clutch MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1176 of 1865

7C INSPECTION AND REPAIR

REAR CLUTCH

Disassembly

Disassemble in the sequence shown in the figure, referring to the disassembly note for specially marked

parts.

76G07C-153

1. Snap ring

2. Retaining plate

3. Drive and driven

plates

4. Dished plate

5. Snap ring

6. Spring retainer

7. Return spring

8. Piston

9. Seal rings

10. Rear clutch

drum

63U07B-109

Disassembly note

Rear clutch clearance

Before disassembling the rear clutch, measure the

rear clutch clearance.

Rear clutch clearance:

0.8—1.0 mm (0.031—0.039 in)

Note

If the clearance is not within specification, ad-

just it by selecting a proper retaining plate.

(Refer to page 7C—64.)

76G07C-154

Snap ring

Compress the clutch spring, with the SST ; then re-

move the snap ring with a screwdriver.

76G07C-156

7C-62

Page 1177 of 1865

INSPECTION AND REPAIR 7C

Piston

Remove the piston by blowing compressed air into

the fluid hole as shown.

76G07C-156

76G07C-157

76G07C-158

Inspection

Check the following and repair or replace any faulty

parts.

1. Drive and driven plates for damage or wear

Drive plate thickness

Standard: 1.6 mm (0.063 in)

Minimum: 1.4 mm (0.055 in)

2. Clutch piston for damage or cracks

3. Clutch drum for damage or deformation

4. Seal contact areas for damage

5. Check ball for leaking or sticking

6. Spring retainer for deformation

7. Broken or worn snap ring

8. Broken or weakened spring

Free length of spring:

26.2 mm (1.031 in)

Assembly

1. Apply ATF to the inner seal ring and install it into

the rear clutch drum.

2. Apply ATF to the outer seal ring, and install it onto

the piston.

3. Install the piston by pushing evenly around the cir-

cumference, being careful not to damage the seal

rings.

4. Install the return springs and spring retainer into

the piston.

76G07C-159

7C-63

Page 1178 of 1865

7C INSPECTION AND REPAIR

5. Install the snap ring.

(1) Place the SST on the spring retainer and com-

press only enough to install the snap ring.

(2) Install the snap ring in the groove.

(3) Remove the SST.

76G07C-160

6. Install the dished plate with the beveled side fac-

ing the piston as shown; then install the drive and

driven plates.

Note

Installation order:

Driven-Drive-Driven-Drive-Driven-Drive-

Driven-Drive

7. Install the retaining plate with the step facing up-

ward; then install the snap ring.

76G07C-161

76G07C-162

7C-64

8. Check the rear clutch clearance.

(1) Measure the clearance between the snap ring

and retaining plate of the rear clutch with a feel-

er gauge.

Rear clutch clearance:

0.8—1.0 mm (0.031—0.039 in)

(2) If the clearance is not with in specification, ad-

just it by selecting a proper retaining plate.

Retaining plate sizes mm (in)

4.8 (0.189) 5.0 (0.197) 5.2 (0.205) I 5.4 (0.213)

5.6 (0.220) 5.8 (0.228) 6.0 (0.236) 6.2 (0.244)

9. Check the rear clutch operation.

(1) Assemble the front clutch, and rear clutch; then

set the clutch assembly onto the oil pump.

(2) Check the rear clutch operation by applying

compressed air through the fluid passage as

shown.

Air pressure:

392 kPa (4.0 kg/cm2, 57 psi) max.

Caution

Apply air for no more than 3 seconds.

Page 1179 of 1865

INSPECTION AND REPAIR 7C

(3) Pour ATF into the rear clutch until the clutch

piston is fully submerged.

76G07C-164

(4) Check that no bubbles come from between the

piston and drum seal while applying com-

pressed air through the fluid passage shown.

Air pressure:

392 kPa (4.0 kg/cm2, 57 psi) max.

Caution

Apply air for no more than 3 Seconds

76G07C-165

REAR CLUTCH HUB

Disassembly

Disassemble in the sequence shown in the figure. 76G07C-166

1. Snap ring

2. Rear clutch hub

:

3;,

3. Internal gear

63U07B-124

7C—65

Page 1180 of 1865

7C INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Broken or worn snap ring

2, Damaged or worn internal gear

76G07C-167

Assembly

1. Set the rear clutch hub into the internal gear.

Note

Align the splines of the rear clutch hub and

internal gear

2. Install the snap ring.

76G07C-168

DRUM HUB

Disassembly

Disassemble in the sequence shown in the figure, referring to the disassembly note for specially marked

part. 76G07C-169 1. Parking gear

spring

2. Parking gear

3. Snap ring

4. Internal gear

5. Drive hub

6. Pin

76G07C-170

7C-66

Page 1182 of 1865

7C INSPECTION AND REPAIR

4. Install the parking gear spring.

76G07C-175

ONE-WAY CLUTCH INNER RACE

Disassembly

Disassemble in the sequence shown in the figure. 76G07C-176

1. Snap ring

2. Planetary carrier

(Rear)

3. One-way clutch

inner race

63U07B-127

Inspection

Check the following and replace any faulty parts.

1. Broken or worn snap ring

2. Damaged or worn gear

3. Worn one-way clutch inner race

4. Rotation of pinion gear

76G07C-177

7C-68

Page 1183 of 1865

INSPECTION AND REPAIR 7C

5. Clearance between the pinion washer and plane-

tary carrier

Clearance: 0.8 mm (0.031 in) max.

76G07C-178

Assembly

Install the rear planetary carrier into the one-way

clutch inner race; then install the snap ring.

76G07C-179

BAND SERVO

Disassemble in the sequence shown in the figure.

1. Return spring

2. Servo piston

3. Outer seal ring

4. Inner seal ring

5. Servo retainer

6. Seal ring

76G07C-180

7C—69

Page 1185 of 1865

INSPECTION AND REPAIR 7C

76G07C-185

76G07C-186

76G07C-187

PLANETARY CARRIER (FRONT)

Inspection

Check the following and replace any faulty parts.

1. Rotation of pinion gear

2. Clearance between pinion washer and planetary

carrier

Clearance: 0.8 mm (0.031 in) max.

ONE-WAY CLUTCH

Inspection

Check the following and replace any faulty parts.

1. One-way clutch operation

(1) Install the one-way clutch into the one-way

clutch inner race.

(2) Make sure that when the one-way clutch is held

and the inner race is turned, the clutch turns

smoothly in one direction only.

2. Worn bushing

Bushing inner diameter:

130.063 mm (5.121 in) max.

76G07C-188

LOW AND REVERSE BRAKE

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn drive and driven plates

Drive plate thickness

Standard: 1.6 mm (0.063 in)

Minimum: 1.4 mm (0.055 in)

2. Broken or worn snap ring

3. Deformed low and reverse brake hub

4. Broken or weakened spring

Free length of spring:

27.7 mm (1.091 in)

5. Damaged or worn piston

6. Damaged seal contact area of transaxle case

7C-71

Page 1189 of 1865

INSPECTION AND REPAIR 7C

CONTROL VALVE BODY

Precaution

(1) Pay close attention when handling the control valve because it consists of the most precise and

delicate parts of the transaxle.

(2) Neatly arrange the removed parts in order to avoid mixing up similar parts.

(3) Disassemble the control valve assembly and thoroughly clean it when the clutch and/or brake

bands are burned, and/or when the automatic transaxle fluid is degenerated.

Disassembly

Disassemble in the sequence shown in the figure.

2.5—3.4 N m _ (25—35 cm-kg, (7) 22—30 in-lb)

2.5—3.4 N-m (25—35 cm-kg 22—30 in-lb)

. 2.5—3.4 N-m (25—35 cm-kg, 22—30 In-lb)

2.5—3.4 N-m (25—35 cm-kg, 22—30 in-lb)

5—7 N-m {50—70 cm-kg, 43—61 In-lb)

2.5—3.4 N-m (25—35 cm-kg, 22—30 in-lb)

2.5—3.4 N-m (25—35 cm-kg, 22—30 in-lb)

5—7 N-m (50—70 cm-kg, 43—61 in-lb)

^ - 3—4 N-m (30—40 cm-kg, 26—35 in-lb)

76G07C-201

1. Manual valve

2. Oil strainer

3. Lower body

4. Separator plate

5. Throttle relief ball and

spring

6. Orifice check valve and

spring

7. Sub-body

8. Orifice check valve

9. Side plate

10. Vacuum throttle valve

11. Spring

12. Throttle backup valve

13. Downshift valve

14. Spring

15. Side plate

16. Modifier valve

17. 2-3 shift valve

18. Spring

19. 2-3 shift plug

20.1-2 shift valve

21. Spring

22. Side plate

23. Spring

24. Second lock valve

25. Pressure regulator sleeve

26. Pressure regulator plug

27. Spring seat

28. Spring

29. Pressure regulator valve

30. Upper body

7C-75

Page 1217 of 1865

ASSEMBLY 7C

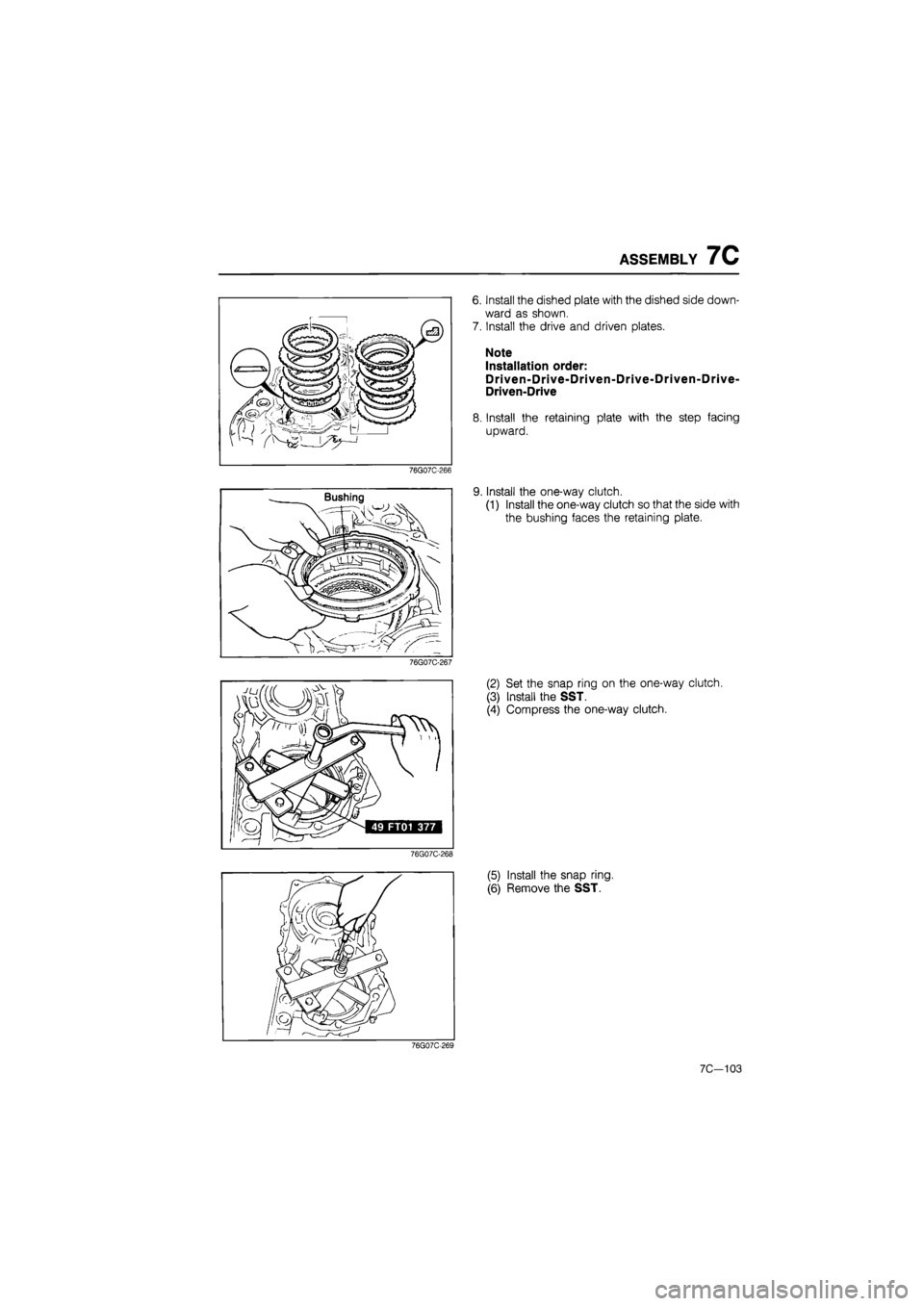

6. Install the dished plate with the dished side down-

ward as shown.

7. Install the drive and driven plates.

Note

Installation order:

Driven-Drive-Driven-Drive-Driven-Drive-

Driven-Drive

8. Install the retaining plate with the step facing

upward.

76G07C-266

9. Install the one-way clutch.

(1) Install the one-way clutch so that the side with

the bushing faces the retaining plate.

76G07C-267

(2) Set the snap ring on the one-way clutch.

(3) Install the SST.

(4) Compress the one-way clutch.

76G07C-268

(5) Install the snap ring.

(6) Remove the SST.

76G07C-269

7C—103