wiring MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 669 of 1865

4C CONTROL SYSTEM

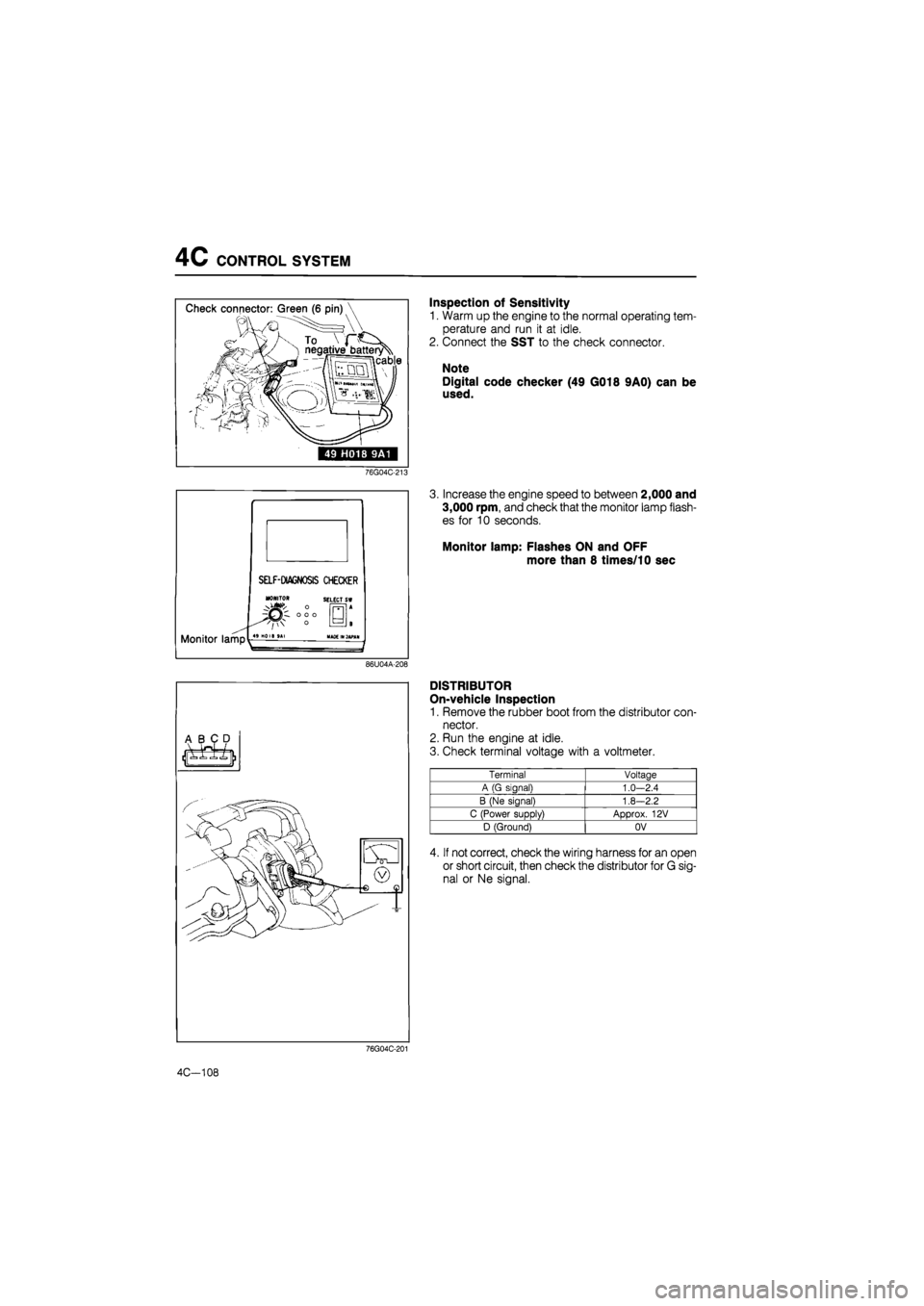

Check connector: Green (6 pin)

cable

49 H018 9A1

Inspection of Sensitivity

1. Warm up the engine to the normal operating tem-

perature and run it at idle.

2. Connect the SST to the check connector.

Note

Digital code checker (49 G018 9A0) can be

used.

76G04C-213

Increase the engine speed to between 2,000 and

3,000 rpm, and check that the monitor lamp flash-

es for 10 seconds.

Monitor lamp: Flashes ON and OFF

more than 8 times/10 sec

86U04A-208

A B C D

/llkw^ - ®

I « ^

76G04C-201

4C—108

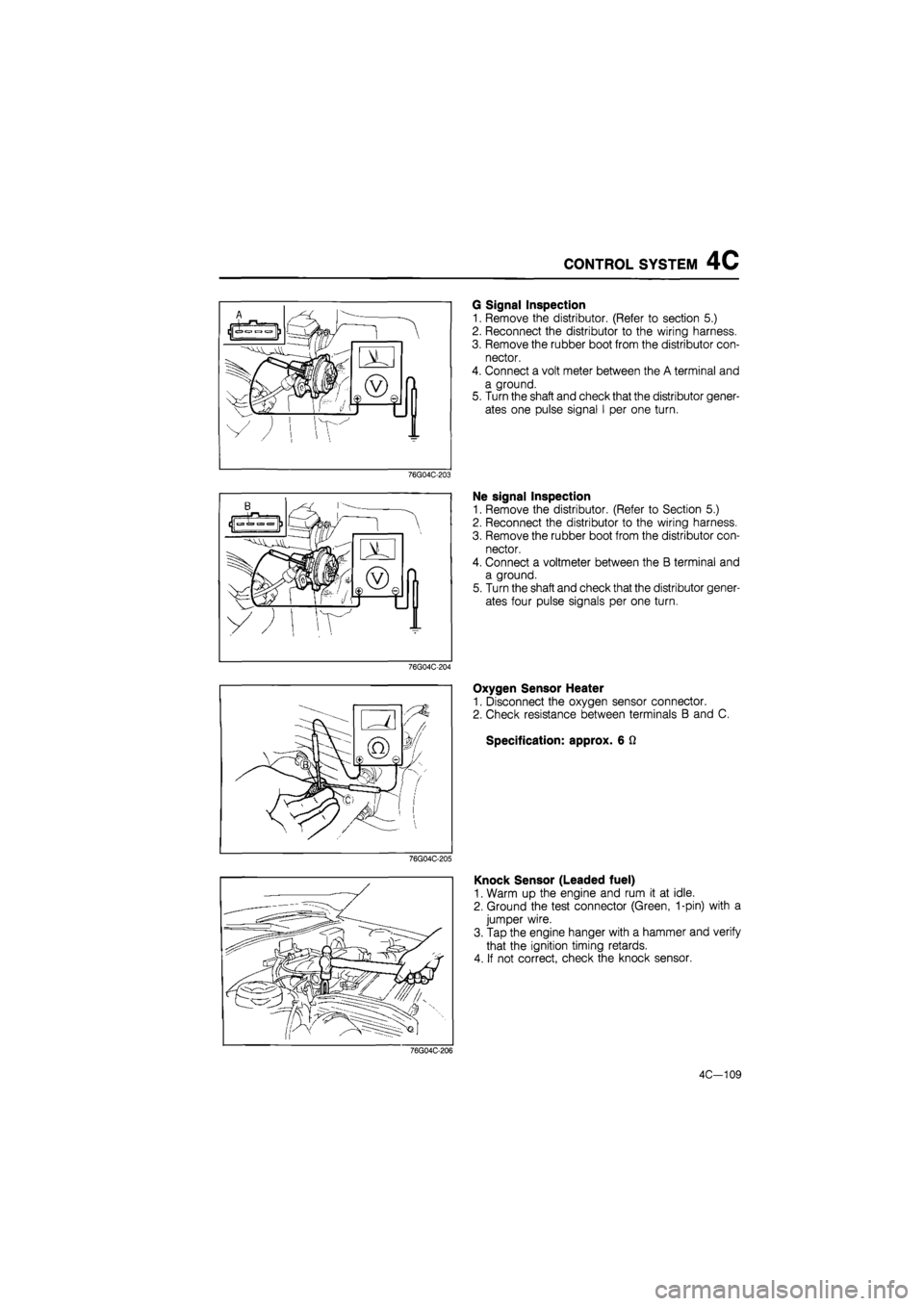

DISTRIBUTOR

On-vehicle Inspection

1. Remove the rubber boot from the distributor con-

nector.

2. Run the engine at idle.

3. Check terminal voltage with a voltmeter.

Terminal Voltaae

A (G signal) 1.0—2.4

B (Ne sianaB 1.8—2.2

C (Power supply) Approx. 12V

D (Ground) OV

4. If not correct, check the wiring harness for an open

or short circuit, then check the distributor for G sig-

nal or Ne signal.

Page 670 of 1865

CONTROL SYSTEM 4C

76G04C-203

76G04C-204

76G04C-205

G Signal Inspection

1. Remove the distributor. (Refer to section 5.)

2. Reconnect the distributor to the wiring harness.

3. Remove the rubber boot from the distributor con-

nector.

4. Connect a volt meter between the A terminal and

a ground.

5. Turn the shaft and check that the distributor gener-

ates one pulse signal I per one turn.

Ne signal Inspection

1. Remove the distributor. (Refer to Section 5.)

2. Reconnect the distributor to the wiring harness.

3. Remove the rubber boot from the distributor con-

nector.

4. Connect a voltmeter between the B terminal and

a ground.

5. Turn the shaft and check that the distributor gener-

ates four pulse signals per one turn.

Oxygen Sensor Heater

1. Disconnect the oxygen sensor connector.

2. Check resistance between terminals B and C.

Specification: approx. 6 Q

Knock Sensor (Leaded fuel)

1. Warm up the engine and rum it at idle.

2. Ground the test connector (Green, 1-pin) with a

jumper wire.

3. Tap the engine hanger with a hammer and verify

that the ignition timing retards.

4. If not correct, check the knock sensor.

76G04C-206

4C-109

Page 713 of 1865

TROUBLESHOOTING GUIDE 5

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Starter does not turn at all, or Its turning speed Is too slow to start the engine.

Battery and related parts Poor contact of battery terminals Poor grounding of negative cable Voltage drop caused by discharged battery Insufficient voltage caused by battery malfunction

Clean and tighten Clean and repair Recharge Replace

5- 8

5- 8 5- 8

Ignition switch and related parts Poor contact of ignition switch Loose ignition switch wiring or connector Broken wire between ignition switch and magnetic switch

Replace Repair Repair or replace 5-38,45,56,66

Magnetic switch and related parts Loose wiring and/or connectors Burnt magnetic switch contact plate or improper contact Broken wire in magnetic switch pull-in coil Broken wire magnetic switch holding coil

Repair Replace

Replace Replace

5-38,45,56,66 5-43,54,64,74

5-43,54,64,74 5-43,54.64,74

Starter Poor contact of brushes

Fatigued brush spring Poor grounding of field coil Poor soldering of field coil Commutator mulfunction Grounded armature Worn parts

Adjust contact or replace Replace Replace Repair Repair or Replace Replace Replace

5-43,54,64,74

Starting problem Gasoline engine Insufficient battery capacity Malfunction of spark plug (s)

Loose positive terminal Damaged distributor cap or rotor Ignition coil malfunction laniter malfunction

Recharge Clean, adjust or replace Tighten Replace Replace Renlane

5— 8 5— 9

5—16 5—10 5-16,20

Diesel engine Insufficient battery capacity QSS svstem malfunction Recharge ReDlace 5— 8 5-76

Starter turns but pinion gear does not mesh with ring gear

Starter Tip of overrunning clutch pinion is worn Weakened overrunning clutch drive spring Worn overrunning clutch Improper sliding of spline

Worn bushing Worn ring gear

Replace Replace Replace Adjust contact and repair, or replace Replace ReDlace

5-40,54,70

Starter turns continuously (does not stop) Magnetic switch Sticking contact place of magnetic switch Layer shorting coil of magnetic switch Ignition switch does not return

Replace Replace Rfinlanfi

5-43,54,64,74 5-43,54,64,74

Misfiring Dirty or damaged spark plug (s) Malfunction of wiring, or open circuit Damaged distributor cap

Clean or replace Repair or Replace Replace

5- 9 5—10 5—16

Discharging of battery Alternator Loose drive belt Grounded or broken stator coil Broken rotor coil Poor contact of brush and slip ring

Malfunction of rectifier Malfunction of IC regulator Battery and related parts Insufficient or unsuitable battery electrolyte Malfunction of battery electrode (internal short-circuit) Poor contact of battery terminal (s) Excessive electric load

Adjust Replace Replace Clean, repair or replace Replace Replace

Adjust Replace

Clean and tighten Check power consump-tion and short circuit

5-37 5-32 5-32 5-32

5-34

5— 8 5- 8

5— 8

Overcharging of battery IC regulator malfunction Operating in extremely high temperature Replace Reoair

Poor acceleration Mis-adjusted ignition timing Distributor malfunction Adjust Repair or replace 5—11 5—11

Knocking Mis-adjusted ignition timing | Distributor malfunction Adjust Repair or replace 5—11 5—11

76G05X-003

5-7

Page 720 of 1865

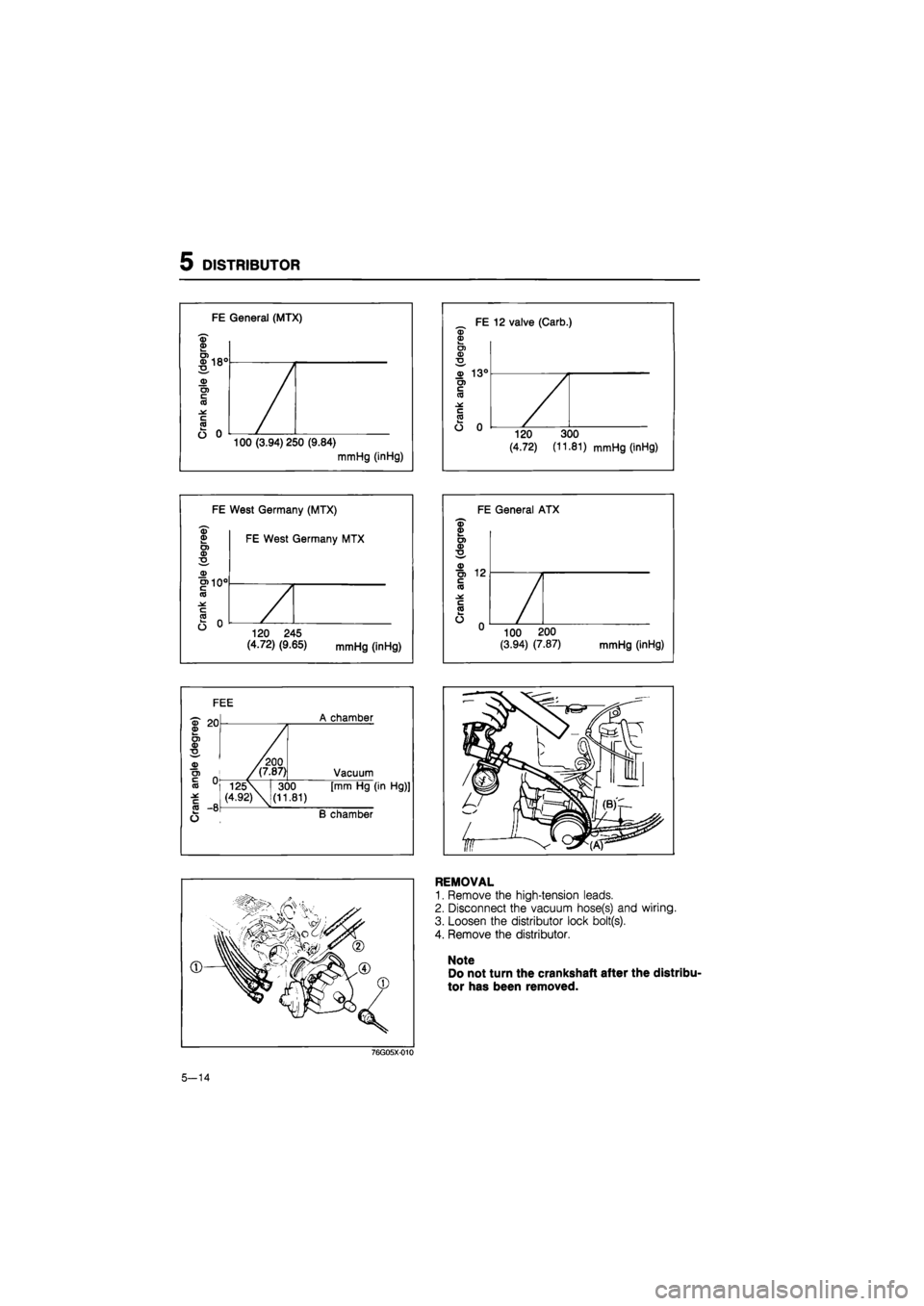

5 DISTRIBUTOR

FE General (MTX)

© a>

|18° ©

o> c (0 J*

c CO

O o 100 (3.94)250 (9.84)

mmHg (inHg)

c (0

FE 12 valve (Carb.)

13e

O 0 300

(11.81) mmHg (inHg)

FE West Germany (MTX)

© ©

O) ©

© 0)10° CO

c CO 6 0

FE West Germany MTX

120 245

(4.72) (9.65) mmHg (inHg)

FE General ATX

© S> o> © •o

O) 12 © CJ) c (0

c <0

O

100 200

(3.94) (7.87) mmHg (inHg)

FEE

© ©

O) ©

© O) C cd JC c CO

20 A chamber

/200

/(7-87) Vacuum

co -8 w

300

|(11.81)

[mm Hg (in Hg)]

B chamber

REMOVAL

1. Remove the high-tension leads.

2. Disconnect the vacuum hose(s) and wiring.

3. Loosen the distributor lock bolt(s).

4. Remove the distributor.

Note

Do riot turn the crankshaft after the distribu-

tor has been removed.

76G05X-010

5—14

Page 730 of 1865

5 ALTERNATOR

3. Alternator warning light operates properly, but battery discharged

OK

NG OK

1

a) Poor connection between B terminal and positive battery cable

b) Poor connection of negative battery cable c) Poor connection between alternator connector (2-pin) and positive battery terminal d) Stator coil or diodes malfunction (Refer to page 5—32 or 5—34.)

Perform TEST 2. (Refer to page 5--25.)

NG

Perform TEST 3. (Refer to Dage 5--26.)

I OK

Perfrom TEST 4. (Refer to page 5--26.)

NG

Perform TEST 5 (F Refer to page 5—26)

OK

Alternator normal.

Check other electrical components.

NG

Alternator normal.

Check other electrical components.

Perform TEST 5. (Refer to page 5—26.)

OK

Stator coil, diode, main fuse, or wiring har-ness between B ternimal and battery mal-function.

(Refer to page 5—32 or 5—34.)

IC regulator, bush, or rotor coil malfunction. (Refer to page 5—32 or 5—33)

NG

76G05X-027

4. Battery overcharged

Less than 14.1V

(At 20°C, 68°F)

More than 14.7V

(At 20oC,68°F)

IC regulator malfunction,

Perform TES T 6. (Refer to page 5—27.)

NG OK

Wiring harness malfunction.

76G05X-028

5—24

Page 738 of 1865

5 ALTERNATOR

86U05X-078

86U05X-080

86U05X-081

INSPECTION

Rotor

1. Wiring damage

(1) Check the resistance between the slip rings us-

ing an ohmmeter.

Specification: 2—6 U

(2) If it is not within specification, replace the rotor

2. Ground of the field coil

(1) Check for continuity between the slip ring and

the core using an ohmmeter.

(2) Replace the rotor if there is continuity.

3. Slip ring surface

If the slip ring surface is rough, use a lathe or fine

sandpaper to repair it.

Stator

1. Wiring damage

(1) Check for continuity between the stator coil

leads using an ohmmeter.

(2) Replace the stator if there is no continuity.

2. Ground of the stator coil

(1) Check for continuity between the stator coil

leads and the core using a circuit tester.

(2) Replace the stator if there is continuity.

86U05X-082

5—32

Page 744 of 1865

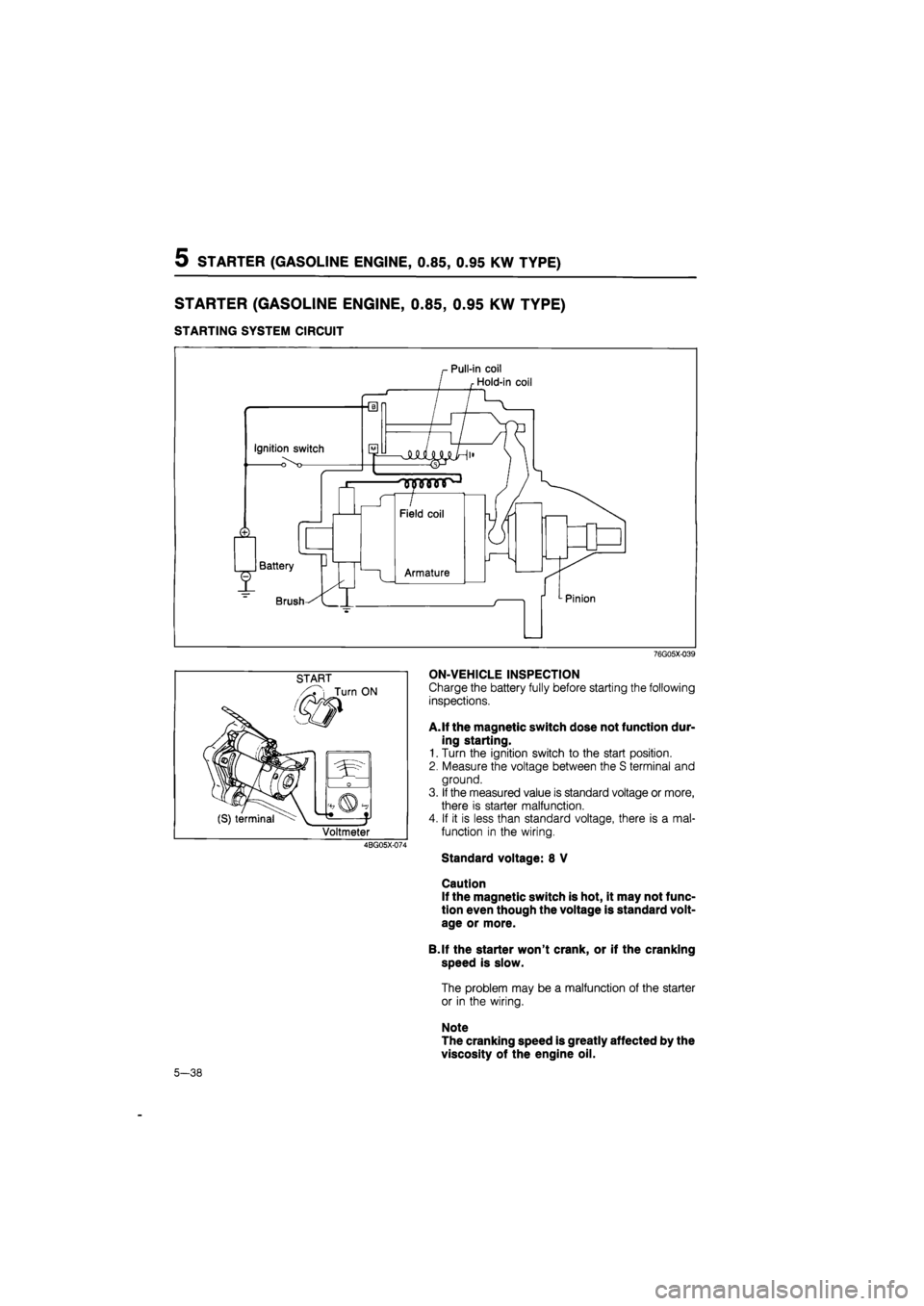

5 STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE)

STARTER (GASOLINE

ENGINE, 0.85, 0.95

KW TYPE)

STARTING SYSTEM CIRCUIT

76G05X-039

START

i Turn ON

(S) terminal

0

t* t

Voltmeter

4BG05X-074

ON-VEHICLE INSPECTION

Charge the battery fully before starting the following

inspections.

A. If the magnetic switch dose not function dur-

ing starting.

1. Turn the ignition switch to the start position.

2. Measure the voltage between the S terminal and

ground.

3. If the measured value is standard voltage or more,

there is starter malfunction.

4. If it is less than standard voltage, there is a mal-

function in the wiring.

Standard voltage: 8 V

Caution

If the magnetic switch is hot, it may not func-

tion even though the voltage is standard volt-

age or more.

B.lf the starter won't crank, or if the cranking

speed is slow.

The problem may be a malfunction of the starter

or in the wiring.

Note

The cranking speed is greatly affected by the

viscosity of the engine oil.

5-38

Page 745 of 1865

STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE) 5

76G05X-040

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Raise the front of the vehicle and support it with

safety stands.

4. Remove the intake manifold bracket. (Fuel Injec-

tion Engine)

5. Remove the starter bolts.

6. Draw out the starter from lower side of the vehicle.

Installation in the revers order of removal.

Tightening torque

Bolts 37—52 N m

(3.8—5.3 m-kg, 27—38 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

Intake manifold bracket bolt

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

Nut

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly is the reverse order of disassembly. 4BG05X-049

4BG05X-075

1. Magnetic switch

2. Bolt

3. Rear cover

4. Brush-holder assembly

5. Yoke

6. Lever

7. Drive housing

(front cover)

8. Drive pinion

9. Armature

5-39

Page 746 of 1865

5 STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE)

4BG05X-078

4BG05X-079

4BG05X-080

Drive Pinion

Remove the stopper for the overrunning clutch by us-

ing a pipe as shown in the figure.

Adjustment of Pinion Gap

1. Disconnect the wiring from terminal (M).

2. Apply battery power to the terminal (S) and ground

the starter motor body, the pinion will eject outward

and then stop.

3. Measure the clearance (pinion gap) between the

pinion and the stopper.

Pinion gap: 0.5—2.0 mm (0.020—0.079 in)

Caution

Do not let electricity flow continuously for

more than 10 seconds.

If the pinion gap is not within the specified range,

make the adjustment by increasing or decreasing

the number of washers used between the magnetic

switch and the drive housing. The gap will become

smaller if the number of washers is increased.

Caution

Do not use the washers

(0.079 in) in all.

more than 2 mm

INSPECTION

Armature Coil

1. Ground of the armature coil

(1) Check for continuity between the commutator

and the core by using a circuit tester.

(2) Replace the armature if there is continuity.

4BG05X-081

5—40

Page 747 of 1865

STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE) 5

4BG05X-082

4BG05X-083

4BG05X-084

2. Vibration of the commutator

(1) Place the armature on V blocks, and measure

the vibration by using a dial gauge.

(2) If the vibration is Limit or more, repair so that

it becomes standard by using a lathe, or re-

place the armature.

Standard vibration: 0.05 mm (0.002 in)

Limit: 0.4 mm (0.018 in)

Note

Before checking, be sure that there is no play

in the bearings.

3. Outer diameter of the commutator

Replace the armature if the outer diameter of the

commutator is grind limit or less.

4. Roughness of the commutator surface

(1) If the commutator surface is dirty, wipe it with

a cloth.

(2) If it is rough, repair it by using a lathe or fine

sandpaper.

Grind limit: 31 mm (1.22 in)

5. Segment groove depth

If the depth of the mold between segments is limit

depth or less, undercut the grooves by standard

depth.

Standard depth:

0.5—0.8 mm (0.020—0.031 in)

Limit depth: 0.2 mm (0.008 in)

Field Coil

1. Wiring damage

(1) Check for continuity between the connector

and brushes by using a circuit tester.

(2) Replace the yoke assembly if there is no con-

tinuity.

4BG05X-085

5—41