wiring MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 517 of 1865

FUEL SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connections before checking the sensors or switches

below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible \ cause

\ Page

Solenoid valve (Pres-sure regula-tor control)

Water thermo

sensor Intake air

thermo sensor

Engine con-trol unit terminal

2K

System inspection

Symptom 4B—56 4B—97 4B—94 4B—89 4B—55

Engine stalls or rough after hot starting 2 3

A

5 1

76G04B-074

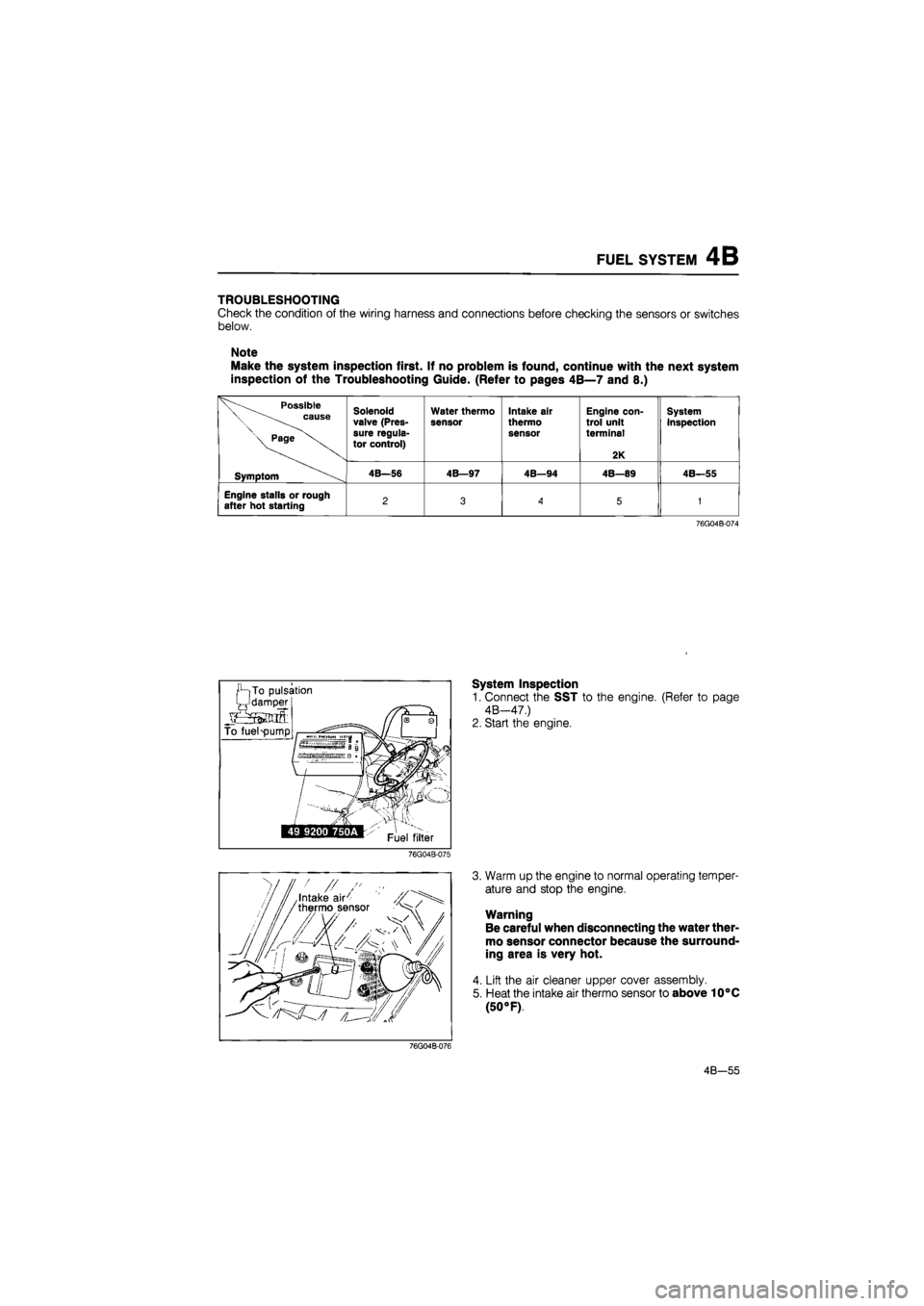

System Inspection

1. Connect the SST to the engine. (Refer to page

4B—47.)

2. Start the engine.

76G04B-075

3. Warm up the engine to normal operating temper-

ature and stop the engine.

Warning

Be careful when disconnecting the water ther-

mo sensor connector because the surround-

ing area is very hot.

4. Lift the air cleaner upper cover assembly.

5. Heat the intake air thermo sensor to above 10°C

(50 °F).

76G04B-076

4B—55

Page 528 of 1865

4B DECELERATION CONTROL SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to page 4B—7 and 8.)

Possible

^^ cause

Symptom

Dashpot Water thermo

sensor

Electrical signal

inspection

(Injector)

Possible

^^ cause

Symptom 4B—67 4B—97 4B-66

High idle speed after warming up 1

Runs rough on deceleration 1 3 2

Afterburn in exhaust system 1 3 2

Poor fuel consumption 1 3 2

Fails emission test 1 3 2

76G04B-090

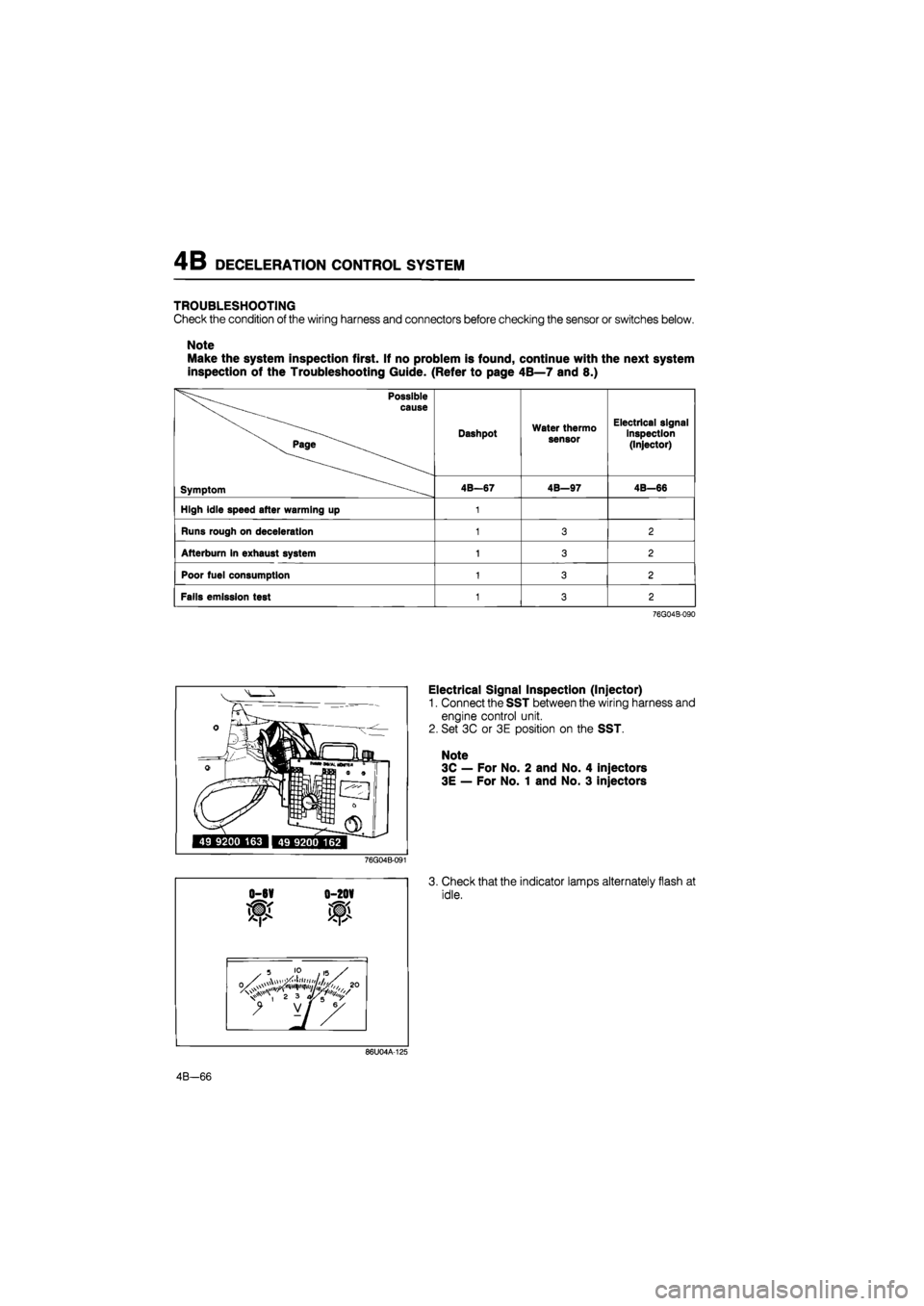

Electrical Signal Inspection (Injector)

1. Connect the SST between the wiring harness and

engine control unit.

2. Set 3C or 3E position on the SST.

Note

3C — For No. 2 and No. 4 injectors

3E — For No. 1 and No. 3 injectors

76G04B-091

0-6V 0-20V

3. Check that the indicator lamps alternately flash at

idle.

86U04A-125

4B—66

Page 531 of 1865

AIR INJECTION SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switch.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause Air control valve Reed valve System inspection

Page 4B—69 4B—70 4B—69

Checking order 2 3 1

76G04B-097

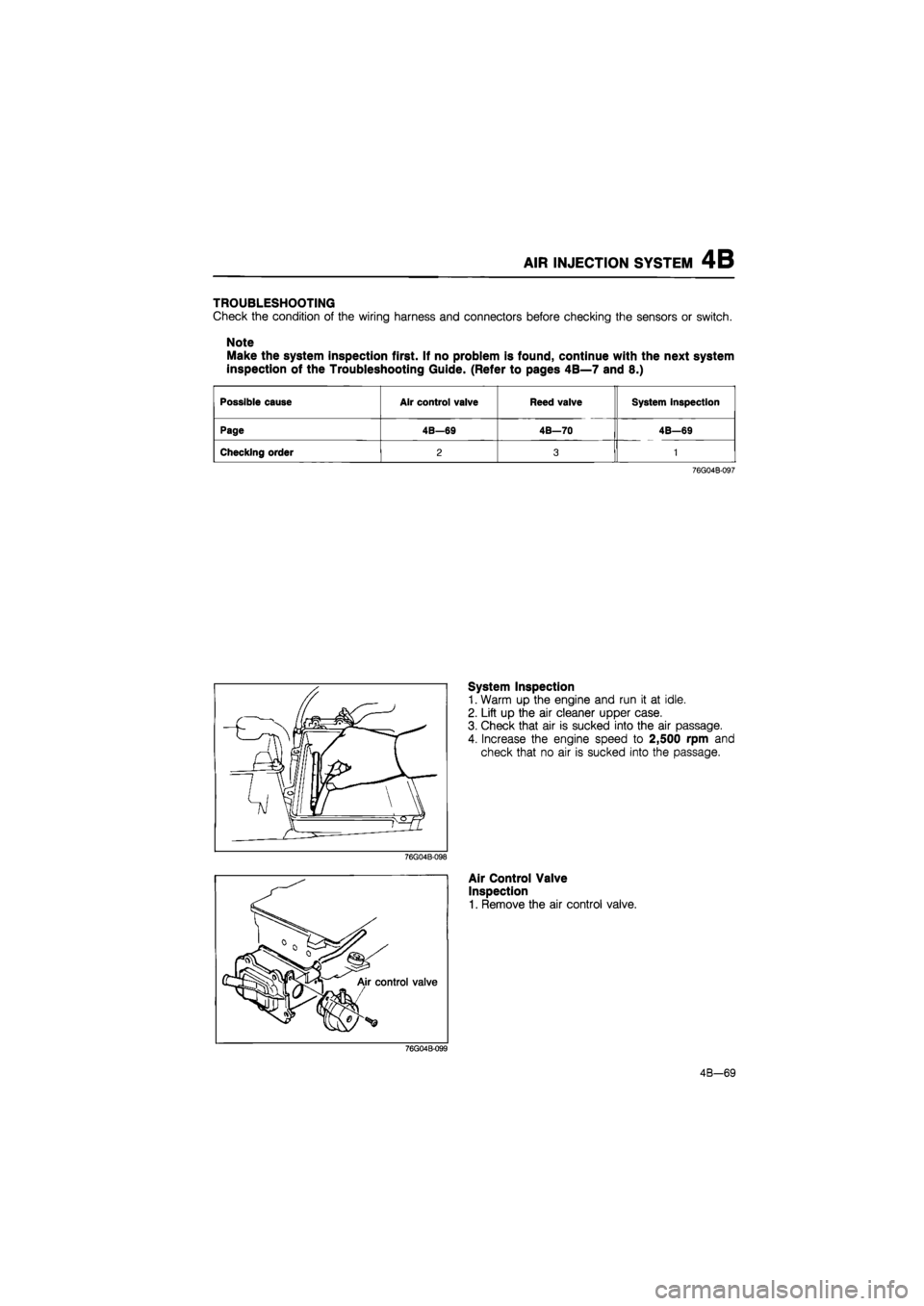

System Inspection

1. Warm up the engine and run it at idle.

2. Lift up the air cleaner upper case.

3. Check that air is sucked into the air passage.

4. Increase the engine speed to 2,500 rpm and

check that no air is sucked into the passage.

Air Control Valve

Inspection

1. Remove the air control valve.

4B-69

Page 534 of 1865

4B EGR SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause

Solenoid

valve (EGR)

EGR modula-tor valve

EGR con-trol valve

Water

thermo sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4B—72 4B—73 4B—73 4B—97 4B—97 4B—90 4B—72

Checking order 3 2 4 6 5 7 1

76G04B-103

86U04A-130

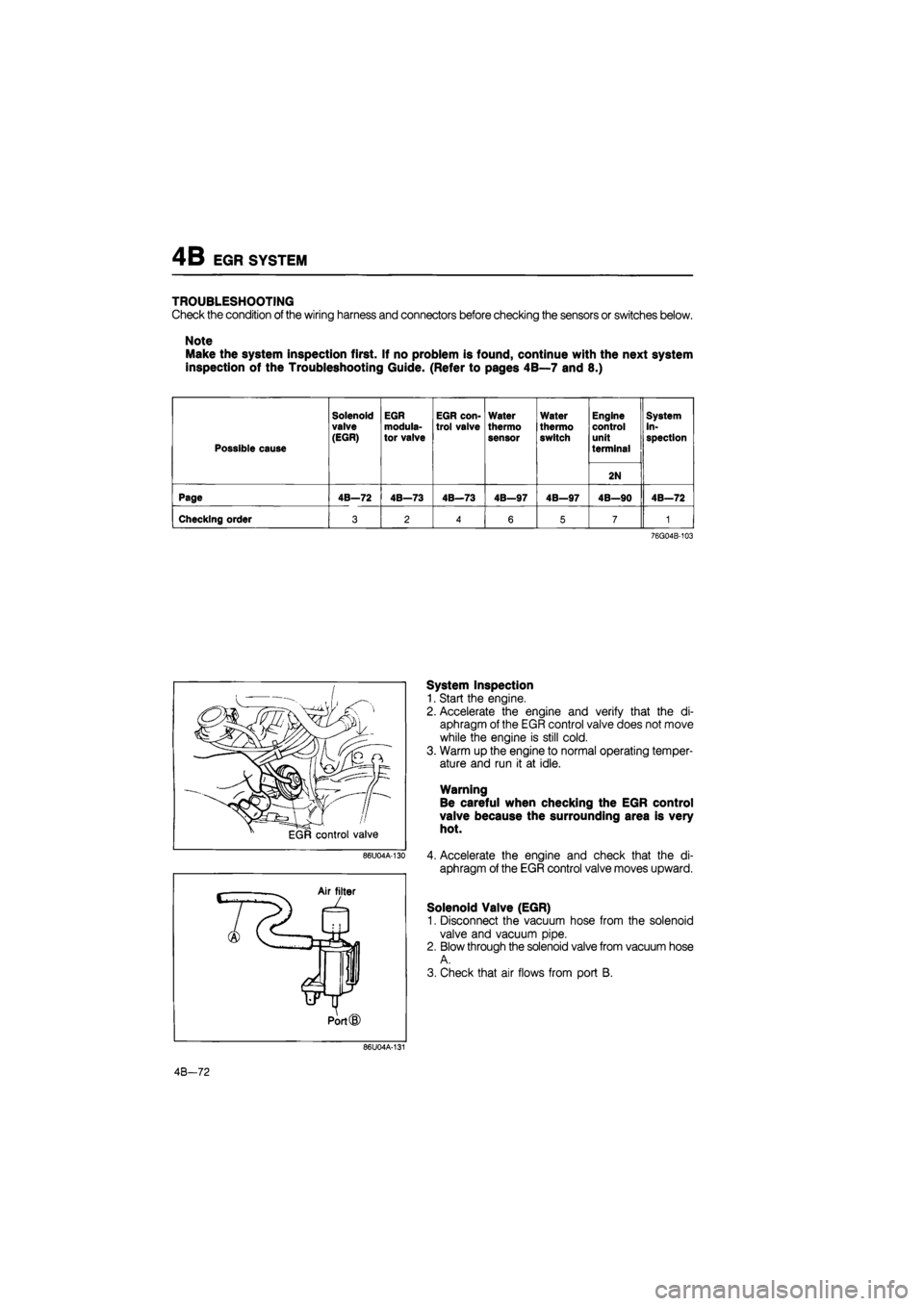

System Inspection

1. Start the engine.

2. Accelerate the engine and verify that the di-

aphragm of the EGR control valve does not move

while the engine is still cold.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve because the surrounding area is very

hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves upward.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-131

4B-72

Page 537 of 1865

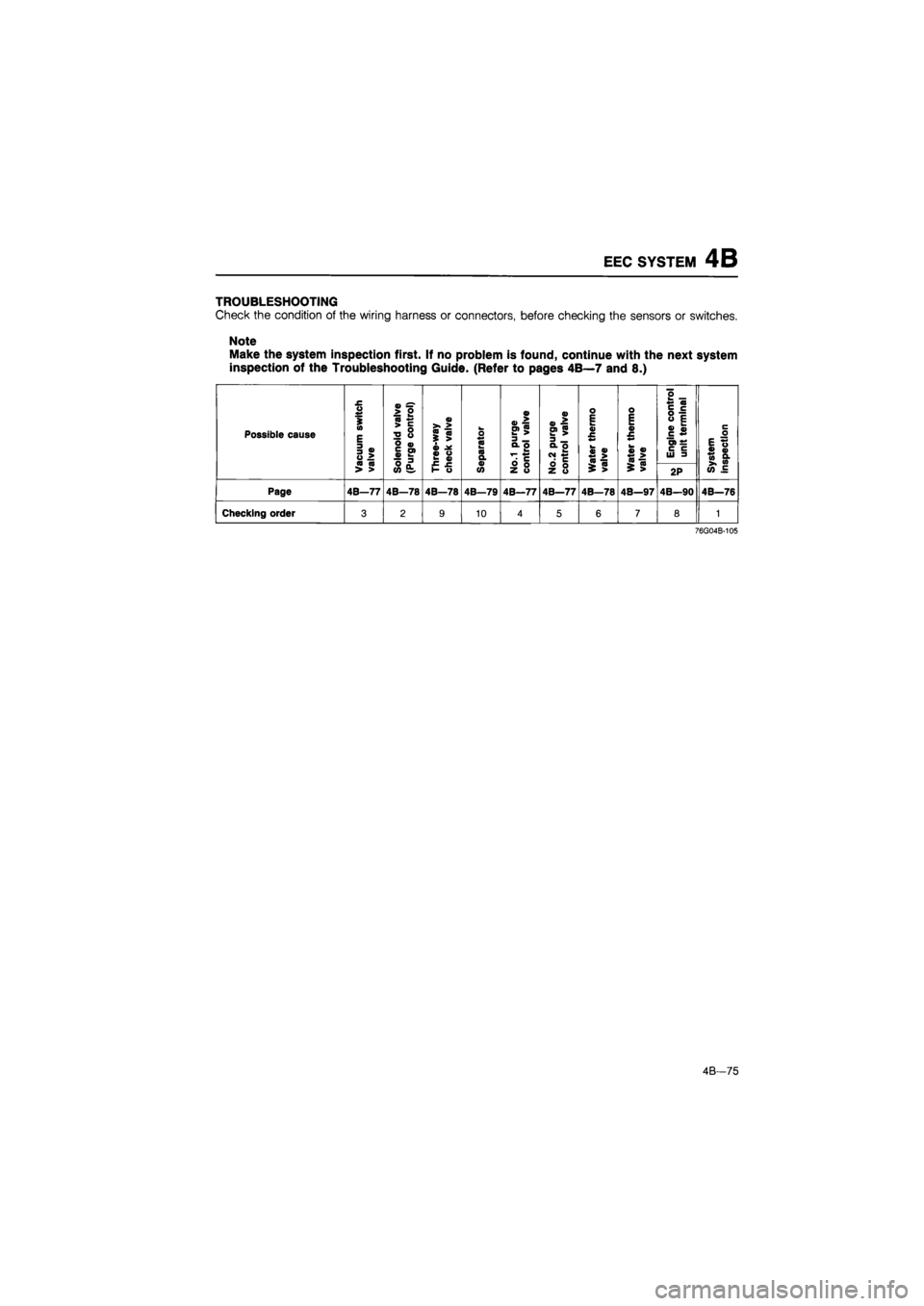

EEC SYSTEM

4B

TROUBLESHOOTING

Check

the

condition

of the

wiring harness

or

connectors, before checking

the

sensors

or

switches.

Note

Make the system inspection first.

If no

problem

is

found, continue with

the

next system

inspection

of the

Troubleshooting Guide. (Refer

to

pages 4B—7 and

8.)

Possible cause

Vacuum

switch

valve

Solenoid

valve

(Purge

control)

0)

<0

m

i

>

« «

o

•C

?

o ** «0 a a

No.1

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

o E tm 0) £

«>

0)

^

>

Engine

control

unit

terminal

System inspection Vacuum

switch

valve

Solenoid

valve

(Purge

control)

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

$

>

2P

System inspection

Page 4B—77 4B—78 4B—78 4B—79 4B—77 4B—77 4B—78 4B—97 4B—90 4B—76

Checking order 3 2 9 10 4 5 6 7 8 1

76G04B-105

4B—75

Page 549 of 1865

CONTROL SYSTEM 4B

ENGINE CONTROL UNIT

Engine Signal Monitor (49 9200 162) and Adapter (49 9200 163).

Adapter harness 49 9200 163

Engine wiring harnessN

Selector switch

Monitor switch

Engine control unit

terminal number

Terminals

(A and 8)

ENGINE SIGNAL MONITOR

86U04A-171

The Engine Signal Monitor (49 9200 162) was developed to check the control unit terminal voltages.

This monitor easily inspects the individual terminal voltages through selection of the monitor switch.

How to Use the Engine Signal Monitor

1. Connect the Engine Signal Monitor (49 9200 162) between the engine control unit and the en-

gine harness using the adapter (49 9200 163).

2. Turn the selector switch and monitor switch to select the terminal number.

3. Check the terminal voltage.

Caution

Never apply voltage to terminals A and B.

4B-87

Page 550 of 1865

4B CONTROL SYSTEM

Terminal Voltage

If the input and output devices and related wiring are normal, but the engine control unit terminal volt-

age is incorrect, replace the engine control unit.

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

1A — — — — —

1B o Self-Diagnosis Checker (Code number)

For 3sec. after ignition switch OFF ->• ON: below 6.2V (Buzzer sounds) After 3sec.: Battery voltage (Buzzer does not sound)

• Using Self-Diagnosis Check-er and test con-nector grounded • Buzzer sounds: below 6.2V • Buzzer does not sound: Battery voltage

1C — — — — —

1D o Self-Diagnosis Checker (Monitor lamp)

Test connector grounded

For 3sec. after igni-tion switch OFF ON:

below 6.2V (light il-luminates) After 3sec.: Battery voltage (light does not illuminate)

(Test connector grounded) approx. 10V (Test connector not grounded) Monitor lamp ON: below 6.2V Monitor lamp OFF: Battery voltage

With Self-Diagnosis

Checker

1E O Idle switch Accelerator pedal released: below 1.5V

Accelerator pedal depressed: Battery voltage

1F o A/C relay A/C switch ON: below 2.5V A/C switch OFF: Battery voltage

Blower motor ON

1G — — — — —

1H o Water thermo switch Below 1,5V Radiator temp.:

above 17°C (63°F)

11 o Electrical load con-trol unit Electrical load ON: below 1.5V Electrical load OFF: Battery voltage Electrical load: Rear defroster Headlight Blower motor (3rd & 4th position) Electrical fan

1J o Brake light switch Brake pedal released: below 1.5V

Brake pedal depressed: battery voltage

1K — — — — — —

1L o A/C switch A/C switch ON: below 1.5V

A/C switch OFF: battery voltage

Blower motor: ON

1M o Ignition coil © terminal Battery voltage *1 Battery voltage *1 Engine Signal Monitor: green and red lights flash

1N — — — — —

10 — — — —

4B-88

Page 573 of 1865

4C TROUBLESHOOTING WITH SST

Check connector: (Green, 6 pin)

49 H018 9A1

86U04A-011

Test connector: (Green, 1 pin)'

INSPECTION PROCEDURE

1. Connect the SST to the check connector. (Green,

6-pin) and the negative battery terminal.

2. Set the select switch to position A.

Note

The check connector is located at the rear of

the left side wheel housing.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

Note

The test connector is located near the Self-

Diagnosis Checker check connector.

86U04A-012

OO

uu

SELF-DIAGNOSIS CHECKER

MONITOR LAMP SELECT SW «

o o o

o

76G04C-012

4. Turn the ignition switch ON.

5. Verify that 88 flashes on the digital display and that

the buzzer sounds for three seconds after turn-

ing the ignition switch ON.

6. If 88 does not flash, check the control relay (refer

to page 4C—96), power supply circuit, and check

connector wiring.

7. If 88 flashes and the buzzer sounds continuously

for more than 20 seconds check the check con-

nector wiring, then replace the engine control unit

and perform steps 3 and 4 again.

8. Note the code numbers and check for the causes

by referring to the check sequences shown on

pages 4C—16 to 4C—24. Repair as necessary.

Note

Cancel the code numbers by performing the

after-repair procedure after repairing.

AFTER-REPAIR PROCEDURE

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery cable and depress the

brake pedal for at least five seconds.

76G04C-013

4C-12

Page 579 of 1865

4C TROUBLESHOOTING WITH SST

Is there continuity between air flow sensor and

engine control unit?

Air flow sensor Engine control unit

D (RB wire) 2E

E (RW wire) 2B

NO

YES

Is there 12V at terminal B of air flow sensor connector? (Refer to page 4C—103)

YES

Is there continuity between terminal F of air flow sensor and ground? (Refer to page 4C-103)

YES

NO

NO

PC: Open circuit in wiring harness

PC: Open or short circuit in wiring harness from terminal B to control relay

PC: Open circuit in wiring harness

PC: • Engine control unit malfunction • Short circuit in wiring from terminal D of air flow sensor to engine control unit

76G04C-022

Code No. 09 (Water thermo sensor)

Are there poor connections in water thermo sensor circuit?

NO

Is there continuity between water thermo sensor and engine control unit?

YES

Is resistance of the water thermo sensor OK? Resistance:

YES

Water thermo sensor Enaine control unit

A (YB wire) 21

B (LgY wire) 2C

NO

Coolant temp Resistance

-20°C ( —4°F) 14.5-17.8 kfl

20°C ( 68°F) 2.2- 2.7 kfi

40°C {104°F) 1.0- 1.3 kfi

60°C (140°F) 500-640 fi

80°C (176°F) 280-350 fi

NO

YES

Is same Code No. present after performing after-repair procedure? (Refer to page 4C—12)

YES

Are engine control unit 21 and 2C terminal voltages OK? (Refer to page 4C—98)

YES

NO

NO

PC: Possible Cause

Repair or replace connector

PC: Open circuit in wiring harness from water thermo sensor to engine control unit

Replace water thermo sensor

Water thermo sensor and circuit OK

PC: Short circuit in wiring harness

PC: Engine control unit malfunction

76G04C-023

4C—18

Page 580 of 1865

TROUBLESHOOTING WITH SST 4C

No. 11 Code (Intake air thermo sensor) PC: Possible Cause

NO

Is there continuity between intake air thermo sensor

(dynamic chamber) and engine control unit?

Intake air thermo sensor (dynamic chamber) Engine control unit

A (RC wire) 2J

B (LgY wire) 2C

YES

Is resistance of intake air thermo sensor (dynamic chamber) OK? Resistance:

NO PC: Open circuit in wiring harness

Temperature Resistance

20°C (68°F) 29.7-36.3 kQ

50°C (122°F) 8.4-10.2 kQ

85°C (185°F) 2.5-3.1 kQ

NO Replace intake air thermo sensor (dynamic chamber)

YES

76G04C-024

Code No. 12 (Throttle sensor) PC: Possible cause

Next step

4C-19