coolant temperature MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 515 of 1865

FUEL SYSTEM 4B

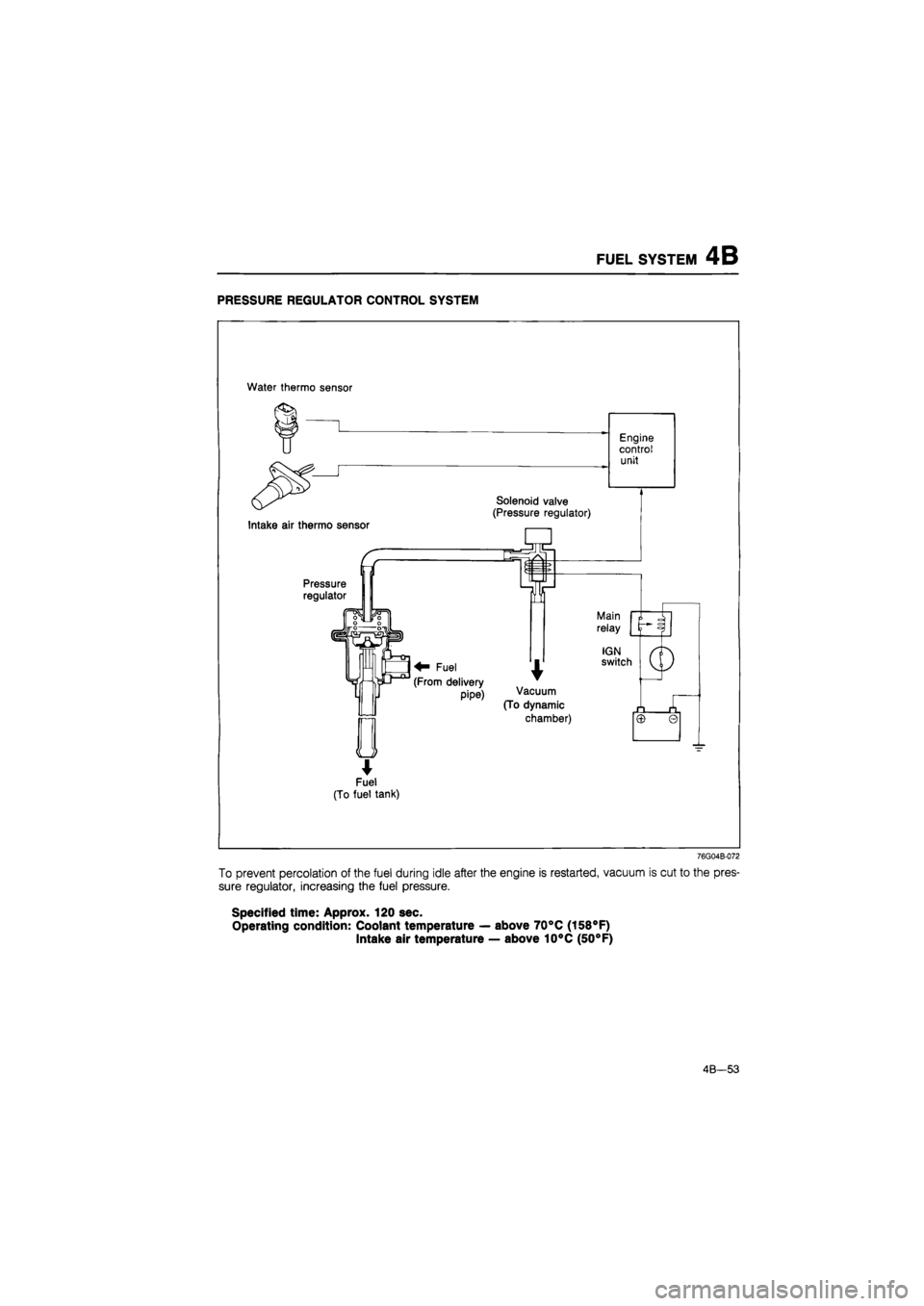

PRESSURE REGULATOR CONTROL SYSTEM

Water thermo sensor

*

Fuel

(To fuel tank)

76G04B-072

To prevent percolation of the fuel during idle after the engine is restarted, vacuum is cut to the pres-

sure regulator, increasing the fuel pressure.

Specified time: Approx. 120 sec.

Operating condition: Coolant temperature — above 70°C (158°F)

Intake air temperature — above 10°C (50°F)

4B—53

Page 516 of 1865

4B FUEL SYSTEM

COMPONENT DESCRIPTIONS

Component Function Remarks

Engine control unit Detects signals from input sensors and

switches; controls solenoid valve (Pres-

sure regulator control)

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Ignition switch

(ST position)

Sends engine cranking signal to engine control unit

Intake air thermo sensor Detects intake air temperature; sends signal to engine control unit

Installed in air flow meter

Pressure regulator Adjusts fuel pressure supplied to injectors

Solenoid valve (Pres-sure regulator control) Controls vacuum line to pressure regulator Closes vacuum line when hot

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

76G04B-073

4B—54

Page 526 of 1865

4B DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

This system consists of the dashpot and fuel cut system. The dashpot is to prevent after-burn so that

the throttle valve gradually closes during deceleration.

The control unit detects engine deceleration judging from the engine speed and the idle switch, and

signals a fuel cut operation to match the engines need, based on the coolant temperature and the

driving condition.

4B—64

Page 527 of 1865

DECELERATION CONTROL SYSTEM 4B

COMPONENT DESCRIPTIONS

Component Function Remarks

Brake light switch Detects braking operation (deceleration);

sends signal to engine control unit

Clutch switch Detects in-gear condition;

sends signal to engine control unit Switch ON when clutch pedal released

Dashpot (MTX) Prevents sudden closing of throttle valve during deceleration or shifting Adjustment speed: 1,900—2,100 rpm

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Neutral switch Detects in-gear condition; sends signal to engine control unit Switch ON when in-gear

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04B-089

4B—65

Page 533 of 1865

EGR SYSTEM 4B

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM

EGR modulator valve Solenoid valve (EGR)

86U04A-127

This system introduces exhaust gas into the intake manifold to reduce NOx in the exhaust gas. It oper-

ates depending on the engine load, engine speed (above 1,500 rpm), engine coolant temperature

(above 70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTIONS

Component Function Remarks

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control

valve

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (EGR)

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum line to EGR control

valve

Throttle sensor Detects throttle valve opening angle; sends signal to engine control unit Integrated idle switch

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit

ON: above 17°C (63°F)

76G04B-102

4B-71

Page 536 of 1865

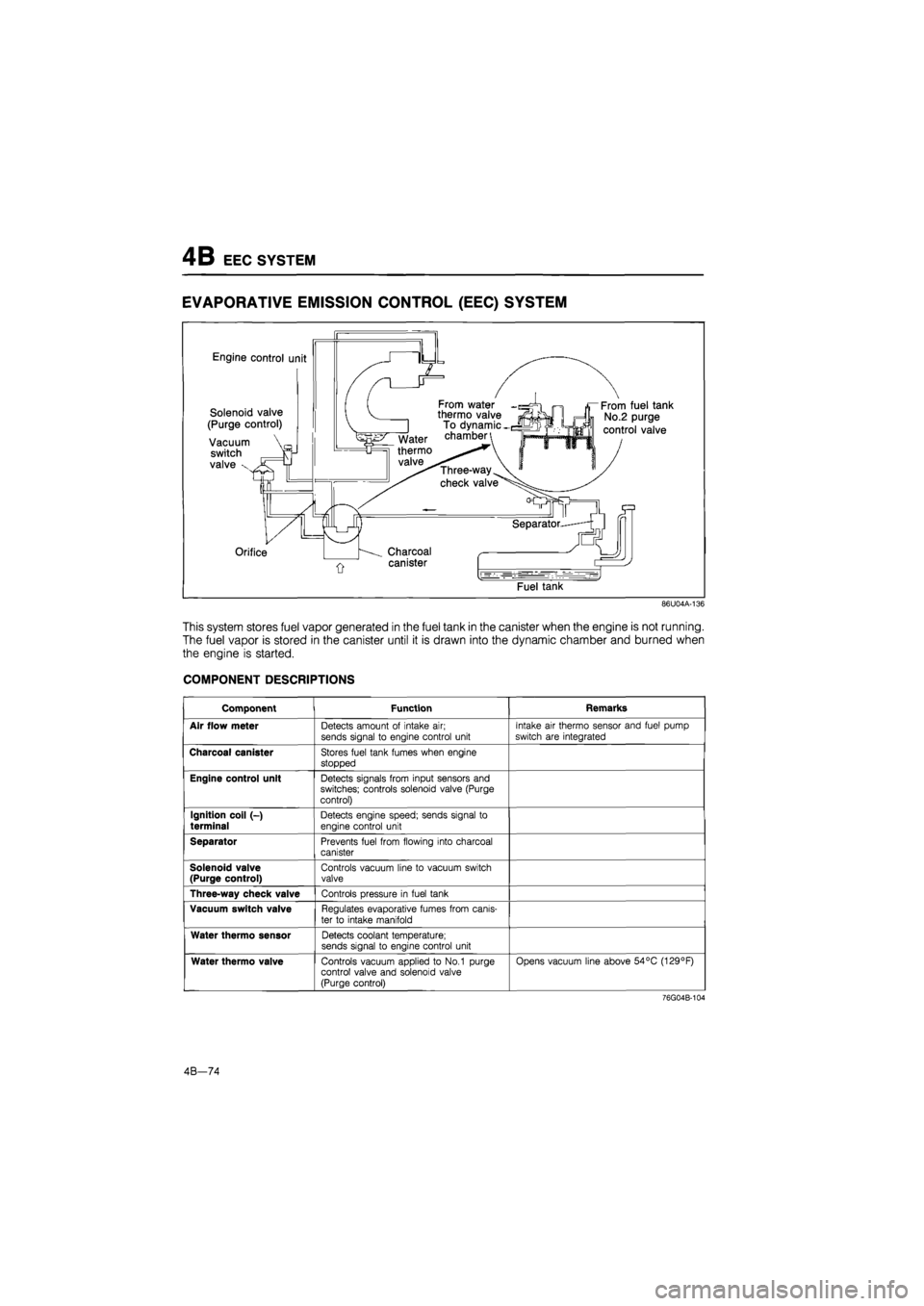

4B EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Engine control unit

Solenoid valve

(Purge control)

Vacuum

switch

valve x

From water thermo valve To dynamic -chamber

Three-way

check valve

Orifice Charcoal

canister

From fuel tank

No.2 purge

control valve

Fuel tank

86U04A-136

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter Detects amount of intake air; sends signal to engine control unit

Intake air thermo sensor and fuel pump

switch are integrated

Charcoal canister Stores fuel tank fumes when engine

stopped

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Purge control)

Ignition coil (-)

terminal Detects engine speed; sends signal to

engine control unit

Separator Prevents fuel from flowing into charcoal canister

Solenoid valve (Purge control) Controls vacuum line to vacuum switch valve

Three-way check valve Controls pressure in fuel tank

Vacuum switch valve Regulates evaporative fumes from canis-

ter to intake manifold

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo valve Controls vacuum applied to No.1 purge control valve and solenoid valve (Purge control)

Opens vacuum line above 54°C (129°F)

76G04B-104

4B—74

Page 605 of 1865

4C ISC SYSTEM

IDLE

SPEED CONTROL

(ISC)

SYSTEM

Air valve BAC valve (ISC valve + air valve)

ISC valve

Air passage

c=£> Coolant passage

Idle switch

Large

Bypass air

amount

Small

Characteristics of air valve

Low 50°C (122°F) High

Coolant temperature

76G04C-077

To improve idle smoothness, the ISC system controls the intake air amount by regulating the bypass

air amount that passes through the throttle body.

This system consists of the BAC valve and the control system.

The BAC valve consists of the air valve which functions only when the engine is cold (below 50°C

(122°F)) and the ISC valve which works throughout the entire engine speed range.

4C-44

Page 606 of 1865

ISC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

A/C switch Detects air conditioner operation; sends

signal to engine control unit Switch ON when air conditioner

operating

Air valve When cold, supplies bypass air into dy-namic chamber • Engine speed increased to shorten warm-up period • Thermo wax type

• Installed in BAC valve

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

E/L control unit Detects that E/L is being applied; sends

signal to engine control unit

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Idle speed control)

Idle switch Detects when throttle valve fully closed;

sends signal to engine control unit

Installed on throttle body

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

P/S pressure switch Detects P/S operation; sends signal to engine control unit Switch ON when steering wheel turned right or left

Solenoid valve (Idle speed control) Controls bypass air amount • Controlled by duty signal from engine control unit • Installed in BAC valve

• Operates idle-up

Test connector For initial idle speed adjustment • Gerrn, 1-pin

• Idle speed feedback control cancelled when connector grounded

Water thermo sensor Detects coolant temperature; sends

signal to engine control unit

76G04C-078

4C—45

Page 611 of 1865

4C FUEL SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Air flow sensor Detects amount of intake air;

sends signal to engine control unit

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

Engine control unit Detects signals from input sensors and switches; controls injector and fuel pump operations

Fuel filter Filters fuel

Fuel pump Provides fuel to injectors • Operates while engine running

• Installed in fuel tank

Fuel pump control unit (4WS) Monitors fuel level in left section; controls transfer pump operation

G signal pick-up Detects No.1 cylinder TDC; sends signal to engine control unit Installed in distributor

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed on throttle body

Ignition switch (ST position) Sends engine cranking signal to engine control unit

Injector Injects fuel into intake port • Controlled by signals from engine control unit • High-ohmic injector

Intake air thermo sensor Detects intake air temperature; send signal to engine control unit

Control relay Supplies electric current to injectors fuel pump and engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

Oxygen sensor (Unleaded fuel) Detects oxygen concentration; sends signal to engine control unit

• Zirconia ceramic and platinum coating • Integrated heater coil

Pressure regulator Adjusts fuel pressure supplied to injectors

Pulsation damper Absorbs fuel pulsation

Throttle sensor Detects throttle valve opening angle;

sends signal to engine control unit

Installed on throttle body

Transfer pump (4WS) Pumps fuel from the left to the right side Controlled by fuel pump control unit

Transfer pump switch (4WS) Detects fuel level in left section;

sends signal to control unit

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch (Unleaded fuel) Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-088

4C-50

Page 629 of 1865

4C PRC SYSTEM

PRESSURE REGULATOR CONTROL

(PRC)

SYSTEM

Distributor (Ne signal)

I Fuel

(To fuel tank)

76G04C-128

To prevent percolation of the fuel during idle after the engine is restarted, vacuum is cut to the pres-

sure regulator, increasing the fuel pressure.

Specified time: Approx. 120 sec.

Operating condition: Coolant temperature — above 70°C (158°F)

Intake air temperature — above 30°C (86°F)....Unleaded fuel

above 50°C (122°F)....Leaded fuel

4C-68