MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Page 1205 of 1865

ASSEMBLY 7C

(5) Install the outer race removed in step (3) to the

SST; then mount them on the output gear as-

sembly.

Caution

Eliminate the gap (arrow) by turning A or B of

the selector.

76G07C-233

(7) Set the bearing housing on the SST (selector)

and install the four SST (bolts); then tighten

them to the specified torque,

Tightening torque:

19ā26 N m (1.9ā2.6 m-kg, 14ā19 ft-lb)

76G07C-234

(8) Turn the SST (selector) to increase the clear-

ance (indicated by the arrow) with the SST

(bars) until it no longer turns.

Note

This is to seat the bearing.

(9) Turn the selector in the opposite direction un-

til the preload is eliminated (gap is reduced).

7Cā91

Page 1206 of 1865

7C ASSEMBLY

(10) Mount the SST and pull scale or torque

wrench on the output gear.

(11) Increase the clearance between A and B

to obtain the specified preload/pull scale

reading.

Preload: 0.5ā0.9 N-m

(5.0ā9.0 cm-kg, 4.34ā7.81 in-lb)

Reading on pull scale: 5ā9 N

(0.5ā0.9 kg, 1.1ā1.98 lb)

Note

Read the preload when the output gear starts

to turn.

(12) Measure the clearance. Select adjust

shim(s) equivalent to the measured

clearance.

Thickness of shim

0.10 mm (0.004 in) 0.12 mm (0.005 in) 0.14 mm (0.006 in)

0.16 mm (0.0063 in) 0.20 mm (0.008 in) 0.50 mm (0.020 in)

Caution

a) Measure the clearance around the entire cir-

cumference, and select shims equivalent to

the maximum clearance.

b)The maximum allowable number of shims

is 7.

83U07B-377

7C-92

Page 1207 of 1865

ASSEMBLY 7C

76G07C-238

76G07C-239

76G07C-240

(13) Remove the bearing housing and SST.

(14) Install the required shim(s) and press the

bearing race into the bearing housing with

a suitable pipe.

(15) Install the bearing housing.

Tightening torque:

19ā26 N m (1.9ā2.6 m-kg, 14ā19 ft-lb)

(16) Check that the preload/pull scale reading

is within specification. If not within specifi-

cation return to step (3).

Preload: 0.03ā0.9 N-m

(0.3ā9.0 cm-kg, 0.26ā7.81 in-lb)

Reading on pull scale:

0.3ā9 N (0.03ā0.9 kg, 0.066ā1.98 lb)

(17) Remove the bearing housing and output

gear assembly.

2. Mount the side bearing housing to transaxle case

by gradually tightening the mounting bolts in a di-

agonal pattern.

Tightening torque:

19ā26 N-m (1.9ā2.6 m-kg, 14ā19 ft-lb)

76G07C-241

7C-93

Page 1209 of 1865

ASSEMBLY 7C

(4) Set the six SST in the positions shown.

83U07B-382

Note

Install the bolts in the positions shown in the

illustration above.

76G07C-244

(5) Set the transaxle case on the selectors.

(6) Tighten the SST (bolts) to the specified torque.

Tightening torque:

29ā46 Nm (3.0ā4.7 m-kg, 22ā34 ft-lb)

76G07C-245

(7) Turn the SST (selector) to increase the clear-

ance (indicated by the arrow) with the SST

(bars), until it no longer turns.

Note

a )This is to seat the bearings.

b )To turn the SST (B), bend the bar as shown.

(8) Turn the selector in the opposite direction until

the preload is eliminated (gap is reduced).

83U07B-385

7C-95

Page 1210 of 1865

7C ASSEMBLY

(9) Insert the SST through the oil seal hole of the

transaxle case and attach

it

to the pinion shaft.

(10) Mount the SST and pull scale or torque

wrench.

(11) Widen the clearance between A and B to ob-

tain the specified preload/pull scale reading.

Preload:

0.5 N-m (5 cm-kg, 4.3 in-lb)

Reading on pull scale: 5 N (0.5 kg, 1.1 lb)

Note

Read the preload when the differential starts

to turn.

(12) Measure the clearance between A and B.

(13) Add 0.15 mm (0.0059 in) to the measured

clearance, and select the shim(s) closest in

valve to that measurement.

76G07C-246

Thickness

of

shim

0.10

mm

(0.004

in)

0.12

mm

(0.005

in)

0.14

mm

(0.006

in)

0.16

mm

(0.0063

in)

0.18 mm (0.007

in)

0.20 mm (0.008

in)

0.50 mm (0.020

in)

0.70

mm

(0.028

in)

1.00 mm (0.039

in)

76G07C-247

Caution

a) Measure the clearance around the entire cir-

cumference, and select shims equivalent to

the maximum clearance.

b)The maximum allowable number of shims

is 3.

(14) Remove the transaxle case and selector.

(15) Install the required shim(s) and tap the bear-

ing race into the side bearing housing.

76G07C-248

7C-96

Page 1211 of 1865

ASSEMBLY 7C

76G07C-249

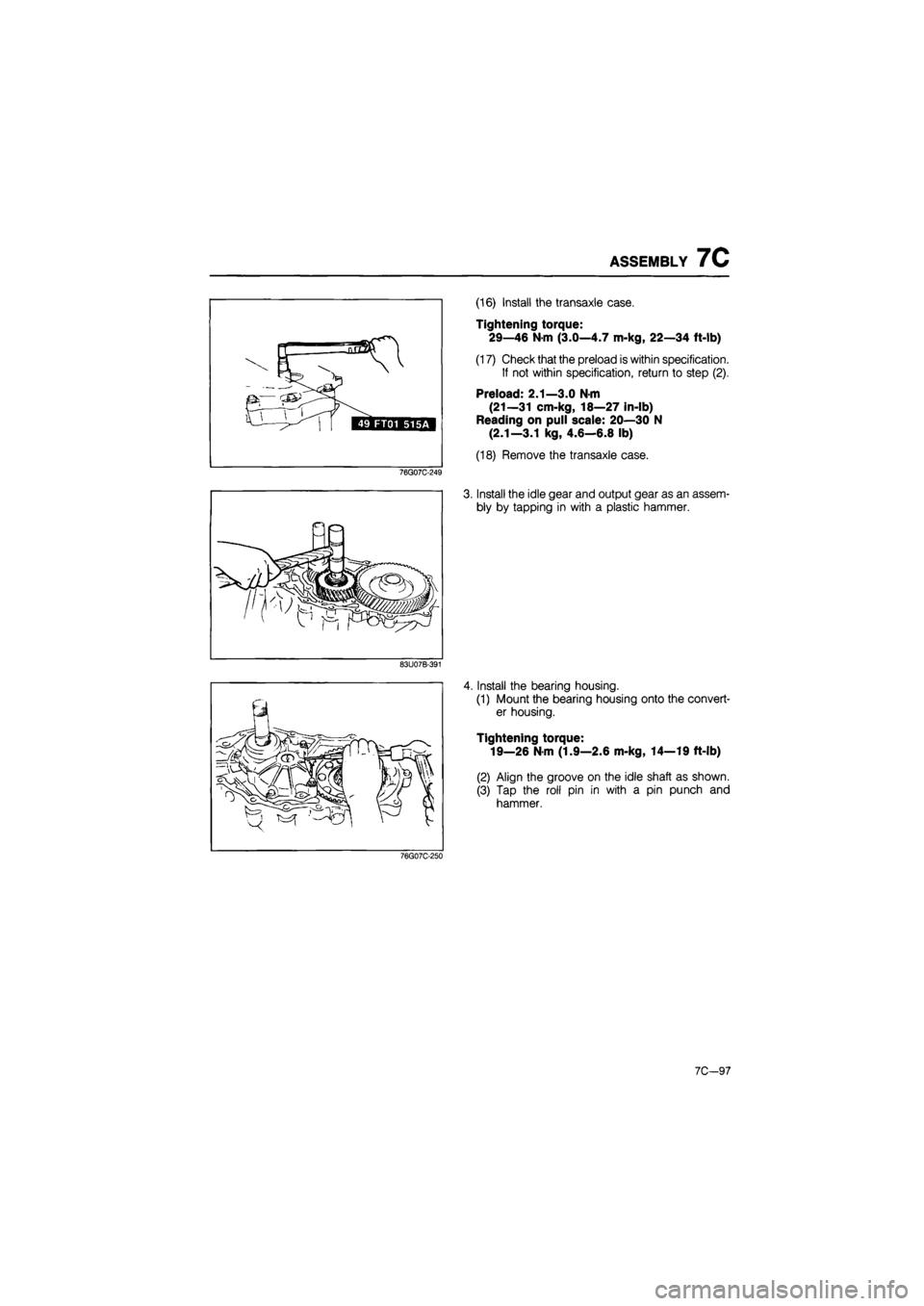

(16) Install the transaxle case.

Tightening torque:

29ā46 N-m (3.0ā4.7 m-kg, 22ā34 ft-lb)

(17) Check that the preload is within specification.

If not within specification, return to step (2).

Preload: 2.1ā3.0 N-m

(21ā31 cm-kg, 18ā27 in-lb)

Reading on pull scale: 20ā30 N

(2.1ā3.1 kg, 4.6ā6.8 lb)

(18) Remove the transaxle case.

3. Install the idle gear and output gear as an assem-

bly by tapping in with a plastic hammer.

83U07B-391

4. Install the bearing housing.

(1) Mount the bearing housing onto the convert-

er housing.

Tightening torque:

19ā26 N-m (1.9ā2.6 m-kg, 14ā19 ft-lb)

(2) Align the groove on the idle shaft as shown.

(3) Tap the roll pin in with a pin punch and

hammer.

76G07C-250

7C-97

Page 1212 of 1865

7C ASSEMBLY

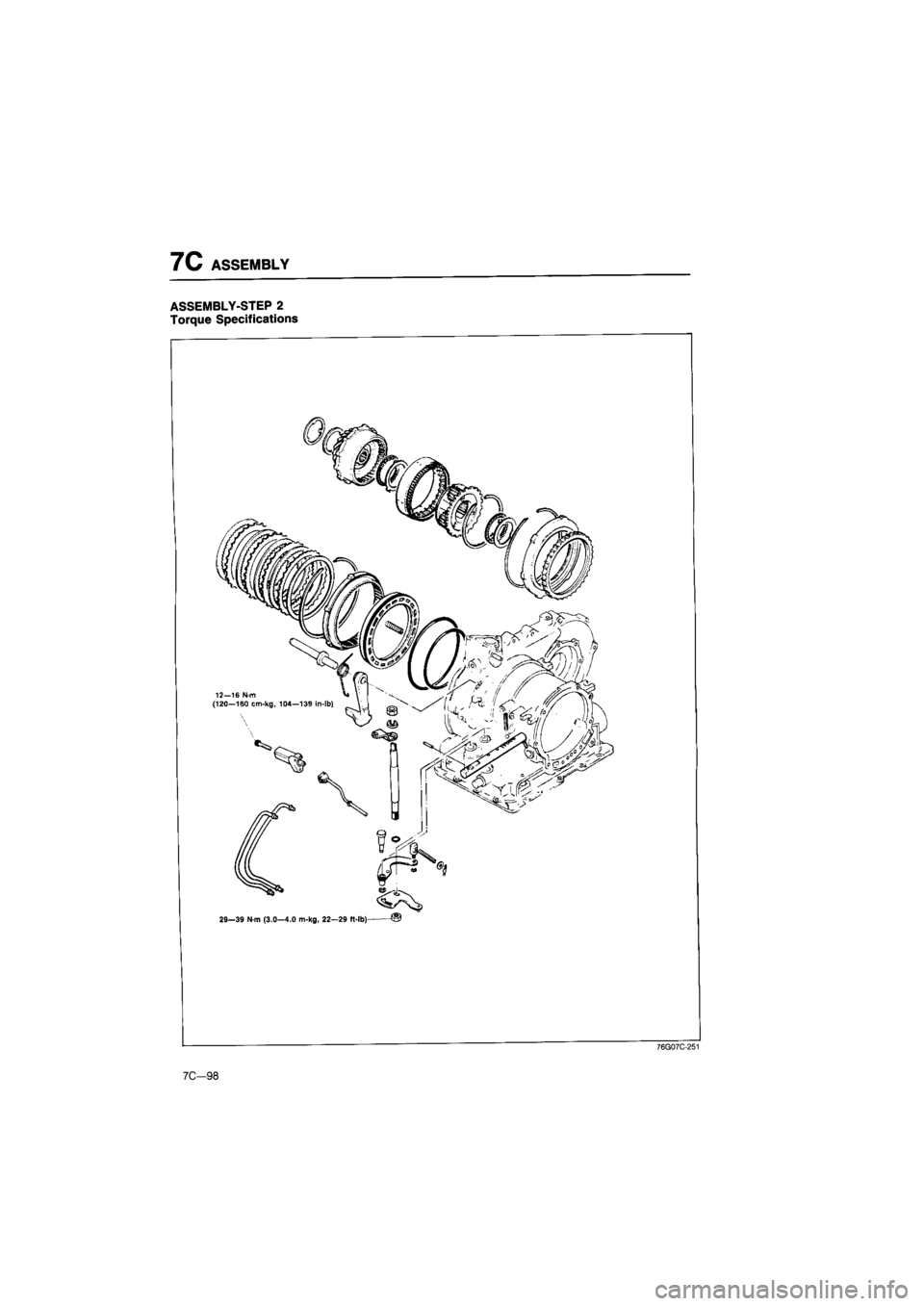

ASSEMBLY-STEP 2

Torque Specifications

29ā39 N-m (3.0ā4.0 m-kg, 22ā29 ft-lb) Ā©

7C-98

76G07C-251

Page 1213 of 1865

ASSEMBLY 7C

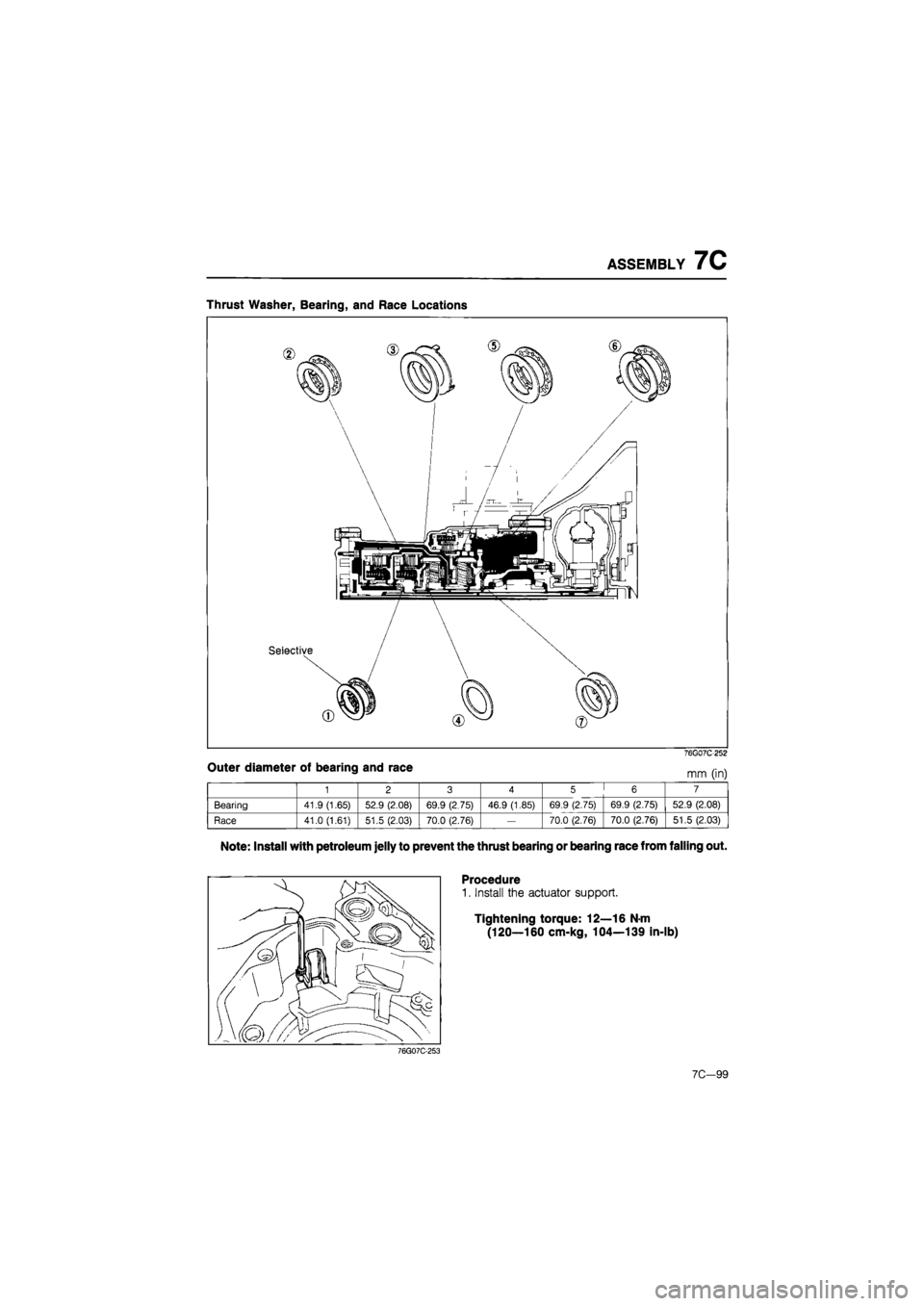

Thrust Washer, Bearing, and Race Locations

Outer diameter of bearing and race

76G07C252

mm (in)

1 2 3 4 5 6 7

Bearing 41.9 (1.65) 52.9 (2.08) 69.9 (2.75) 46.9 (1.85) 69.9 (2.75) 69.9 (2.75) 52.9 (2.08)

Race 41.0 (1.61) 51.5 (2.03) 70.0 (2.76)

ā

70.0 (2.76) 70.0 (2.76) 51.5 (2.03)

Note: Install with petroleum jelly to prevent the thrust bearing or bearing race from falling out.

Procedure

1. Install the actuator support.

Tightening torque: 12ā16 N-m

(120ā160 cm-kg, 104ā139 in-lb)

76G07C-253

7Cā99

Page 1215 of 1865

ASSEMBLY 7C

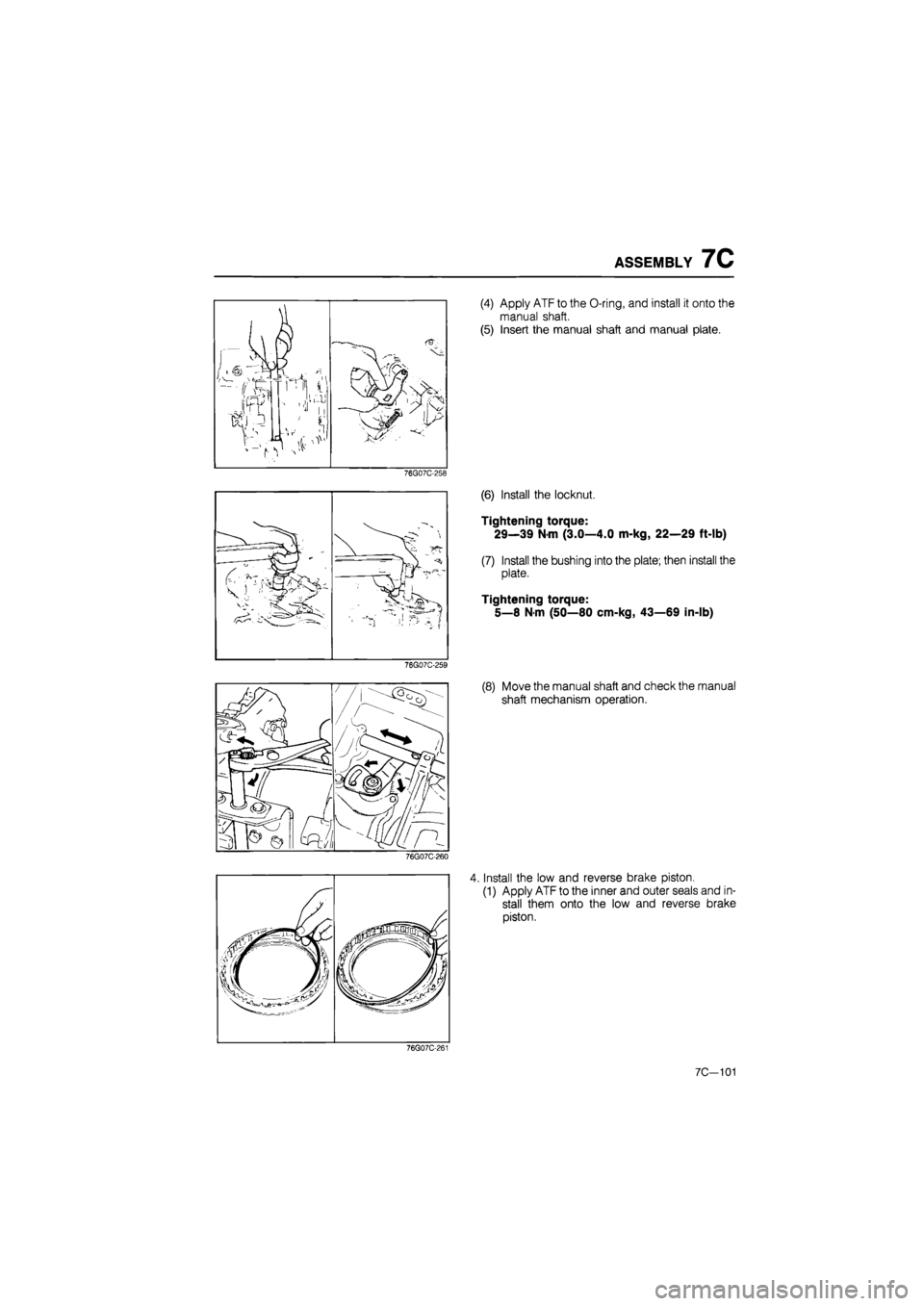

(4) Apply ATF to the O-ring, and install it onto the

manual shaft.

(5) Insert the manual shaft and manual plate.

76G07C-258

(6) Install the locknut.

Tightening torque:

29ā39 N-m (3.0ā4.0 m-kg, 22ā29 ft-lb)

(7) Install the bushing into the plate; then install the

plate.

Tightening torque:

5ā8 N-m (50ā80 cm-kg, 43ā69 in-lb)

76G07C-260

4. Install the low and reverse brake piston.

(1) Apply ATF to the inner and outer seals and in-

stall them onto the low and reverse brake

piston.

76G07C-261

7C-101

Page 1220 of 1865

7C ASSEMBLY

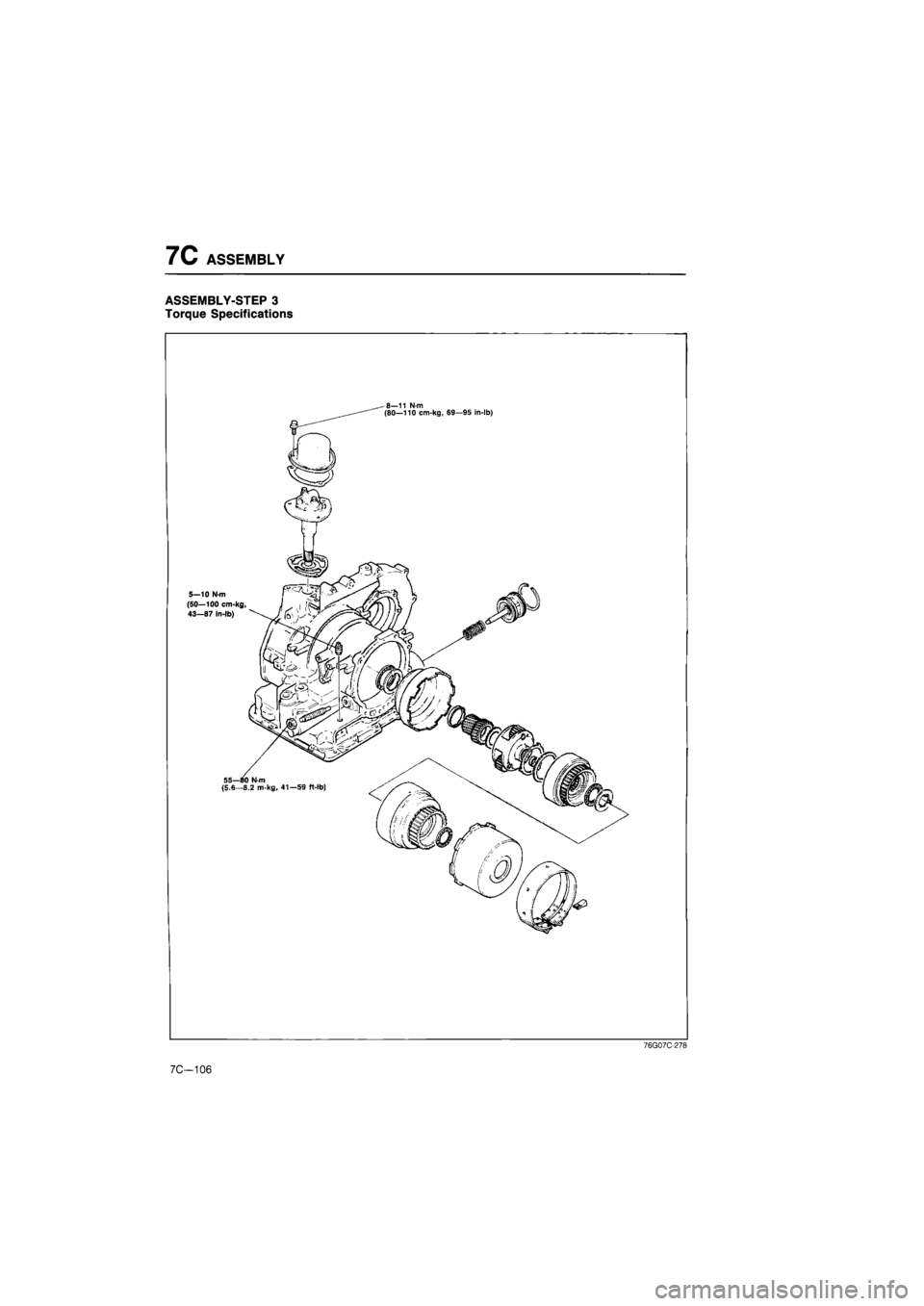

ASSEMBLY-STEP 3

Torque Specifications

76G07C-278

7C-106