steering MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 434 of 1865

IDLE-UP CONTROL SYSTEM 4A

DUAL-SERVO DIAPHRAGM TYPE

With P/S and A/C

Solenoid valve (for P/S)

69G04B-124

Operation

A/C ON and compressor operating

Current flows through the A/C relay to the two-way solenoid valve for the A/C. Vacuum port A is opened,

and vacuum is applied to the servo diaphragm, which in turn pulls the throttle plates slightly open

at low speeds.

P/S operating

Current flows through the P/S switch to the three-way solenoid valve for power steering. Vacuum port

B is opened and vacuum is applied to the servo diaphragm, which in turn pulls the throttle plates slightly

open.

Relationship

Equipment

Type P/S A/C P/S & A/C

Single-servo

diaphragm type O O

Dual-servo

diaphragm type O

4A—69

Page 439 of 1865

![MAZDA 626 1987 User Guide

4A IDLE-UP CONTROL SYSTEM

76G04A-144

76G04A-145

76G04A-146

Vacuum Signal [Equipped with A/C, only FE and

F8 (Except Middle East and General)]

1. Start the engine and run it at idle.

2. Disconn MAZDA 626 1987 User Guide

4A IDLE-UP CONTROL SYSTEM

76G04A-144

76G04A-145

76G04A-146

Vacuum Signal [Equipped with A/C, only FE and

F8 (Except Middle East and General)]

1. Start the engine and run it at idle.

2. Disconn](/img/28/57059/w960_57059-438.png)

4A IDLE-UP CONTROL SYSTEM

76G04A-144

76G04A-145

76G04A-146

Vacuum Signal [Equipped with A/C, only FE and

F8 (Except Middle East and General)]

1. Start the engine and run it at idle.

2. Disconnect the vacuum hose from the servo di-

aphragm.

3. Place a finger over the hose.

4. Increase the engine speed, and check for vacuum.

Engine model Engine speed Vacuum

pj| (Except Middle) Below 2,300 rpm Yes pj| (Except Middle) Above 2,300 rpm No

FE (Unleaded fuel) Below 1,500 rpm Yes FE (Unleaded fuel) Above 1,500 rpm No

F6 (Singapore) Below 2,100 rpm Yes F6 (Singapore) Above 2,100 rpm No

General and Middle East

1. Start the engine and run it at idle.

2. Disconnect the vacuum hose from the servo di-

aphragm.

3. Place a finger over the hose.

4. Operate the A/C or P/S.

5. Check that vacuum is felt.

P/S Switch

1. Start the engine and run it at idle.

2. Disconnect the power steering switch connector.

3. Connect an ohmmeter to the power steering

switch.

4. Turn the steering wheel all the way to either the

right or left, and check for continuity.

P/S Continuity

Operated Yes

Not operated No

5. Replace if necessary.

Solenoid Valve (A/C)

1. Disconnect vacuum hose A from the servo di-

aphragm.

2. Disconnect vacuum hose B from the solenoid

valve.

3. Disconnect the solenoid valve connector.

4. Blow air through the valve from hose A and check

that it comes out of port C.

76G04A-147

4A-74

Page 498 of 1865

4B IDLE-UP SYSTEM

COMPONENT DESCRIPTIONS

Component Function Remarks

Air bypass solenoid

valve

Controls bypass

air

amount Operates A: A/C

: ON

B: Intake

air

temp, high

or at

high

al-

titude C: P/S

:

ON, E/L applied

or

hot start

Air valve

When cold, supplies bypass

air

into

dy-

namic chamber

• Engine speed increased

to

shorten

warm-up period

• Bimetal type

Atmospheric pressure sensor

Detects atmospheric pressure; sends sig-

nal

to

engine control unit

E/L control unit

Detects electrical load applied; sends sig-nal

to

engine control unit

Engine control unit

Detects signals from input sensors and switches; controls

air

bypass solenoid valve

Intake air thermo sensor

Detects intake

air

temperature; sends sig-

nal

to

engine control unit

Installed

in air

flow meter

P/S pressure switch

Detects P/S operation; sends signal

to

engine control unit P/S:

ON

when steering wheel turnefl right

or

left

76g04b-044

4B-36

Page 501 of 1865

IDLE-UP SYSTEM 4B

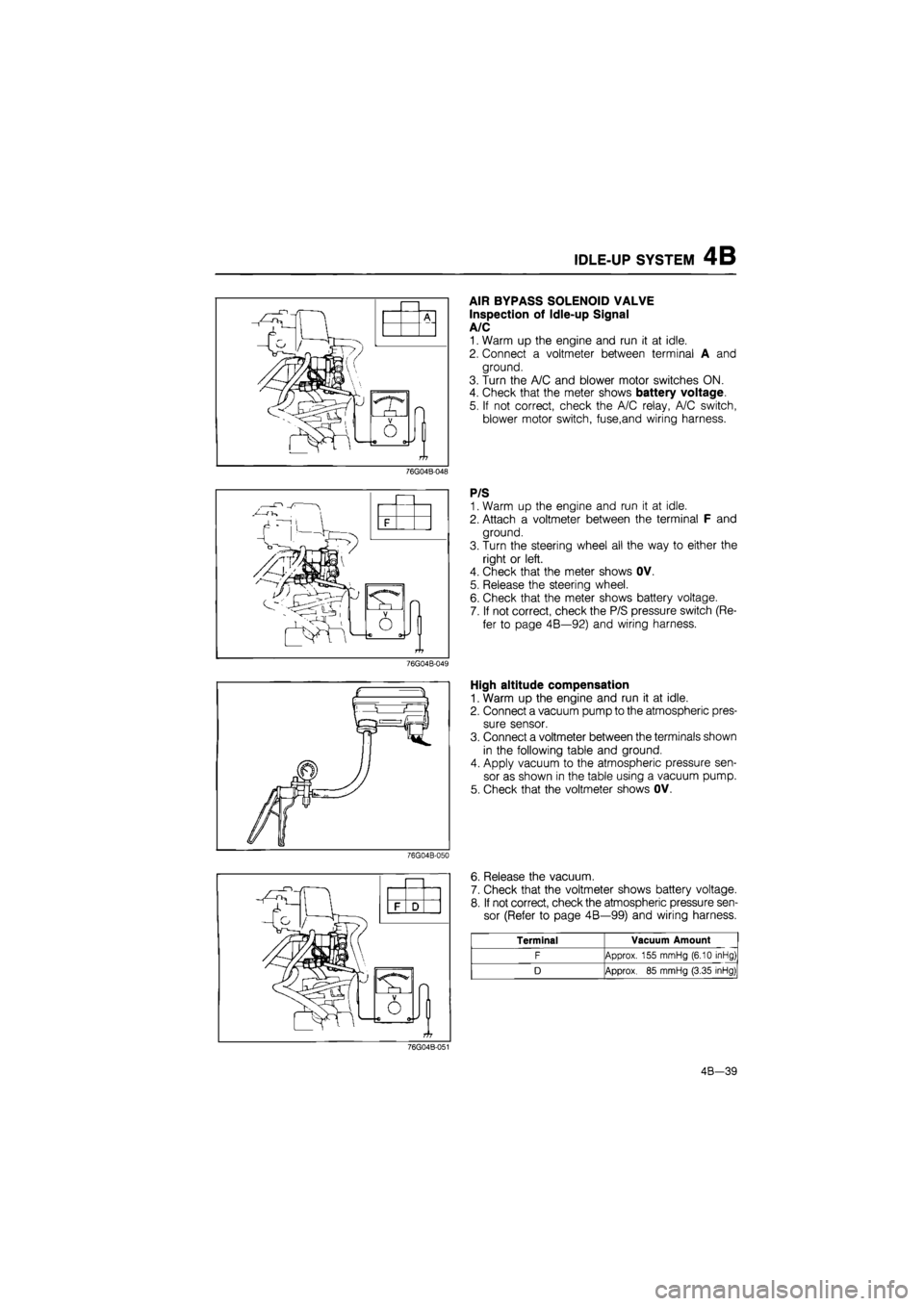

AIR BYPASS SOLENOID VALVE

Inspection of Idle-up Signal

A/C

1. Warm up the engine and run it at idle.

2. Connect a voltmeter between terminal A and

ground.

3. Turn the A/C and blower motor switches ON.

4. Check that the meter shows battery voltage.

5. If not correct, check the A/C relay, A/C switch,

blower motor switch, fuse,and wiring harness.

76G04B-048

P/S

1. Warm up the engine and run it at idle.

2. Attach a voltmeter between the terminal F and

ground.

3. Turn the steering wheel all the way to either the

right or left.

4. Check that the meter shows OV.

5. Release the steering wheel.

6. Check that the meter shows battery voltage.

7. If not correct, check the P/S pressure switch (Re-

fer to page 4B—92) and wiring harness.

76G04B-049

High altitude compensation

1. Warm up the engine and run it at idle.

2. Connect a vacuum pump to the atmospheric pres-

sure sensor.

3. Connect a voltmeter between the terminals shown

in the following table and ground.

4. Apply vacuum to the atmospheric pressure sen-

sor as shown in the table using a vacuum pump.

5. Check that the voltmeter shows OV.

76G04B-050

J

O

6. Release the vacuum.

7. Check that the voltmeter shows battery voltage.

8. If not correct, check the atmospheric pressure sen-

sor (Refer to page 4B—99) and wiring harness.

Terminal Vacuum Amount

F Approx. 155 mmHg (6.10 inHg)

D Approx.

85

mmHg (3.35 inHg)

76G04B-051

4B-39

Page 554 of 1865

4B CONTROL SYSTEM

P/S pressure switch-^—^

86U04A-176

P/S PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine. Check continuity of the switch

while turning the steering wheel at idle.

P/S Continuity

Turning Yes

Not turning No

4. Connect the switch connector after checking.

Note

Refer to section 10 for replacement of the P/S

pressure switch.

INHIBITOR SWITCH

Inspection

1. Disconnect the inhibitor switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Position Continuity

P and N ranges Yes

Other ranges No

4. Connect the switch connector after checking.

Note

Refer to Section 7B for replacement of the in-

hibitor switch.

4B—92

Page 569 of 1865

4C OUTLINE

SPECIFICATIONS

Item Engine type Unleaded Fuel Leaded Fuel

Idle speed rpm 750 ± 50

Throttle body

Type Horizontal draft (2-barrel)

Throat diameter mm (in) No. 1 46 (1.8) Throat diameter mm (in) No. 2 40 (1.6)

Fuel pump

Type Impeller (in tank)

Output pressure kPa (kg/cm2, psi) Main pump: 441-588 (4.5—6.0, 64—85) Transfer pump: 20—25 (0.20—0.25, 2.8—3.6)

Feeding capacity cc (cu in)/10 sec. Main pump: More than 220 (13.4) Transfer pump: More than 190 (11.6)

Fuel filter

Type Low pressure side Nylon element Type High pressure side Paper element

Pressure regulator

Type Diaphragm

Regulating pressure kPa (kg/cm2, psi) 235-275 (2.4 -2.8, 34-40)

Injector

Type High-ohmic

Type of drive Voltage

Resistance G 12--16

Injection amount cc (cu in)/15 sec. 66-91 (4.03-5.55)

Idle speed control valve

Solenoid resistance a 6.3--9.9

Fuel tank

Capacity liters (US gal, Imp gal) 60 (15.9, 13.2), 57 (15.0, 12.5): 4-wheel steering vehicle

Air cleaner

Element type Dry

Fuel

Specification Unleaded (95 RON or more) Leaded or unleaded fuel

(95 RON or more)

76G04C-008

4C-8

Page 606 of 1865

ISC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

A/C switch Detects air conditioner operation; sends

signal to engine control unit Switch ON when air conditioner

operating

Air valve When cold, supplies bypass air into dy-namic chamber • Engine speed increased to shorten warm-up period • Thermo wax type

• Installed in BAC valve

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

E/L control unit Detects that E/L is being applied; sends

signal to engine control unit

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Idle speed control)

Idle switch Detects when throttle valve fully closed;

sends signal to engine control unit

Installed on throttle body

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

P/S pressure switch Detects P/S operation; sends signal to engine control unit Switch ON when steering wheel turned right or left

Solenoid valve (Idle speed control) Controls bypass air amount • Controlled by duty signal from engine control unit • Installed in BAC valve

• Operates idle-up

Test connector For initial idle speed adjustment • Gerrn, 1-pin

• Idle speed feedback control cancelled when connector grounded

Water thermo sensor Detects coolant temperature; sends

signal to engine control unit

76G04C-078

4C—45

Page 608 of 1865

ISC SYSTEM 4C

76G04C-081

76G04C-082

Cooling fan switch

Rear defroster switch

Head light switch

Blower motor switch

ISC "valve

76G04C-083

(ISC valve)

6. Connect the ISC valve connector.

Note

a) Make sure that the initial idle speed is set

to specification.

b) All accessory must be OFF.

7. Again disconnect the ISC valve connector (engine

at normal operating temperature).

8. Check that the engine speed decreases.

9. Reconnect the ISC valve connector.

10 Remove the jumper wire from the test connector

and make sure that the idle speed is within specifi-

cations.

(Load Test)

11. Apply power steering, electrical, and air conditioner

loads and check that the idle speed is controlled

to within specifications.

Load Idle speed

P/S 750 ± 50

E/L 800 ± 50

A/C 800 ± 50

E/L and A/C 800 ± 50

BAC Valve

Air valve

1. Remove the BAC valve from the throttle body.

2. Blow air through the valve from port A and check

that air comes out of port B when the BAC valve

is cold..

3. If not correct, replace the BAC valve.

Note

Refer to "Installation" on this page for the

BAC valve installation.

86U04A-063

4C—47

Page 610 of 1865

FUEL SYSTEM 4C

FUEL SYSTEM

76G04C-087

This system supplies the necessary fuel for combustion at a constant pressure to the injectors. Fuel

is metered and injected into the intake manifold according to the injection control signals from the en-

gine control unit. It consists of the fuel pump, fuel filters, delivery pipe, pulsation damper, pressure

regulator, injectors, fuel pump control unit, and the control relay.

The fuel pump is mounted in the fuel tank to minimize the operating noise of the fuel pump. The injec-

tors directly supplied with battery voltage through the control relay. The connector of the injectors is

white to distinguish the injectors for FE DOHC from those of other engines.

Due to the installation of the steering angle transfer shaft for the 4-wheel steering (4WS) the fuel tank

of 4WS vehicles is designed with separate right and left sections. A transfer pump is used to pump

fuel from the left side to the right side.

4C—49

Page 620 of 1865

FUEL SYSTEM 4C

5. Connect the SST to the battery and injector.

6. Check the injection volume with a graduated con-

tainer.

Injection volume:

Approx. 66—91 cc (4.03—5.55 cu in) /15 sec.

Caution

When using the SST, make sure of the SST

number and use correct one.

7. If not correct, replace the injector.

76G04C-107

Rear seat Cushion Release Button -

76G04C-108

TRANSFER PUMP CONTROL SYSTEM (4 WHEEL

STEERING)

1. Remove the rear seat. (Refer to 14 section.)

2. Remove the fuel filler cap.

3. Turn the ignition switch ON.

Note

a) The tank should be more than 1/3 full.

b) Due to the delay timer, transfer pump oper-

ation begins approx. 10 sec. after the igni-

tion switch is turned ON.

4. Listen for the operational sound of the transfer

pump.

5. Install the fuel filler cap.

6. If no sound was heard, check the voltage at the

transfer pump connector.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

86U04B-075

I C A

lb d

cp a • • •

J

76G04C-211

7. If the voltages are correct, replace the transfer

pump.

8. If not correct, disconnect the transfer pump con-

nector.

9. Check the voltage at the terminals below.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

10. If the voltages are correct, replace the transfer

pump.

4C—59