedometer driven gear 34. Diaphragm spring

8. Bolt assembly 35. Adjust shim

9. Change arm 22. O-ring 36. Bearing outer race

10. Roll pin 23. Roll pin 37. Adjust shim

11. Change rod 24. Driven gear 38. Oil seal

12. Boot 25. Gear case 39. Back-up light switch

13. Spring 26. Oil seal 40. Oil passage

14. Reverse gate 27. Bearing outer race

7A-20

Page 848 of 1865

7 A ASSEMBLY

86U07A-106

86U07A-107

86U07A-108

8. Install the new breather.

9. Install the new change rod oil seal.

10. Install the change rod ©, the boot the spring

(3),

the reverse gate @, and selector ©, as shown.

11. Install the new roll pin.

12. Install the change arm.

Tightening torque: 12—14 N-m

(120—140 cm-kg, 104—122 in-lb)

13. Install the guide plate.

Tightening torque:

©8—11 N-m

(80—115 cm-kg, 69—100 in-lb)

(1)22—33 N-m

(2.25—3.35 m-kg, 16—25 ft-lb)

14. Install reverse lever, and reverse lever shaft.

15. Install the new roll pin.

16. Install the speedometer driven gear assembly.

86U07A-109

7A-42

Page 880 of 1865

7B TROUBLESHOOTING (G4A-EL)

ON VEHICLE-

-f-

—OFF VEHICLE

\ Inspection point

and

\ reference page

Condition

•

Electronic control system Prelim-

inary

Hydraulic

control

system

Power train \ Inspection point

and

\ reference page

Condition

•

7B-66

m CO I m r--

7B-63

i

cn to I m

Section

4B

|

Section

4B

|

ID to i m

CO CO 1 CD

7B-68

|

en CO 1 IX)

to 1 00 r-.

cn CD 1 CO

7B-69

|

1 CD r--

cn s-1 m

Section

4B

r*-cn

S-1 CD h-

"=1-

rJ CO

7 CD r-

(XI o

1 m

cn CM 1 CD

7B-107

|

CD

7 CD 7 m

I

7B-113

I

CO CM

7 CO r-.

m cn

7 CO r-.

cn

7 DO r-

CM CM

7 CO

|

7B-126

CO

1*-r*-

7 m r-

\ Inspection point

and

\ reference page

Condition

•

Brake

light

switch

|

Inhibitor

switch

|

Mode

switch

|

1

CO. •o o X

Idle

switch

Throttle

sensor

|

Water

temp,

switch

|

0 tn c 0) cn

s

ffi

Q tn 01 o Hi >

Pulse

generator

|

"a o c 0) a to CM

TJ O CL ID s CO C\l 3-4

solenoid

|

Lock-up

solenoid

I

ATF

level

and

condition

|

Selector

lever

m Xj CO CJ 03

1 sz

Idle

speed

and

Ignition

timing

Control

valves

Accumulators

Oil

pump

Hydraulic

circuit

Torque

converter

Forward

clutch

Coasting

clutch

Reverse

clutch

JT O

u TT ro 2-4

brake

band

and

servo

$ 2

B cn cii > £ "O C CO

o

XI y

o >. CO S cb a O

One-way

clutch

2

s CI Cn tz JC 5 0-

Planetary

gear

Differential

assembly

Accelerating

Vehicle does

not

move

in

D,

S,

L,

or R

range

O O O O O O O O O O 0

Accelerating

Vehicle moves

in N

range -0 0 -—

Accelerating

Excessive creep

-0 O O -—

Accelerating

No creep

at all

O o o o

o

G 0 O O

Shifting

|

No shift

O O o

o

0 O 0 0

o

o O

Shifting

|

Abnormal shift sequence

0 o O O 0

o

o 0 O o o 0 O

Shifting

|

Frequent shifting 0 o 0 0 o 0 O O 0

Shifting

|

Excessively high

or

low

shift point 0 o 0 O 0 0 o 0 O 0 0

Shifting

|

No lock-up

0 o 0 0 o 0 O O o O

Shifting

|

No kick-down o o o o

Slipping

Engine

run

away

or

slip when

starting vehicle 0 o 0 O o O

Slipping

Engine

run

away

or

slip when

up-

or

down-shifting o o o 0 o O 0 0 O

8 n cn 4S SI V)

Excessive

N to D or N to R

shift shock o O o o o O

8 n cn 4S SI V)

Excessive shift shock when

up-

shifting

or

downshifting o o o o 0 0 0 8 n cn 4S SI V) Excessive shift shock when

changing range 0 0 o 0 o

j

Noise

Transaxle noisy

in N or P

range o o 0 O

j

Noise

Transaxle noisy

in D, S, L,

or

R range o 0 0 O

I

Others

j

No engine braking o O o 0 o o

I

Others

j

No mode change o 0 o o o o o o o

O

o

0

I

Others

j

Transaxle overheats

o o

0 o 0 o 0

I

Others

j

Vehicle moves

in

"P",

or

park-ing gear

not

disengaged when

"P"

is

dis-

engaged

0 O

I

Others

j

Hold indicator flashes o

0

o

0

o

O

o — — —

I

Others

j

Engine will

not

start

o

o

O — — —

76G07B-014

7B—14

Page 1661 of 1865

15 INTRODUCTION

ELECTRICAL SYMBOLS

Switches and Relays

There is an NC (normally closed) and NO (normally open) indication for switches and relays; this indi-

cates the condition when there has been no change of operating conditions.

Relay

NO type relay NC type relay

Switch

NO switch NC switch

Not

in

operation (No power supply)

—Jtfiifij —o o—

Flow Stop Flow

In operation (Power supply)

^

^aijuiy—'

Flow

l=3X

Stop

Flow

Stop

Other Electrical Symbols

Holder

Box —

© ©

Holder

Box —

Holder

Box —

BATTERY BODY GROUND FUSE FUSIBLE LINK

(£)

* 1 fc

MOTOR COIL, SOLENOID RESISTOR VARIABLE RESISTOR

1

ii

-L ©

THERMISTER DIODE CONDENSER LIGHT

1

TRANSISTOR SPEAKER CIGARETTE LIGHTER HEATER

69G15X-009

15—6

Page 1792 of 1865

OUTLINE 16

Discharging the Refrigeration System

1. Connect the manifold gauge set to the system.

2. Place the free end of the center hose on a shop

towel.

3. Slowly open the high pressure manual valve to ad-

just the refrigerant flow. Open the valve only slightly.

Caution

If refrigerant is allowed to escape too fast, the

compressor oil will be drawn out of the

system.

4. Check the shop towel to make sure no oil is being

discharged.

If oil is present, partially close the manual valve.

5. After the manifold gauge reading drops below 343

kPa (3.5 kg/cm2, 50 psi), slowly open the low

pressure manual valve.

6. As the system pressure drops, gradually open both

the high- and low-pressure manual valves until both

gauges read 0 kPa (0 kg/cm2, 0 psi).

76G16X-631

Evacuation of the Refrigeration System

Whenever the air-conditioning system has been ex-

posed to the atmosphere, it must be evacuated.

1. Connect the manifold gauge set.

2. Connect the center hose of the gauge set to the

vacuum pump inlet.

3. Operate the vacuum pump, then open both man-

ual valves.

4. When the low pressure gauge indicates approxi-

mately 710 mmHg (28 inHg), close both manual

valves and stop the vacuum pump.

5. Check to be sure that the degree of pressure does

not change after 10 minutes or more in this condi-

tion.

If

the pressure changes, check the system for

leaks, and repair if necessary.

6. If no leaks are found, once again operate the vacu-

um pump and open both manual valves to obtain

760 mmHg (30 inHg).

7. Close both manual valves, and stop the vacuum

pump.

Disconnect the hose from the vacuum pump.

69G16X-019

16-9

Page 1799 of 1865

16 COMPRESSOR

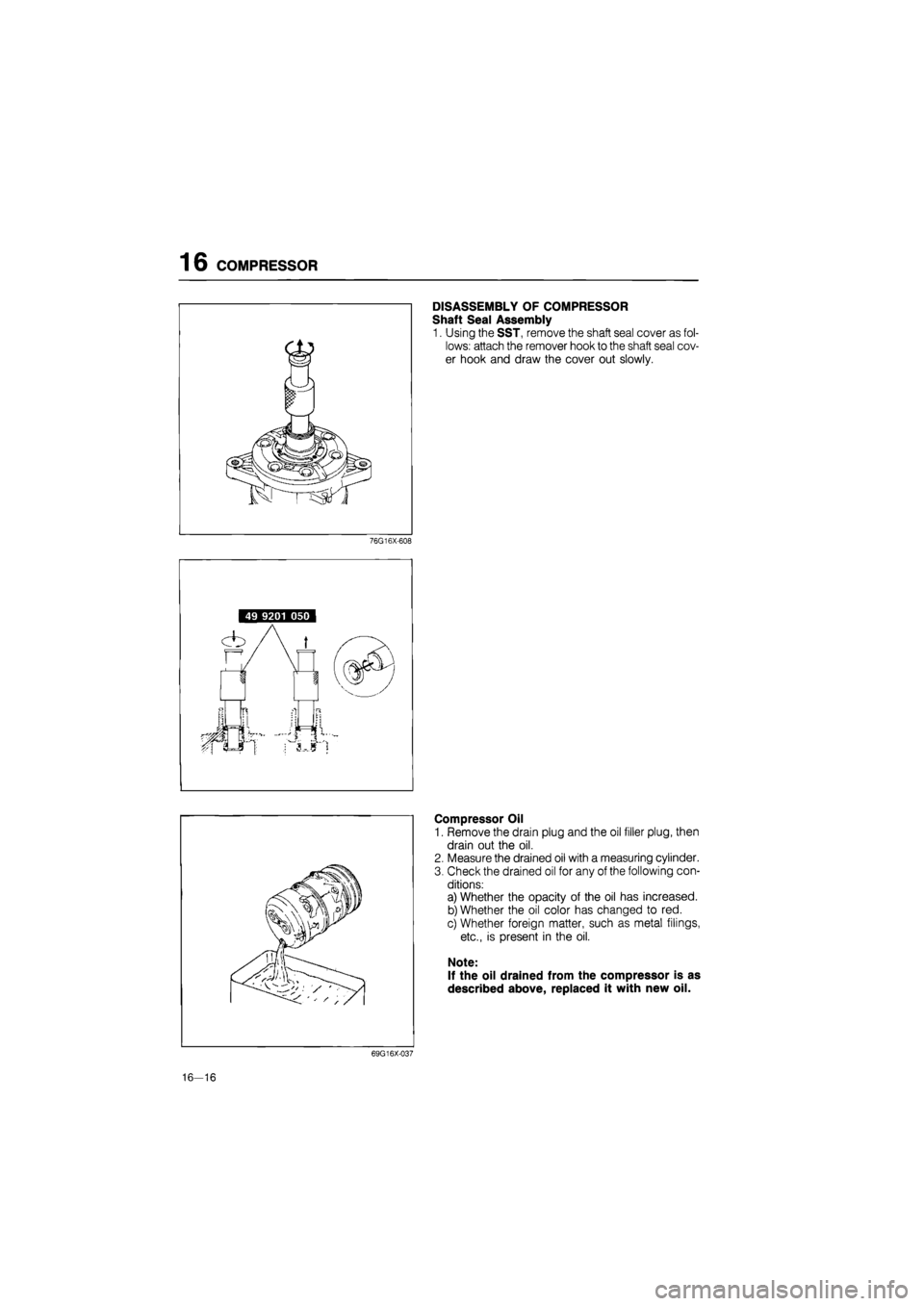

DISASSEMBLY OF COMPRESSOR

Shaft Seal Assembly

1. Using the SST, remove the shaft seal cover as fol-

lows: attach the remover hook to the shaft seal cov-

er hook and draw the cover out slowly.

76G16X-608

Compressor Oil

1. Remove the drain plug and the oil filler plug, then

drain out the oil.

2. Measure the drained oil with a measuring cylinder.

3. Check the drained oil for any of the following con-

ditions:

a) Whether the opacity of the oil has increased.

b) Whether the oil color has changed to red.

c) Whether foreign matter, such as metal filings,

etc., is present in the oil.

Note:

If the oil drained from the compressor is as

described above, replaced it with new oil.

69G16X-037

16—16