fuel cap MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 618 of 1865

FUEL SYSTEM 4C

Pulsation damper

76G04C-100

Intake mainfold

3. Turn the ignition switch ON for 10 seconds, and

check the feeding capacity with graduated

cylinder.

Feeding capacity:

Minimum 220 cc (13.4 cu in)/10 sec.

4. If not within specification, check the fuel filter, fuel

lines and fuel pump.

5. Turn the ignition switch OFF and disconnect the

jumper wire.

PULSATION DAMPER

1. Run the engine at idle.

2. Place a finger on the screw of the pulsation damper

head.

3. Check that pulsation is felt.

86U04A-083

Injector

INJECTOR

On-vehicle Inspection

1. Warm up the engine and run it at idle.

2. Listen for operational sound of the injector with a

screwdriver or a sound scope.

76G04C-101

3. Ground the test connector (Green, 1-pin).

76G04C-102

4C-57

Page 620 of 1865

FUEL SYSTEM 4C

5. Connect the SST to the battery and injector.

6. Check the injection volume with a graduated con-

tainer.

Injection volume:

Approx. 66—91 cc (4.03—5.55 cu in) /15 sec.

Caution

When using the SST, make sure of the SST

number and use correct one.

7. If not correct, replace the injector.

76G04C-107

Rear seat Cushion Release Button -

76G04C-108

TRANSFER PUMP CONTROL SYSTEM (4 WHEEL

STEERING)

1. Remove the rear seat. (Refer to 14 section.)

2. Remove the fuel filler cap.

3. Turn the ignition switch ON.

Note

a) The tank should be more than 1/3 full.

b) Due to the delay timer, transfer pump oper-

ation begins approx. 10 sec. after the igni-

tion switch is turned ON.

4. Listen for the operational sound of the transfer

pump.

5. Install the fuel filler cap.

6. If no sound was heard, check the voltage at the

transfer pump connector.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

86U04B-075

I C A

lb d

cp a • • •

J

76G04C-211

7. If the voltages are correct, replace the transfer

pump.

8. If not correct, disconnect the transfer pump con-

nector.

9. Check the voltage at the terminals below.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

10. If the voltages are correct, replace the transfer

pump.

4C—59

Page 626 of 1865

FUEL SYSTEM 4C

FUEL TANK

Removal

Caution

a) Before performing the following procedure, release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire. (Refer to page 4C—52.)

b)When removing the fuel tank, keep sparks, cigarettes, and open flames away from the

fuel tank.

Remove in the sequence shown in the figure.

76G04C-125

Note

Drain the fuel from the fuel tank before removing the tank.

1. Remove fuel filler cap.

2. Fuel pump connectors

3. Fuel hoses

4. Steering angle transfer shaft (4-wheel

steering)

(Refer to section 10)

5. Cross member (4-wheel steering)

6. Evaporative hoses

7. Fuel filler hose

8. Breather hose

9. Parking cable bracket

10. Fuel tank strap

11. Fuel tank

4C-65

Page 673 of 1865

4D OUTLINE

OUTLINE

The Mazda 626 offers two diesel engines; a Comprex supercharged RF-CX engine, and a normally

aspirated RF-N engine.

SPECIFICATIONS

—Engine model

Item ———

ECE UK, GENERAL —Engine model

Item ——— RF-CX RF-N

Fuel tank Capacity liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel filter Type Cartridge, paper element

Sedimenter Type With detector

Injection pump

Type Bosch VE distributor

Injection pump

Manufacturer Diesel Kiki Co,, Ltd.

Injection pump

Direction of rotation Clockwise Injection pump

Drive method Timing belt

Injection pump

Plunger diameter mm (in) 9.0 (0.35) 8.0 (0.31)

Injection pump

Cam lift mm (in) 2.2 (0.087)

Injection nozzle Type Throttle Injection nozzle

Injection pressure kPa (kg/cm2, psi) 13,240 (135 , 1,920)

Injection timing ATDC

1

° TDC 0°

Idle speed rpm 720 _+f0

Fast idle speed (A/C ON) rpm 700-750

Cold start device Engine speed rpm 1.100 Cold start device

Advance degree 6°

Air cleaner Type Cartridge, paper element Air cleaner Type

Wet Dry

PCV system Type Open Closed

76G04D-002

4D—2

Page 711 of 1865

OUTLINE 5

SPECIFICATIONS

Gasoline Engine

item

Engine

F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE

(DOHC)

Battery

Voltage

Type and capacity

12. Negative ground

(20 hour rate) 34B19L(S) (33 Ah): General 50D20L (50 Ah), 55D23L (60 Ah): ECE

Alternator

Type A.C.

Output V-A 12-70

Regulator type Transistorized (built-in IC regulator)

Regulated voltage 14.1-14.7

Brush length

mm (in) Standard 16.5 (0.650)

Minimum 8.0 (0.315)

Drive belt tension

mm (in)/98 N (10 kg, 22 lb) New: 6-8 (0.24-0.32), Used: 7-9 (0.28-0.35)

Starter

Type Coaxial reduction: Middle East & General (FE • carburetor)

Non-reduction: Others

Output V-kW 12-0.85

Brush length

mm (in)

12-0.95

Standard 17.0 (0.669)

Minimum 11.5 (0.453)

Unleaded fuel

17.0 (0.669)

Others

17.51

Unleaded fuel 11.5(0.453) Others 10,0 (0.394)

12-1.4 12-0.95

17.0 (0.669)

11.5 (0.453)

Ignition timing 6 ± 10 BTDC (Vacuum hose disconnected)

12

±

1° BTDC

(Test connector

grounded)

Distributor

Type Fully transistorized (HEI)

Electronic spark advance

Centrifugal spark advance

(crank angle/engine speed)

degree/rpm

F6

-2-2/1,000 6-10/2,100 14-18/6,100

F8 -2—2/1,000 10-14/2,100 18-22/6,100

FE (8 VALVE)—Carburetor Unleaded fuel

(MTX)-2—2/1,760 12—16/3,360 22—26/5,320 (ATX)-2-2/1,300 12-16/3,360 22-26/5,320

Others

-2—2/1,460 10—14/2,540 22—26/5,540

FE (12 VALVE)—Carburetor -2-2/1,200 10—14/2,400 10—14/4,000 16-20/5,000

FE—Fuel injection (except FE DOHC) -2—2/1,000 10—14/2,600 10—14/4,600 16—20/5,800

Unleaded fuel model 76G05X-503

5-5

Page 712 of 1865

5 OUTLINE

Item

Engine F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE (DOHC)

F6 and F8

-2-2/100 6-10/300

FE (8 VALVE)—Carbu retor Unleaded fuel -2—2/120 8—12/245

Distributor

Vacuum spark advance (Crank angle/Vacuum)

Others (MTX) -2-(ATX) -2--2/100 16-

-2/100 10-

-20/250

-14/200

degree/mmHg (inHg) FE (12 VALVE)—Carburetor

-2-2/120 11-15/300

FE—Fuel injection (except FE DOHC) [A chamber] -2-2/125 18-22/300

[B chamber] -2-2/125 -6 10/200

Spark plug

Type

FE (8 VALVE)*1 NGK: BPR5ES-11, BPR6ES-11 Nippon Denso: W16EXR-U11, W20EXR-U11 Others

NGK: BPR5ES, BPR6ES Nippon Denso: W16EXR-U, W20EXR-U

NGK:

BCPR5E, BCPR6E Nippon

Denso: Q16PR-U, Q20PR-U

Unleaded fuel

NGK: BCPR5E-11 BCPR6E-11 BCPR7E-11

Leaded fuel NGK: BCPR5E BCPR6E

Plug gap mm (in)

0.75-0.85 (0.030-0.033), FE (8 VALVE)*1 1.0-1.1 (0.039-0.043)

0.7-0.8

(0.028-0.031)

1.0-1.1 "

/n noo

n n/9

0.7-0.8 *2 (0.028-0.031)

Firing order 1-3—4-2 76G05X-504

Diesel Engine

——Engine Item RF-N RF-CX

Battery

Voltage V 12, Negative ground Battery Type and capacity

(20 hour rate) 80D26L (65)

50D20L, 50D20R (50)-ECE 80D26L (65)

65D23L, 65D23R (55)

Alternator

Type A.C.

Alternator

Output V-A 12-70 12-75

Alternator

Regulator type Transistorized (built-in IC regulator)

Alternator Regulated voltage V 14.1-14.7 Alternator

Brush length mm (in)

Standard 16.5 (0.650) 21.5 (0.846)

Alternator

Brush length mm (in) Minimum 8.0 (0.315) 8.0 fO.315)

Alternator

Drive belt tension

mm (in)/98 N (10 kg. 92 lb) New: 9-11 (0.35-0.43), Used: 12-14 (0.47-0.55)

Starter

Type Reduction

Starter Output V—kW 12—2.0, 12-2.2 (Cold area) Starter Brush length

mm (in)

Standard 2.0 kW: 17.0 (0.669). 2.2 kW: 18.0 (0.709) Starter Brush length

mm (in) Minimum 2.0 kW: 11.0 (0.453), 2.2 kW: 11.0 (0.453)

Firing order 1-3-4-2

Unleaded fuel model *2 Leaded fuel model

76G05X-505

5-6

Page 1490 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

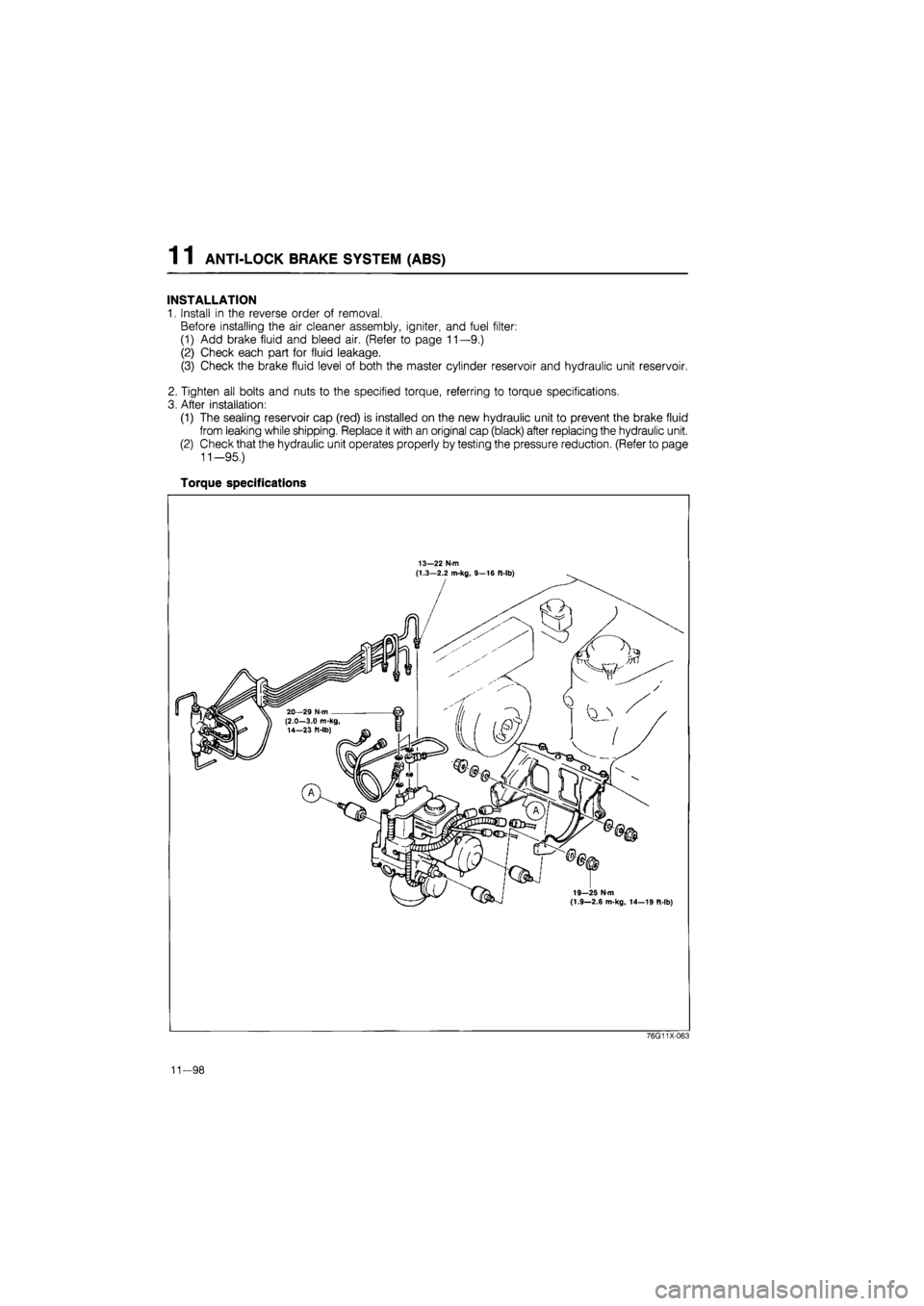

INSTALLATION

1. Install in the reverse order of removal.

Before installing the air cleaner assembly, igniter, and fuel filter:

(1) Add brake fluid and bleed air. (Refer to page 11—9.)

(2) Check each part for fluid leakage.

(3) Check the brake fluid level of both the master cylinder reservoir and hydraulic unit reservoir.

2. Tighten all bolts and nuts to the specified torque, referring to torque specifications.

3. After installation:

(1) The sealing reservoir cap (red) is installed on the new hydraulic unit to prevent the brake fluid

from leaking while shipping. Replace it with an original cap (black) after replacing the hydraulic unit.

(2) Check that the hydraulic unit operates properly by testing the pressure reduction. (Refer to page

11-95.)

Torque specifications

11-98

Page 1832 of 1865

30 TECHNICAL DATA

4A. FUEL AND EMISSION CONTROL SYSTEM (CARBURETOR)

F6 and F8 Engine

Engine F6 F8

Spec. General Singapore General

ECE, Hong

Kong, &

Singapore

Idle speed rpm MTX 800

+ 50

0 Idle speed rpm ATX (in

N

range)

—

950 +58 900

+ 50

0

CO concentration °/o 2.0

± 0.5

Carburetor

Type Down draft two barrel

Throat diameter mm (in) Primary 30 (1.18) Throat diameter mm (in) Secondary 34 (1.34)

Venturi diameter mm (in) Primary 23.5 (0.93) Venturi diameter mm (in) Secondary 29.0 (1.14)

Main nozzle mm (in) Primary 2.6 (0.10) Main nozzle mm (in) Secondary 2.8 (0.11)

Primary MTX 1.10 1.09 (0.0429) 1.14 (0.045)

Main

jet

mm (in) Primary ATX (0.0433) 1.08 (0.0425) 1.12 (0.044)

Secondary 1.50 (0.059)

Primary MTX 0.60 0.60 (0.024) 0.55 (0.022)

Main

air

bleed mm (in) Primary ATX (0.024) 0.80 (0.031) 0.60 (0.024)

Secondary 0.50 (0.020)

Slow

jet

mm (in) Primary 0.48 (0.019) 0.46 (0.018) Slow

jet

mm (in) Secondary 1.00 (0.039) 1.10 (0.043)

Primary No.

1

0.80 (0.031)

Slow

air

bleed Primary No.

2

1.90 (0.075)

mm (in) Secondary No.

1

1.00 (0.039) 0.80 (0.031) Secondary No.

2

0.50 (0.020)

Power

jet

mm (in) 0.50 (0.020)

Fast idle adjustment

mm (in)

Clearance between primary throttle valve and bore 1.40-1.76(0.055-0.069) MTX: 0.48-0.64 (0.019-0 025) ATX: 0.56-0.72 (0.022-0.028)

Max. fuel flow

"L"

44 (17.3)

Float level adjustment Clearance between float and

air

horn without gasket

mm (in) Fuel stop

"H •

12.5 (0.49)

Clearance between float and

air

horn/without gasket; float lowered

by

own weight

Choke breaker diaphragm Start 180-240 (7.1-9.5) 100—160 (3.9-6.3)

mmHg

(in Hg)

Stop 290—350 (11.4-13.8) 220-280 (8.7-11.0)

Choke opener Start

—

35-65 (1.4-2.6)

—

35-65 (1.4-2.6)

mmHg

(in Hg)

Stop

—

130-190 (5.1-7.5)

—

130-190

(5,1-7.5)

Accelerator linkage

Free plav

of

cable

at

carburetor mm (in) 1-3 (0.039—0.118)

Fuel tank

Capacity Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel pump

Type Mechanical pump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8-3.8)

Feedina capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

Type Paper element with magnet

Air cleaner

Fresh-Hot switching Manual Diaphragm type

Element

tvDe

Oil permeated paper

Fuel specification Leaded regular

30-18

Page 1833 of 1865

TECHNICAL DATA 30

FE Engine

Engine 8 Valve 12 Valve 8 Valve

Spec. General Middle

East

ECE,

Hong Kong, &

Singapore

Unleaded

Fuel

(West Germany)

Idle speed rpm MTX 800

+5§

850 Idle speed rpm ATX 900 +5S

(ir

N range)

CO concentration

%

2.0

± 0,5

Carburetor

Type Down draft, two barrel

Throat diameter mm (in) Primary 30 (1.18) Throat diameter mm (in) Secondary 34 (1.34)

Venturi diameter mm (in) Primary 23.5 (0.93) Venturi diameter mm (in) Secondary 29.0 (1.14)

Main nozzle mm (in) Primary 2.6 (0.10) Main nozzle mm (in) Secondary 2.8 (0.11)

Primary MTX 1.14 (0.045) 1.09 (0.0429) 1.14 (0.045) 1.09 (0.0429) Main

jet

mm (in) Primary ATX 1.12 (0.044) 1.08 (0.0425) 1.12 (0.044) 1.09 (0.0429)

Secondary 1.55 (0.061) 1.50 (0.059) 1.55 (0.061) 1.50 (0.059)

Primary MTX 0.50 (0.020) 0.60 (0.024) 0.50 (0.020) 0.50 (0.020) Main

air

bleed mm (in) Primary ATX 0.55 (0.022) 0.80 (0.031) 0.55 (0.022) 0.50 (0.020)

Secondary 0.50 (0.020)

Primary 0.46 (0.018)

Slow jet mm (in) Secondary MTX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 0.90 (0.035) Secondary ATX 1.10 (0.043) 1.00 (0.039) 1.10 (0.043) 1.00 (0.031)

Primary No.

1

0.80 (0.031)

Slow

air

bleed Primary No.

2

1.90 (0.075)

mm (in) Secondary No.

1

0.80 (0.031) 1.00 (0.039) 0.80 (0.031) 1.00 (0.039) Secondary No.

2

0.50 (0.020)

Power jet mm (in) MTX 0.50 (0.020) 0.50 (0.020) Power jet mm (in) ATX 0.50 (0.020) 0.40 (0.016)

Fast idle adjustment mm (in) MTX 0.48-0.64 (0.019-0.025) 1 40—1

76

0.48-0.64 (0.019-0.025) 1

40

1

76

Clearance between primary throttle valve and bore ATX 0.56-0.72

(0.022-0.028) (0.055-0.069) 0.56-0.72 (0.022-0.028) (0.055-0.069)

Max. fuel flow

"L"

44 (17.3)

Float level adjustment Clearance between float and

air

horn without aasket

mm (in) Fuel stop

"H •

12.5 (0.49)

Clearance between float and

air

horn without aasket float lowered

bv

own weiaht

Choke breaker diaphragm Start

100-160 (3,9-6.3) 180-240 (7.1-94) 100-160 (39-6.3) 180-240 (7.1-9,4)

mmHg

(in Hg)

Stop

220-280 (8.7-11,0) 290-350 (11,4-13.8) 220-280 (8.7-11.0) 290-350 (11.4-13.8)

Choke opener mmHg (in

Hg)

Start

—

80-120 (3.1-8.7) 30-70 (1.2-2.8)

—

Choke opener mmHg (in

Hg)

Stop

—

220-280 (87-11.0) 130-190 (5.1-7.5)

—

Accelerator llnkaae

Free play

of

cable

at

carburetor mm (in) 1-3 (0.039-0.118)

Fuel tank

Capacity Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel pump

TvDe

Mechanical pump

Delivery pressure kPa (kg/cm2,

psi)

20-26 (0.20-0.27, 2.8-3.8)

20-29 (0.20-030, 2.8-4.3) 20-26

(020-0.27, 28-38)

Feeding capacity cc/min (cu in/min) More than 860 (52.5)

at

idle

Fuel filter

TvDe

Paoer element with maanet

Air cleaner

Fresh-Hot switchina Diaohraam Manual Diaohraam Bimetal

Element tvoe Oil oermeated oaoer

Fuel specification Leaded super Unleaded super Leaded regular Leaded super Unleaded super Unleaded regular

30-19

Page 1834 of 1865

30 TECHNICAL DATA

4B. FUEL AND EMISSION CONTROL SYSTEMS (FUEL INJECTION FE)

Item Specifications

Fuel tank capacity Liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel pump

Type In-tank, electric motor

Fuel pump Fuel pressure kPa (kg/cm2, psi) 441-588 (4.5-6.0, 64-85) Fuel pump

Feeding capacity cc (cu in)/10 sec. 220 (13.4) min.

Air cleaner Element type Oil permeated

Accelerator cable Deflection

mm

(in) 1—3 (0.04-0.12)

Idle speed

rpm

ATX: 800 +58 (Neutral), ATX: 900 +600

(P

range)

Dash

pot

Adjustment speed

rpm

1,900-2.100

EGR control valve Starts

to

open mmHg (in Hg) 40-60 (1.6-2.4)

Air control valve Starts

to

open mmHg (in Hg) 180-280 (7.1-11)

Water thermo valve Opened

°C

(°F) Higher than 46—54 (115-129)

Water thermo switch Opened

At

radiator

°C

(°F) Lower than 15—19 (59—66)

Vacuum switch valve Starts to open mmHg (in Hg) 66—106 (2.6—4.2)

Water thermo sensor Resistance

-20°C (-4°F)k!) 14.5-17.8

Water thermo sensor Resistance 20°C (68°F)

kQ

2.2-2.7 Water thermo sensor Resistance

80°C (176°F)k!i 0.28-0.35

Throttle sensor

Resistance

at

fully closed

B

C kQ

4-6

Throttle sensor

Resistance

at

fully closed A

« B Q

Approx.

500

Throttle sensor Resistance

at

fully opened A

«• B kQ

Approx.

4.5

Throttle sensor

Setting Closed at mm (in) 0.4 (0.0157)

Throttle sensor

Setting Open at mm (in) 0.55 (0.022)

Air flow meter

Resistance

of

full closed

E2 « Vs fi

More than

20

Air flow meter

Resistance

of

full closed

E2 •+ Vc 0

100-300

Air flow meter

Resistance

of

full closed

E2 VB Q

200-400 Air flow meter

Resistance

of

full closed

Ei

•+ Fc Q OO

Air flow meter

Resistance

at

full open Ei

•+ Fc Q

0

Intake

air

thermo sensor Resistance

-20°C M°RkQ 13.6-18.4

Intake

air

thermo sensor Resistance 20°C (68°F) kfi 2.21—2.69 Intake

air

thermo sensor Resistance

60°C (140°RkQ 0.493-0.667

Pressure regulator Regulating pressure At idling kPa

(kg/cm

,

psi) 235-275 (2.4—2.8, 34-40)

Injector

Injection amount cc (cu in)/15 sec. 38-53 (2.3-3.2) Injector

Resistance

Q

12-16

Circuit opening relay Resistance STA Ei Q 15-30 Circuit opening relay Resistance B

Fc fi

80-150

Fuel Unleaded gasoline

30-20