check oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1695 of 1865

15 WARNING AND SENDER

86U15X-068

86U15X069

86U15X-070

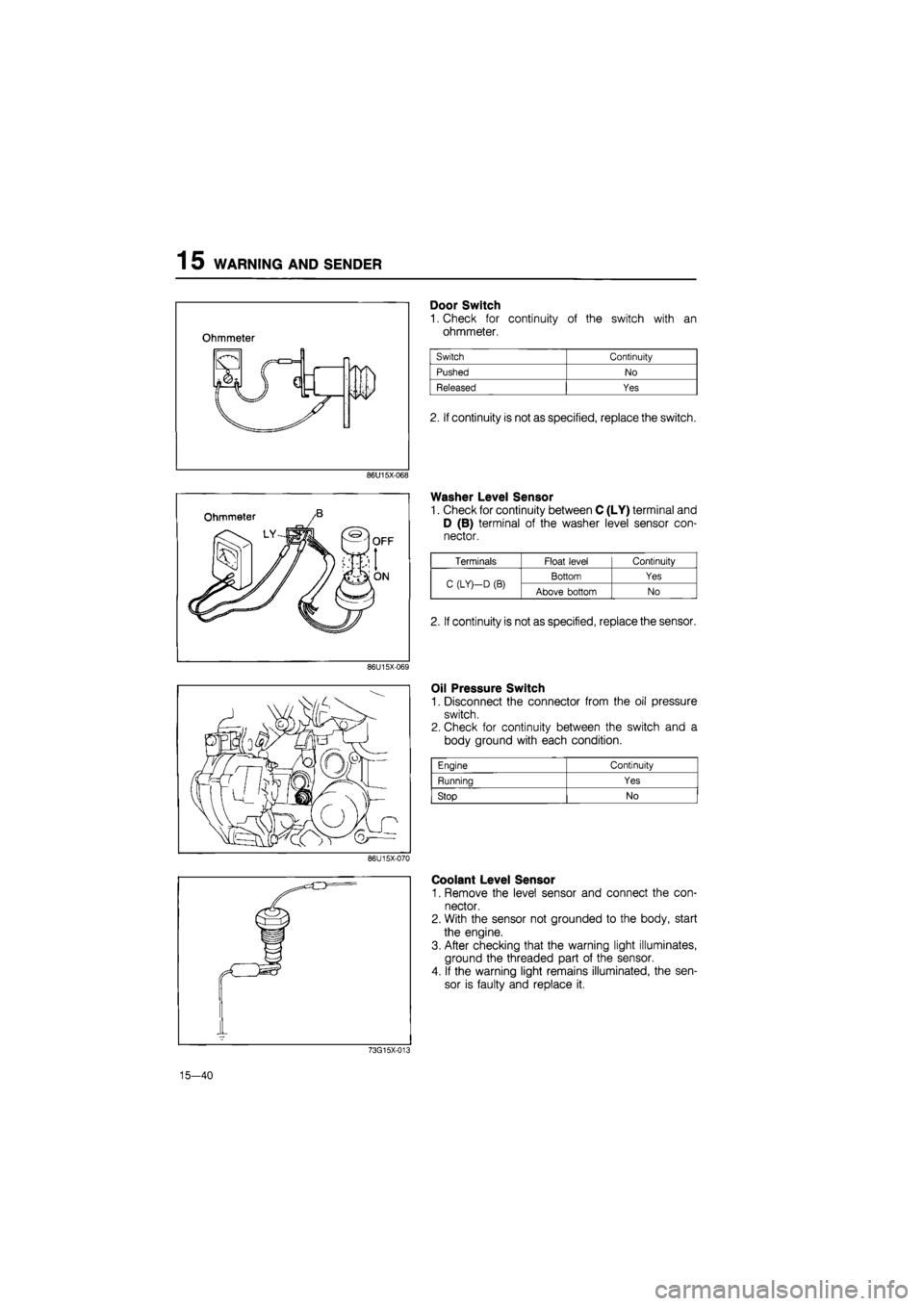

Door Switch

1. Check for continuity of the switch with an

ohmmeter.

2. If continuity is not as specified, replace the switch.

Washer Level Sensor

1. Check for continuity between C (LY) terminal and

D (B) terminal of the washer level sensor con-

nector.

Oil Pressure Switch

1. Disconnect the connector from the oil pressure

switch.

2. Check for continuity between the switch and a

body ground with each condition.

Coolant Level Sensor

1. Remove the level sensor and connect the con-

nector.

2. With the sensor not grounded to the body, start

the engine.

3. After checking that the warning light illuminates,

ground the threaded part of the sensor.

4. If the warning light remains illuminated, the sen-

sor is faulty and replace it.

73G15X-013

15—40

Engine Continuity

Running Yes

Stop No

Terminals Float level Continuity

C (LY)—D

(B)

Bottom Yes C (LY)—D

(B)

Above bottom No

2. If continuity is not as specified, replace the sensor.

Page 1739 of 1865

1 5 CRUISE CONTROL SYSTEM

ON-VEHICLE INSPECTION (USING ACC CHECKER 49 9200 010)

76G15X-072

Note:

When checking the actuator on '88 models with EC-AT using this checker, the checker

should be modified as shown below in order to avoid damage of the EC-AT control unit.

Modification Procedure

1. Cut the wire at terminal no.6 indicated on ACC

checker connector.

2. Tape exposed end of wire cut in step 1 as shown.

This modification does not affect the usage of the ACC

checker except when used on the '81 RX-7 and 626

models. When the modified ACC checker is used on

these models, use a jumper wire and jump across

terminal no.6 to 3 indicated on ACC checker connec-

tor as shown.

Function of the ACC CHECKER

A. Check lights

Each item is verified by a check light, as described below.

Check light Check items

MAIN SW.

Ignition switch, fuse, main switch and associated wiring harness terminals and con-

nectors.

ACTUATOR—VAC

VAC coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 2

VENT

2

coil continuity

in

the actuator and associated harness.

ACTUATOR—VENT 1

VENT

1

coil continuity

in

the actuator and associated harness.

CLUTCH/BRAKE SW.

Clutch switch (M/T vehicles only), brake switch and associated harness

COMBINATION/INH. SW.

"SET", "COAST" and "RESUME" positions

in

the combination switch, inhibitor

switch (A/T vehicles only), and associated harness.

GENERATOR

Speed sensor output and associated harness.

76U15X-193

15-84

Page 1788 of 1865

OUTLINE 16

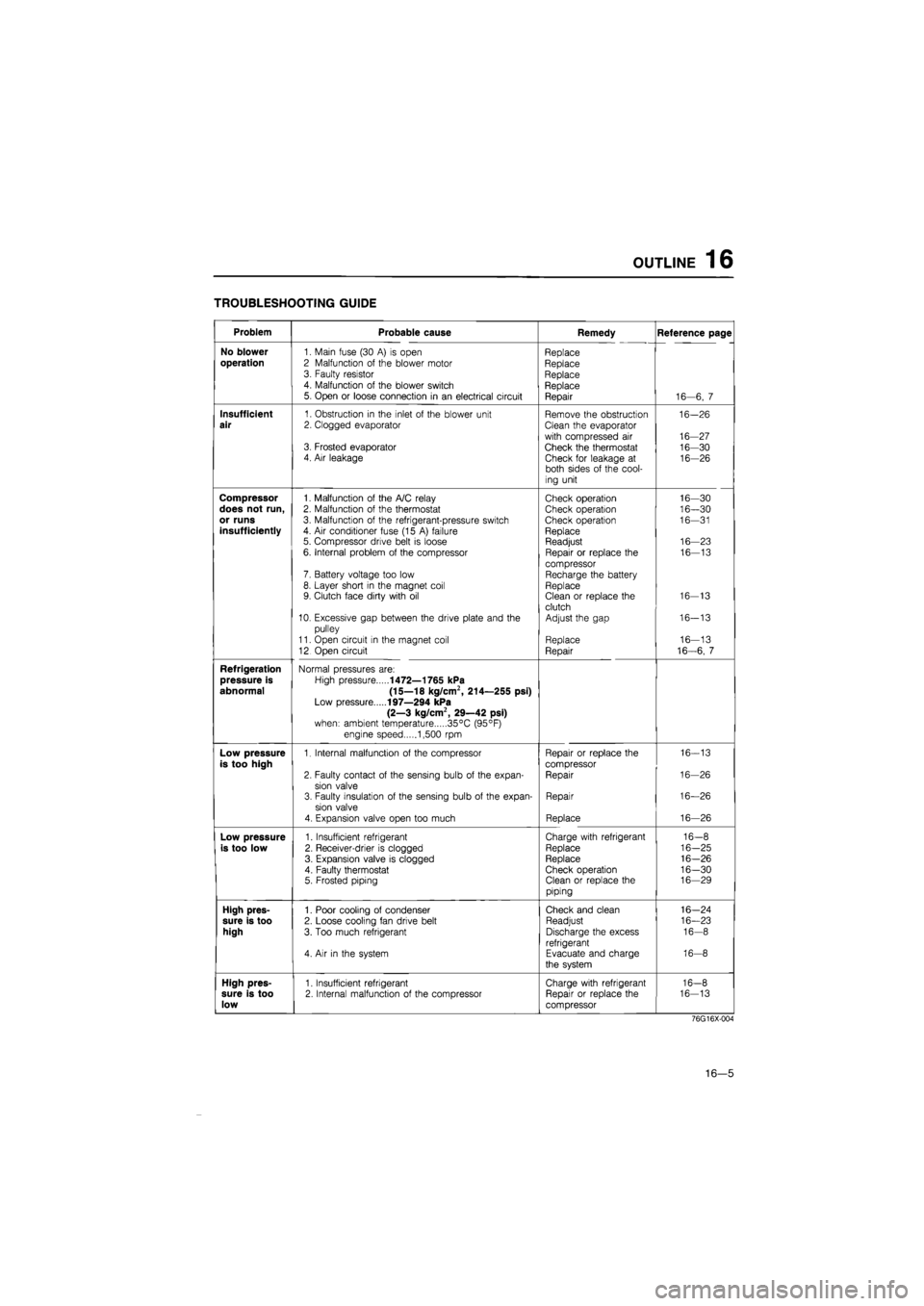

TROUBLESHOOTING GUIDE

Problem Probable cause Remedy Reference page

No blower

1. Main fuse (30

A) is

open Replace

operation

2 Malfunction

of

the blower motor Replace 3. Faulty resistor Replace 4. Malfunction

of

the blower switch Replace 5. Open

or

loose connection

in an

electrical circuit Repair 16—6,

7

Insufficient

1. Obstruction

in

the inlet

of

the blower unit Remove the obstruction 16-26

air

2. Clogged evaporator Clean the evaporator

with compressed

air

16-27 3. Frosted evaporator Check the thermostat 16-30 4. Air leakage Check for leakage

at

16-26 both sides

of

the cool-

ing unit

Compressor

1. Malfunction

of

the A/C relay Check operation 16—30

does not run,

2. Malfunction

of

the thermostat Check operation 16—30

or runs

3. Malfunction

of

the refrigerant-pressure switch Check operation 16—31

insufficiently

4.

Air

conditioner fuse (15

A)

failure Replace 5. Compressor drive belt

is

loose Readjust 16—23

6. Internal problem

of

the compressor Repair

or

replace

the

16—13

compressor 7. Battery voltage too low Recharge the battery 8. Layer short

in

the magnet coil Replace 9. Clutch face dirty with

oil

Clean

or

replace the 16-13

clutch 10. Excessive gap between the drive plate and

the

Adjust the gap 16-13

pulley

11. Open circuit

in

the magnet coil Replace 16—13

12 Open circuit Repair 16-6,

7

Refrigeration

Normal pressures are:

pressure is

High pressure

1472—1765 kPa

abnormal (15—18 kg/cm2, 214—255 psi)

Low pressure

197—294 kPa

(2—3 kg/cm2, 29—42 psi)

when: ambient temperature 35°C (95°F)

engine speed 1,500

rpm

Low pressure

1. Internal malfunction

of

the compressor Repair

or

replace the 16-13

is too high

compressor

2. Faulty contact

of

the sensing bulb

of

the expan-Repair 16-26

sion valve 3. Faulty insulation

of

the sensing bulb

of

the expan-Repair 16—26

sion valve

4. Expansion valve open too much Replace 16—26

Low pressure

1. Insufficient refrigerant Charge with refrigerant 16-8

is too low

2. Receiver-drier

is

clogged Replace 16-25

3. Expansion valve

is

clogged Replace 16-26

4. Faulty thermostat Check operation 16-30 5. Frosted piping Clean

or

replace the 16—29

piping

High pres-

1. Poor cooling

of

condenser Check and clean 16-24

sure is too

2. Loose cooling fan drive belt Readjust 16—23

high

3. Too much refrigerant Discharge the excess 16-8

refrigerant 4.

Air in

the system Evacuate and charge 16-8

the system

High pres-

1. Insufficient refrigerant Charge with refrigerant 16-8

sure is too

2. Internal malfunction

of

the compressor Repair

or

replace the 16-13

low

compressor

76G16X-004

16—5

Page 1792 of 1865

OUTLINE 16

Discharging the Refrigeration System

1. Connect the manifold gauge set to the system.

2. Place the free end of the center hose on a shop

towel.

3. Slowly open the high pressure manual valve to ad-

just the refrigerant flow. Open the valve only slightly.

Caution

If refrigerant is allowed to escape too fast, the

compressor oil will be drawn out of the

system.

4. Check the shop towel to make sure no oil is being

discharged.

If oil is present, partially close the manual valve.

5. After the manifold gauge reading drops below 343

kPa (3.5 kg/cm2, 50 psi), slowly open the low

pressure manual valve.

6. As the system pressure drops, gradually open both

the high- and low-pressure manual valves until both

gauges read 0 kPa (0 kg/cm2, 0 psi).

76G16X-631

Evacuation of the Refrigeration System

Whenever the air-conditioning system has been ex-

posed to the atmosphere, it must be evacuated.

1. Connect the manifold gauge set.

2. Connect the center hose of the gauge set to the

vacuum pump inlet.

3. Operate the vacuum pump, then open both man-

ual valves.

4. When the low pressure gauge indicates approxi-

mately 710 mmHg (28 inHg), close both manual

valves and stop the vacuum pump.

5. Check to be sure that the degree of pressure does

not change after 10 minutes or more in this condi-

tion.

If

the pressure changes, check the system for

leaks, and repair if necessary.

6. If no leaks are found, once again operate the vacu-

um pump and open both manual valves to obtain

760 mmHg (30 inHg).

7. Close both manual valves, and stop the vacuum

pump.

Disconnect the hose from the vacuum pump.

69G16X-019

16-9

Page 1796 of 1865

COMPRESSOR 16

69G16X-026

M10X1.25^45

Low-pressure x pressure

hose hose Compressor

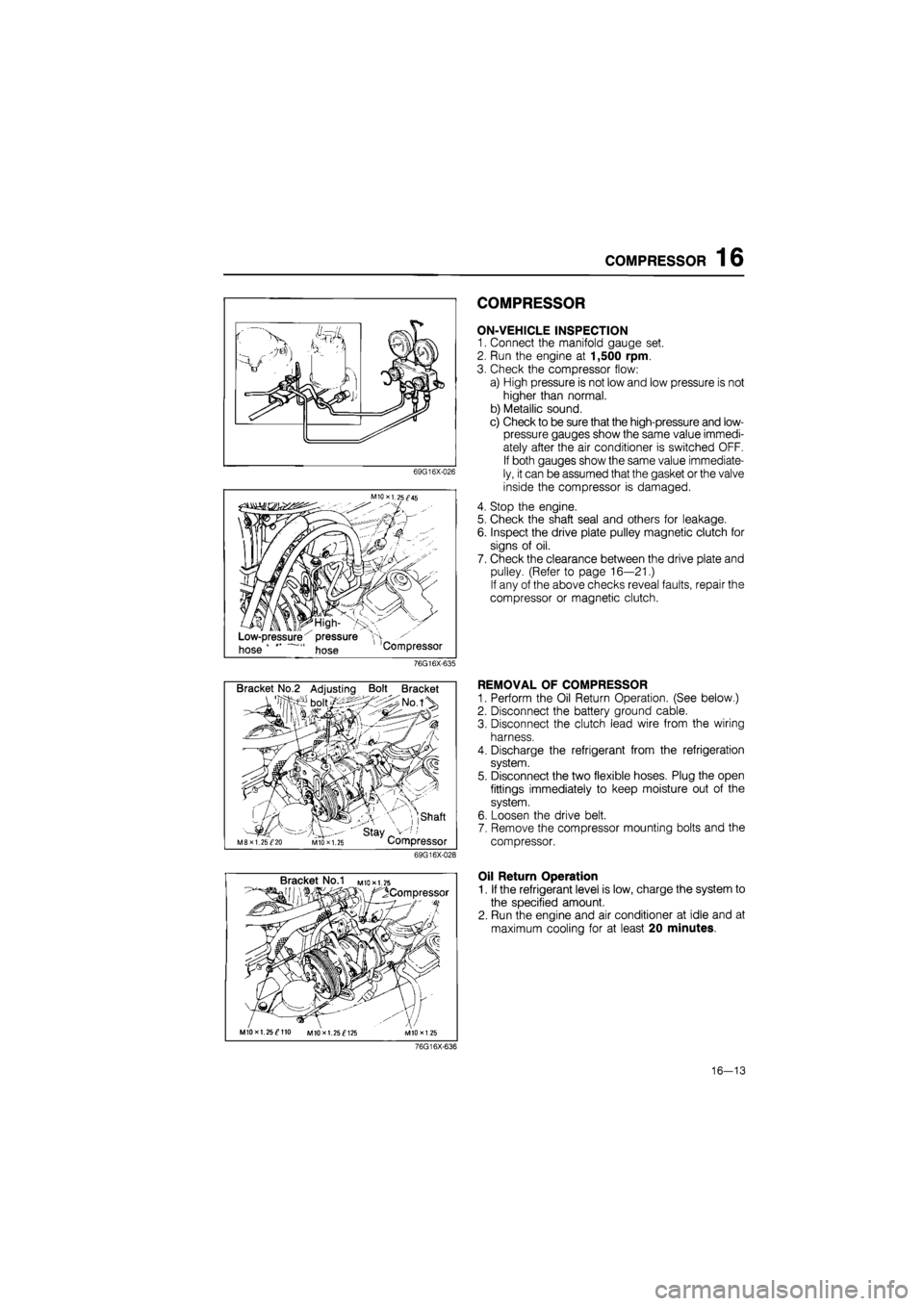

COMPRESSOR

ON-VEHICLE INSPECTION

1. Connect the manifold gauge set.

2. Run the engine at 1,500 rpm.

3. Check the compressor flow:

a) High pressure is not low and low pressure is not

higher than normal.

b) Metallic sound.

c) Check to be sure that the high-pressure and low-

pressure gauges show the same value immedi-

ately after the air conditioner is switched OFF.

If both gauges show the same value immediate-

ly, it can be assumed that the gasket or the valve

inside the compressor is damaged.

4. Stop the engine.

5. Check the shaft seal and others for leakage.

6. Inspect the drive plate pulley magnetic clutch for

signs of oil.

7. Check the clearance between the drive plate and

pulley. (Refer to page 16—21.)

If any of the above checks reveal faults, repair the

compressor or magnetic clutch.

76G16X-635

Bracket No.2 Adjusting Bolt Bracket

, ,shaft

' stay _ M8XI. 25^20 MIO X 1.25 Compressor

69G16X-028

REMOVAL OF COMPRESSOR

1. Perform the Oil Return Operation. (See below.)

2. Disconnect the battery ground cable.

3. Disconnect the clutch lead wire from the wiring

harness.

4. Discharge the refrigerant from the refrigeration

system.

5. Disconnect the two flexible hoses. Plug the open

fittings immediately to keep moisture out of the

system.

6. Loosen the drive belt.

7. Remove the compressor mounting bolts and the

compressor.

Bracket No.1 M

to* 1.25

^Compressor

MIOxl. 25^110 MIOxl. 25^125

Oil Return Operation

1. If the refrigerant level is low, charge the system to

the specified amount.

2. Run the engine and air conditioner at idle and at

maximum cooling for at least 20 minutes.

76G16X-636

16—13

Page 1798 of 1865

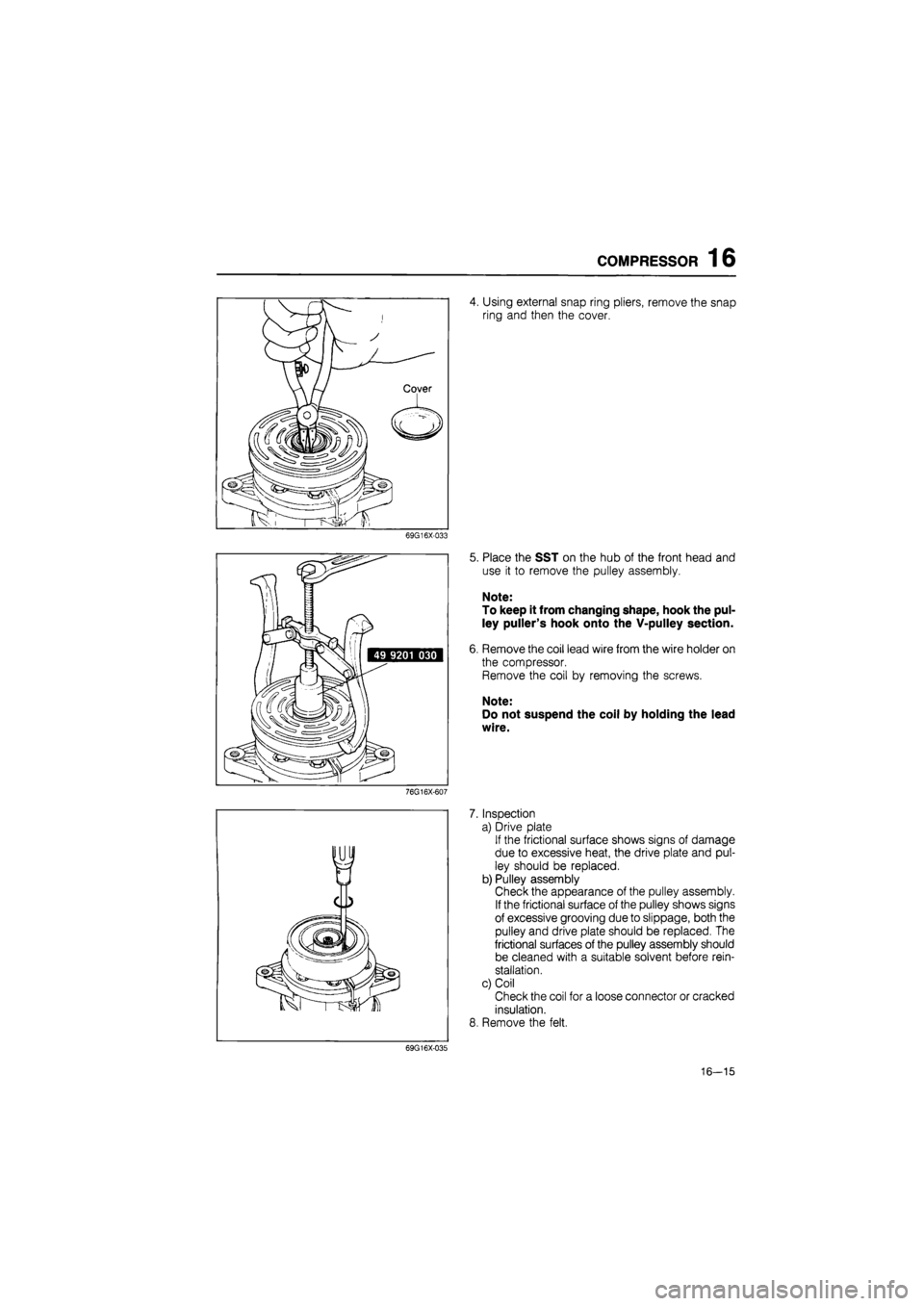

COMPRESSOR 16

4. Using external snap ring pliers, remove the snap

ring and then the cover.

69G16X-033

7.

8.

69G16X-035

Place the SST on the hub of the front head and

use it to remove the pulley assembly.

Note:

To keep it from changing shape, hook the pul-

ley puller's hook onto the V-pulley section.

Remove the coil lead wire from the wire holder on

the compressor.

Remove the coil by removing the screws.

Note:

Do not suspend the coil by holding the lead

wire.

Inspection

a) Drive plate

If the frictional surface shows signs of damage

due to excessive heat, the drive plate and pul-

ley should be replaced.

b) Pulley assembly

Check the appearance of the pulley assembly.

If the frictional surface of the pulley shows signs

of excessive grooving due to slippage, both the

pulley and drive plate should be replaced. The

frictional surfaces of the pulley assembly should

be cleaned with a suitable solvent before rein-

stallation.

c) Coil

Check the coil for a loose connector or cracked

insulation.

Remove the felt.

16—15

Page 1799 of 1865

16 COMPRESSOR

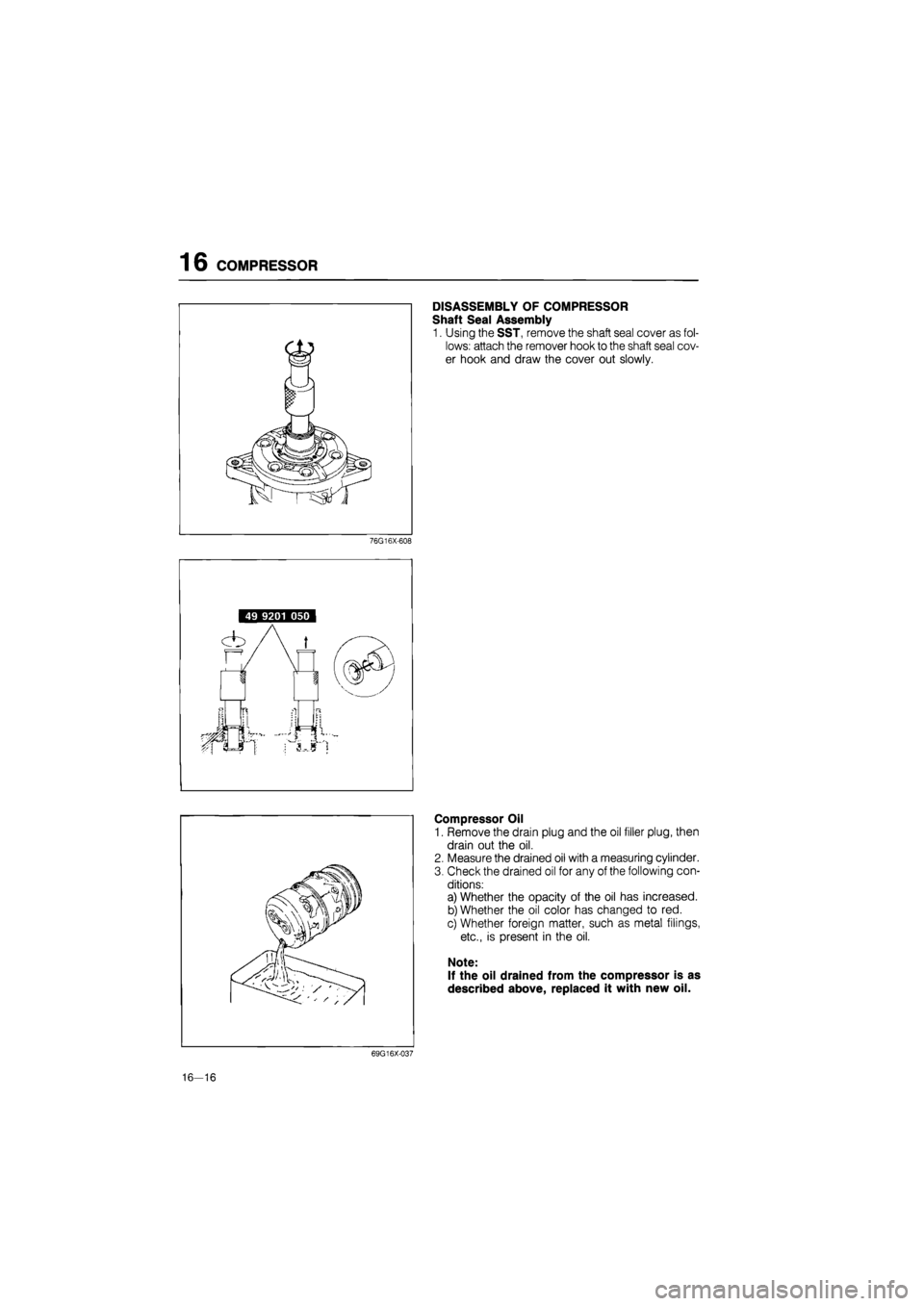

DISASSEMBLY OF COMPRESSOR

Shaft Seal Assembly

1. Using the SST, remove the shaft seal cover as fol-

lows: attach the remover hook to the shaft seal cov-

er hook and draw the cover out slowly.

76G16X-608

Compressor Oil

1. Remove the drain plug and the oil filler plug, then

drain out the oil.

2. Measure the drained oil with a measuring cylinder.

3. Check the drained oil for any of the following con-

ditions:

a) Whether the opacity of the oil has increased.

b) Whether the oil color has changed to red.

c) Whether foreign matter, such as metal filings,

etc., is present in the oil.

Note:

If the oil drained from the compressor is as

described above, replaced it with new oil.

69G16X-037

16—16

Page 1802 of 1865

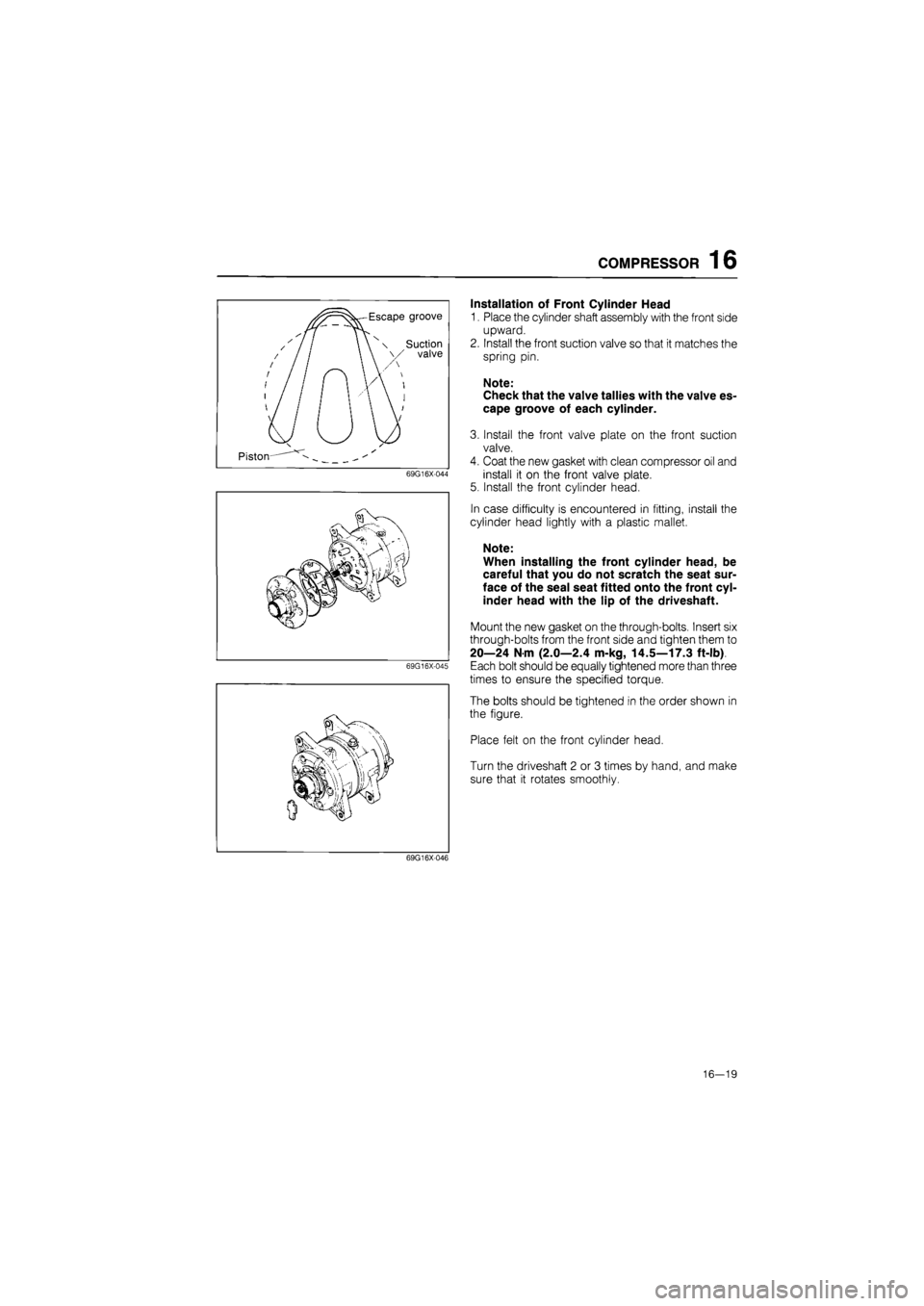

COMPRESSOR 16

Escape groove

^ / / / / j / / ' / / / / /

' / / I / /

1 \ \ x Suction \ \ \/ valve

n W: \ / / y /

I u

Piston— ^

69G16X-044

69G16X-045

Installation of Front Cylinder Head

1. Place the cylinder shaft assembly with the front side

upward.

2. Install the front suction valve so that it matches the

spring pin.

Note:

Check that the valve tallies with the valve es-

cape groove of each cylinder.

3. Install the front valve plate on the front suction

valve.

4. Coat the new gasket with clean compressor oil and

install it on the front valve plate.

5. Install the front cylinder head.

In case difficulty is encountered in fitting, install the

cylinder head lightly with a plastic mallet.

Note:

When installing the front cylinder head, be

careful that you do not scratch the seat sur-

face of the seal seat fitted onto the front cyl-

inder head with the lip of the driveshaft.

Mount the new gasket on the through-bolts. Insert six

through-bolts from the front side and tighten them to

20—24 N m (2.0—2.4 m-kg, 14.5—17.3 ft-lb)

Each bolt should be equally tightened more than three

times to ensure the specified torque.

The bolts should be tightened in the order shown in

the figure.

Place felt on the front cylinder head.

Turn the driveshaft 2 or 3 times by hand, and make

sure that it rotates smoothly.

69G16X046

16—19

Page 1807 of 1865

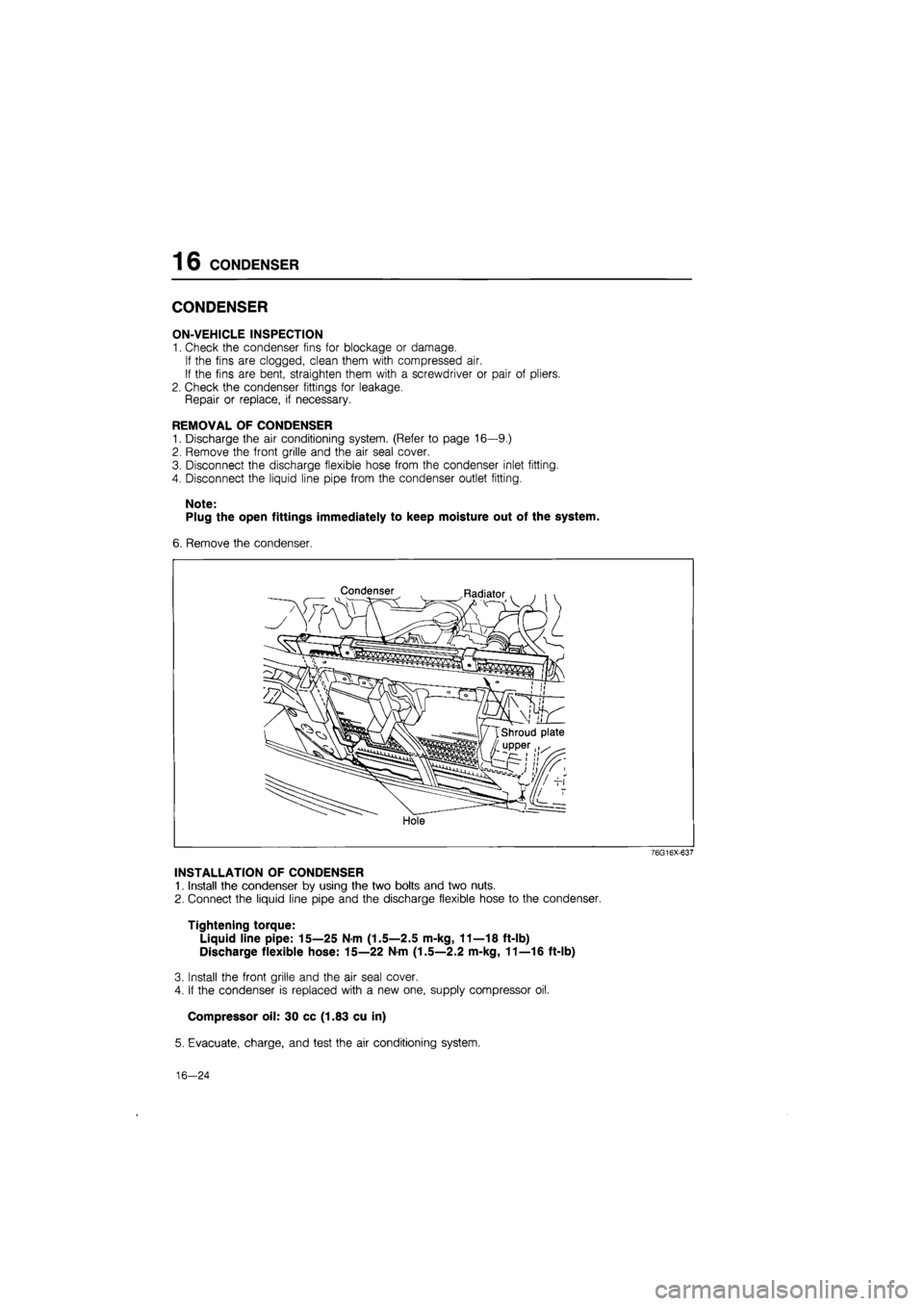

16 CONDENSER

CONDENSER

ON-VEHICLE INSPECTION

1. Check the condenser fins for blockage or damage.

If the fins are clogged, clean them with compressed air.

If the fins are bent, straighten them with a screwdriver or pair of pliers.

2. Check the condenser fittings for leakage.

Repair or replace, if necessary.

REMOVAL OF CONDENSER

1. Discharge the air conditioning system. (Refer to page 16—9.)

2. Remove the front grille and the air seal cover.

3. Disconnect the discharge flexible hose from the condenser inlet fitting.

4. Disconnect the liquid line pipe from the condenser outlet fitting.

Note:

Plug the open fittings immediately to keep moisture out of the system.

6. Remove the condenser.

Condenser Radiator

Hole

76G16X-637

INSTALLATION OF CONDENSER

1. Install the condenser by using the two bolts and two nuts.

2. Connect the liquid line pipe and the discharge flexible hose to the condenser.

Tightening torque:

Liquid line pipe: 15—25 Nm (1.5—2.5 m-kg, 11—18 ft-lb)

Discharge flexible hose: 15—22 N-m (1.5—2.2 m-kg, 11—16 ft-lb)

3. Install the front grille and the air seal cover.

4. If the condenser is replaced with a new one, supply compressor oil.

Compressor oil: 30 cc (1.83 cu in)

5. Evacuate, charge, and test the air conditioning system.

16—24

Page 1808 of 1865

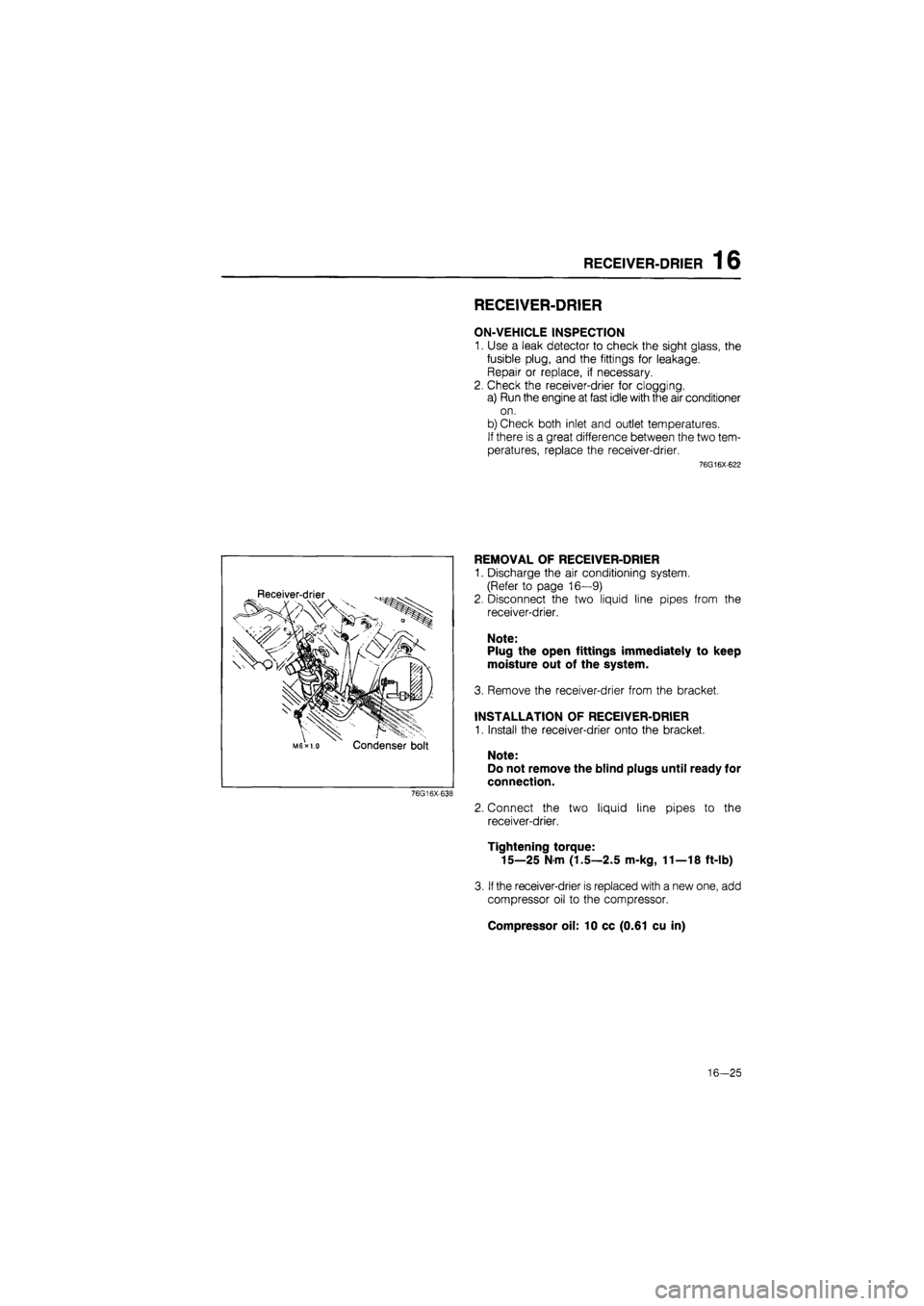

RECEIVER-DRIER 16

RECEIVER-DRIER

ON-VEHICLE INSPECTION

1. Use a leak detector to check the sight glass, the

fusible plug, and the fittings for leakage.

Repair or replace, if necessary.

2. Check the receiver-drier for clogging.

a) Run the engine at fast idle with the air conditioner

on.

b) Check both inlet and outlet temperatures.

If there is a great difference between the two tem-

peratures, replace the receiver-drier.

76G16X-622

Receiver-drier

Condenser bolt

76G16X-638

REMOVAL OF RECEIVER-DRIER

1. Discharge the air conditioning system.

(Refer to page 16—9)

2. Disconnect the two liquid line pipes from the

receiver-drier.

Note:

Plug the open fittings immediately to keep

moisture out of the system.

3. Remove the receiver-drier from the bracket.

INSTALLATION OF RECEIVER-DRIER

1. Install the receiver-drier onto the bracket.

Note:

Do not remove the blind plugs until ready for

connection.

2. Connect the two liquid line pipes to the

receiver-drier.

Tightening torque:

15—25 N m (1.5—2.5 m-kg, 11—18 ft-lb)

3.

If

the receiver-drier is replaced with a new one, add

compressor oil to the compressor.

Compressor oil: 10 cc (0.61 cu in)

16-25