fuel filter MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 468 of 1865

4B OUTLINE

SPECIFICATIONS

Item Specification

Idle speed rpm MTX: 800 +5„° (Neutral), ATX: 900 +5S

(P

range)

Throttle body

Type Horizontal draft (1 -barrel)

Throat diameter mm (in) 50 (2.0)

Air flow meter

E2-VS More than

20

E2-VC 100-300

Resistor

Q

E2-VB 200—400 Resistor

Q

E2-THA -20°C

(

—4°F) 13,600-18,400 20°C

(

68°F) 2,210-2,690 60°C (140°F)

493- 667

Air cleaner

Element type Oil permeated

Fuel pump

Type Impeller

(in

tank)

Output pressure kPa (kg/cm2,

psi)

441-588 (4.5-6.0, 64—85)

Feeding capacity cc (cu in)/10 sec. 220 (13.4) minmum

Fuel filter

Type Low pressure side Nylon element Type High pressure side Paper element

Pressure regulator

Type Diaphragm

Regulating pressure kPa (kg/cm2,

psi)

235-275 (2.4—2.8, 34—40)

Injector

TvDe

Hiqh-ohmic

Type

of

drive Voltage

Resistance

fi

12-16

Injection amount cc (cu

in) 15

seconds 38—53 (2.3-3.2)

Fuel tank

Capacity liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel

Soecification Unleaded reaular

76G04B-506

4B—6

Page 469 of 1865

TROUBLESHOOTING GUIDE 4B

TROUBLESHOOTING GUIDE

This troubleshooting guide shows the malfunction numbers and the symptoms of various failures.

Perform troubleshooting as described below.

Possible cause

Symptom

Input sensors and switches

o>

C

0

Jh c 01

4B-14

a> 4)

E

o

4B-1S

o in c « m o E k_ 0) c.

0 <0 £

4B-16

o CO c a> 0) o E

a>

.x

co

4B-17

o 10 c a) co

4B-18

o in c a> (0

o> o> a>

a) £ a VI o E

4B-19

0 <0 c a> 0) c a> 01

S? o

4B-20

E a> in (0

o 10 A •o 0) 0> u.

4B-21

Output solenoid valves

o «

3 O) 0)

0) 0) 01

0> > 10 >

•o o c V o tt)

4B-22

0)

OI

0> > CO >

TJ

O c 0> o CO

4B-23

oc O u

o> > 75 >

•o o c a> o 05

4B-23

0 a. 3 1

2

0) > (0 >

"D O

o 0> in in a a >. £

4B-23

ffl a 3 • a>

2

a> > 10 >

"O o c a> o

CO Q. >. JO

4B-24

Fault Indicated by SST

Code No. 01 08 09 10 12 14 15 17 25 26 28 34 35

Hard start or won't start

(Cranks OK)

Engine stalls

Rough

idle

While warming up

After warming up

While warming up

After warming up

High idle speed after

warming up

TROUBLESHOOTING PROCEDURE

Note

Step 1 under symptom is to quickly determine what system or unit may be at fault by use of the SST. (Self-Diagnosis Checker 49 H018 9A1)

1st:

Check input sensors and output solenoid valves with the

SST.

(Refer

to

page 4B—10.)

2nd:

Check other switches with the

SST.

(Refer

to

page 4B—26.)

3rd:

Check the following items:

11

Poor acceleration, hesita-

tion or lack of power

Runs rough on deceleration

Afterburn in exhaust system

Poor fuel consumption

Engine stalls or rough after hot starting

Electrical system

1) Battery condition

2) Fuses

Fuel system

1) Fuel level 2) Fuel leakage

3) Fuel filter 4) Idle speed

Engine

1) Compression 2) Overheating

Ignition system

1) Ignition spark 2) Ignition timing

Intake air system

1)

Air

cleaner element 2) Vacuum

or air

leakage 3) Vacuum hose routing

4) Accelerator cable

Others

1) Clutch slippage 2) Brake dragging

Fails emission test 4th:

Check Fuel and Emission Control Systems. (Refer

to

page 4B—8.)

76G04B-003

4B—7

Page 492 of 1865

4B INTAKE AIR SYSTEM

INTAKE AIR SYSTEM

76G04B-036

This system controls the air required by the engine for operation. The system consists of the air duct,

air cleaner, air flow meter, throttle body, dynamic chamber, and intake manifold.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air cleaner

Filters

air

into throttle body

Air flow meter

Detects amount

of

intake air;

sends signal

to

engine control unit Intake

air

thermo sensor and fuel pump

switch are integrated

Throttle body

Controls intake

air

quantity Integrated throttle sensor and idle switch

76G04B-037

4B—30

Page 504 of 1865

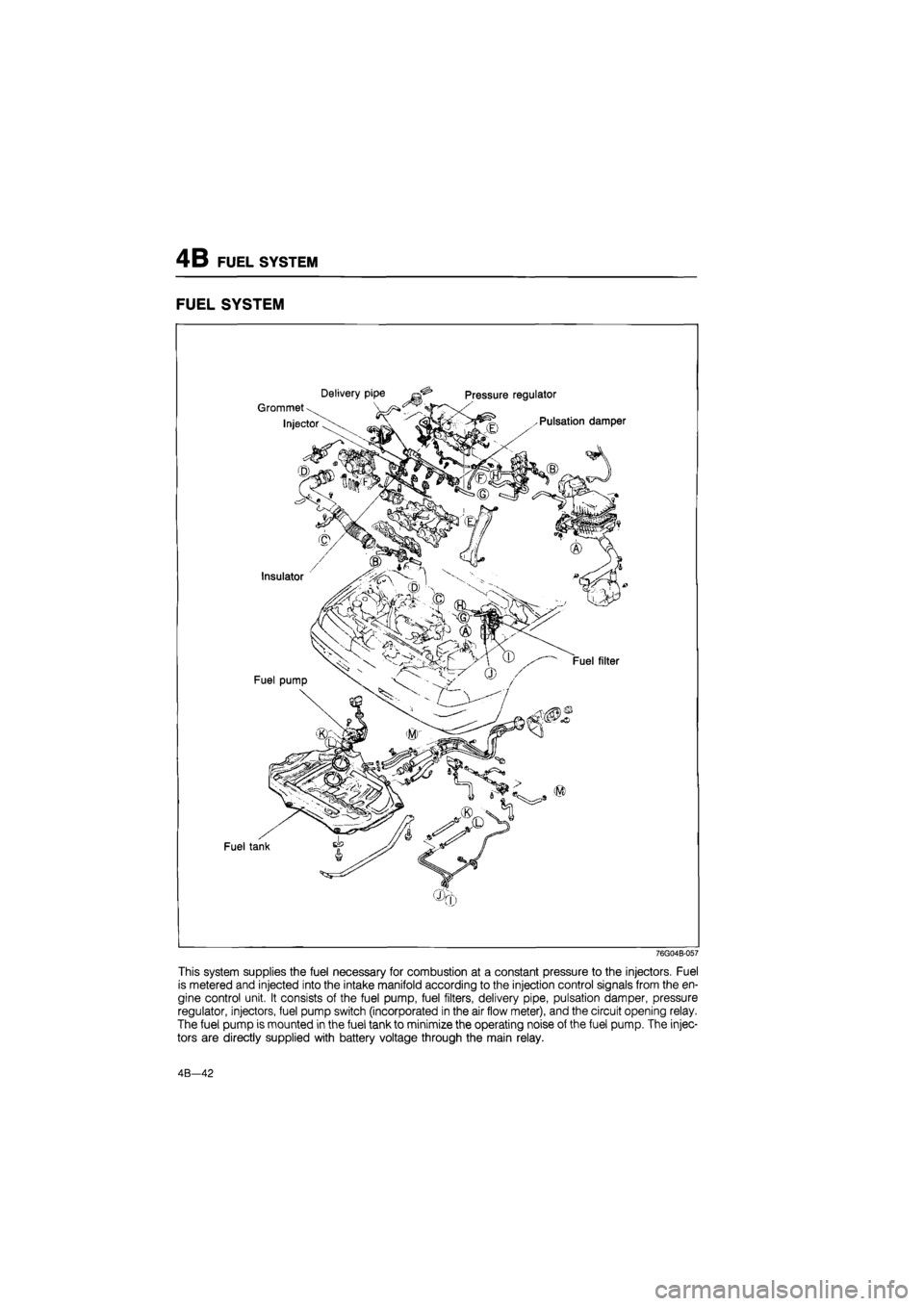

4B FUEL SYSTEM

FUEL SYSTEM

76G04B-057

This system supplies the fuel necessary for combustion at a constant pressure to the injectors. Fuel

is metered and injected into the intake manifold according to the injection control signals from the en-

gine control unit. It consists of the fuel pump, fuel filters, delivery pipe, pulsation damper, pressure

regulator, injectors, fuel pump switch (incorporated in the air flow meter), and the circuit opening relay.

The fuel pump is mounted in the fuel tank to minimize the operating noise of the fuel pump. The injec-

tors are directly supplied with battery voltage through the main relay.

4B—42

Page 505 of 1865

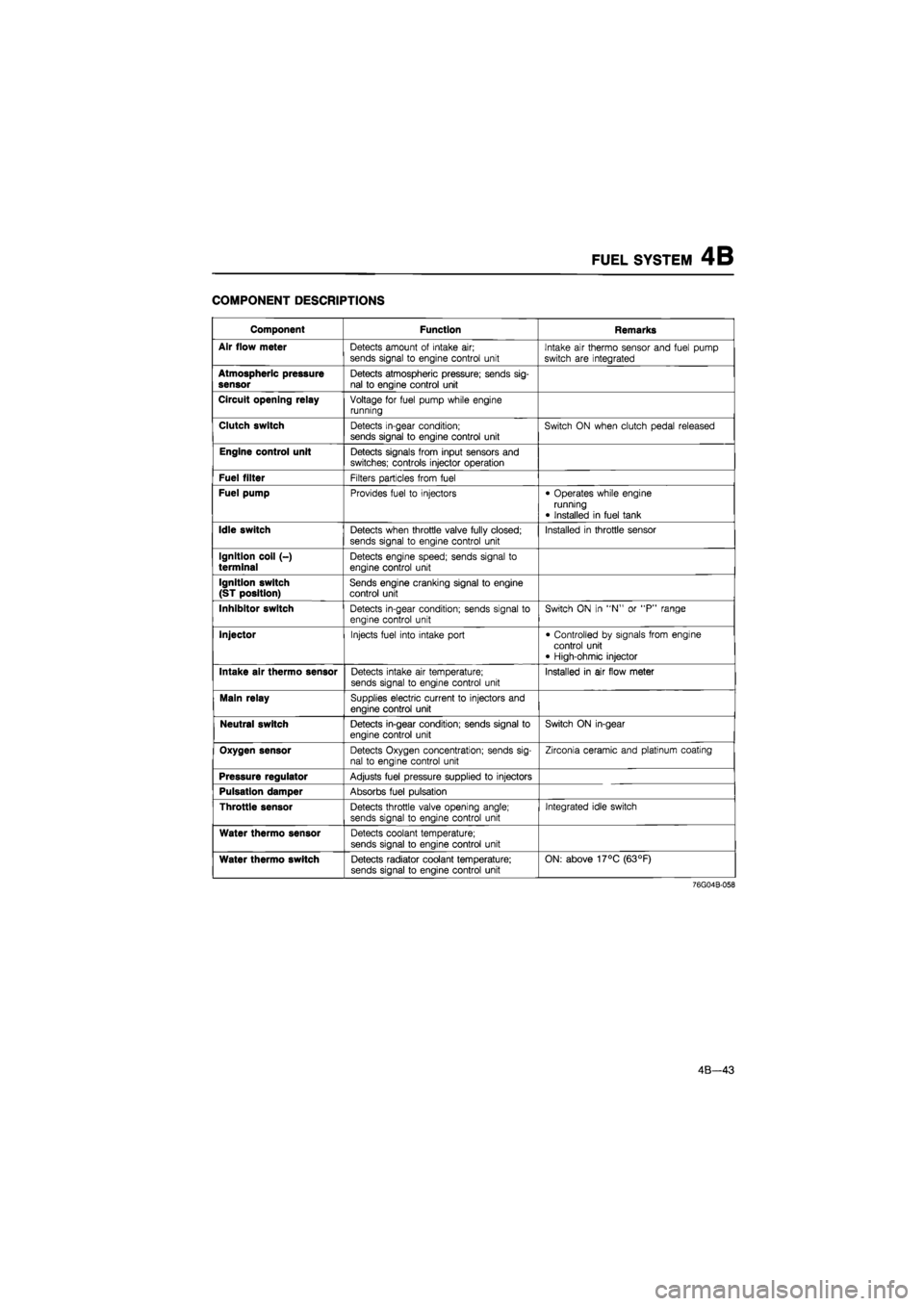

FUEL SYSTEM 4B

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter

Detects amount

of

intake

air;

sends signal

to

engine control unit Intake

air

thermo sensor and fuel pump

switch

are

integrated

Atmospheric pressure sensor

Detects atmospheric pressure; sends sig-nal

to

engine control unit

Circuit opening relay

Voltage

for

fuel pump while engine running

Clutch switch

Detects in-gear condition; sends signal

to

engine control unit Switch

ON

when clutch pedal released

Engine control unit

Detects signals from input sensors and switches; controls injector operation

Fuel filter

Filters particles from fuel

Fuel pump

Provides fuel

to

injectors • Operates while engine running

• Installed

in

fuel tank

Idle switch

Detects when throttle valve fully closed;

sends signal

to

engine control unit

Installed

in

throttle sensor

Ignition coil (-) terminal

Detects engine speed; sends signal

to

engine control unit

Ignition switch (ST position)

Sends engine cranking signal

to

engine control unit

Inhibitor switch

Detects in-gear condition; sends signal

to

engine control unit

Switch

ON in "N" or "P"

range

Injector

Injects fuel into intake port • Controlled

by

signals from engine control unit • High-ohmic injector

Intake air thermo sensor

Detects intake

air

temperature;

sends signal

to

engine control unit Installed

in air

flow meter

Main relay

Supplies electric current

to

injectors and engine control unit

Neutral switch

Detects in-gear condition; sends signal

to

engine control unit

Switch

ON

in-gear

Oxygen sensor

Detects Oxygen concentration; sends sig-nal

to

engine control unit

Zirconia ceramic and platinum coating

Pressure regulator

Adjusts fuel pressure supplied

to

injectors

Pulsation damper

Absorbs fuel pulsation

Throttle sensor

Detects throttle valve opening angle; sends signal

to

engine control unit

Integrated idle switch

Water thermo sensor

Detects coolant temperature;

sends signal

to

engine control unit

Water thermo switch

Detects radiator coolant temperature; sends signal

to

engine control unit ON: above 17°C (63°F)

76G04B-058

4B—43

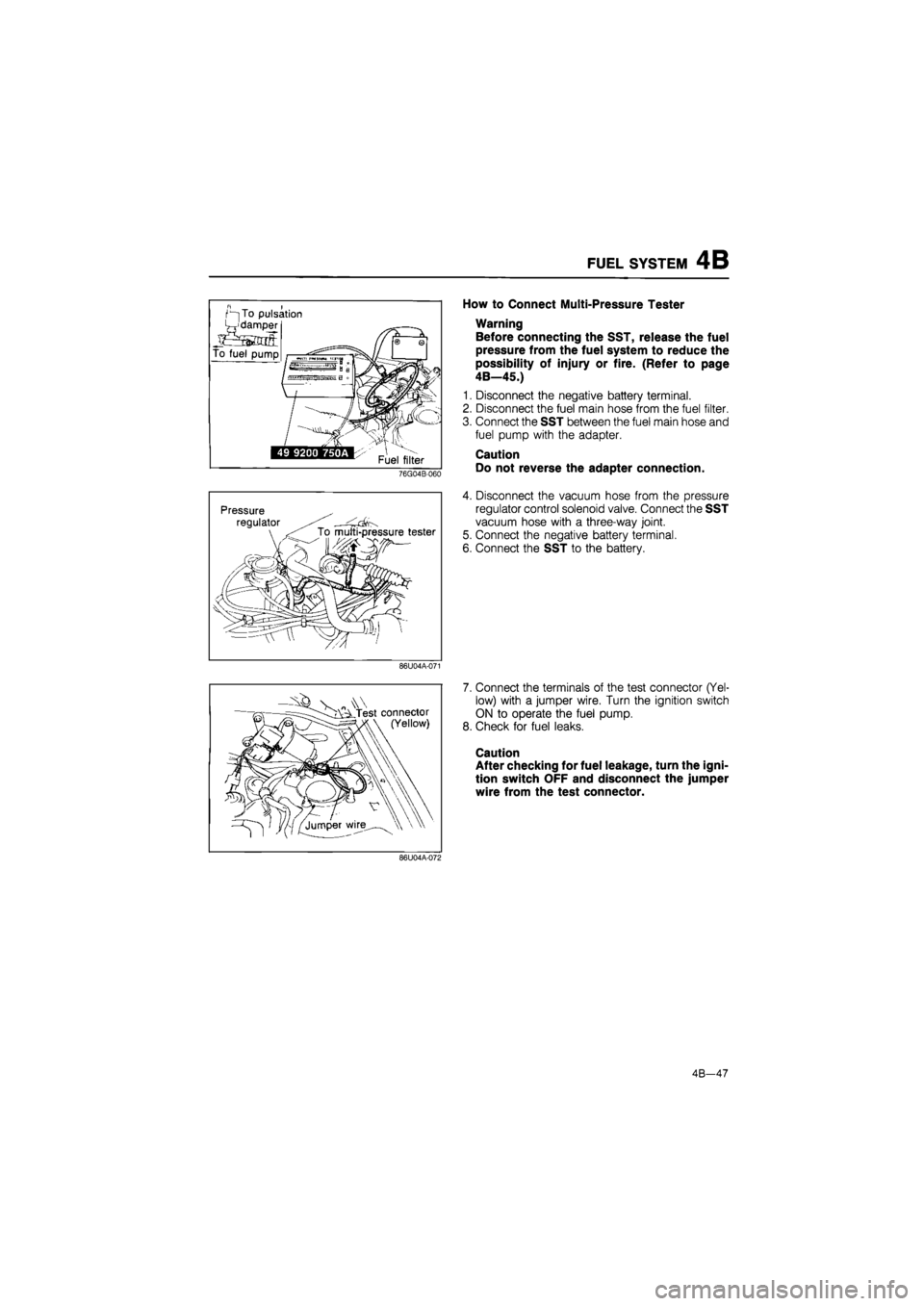

Page 509 of 1865

FUEL SYSTEM 4B

Pressure .

regulator ^^ \ To multi-pressure tester

How to Connect Multi-Pressure Tester

Warning

Before connecting the SST, release the fuel

pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page

4B—45.)

1. Disconnect the negative battery terminal.

2. Disconnect the fuel main hose from the fuel filter.

3. Connect the SST between the fuel main hose and

fuel pump with the adapter.

Caution

Do not reverse the adapter connection.

4. Disconnect the vacuum hose from the pressure

regulator control solenoid valve. Connect the SST

vacuum hose with a three-way joint.

5. Connect the negative battery terminal.

6. Connect the SST to the battery.

86U04A-071

v *

- i\zLTest connector (Yellow)

7. Connect the terminals of the test connector (Yel-

low) with a jumper wire. Turn the ignition switch

ON to operate the fuel pump.

8. Check for fuel leaks.

Caution

After checking for fuel leakage, turn the igni-

tion switch OFF and disconnect the jumper

wire from the test connector.

86U04A-072

4B—47

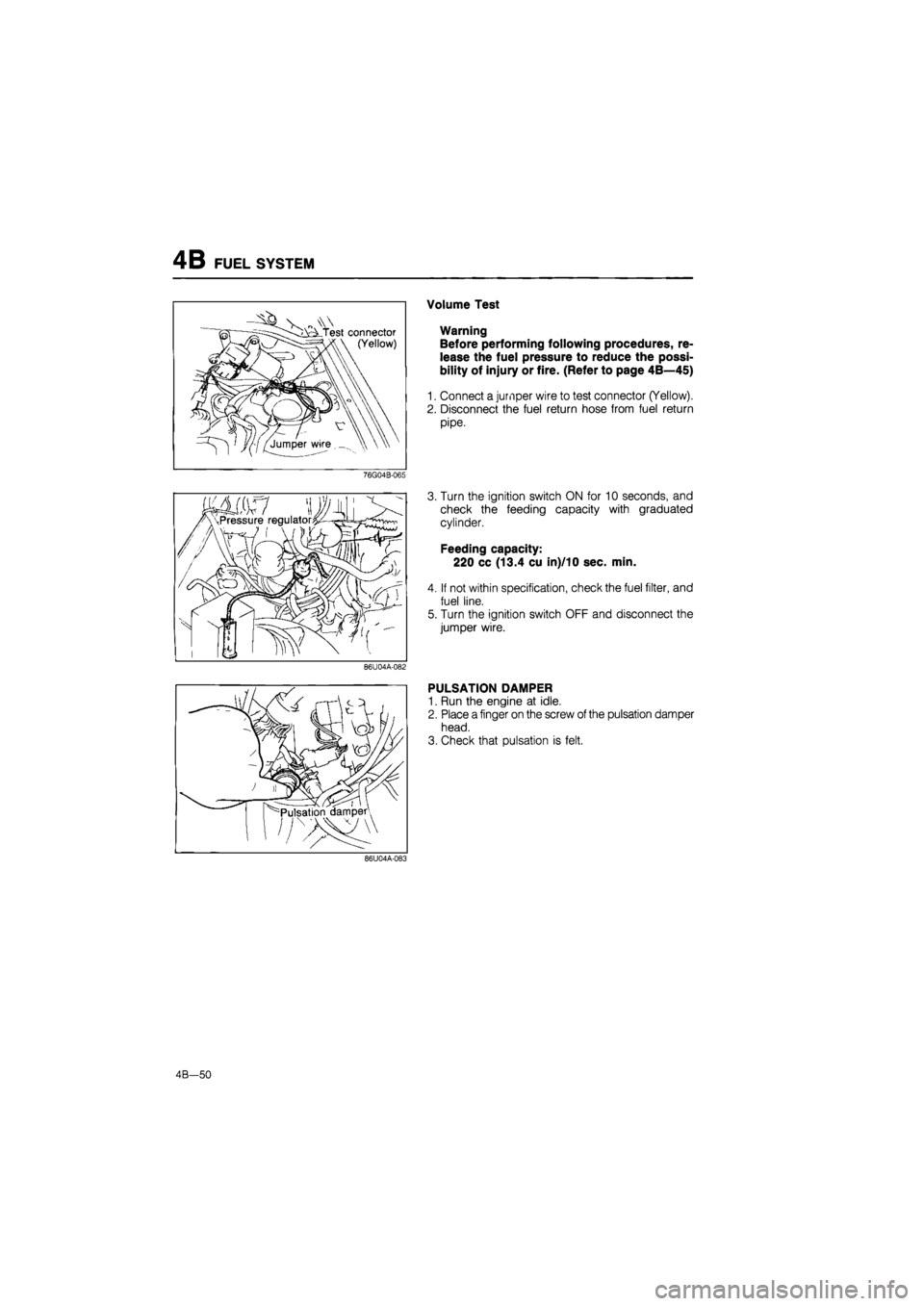

Page 512 of 1865

4B FUEL SYSTEM

Volume Test

Warning

Before performing following procedures, re-

lease the fuel pressure to reduce the possi-

bility of injury or fire. (Refer to page 4B—45)

1. Connect a jumper wire to test connector (Yellow).

2. Disconnect the fuel return hose from fuel return

pipe.

76G04B-065

3. Turn the ignition switch ON for 10 seconds, and

check the feeding capacity with graduated

cylinder.

Feeding capacity:

220 cc (13.4 cu in)/10 sec. min.

4. If not within specification, check the fuel filter, and

fuel line.

5. Turn the ignition switch OFF and disconnect the

jumper wire.

86U04A-082

PULSATION DAMPER

1. Run the engine at idle.

2. Place a finger on the screw of the pulsation damper

head.

3. Check that pulsation is felt.

86U04A-083

4B—50

Page 518 of 1865

4B FUEL SYSTEM

Operating time Fuel line pressure kPa

(kg/cm2, psi)

After starting: for 120

sec.

235-275

(2.4—2.8, 34—40)

After 120 sec, 186-226 (1.9-2.3, 27-33)

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04B-127

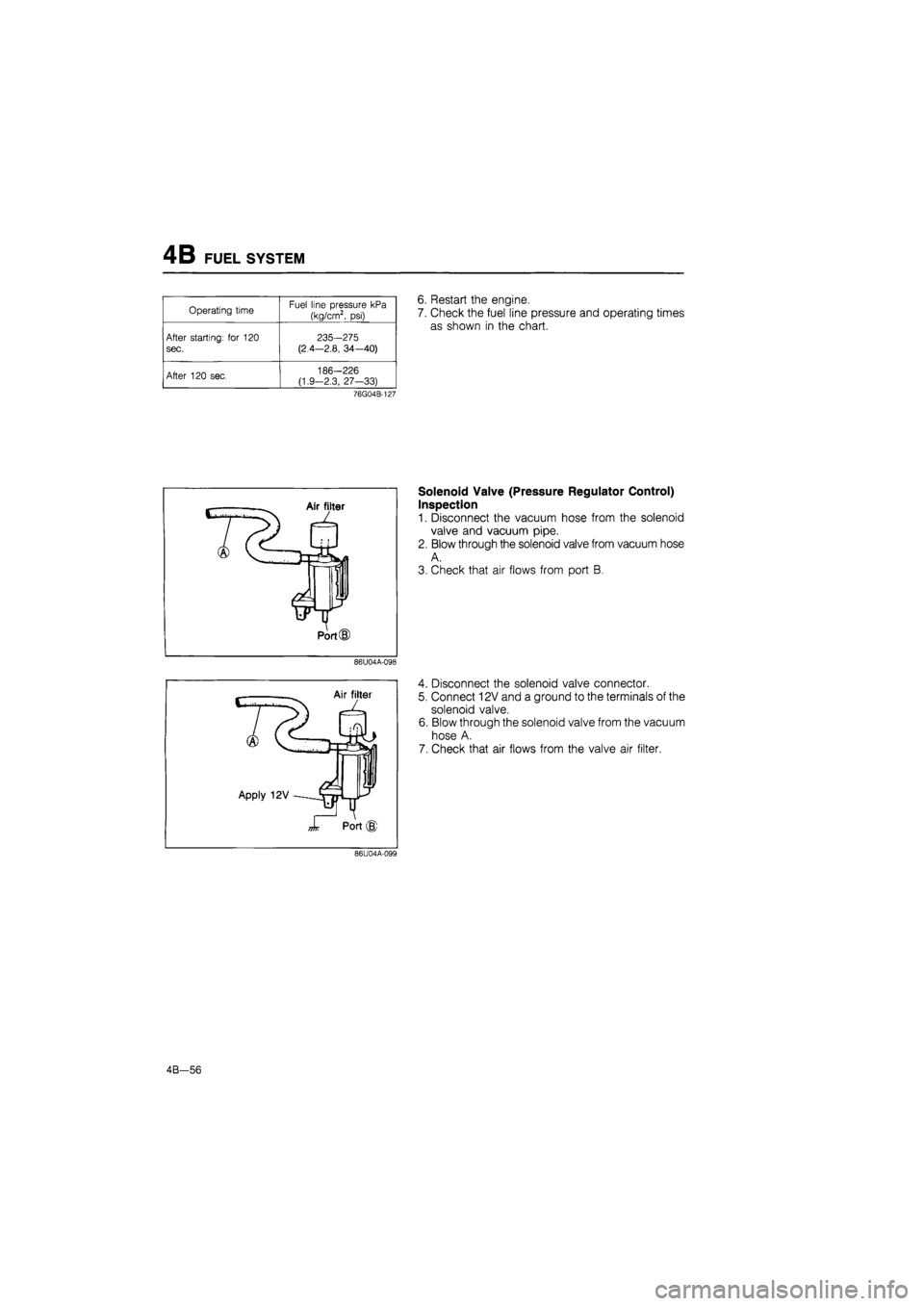

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-098

Air filter

Apply 12V

Port (J)

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from the vacuum

hose A.

7. Check that air flows from the valve air filter.

86U04A-099

4B-56

Page 519 of 1865

FUEL SYSTEM 4B

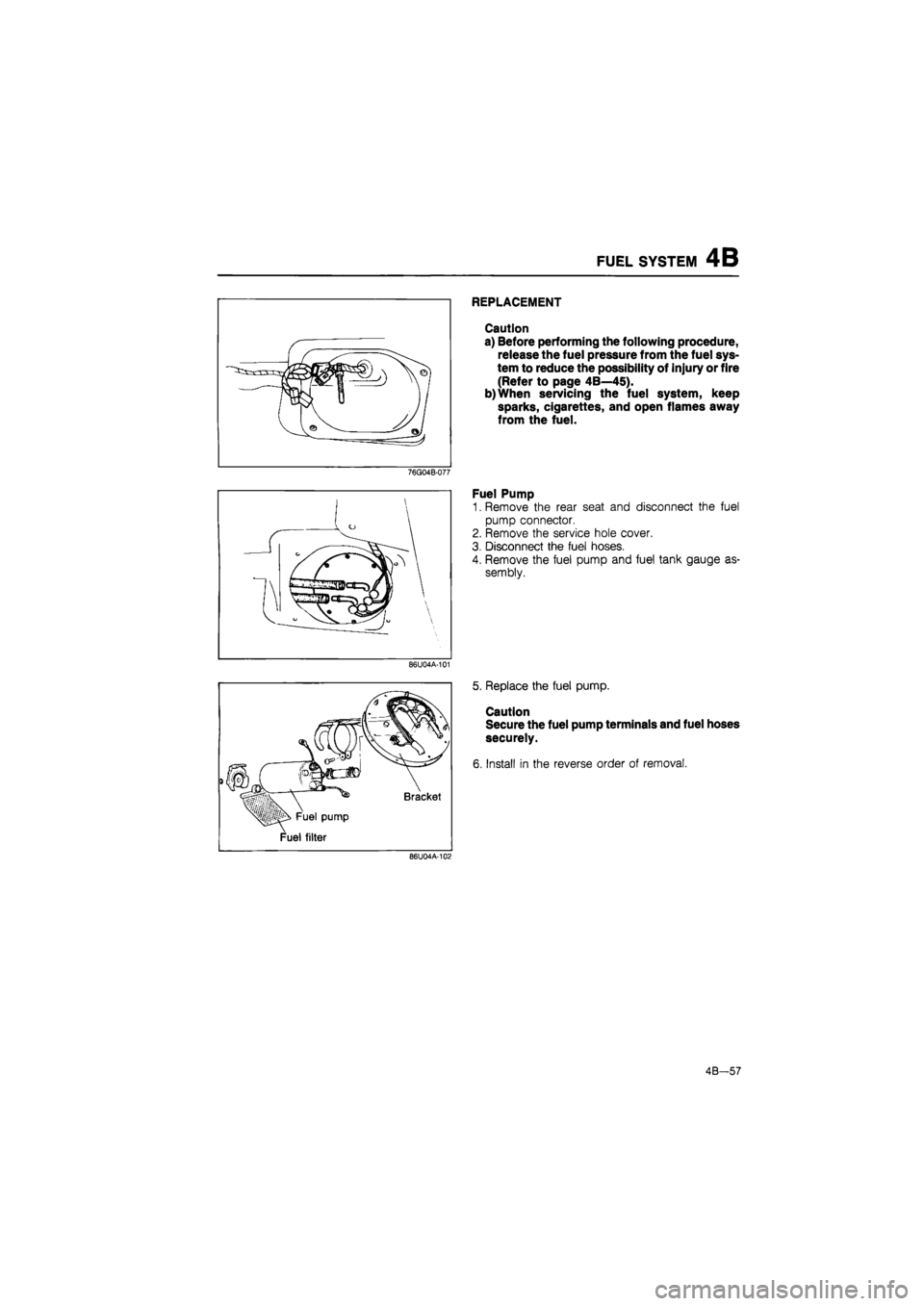

REPLACEMENT

Caution

a) Before performing the following procedure,

release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire

(Refer to page 4B—45).

b)When servicing the fuel system, keep

sparks, cigarettes, and open flames away

from the fuel.

76G04B-077

86U04A-101

M Fuel pump

Fuel filter

Bracket

86U04A-102

Fuel Pump

1. Remove the rear seat and disconnect the fuel

pump connector.

2. Remove the service hole cover.

3. Disconnect the fuel hoses.

4. Remove the fuel pump and fuel tank gauge as-

sembly.

5. Replace the fuel pump.

Caution

Secure the fuel pump terminals and fuel hoses

securely.

6. Install in the reverse order of removal.

4B—57

Page 522 of 1865

4B FUEL SYSTEM

Pressure Regulator

1. Disconnect the vacuum hose and fuel return hose.

2. Remove the pressure regulator.

3. Install in the reverse order of removal.

Tightening torque:

8—11 N-m (0.8—1.1 m-kg, 69—95 in-lb)

76G04B-084

Pulsation Damper

1. Loosen the pulsation damper and remove it.

2. Install in the reverse order of removal.

76G04B-085

^-Fuel hose

ML*? ^-Fuel pump

^silntank filter

ti* e

76G04B-086

h

tS

Is o

Sjfbj

Fuel Filter

Low pressure side

Refer to page 4B—57.

86U04A-116

High pressure side

The fuel filter must be replaced at the intervals out-

lined in the maintenance schedule.

Warning

Always work away from sparks or open

flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and the bracket.

3. Install a new filter and the bracket.

4. Connect the fuel hoses.

Note

When installing the filter, push the fuel hoses

fully onto the fuel filter and secure the hoses

with spring clamps.

4B-60