oil MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1149 of 1865

DISASSEMBLY 7C

DISASSEMBLY

DISASSEMBLY - STEP 1

76G07C-072

1. Torque converter

2. Oil pump shaft

3. Turbine shaft

4. Inhibitor switch

5. Kick-down solenoid

6. Vacuum diaphragm and

rod

7. Oil level gauge and tube

8. Speedometer driven gear

9. Oil pan and gasket

10. Control valve body

11. Steel ball and spring

12. Oil pump

7C—35

Page 1150 of 1865

7C DISASSEMBLY

Procedure

Precaution

(1) Clean the transaxle exterior thoroughly with steam and/or cleaning solvents prior to disassembly.

(2) Disassemble the transaxle in a clean area (dustproof workspace) to prevent dust entry into the

mechanisms.

(3) Inspect the individual transaxle components in accordance with the QUICK DIAGNOSIS CHART

during disassembly.

(4) Use plastic hammers when applying force to separate the light alloy case joints.

(5) Do not use rags during disassembly to prevent contamination.

(6) Neatly arrange the removed parts in order during disassembly.

76G07C-073

1. Remove the torque converter from the converter

housing.

Note

Do not allow the ATF to spill when removing

the torque converter.

83U07B-119

2. Pull out the oil pump shaft by hand.

3. Remove the turbine shaft.

76G07C-074

h

ii ii = J

4. Remove the clip from the turbine shaft.

Note

Do not reuse the clip.

76G07C-075

7C-36

Page 1151 of 1865

DISASSEMBLY 7C

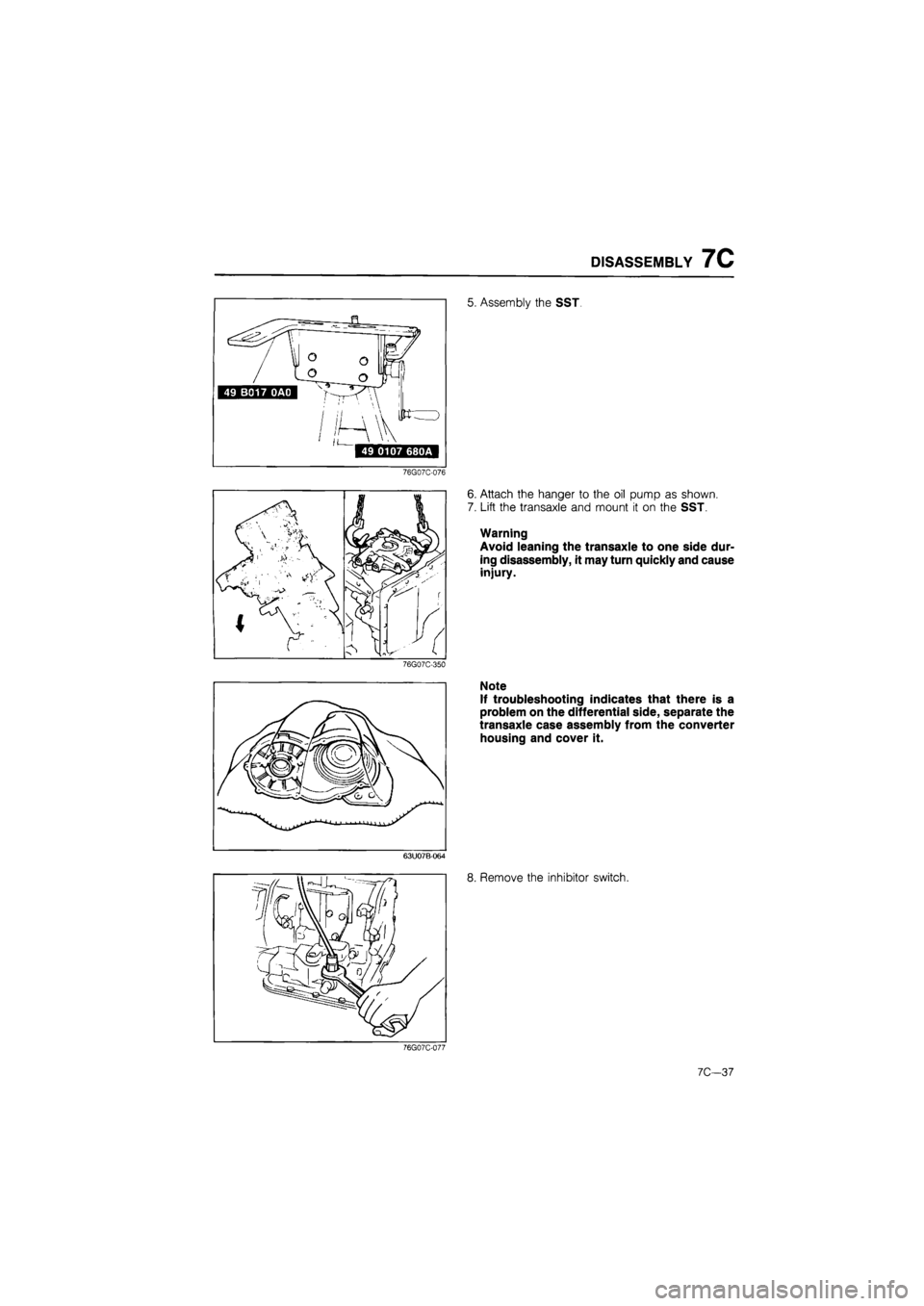

5. Assembly the SST.

76G07C-076

76G07C-350

6. Attach the hanger to the oil pump as shown.

7. Lift the transaxle and mount it on the SST.

Warning

Avoid leaning the transaxle to one side dur-

ing disassembly, it may turn quickly and cause

injury.

Note

If troubleshooting indicates that there is a

problem on the differential side, separate the

transaxle case assembly from the converter

housing and cover it.

63U07B-064

8. Remove the inhibitor switch.

76G07C-077

7C—37

Page 1152 of 1865

7C DISASSEMBLY

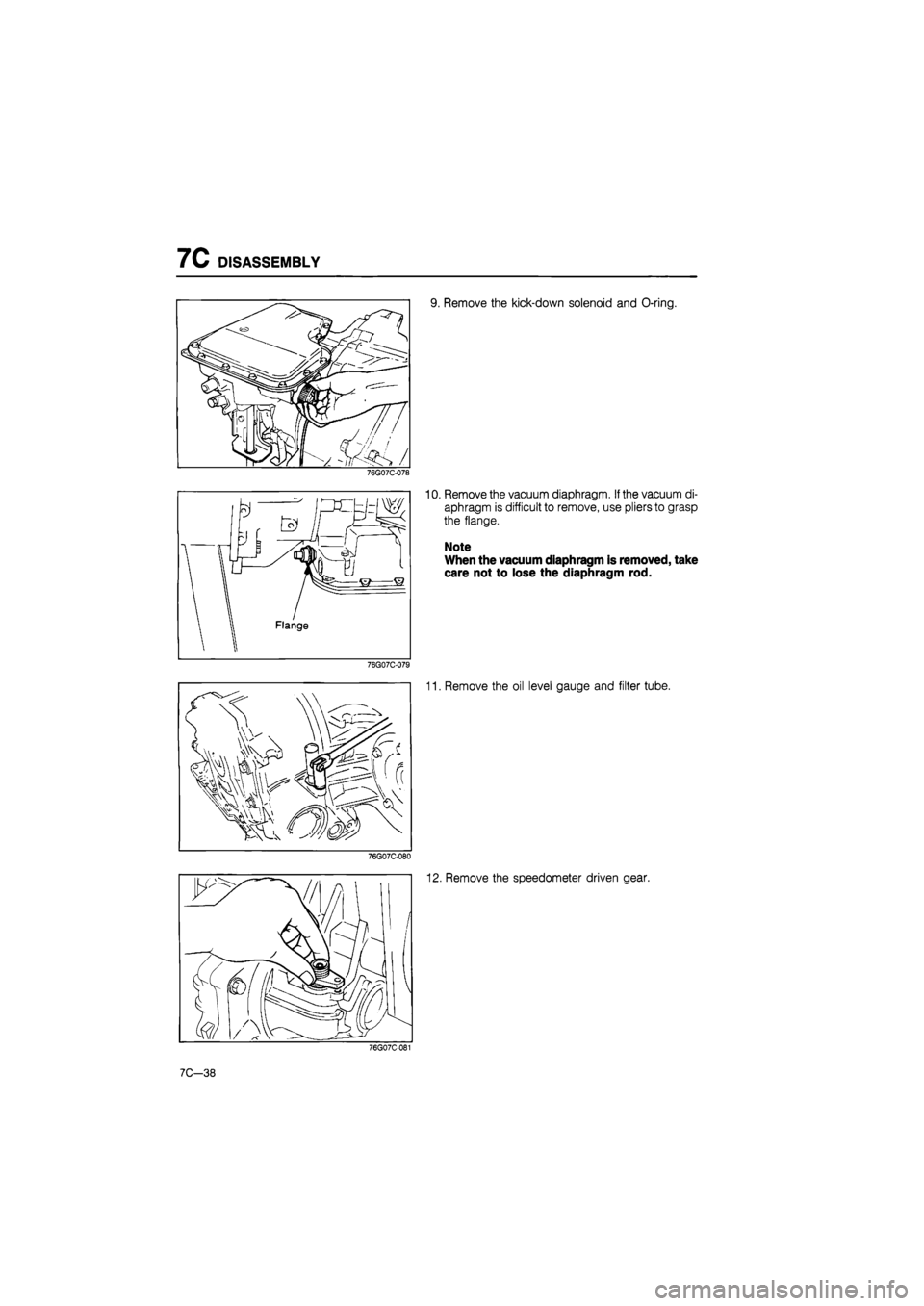

9. Remove the kick-down solenoid and O-ring.

76G07C-078

76G07C-079

10. Remove the vacuum diaphragm. If the vacuum di-

aphragm is difficult to remove, use pliers to grasp

the flange.

Note

When the vacuum diaphragm is removed, take

care not to lose the diaphragm rod.

11. Remove the oil level gauge and filter tube.

76G07C-080

12. Remove the speedometer driven gear.

76G07C-081

7C—38

Page 1153 of 1865

DISASSEMBLY 7C

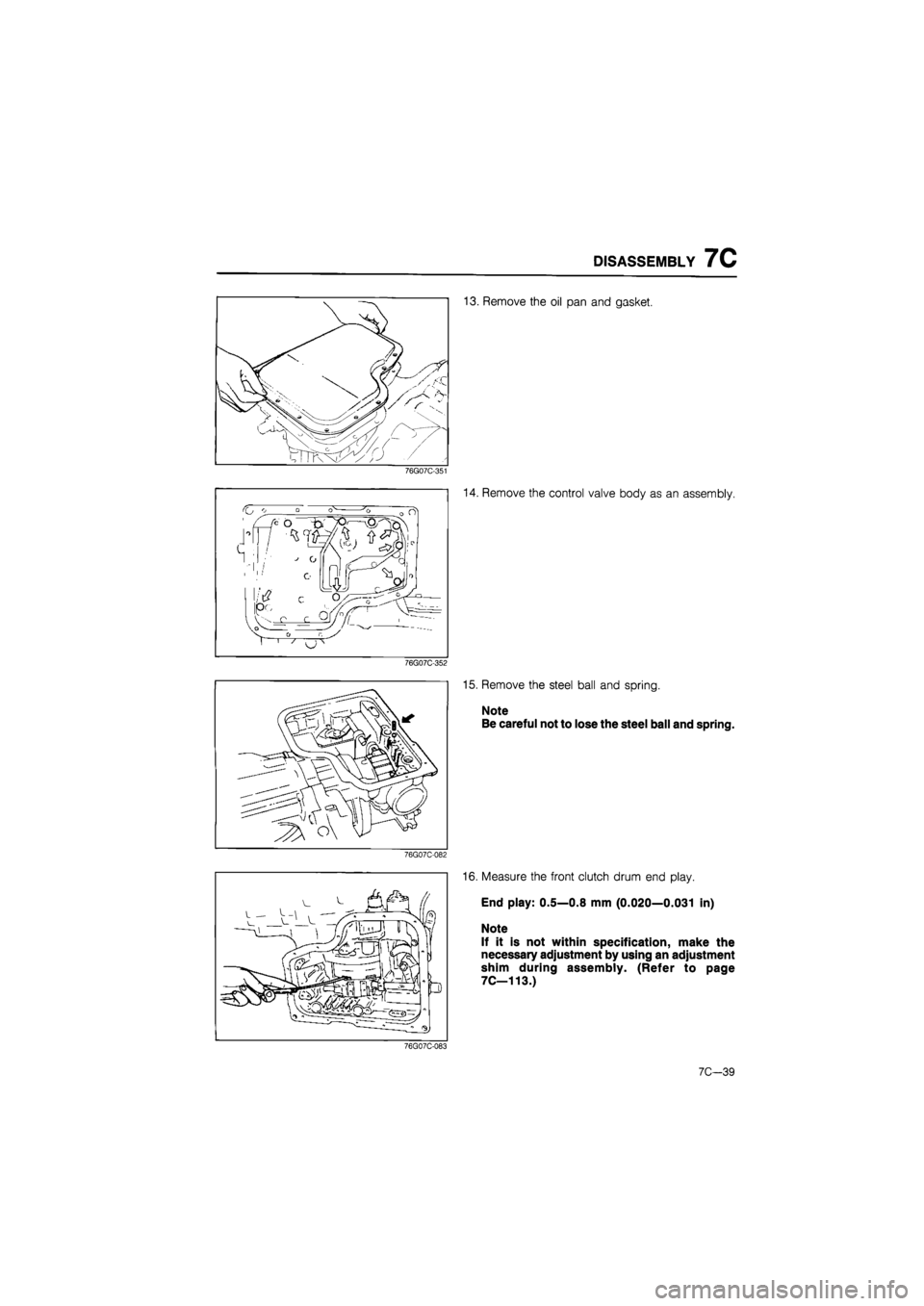

13. Remove the oil pan and gasket.

76G07C-351

76G07C-352

76G07C-082

14. Remove the control valve body as an assembly.

15. Remove the steel ball and spring.

Note

Be careful not to lose the steel ball and spring.

16. Measure the front clutch drum end play.

End play: 0.5—0.8 mm (0.020—0.031 in)

Note

If it is not within specification, make the

necessary adjustment by using an adjustment

shim during assembly. (Refer to page

7C—113.)

76G07C-083

7C-39

Page 1154 of 1865

7C DISASSEMBLY

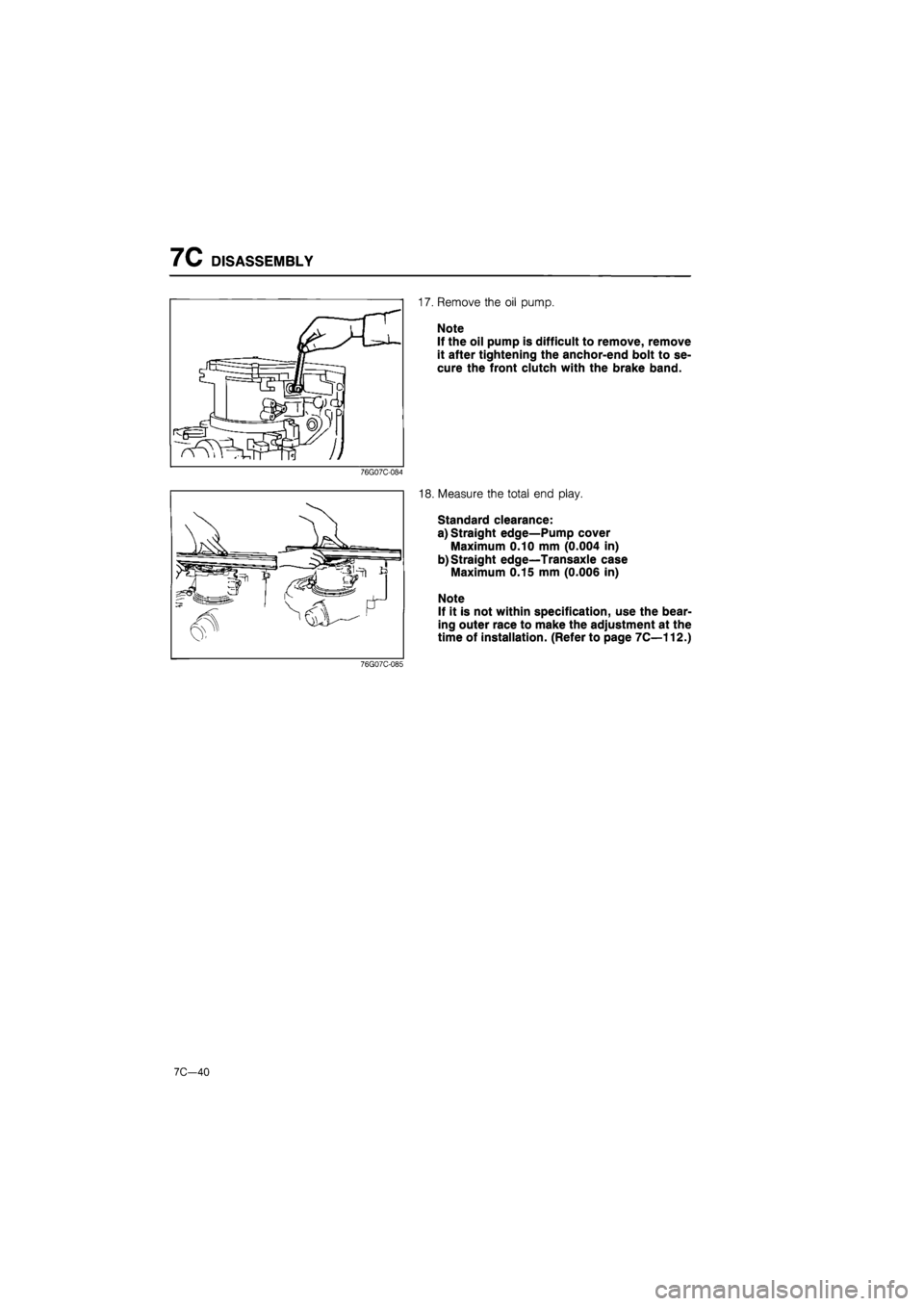

17. Remove the oil pump.

Note

If the oil pump is difficult to remove, remove

it after tightening the anchor-end bolt to se-

cure the front clutch with the brake band.

76G07C-084

18. Measure the total end play.

Standard clearance:

a) Straight edge—Pump cover

Maximum 0.10 mm (0.004 in)

b) Straight edge—Transaxle case

Maximum 0.15 mm (0.006 in)

Note

If it is not within specification, use the bear-

ing outer race to make the adjustment at the

time of installation. (Refer to page 7C—112.)

76G07C-085

7C-40

Page 1159 of 1865

DISASSEMBLY 7C

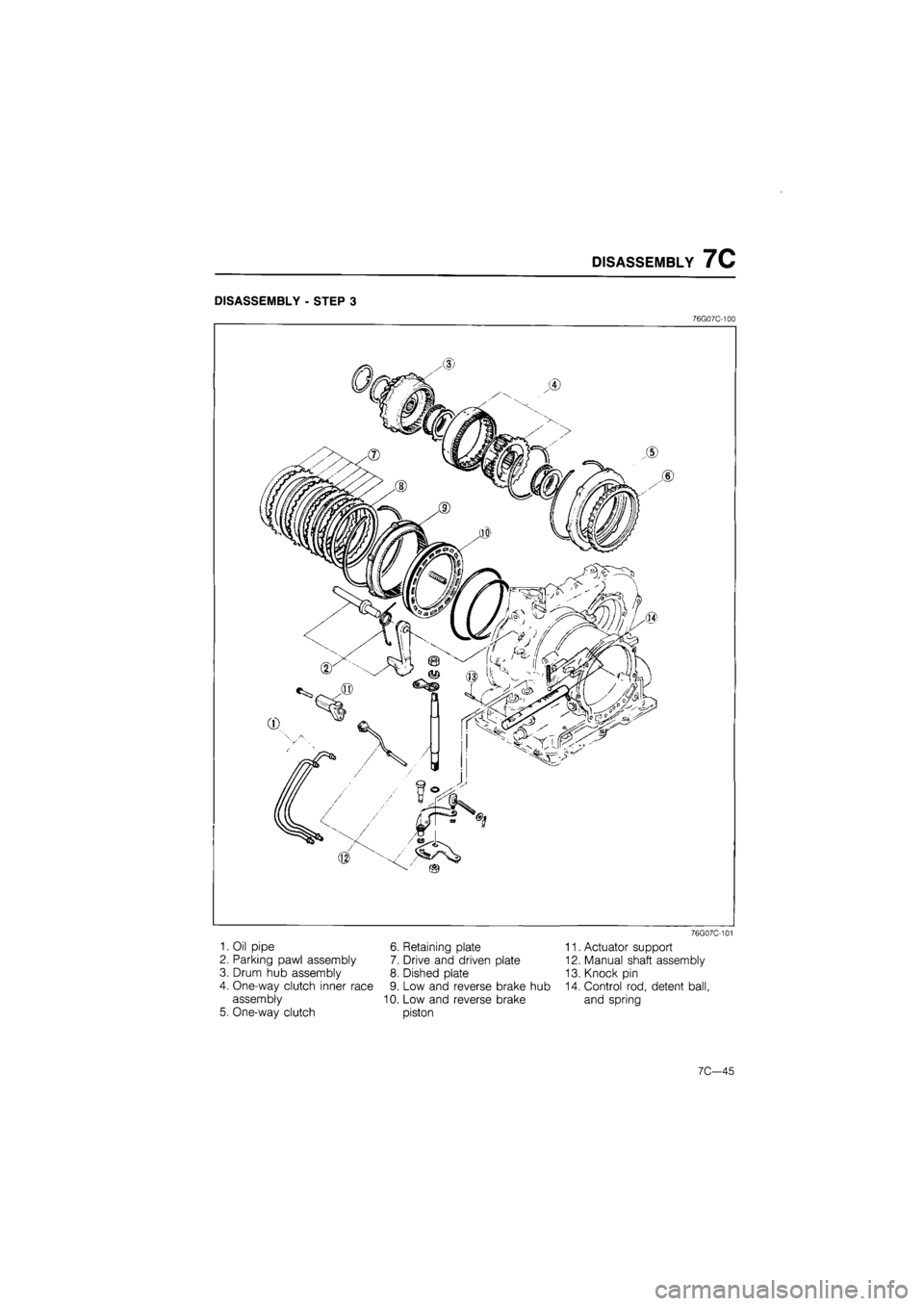

DISASSEMBLY - STEP 3

76G07C-100

1. Oil pipe

2. Parking pawl assembly

3. Drum hub assembly

4. One-way clutch inner race

assembly

5. One-way clutch

6. Retaining plate

7. Drive and driven plate

8. Dished plate

9. Low and reverse brake hub

10. Low and reverse brake

piston

76G07C-101

11. Actuator support

12. Manual shaft assembly

13. Knock pin

14. Control rod, detent ball,

and spring

7C—45

Page 1165 of 1865

DISASSEMBLY 7C

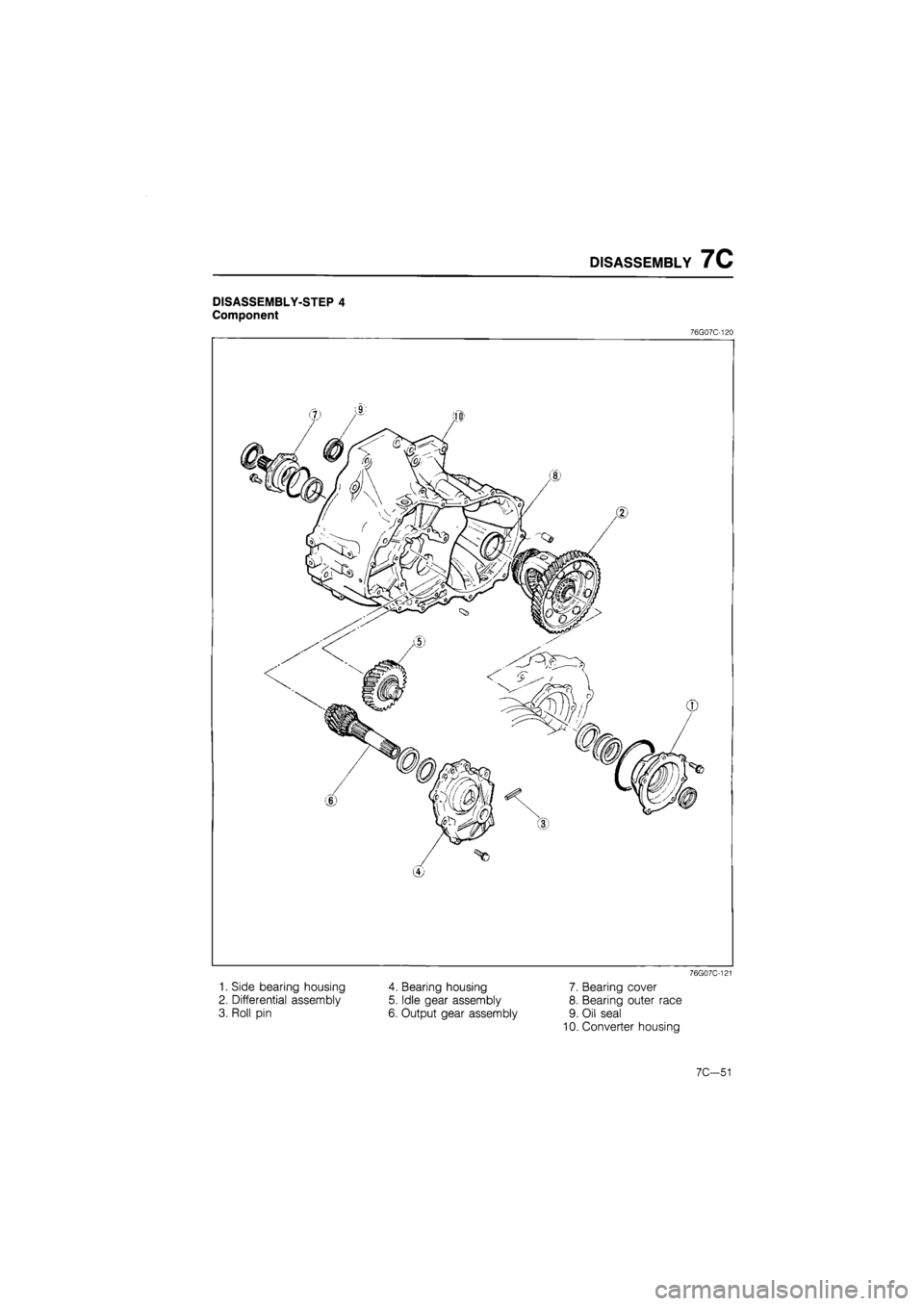

DISASSEMBLY-STEP 4

Component

76G07C-120

76G07C-121

1. Side bearing housing

2. Differential assembly

3. Roll pin

4. Bearing housing

5. Idle gear assembly

6. Output gear assembly

7. Bearing cover

8. Bearing outer race

9. Oil seal

10. Converter housing

7C—51

Page 1167 of 1865

DISASSEMBLY 7C

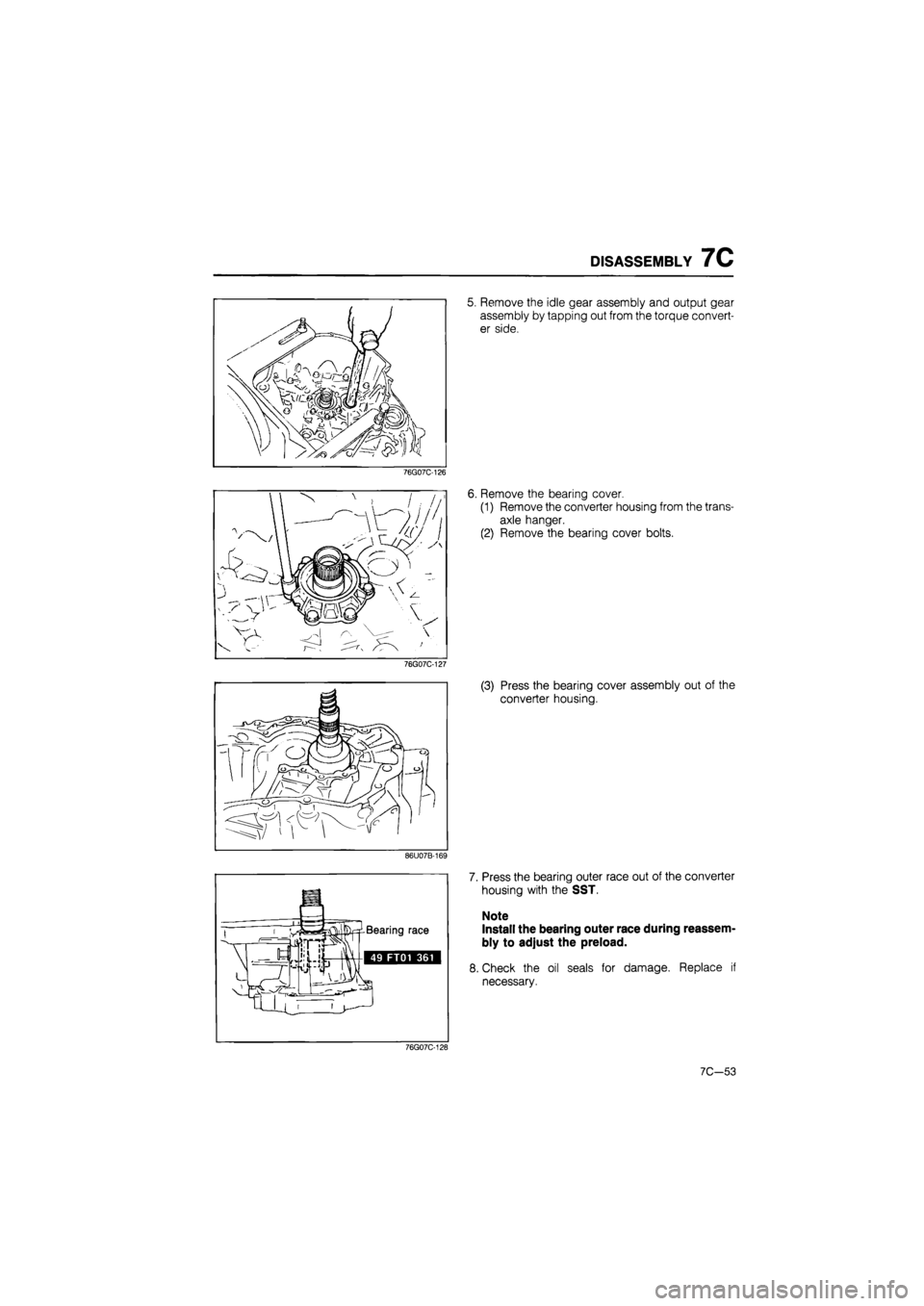

76G07C-126

76G07C-127

86U07B-169

-fct

„ 1 / V.

Bearing race

49 FT01 361

5. Remove the idle gear assembly and output gear

assembly by tapping out from the torque convert-

er side.

6. Remove the bearing cover.

(1) Remove the converter housing from the trans-

axle hanger.

(2) Remove the bearing cover bolts.

(3) Press the bearing cover assembly out of the

converter housing.

7. Press the bearing outer race out of the converter

housing with the SST.

Note

Install the bearing outer race during reassem-

bly to adjust the preload.

8. Check the oil seals for damage. Replace if

necessary.

76G07C-128

7C-53

Page 1168 of 1865

7C INSPECTION AND REPAIR

INSPECTION AND REPAIR

PRECAUTION

(1) Several of the parts resemble each other; organize them so that they do not get mixed up.

(2) Clean each part with cleaning oil, clean out the oil holes and oil passages with compressed air,

and check that there are no obstructions.

(3) When using cleaning oil and compressed air, wear protective eyewear.

(4) If a clutch plate or brake band is replaced with a new one, soak it in ATF for 2 hours or more

before installing.

(5) Before assembly, apply ATF to all seal rings, rotating parts, and sliding parts.

(6) All seals, gaskets and roll pins must be replaced with new ones during assembly.

(7) Use petroleum jelly, not grease where required.

(8) When it is necessary to replace a bushing, replace the assembly which includes that bushing.

76G07C-353

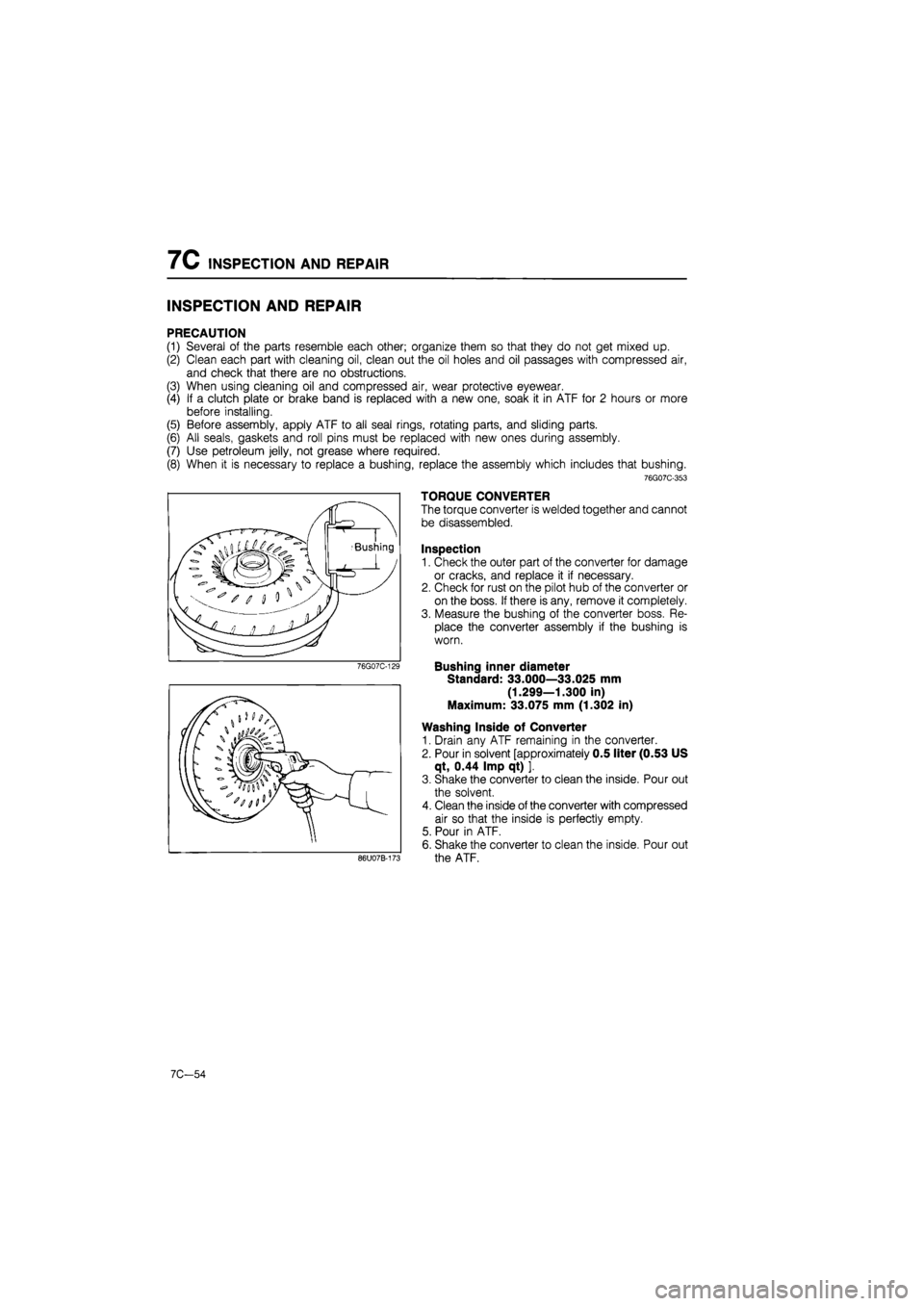

TORQUE CONVERTER

The torque converter is welded together and cannot

be disassembled.

Inspection

1. Check the outer part of the converter for damage

or cracks, and replace it if necessary.

2. Check for rust on the pilot hub of the converter or

on the boss. If there is any, remove it completely.

3. Measure the bushing of the converter boss. Re-

place the converter assembly if the bushing is

worn.

Bushing inner diameter

Standard: 33.000—33.025 mm

(1.299—1.300 in)

Maximum: 33.075 mm (1.302 in)

Washing Inside of Converter

1. Drain any ATF remaining in the converter.

2. Pour in solvent [approximately 0.5 liter (0.53 US

qt, 0.44 Imp qt) ].

3. Shake the converter to clean the inside. Pour out

the solvent.

4. Clean the inside of the converter with compressed

air so that the inside is perfectly empty.

5. Pour in ATF.

6. Shake the converter to clean the inside. Pour out

the ATF.

7C-54