stop start MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 896 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 5 (TIME LAG TEST)

If the selector lever is shifted while the engine is idling, there will be a certain time lapse, or time lag,

before shock is felt. This step checks this time lag for checking condition of the 1-2, N-R, and N-D

accumulators, forward, and one-way clutches, 2-4 brake band, and low and reverse brake.

Preparation

76G07B-030

Procedure

1. Start the engine and check the idle speed in P range.

Idle speed: 900 ±58 rpm

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt, with a stop watch.

4. Shift the selector to N range and run the engine at idle speed for at least one minute.

5. Perform the test for the following shifts in the same manner.

(1) N D range (Hold mode)

(2) N -» R range

Note

Make three measurements for each test and take the average value.

Specified time lag: N -> D range

N -»• R range

Evaluation

Condition Possible Cause

N D (Economy) shifting

More than specification

Insufficient line pressure Forward clutch slipping One-way clutch 1 slipping One-way clutch 2 slipping N D (Economy) shifting

Less than specification N-D accumulator not operating properly

Excessive line pressure

N-D (Hold) shifting

More than specification

Insufficient line pressure Forward clutch slipping 2-4 brake band slipping One-way clutch 1 slipping N-D (Hold) shifting

Less than specification 1-2 accumulator not operating properly

Excessive line pressure

N R shifting

More than specification

Insufficient line pressure Low and reverse brake slipping Revese clutch slipping N R shifting

Less than specification N-R accumulator not operating properly

Excessive line pressure

86U07B-038

0.5—1.0 second

0.5—1.0 second

7B-30

Page 918 of 1865

7B TROUBLESHOOTING (G4A-HL)

STEP 4 (TIME LAG TEST)

If the selector lever is shifted while the engine is idling, there will be a certain time lapse, or time lag,

before shock is felt. This step checks this time lag for checking the condition of the N-D and N-R ac-

cumulators, forward, reverse and one-way clutches, and low and reverse brake.

Preparation

Perform the preparation procedure shown in the STEP 3 (STALL TEST).

Procedure

1. Start the engine and check that the idle speed is 900 l5o rpm.

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt using a stop watch.

4. Shift the selector to N range and run the engine at idle speed for at least one minute.

5. Perform the test for the shift from N range to R range in the same manner.

Note

Make three measurements for each test and take the average value.

Specified time lag: N -> D range 0.4—1.2 second

N -> R range 0.4—1.5 second

Evaluation

Condition Possible Cause

N D shift

More than specification

Insufficient line pressure

N D shift

More than specification Forward clutch slipping

N D shift

More than specification One-way clutch 1 slipping N D shift

More than specification

One-way clutch 2 slipping N D shift

Less than specification N-D accumulator not operating properly

N D shift

Less than specification Excessive line pressure

N-R shift

More than specification

Insufficient line pressure

N-R shift

More than specification Low & reverse brake slipping

N-R shift

More than specification

Reverse clutch slipping N-R shift

Less than specification N-R accumulator not operating properly

N-R shift

Less than specification Excessive line pressure

76G07B-056

7B-52

Page 1131 of 1865

TROUBLESHOOTING 7C

STEP 3 (TIME LAG TEST)

When the selector lever is shifted while the engine is idling, there is a certain time lapse, or time lag,

before shock is felt. This time lag test checks the condition of the front, rear, and one-way clutch, low

and reverse brake, and orifice check valve.

Preparation

Follow the test preparation procedure shown in STEP 2 (STALL TEST).

Procedure

1. Start the engine and verify that the idle speed is 950tso rpm.

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt with a stop watch.

4. Shift the selector to N range and run the engine at idle for one minute or more.

5. Perform the test for N range to R range in the same manner.

Note

Make three measurements for each test and take the average value.

Specified time lag: N D range 0.5—1.0 second

N R range 0.5—1.0 second

Evaluation

Condition Possible Cause

N -» D shift More than specification

Insufficient line pressure

N -» D shift More than specification Rear clutch slipping N -» D shift More than specification

One-way clutch slipping N -» D shift

Less than specification N-D accumulator not operating properly

N-R shift

More than specification

Insufficient line pressure

N-R shift

More than specification Low and reverse brake slipping

N-R shift

More than specification

Front clutch slipping N-R shift

Less than specification Stuck orifice check valve

N-R shift

Less than specification Excessive line pressure

76G07C-027

7C-17

Page 1320 of 1865

1 0 4-WHEEL STEERING GEAR AND LINKAGE

86U10X-301

86U10X-302

86U10X-303

4WS PERFORMANCE INSPECTION

1. Steering Angle Transfer Shaft Alignement

(Simple inspection)

(1) Put masking tape on the steering wheel and

column cover.

(2) Drive the vehicle on a straight, flat road for at

least 30 m (18.6 ft) and note the steering wheel

position. Stop and mark the straight-ahead po-

sition on the steering wheel and column cover

tape. Drive the vehicle again and check the

marks.

(3) With the marks between the steering wheel and

column cover aligned, check that the rear

wheels do not turn off center when the engine

is started.

(4) If the rear wheels move, adjust the steering an-

gle transfer shaft.

(Inspection by dial indicator)

(1) Mark between the steering wheel and column

cover as shown above.

(2) Attach a scale on the column cover as shown

in the illustration.

86U10X-304

10-32

Page 1419 of 1865

POWER BRAKE UNIT 1 1

86U11X-038

0

o

X

\ V^ Third

Second

^ First

86U11X-039

O X

fiSy

V

86U11X-040

Pedal-depression Pre!tur!9au9e

force gauge

^Intake manifold

86U11X-041

POWER BRAKE UNIT

FUNCTION CHECK

Simple Method

First step

1. With the engine stopped, depress the pedal a few

times.

2. With the pedal depressed, start the engine

3. If immediately after the engine starts the pedal

moves down slightly, the unit is operating.

Second step

1. Start the engine.

2. Stop the engine after it has run for

1

or 2 minutes.

3. Depress the pedal with the usual force.

4.

If

the first pedal stroke is long and becomes short-

er with subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the

check valve or vacuum hose, and examine the in-

stallation condition. Repair if necessary, and inspect

it once again.

Third step

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal still depressed.

4. Hold the pedal down for about 30 seconds.

5. If the pedal height does not change, the unit is

operating.

6. If there is a problem, check for damage to the

check valve or vacuum hose, and check the con-

nection. Repair if necessary, and check once

again.

If the nature of the problem is still not clear after fol-

lowing the 3 steps above, follow the more detailed

check described in "Method using tester".

Method Using Tester

Connect a pressure gauge, vacuum gauge, and ped-

al depression force gauge as shown in the figure. Af-

ter bleeding the air from the pressure gauge, conduct

the test as described in the 3 steps below.

Note

Use commercially available gauges and ped-

al depression force gauge.

11—27

Page 1420 of 1865

1 1 POWER BRAKE UNIT

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading

reaches 500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X-065

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a force of 196 N (20

kg, 44 lb).

3. With the brake pedal depressed, stop the engine

when the vacuum gauge reading reaches 500

mmHg (19.7 inHg).

4. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X066

b) Checking for hydraulic pressure

1. If with the engine stopped (when vacuum is 0

mmHg) the relation between pedal force and fluid

pressure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) | 1,177 kPa (12 kg/cm2, 171 psi) mia

76G11X-067

2. Start the engine. Depress the brake pedal when

the vacuum reaches 500 mmHg (19.7 inHg).

If the relation between pedal force and fluid pres-

sure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 7,063 kPa (72 kg/cm2, 1,024 psi) min.

76G11X068

11-28

Page 1457 of 1865

PARKING BRAKE 1 1

86U11X-130

86U11X-131

PARKING BRAKE

ON-VEHICLE MAINTENANCE

Parking Brake Lever Stroke

Inspection

Check that the stroke is within specification when the

parking brake lever is pulled with a force of 98N

(10kg, 22lb).

Stroke: 5—7 notches

Adjustment

1. Before adjustment, start the engine and depress

the brake pedal several times.

2. Stop the engine.

3. Remove the adjust nut clip and turn the adjust nut

at the front of the parking cable.

4. After adjustment, check the following points:

(1) Turn the ignition switch ON, pull the parking

brake lever one notch, and check that the park-

ing brake warning lamp illuminates.

(2) Check that the rear brakes do not drag.

11—65

Page 1551 of 1865

13 REAR WHEEL ALIGNMENT

2. Measure the camber angle with the caster/cam-

ber gauge.

Camber: -0°30' ± 45' (2WS)

0°00' ± 45' (4WS)

86U13X-123

Front

EAR TURNING ANGLE (4WS)

Place the rear wheels on a turning radius gauge.

Jack up the front of the vehicle.

Start the engine and let it idle.

Caution

If the engine is stopped while the steering

wheel is left turned to one side or the other,

the rear wheels will return to the straight-

ahead direction, and, when the engine is later

started once again, the direction of the rear

wheels will change. Be sure, therefore, to

check to be sure that the wheels are not

touching, or close to, anyone's hands or feet,

or any other object, when the engine is

stopped or started.

Turn the steering wheel fully left and right, and

measure the rear turning angle.

Rear turning angle Inner 5°00' ± 45'

Outer 5°00' ± 45'

If not within specification, adjust the rear turning

angle. (Refer to Section 10)

86U13X-125

13—54

Page 1695 of 1865

15 WARNING AND SENDER

86U15X-068

86U15X069

86U15X-070

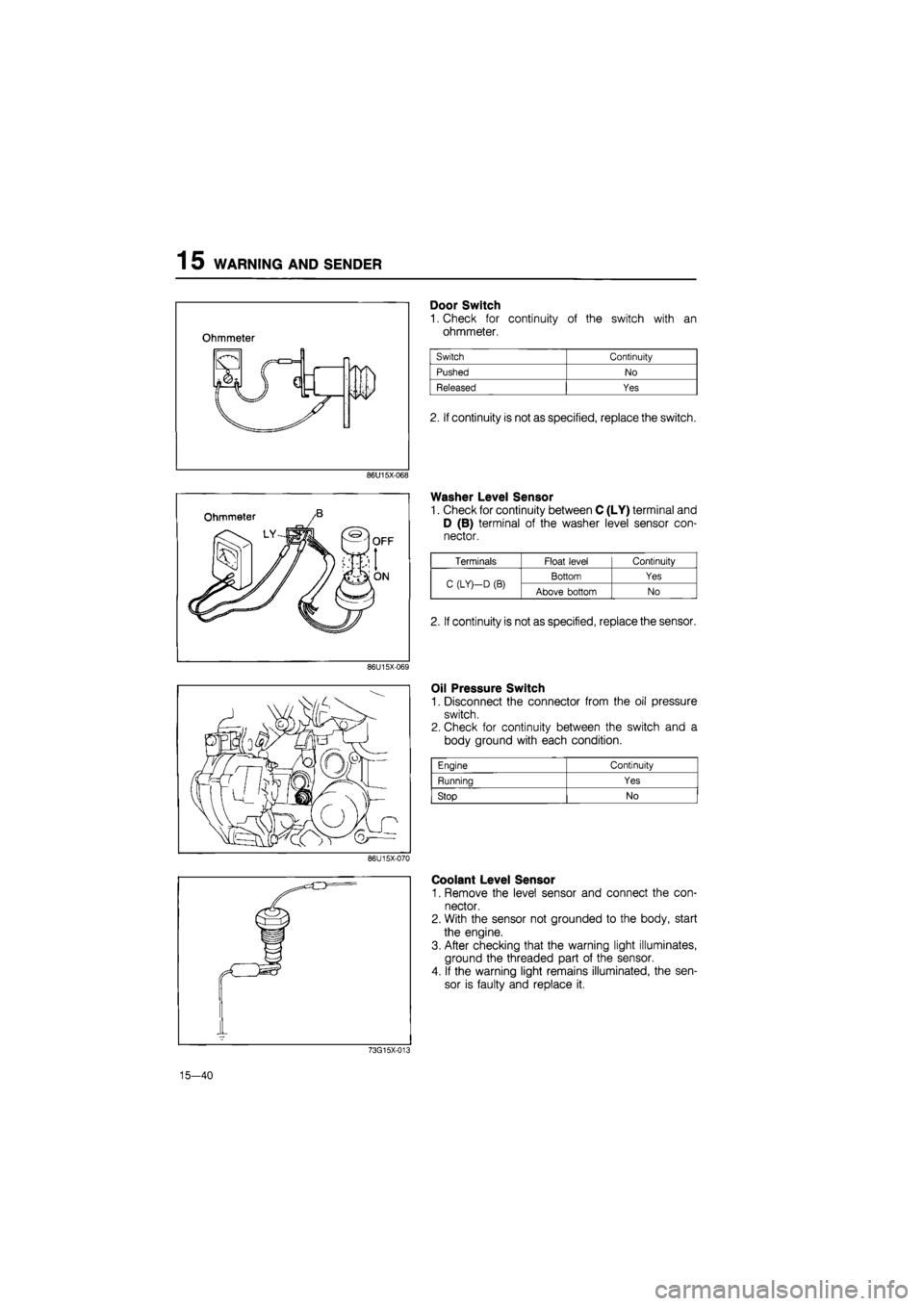

Door Switch

1. Check for continuity of the switch with an

ohmmeter.

2. If continuity is not as specified, replace the switch.

Washer Level Sensor

1. Check for continuity between C (LY) terminal and

D (B) terminal of the washer level sensor con-

nector.

Oil Pressure Switch

1. Disconnect the connector from the oil pressure

switch.

2. Check for continuity between the switch and a

body ground with each condition.

Coolant Level Sensor

1. Remove the level sensor and connect the con-

nector.

2. With the sensor not grounded to the body, start

the engine.

3. After checking that the warning light illuminates,

ground the threaded part of the sensor.

4. If the warning light remains illuminated, the sen-

sor is faulty and replace it.

73G15X-013

15—40

Engine Continuity

Running Yes

Stop No

Terminals Float level Continuity

C (LY)—D

(B)

Bottom Yes C (LY)—D

(B)

Above bottom No

2. If continuity is not as specified, replace the sensor.

Page 1730 of 1865

REAR WINDOW WIPER 1 5

86U15X-132

INSPECTION

Operation Check of Rear Wiper Motor

1. Check that the motor operates continuously when

12V is connected to the (a) terminal and ground

is connected to the (b) terminal of the motor.

2. Start the motor again.

Disconnect the ground from the (b) terminal, and

then connect the ground to the motor body im-

mediately. Check that the motor shaft reaches the

auto-stop position, and that there is conductivity

through the grounding of the motor body.

Note:

Be sure to re-install the rubber seal correctly.

Operation Check of Rear Washer Motor

1. Using a voltmeter, measure the voltage between

the (b) terminal and a body ground with the igni-

tion switch ON.

2. If no voltage, check the fuse or repair the harness.

3. If the (b) terminal voltage is 12 V, connect the (a)

terminal to a body ground.

4. If the washer motor does not operate, replace the

washer motor.

76G15X-094

15-75