differential MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1208 of 1865

7C ASSEMBLY

3. Adjust the differential side bearing preload and select the adjust shim(s) as described below.

Note

To inspect and adjust the preload, use the SST shown below.

76G07C-242

(1) Remove the side bearing housing race and ad-

just shims from the transaxle case. (Refer to

page 7C—88.)

(2) Set the differential assembly into the convert-

er housing.

(3) Install the outer race removed in step (1) into

the SST; then set them on the differential as-

sembly.

Caution

Eliminate the gap by turning either A or B of

the selector.

7C-94

Page 1210 of 1865

7C ASSEMBLY

(9) Insert the SST through the oil seal hole of the

transaxle case and attach

it

to the pinion shaft.

(10) Mount the SST and pull scale or torque

wrench.

(11) Widen the clearance between A and B to ob-

tain the specified preload/pull scale reading.

Preload:

0.5 N-m (5 cm-kg, 4.3 in-lb)

Reading on pull scale: 5 N (0.5 kg, 1.1 lb)

Note

Read the preload when the differential starts

to turn.

(12) Measure the clearance between A and B.

(13) Add 0.15 mm (0.0059 in) to the measured

clearance, and select the shim(s) closest in

valve to that measurement.

76G07C-246

Thickness

of

shim

0.10

mm

(0.004

in)

0.12

mm

(0.005

in)

0.14

mm

(0.006

in)

0.16

mm

(0.0063

in)

0.18 mm (0.007

in)

0.20 mm (0.008

in)

0.50 mm (0.020

in)

0.70

mm

(0.028

in)

1.00 mm (0.039

in)

76G07C-247

Caution

a) Measure the clearance around the entire cir-

cumference, and select shims equivalent to

the maximum clearance.

b)The maximum allowable number of shims

is 3.

(14) Remove the transaxle case and selector.

(15) Install the required shim(s) and tap the bear-

ing race into the side bearing housing.

76G07C-248

7C-96

Page 1221 of 1865

ASSEMBLY 7C

76G07C-279

76G07C-280

76G07C-281

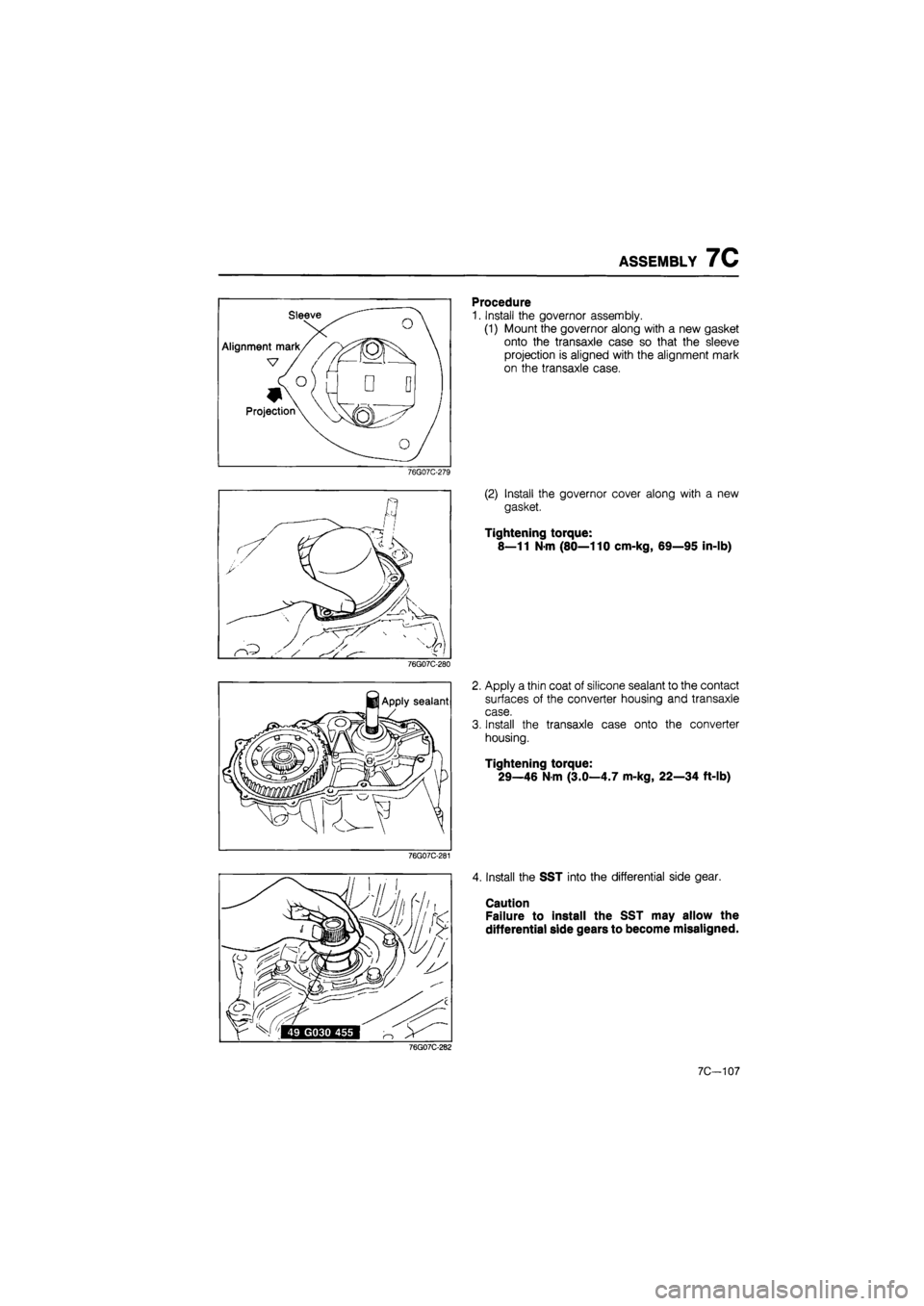

Procedure

1. Install the governor assembly.

(1) Mount the governor along with a new gasket

onto the transaxle case so that the sleeve

projection is aligned with the alignment mark

on the transaxle case.

(2) Install the governor cover along with a new

gasket.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a thin coat of silicone sealant to the contact

surfaces of the converter housing and transaxle

case.

3. Install the transaxle case onto the converter

housing.

Tightening torque:

29—46 N-m (3.0—4.7 m-kg, 22—34 ft-lb)

4. Install the SST into the differential side gear.

Caution

Failure to install the SST may allow the

differential side gears to become misaligned.

76G07C-282

7C-107

Page 1236 of 1865

7C INSTALLATION

(3) Install and tighten the reamer bolts, then install

and tighten the standard bolts.

Tightening torque:

Reamer bolts 7—10 N-m

(70—100 cm-kg, 61—87 in-lb)

Standard bolts 42—62 N m

(4.3—6.3 m-kg, 31—46 ft-lb)

(4) Pull the front hub outward to connect the

driveshaft to the joint shaft.

(5) Push the joint from the differential side to se-

curely connect the driveshaft to the joint shaft.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft is secured.

Install the left driveshaft as follows:

(1) Pull the front hub outward to insert the

driveshaft into the transaxle.

(2) Push the joint from the differential side to con-

nect the driveshaft to the differential side gear.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft is secured.

Install the lower arm ball joints to the knuckles and

tighten the bolts and nuts.

Tightening torque:

36—54 N-m (3.7—5.5 m-kg, 27—40 ft-lb)

Install the under cover.

Install the stabilizer bar control link as follows:

(1) Install the stabilizer bar control link.

(2) Adjust length A to 20.1 mm (0.79 in).

(3) Tighten bolt B to the specified torque.

Tightening torque:

16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

Install the tie-rod ends and cotter pins.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

7C-122

Page 1251 of 1865

9 OUTLINE

OUTLINE

STRUCTURAL VIEW

Driveshaft (MTX)

86U09X-080

1. Lock nut

2. Shaft and ball joint as-

sembly

3. Boot

4. Boot band

5. Ball joint assembly

(differential side)

6. Snap ring

7. Clip

8. Clip

9. Joint shaft assembly

10. Reamer bolt

11. Bracket mounting bolt

9—2

Page 1279 of 1865

9 DRIVESHAFT

86U09X-055

86U09X-056

Driveshaft

Disconnect the driveshaft from the transaxle with a

prybar.

Note

Do not damage the boot or the oil seal.

Joint shaft

As shown in the figure, insert a pry bar between the

driveshaft and the joint shaft and tap on the bar to

uncouple them.

Front wheel hub

Use the SST to push the shaft out if it is stuck in the

front wheel hub.

86U09X-057

Differential

Install the SST to hold the side gear after removing

the driveshaft.

86U09X-058

9—30

Page 1280 of 1865

![MAZDA 626 1987 Repair Manual

DRIVESHAFT 9

[MTX]

DISASSEMBLY

Disassemble in the sequence shown in the figure referring to the disassembly note for specially marked

parts.

Note

a) Clamp the shaft in a vice. Use protectors in MAZDA 626 1987 Repair Manual

DRIVESHAFT 9

[MTX]

DISASSEMBLY

Disassemble in the sequence shown in the figure referring to the disassembly note for specially marked

parts.

Note

a) Clamp the shaft in a vice. Use protectors in](/img/28/57059/w960_57059-1279.png)

DRIVESHAFT 9

[MTX]

DISASSEMBLY

Disassemble in the sequence shown in the figure referring to the disassembly note for specially marked

parts.

Note

a) Clamp the shaft in a vice. Use protectors in the vice to avoid damage.

b)Do not allow dirt or foreign matter in the joint during disassembly or assembly.

c) Do not disassemble the ball-joint at the wheel side. Do not wipe the grease off if there

is no problem.

d)Do not remove the clip used to secure the outer ring to the ball-joint at the differential

side if there is no problem.

If the clip is removed, replace it with a new one.

1. Boot band

2. Clip

3. Outer ring

4. Snap ring

86U09X-059

5. Ball joint

6. Boot band

7. Boot

8. Clip

9. Sensor rotor (Refer to Section 11)

Clip

1. Make matching marks on the driveshaft and out-

er ring for proper reassembly.

Note

Mark with paint, do not use a punch.

2. Remove the clip.

86U09X-091

9-31

Page 1282 of 1865

DRIVESHAFT 9

ASSEMBLY

Boot

Wrap the shaft splines with tape before installing the

boot.

86U09X-093

Wheel side

Note

a) The wheel side arid differential side boots

are different as shown in the figure.

b) Fill the inside of the ball joint with the speci-

fied grease included in the kit.

c) Securely fit the boot to the shaft and the

outer race boot grooves.

86U09X-062

Balls, inner ring and cage

1. Align the matching marks and install the balls.

86U09X-094

2. Apply molybdenum disulfide grease to the joint.

Note

Do not use other than specified grease.

86U09X-095

9-33

Page 1285 of 1865

9 DRIVESHAFT

INSPECTION

Check and replace any faulty parts.

1. Twisted, bent, or damaged shaft.

2. Wear or scoring of splines.

3. Wear, excessive looseness, seizure, rust, or dam-

age of bearing.

4. Checking, damage, or deterioration of boots.

5. Excessive play or heat damage of joint shaft

bearing.

86U09X-066

Wheel side Differential side

86U09X-067

ASSEMBLY

Assemble in the reverse order of disassembly, refer-

ring to assembly note.

Assembly Note

Note

a) The wheel side and differential side boots

are different as shown in the figure.

b) Fill the inside of the ball joint with the speci-

fied grease included in the kit.

c) Securely fit the boot to the shaft and the

outer race boot grooves.

Tripod joint

Install the snap ring to the joint.

86U09X-068

Clip

Install a new clip.

86U09X-069

9-36

Page 1828 of 1865

30 TECHNICAL DATA

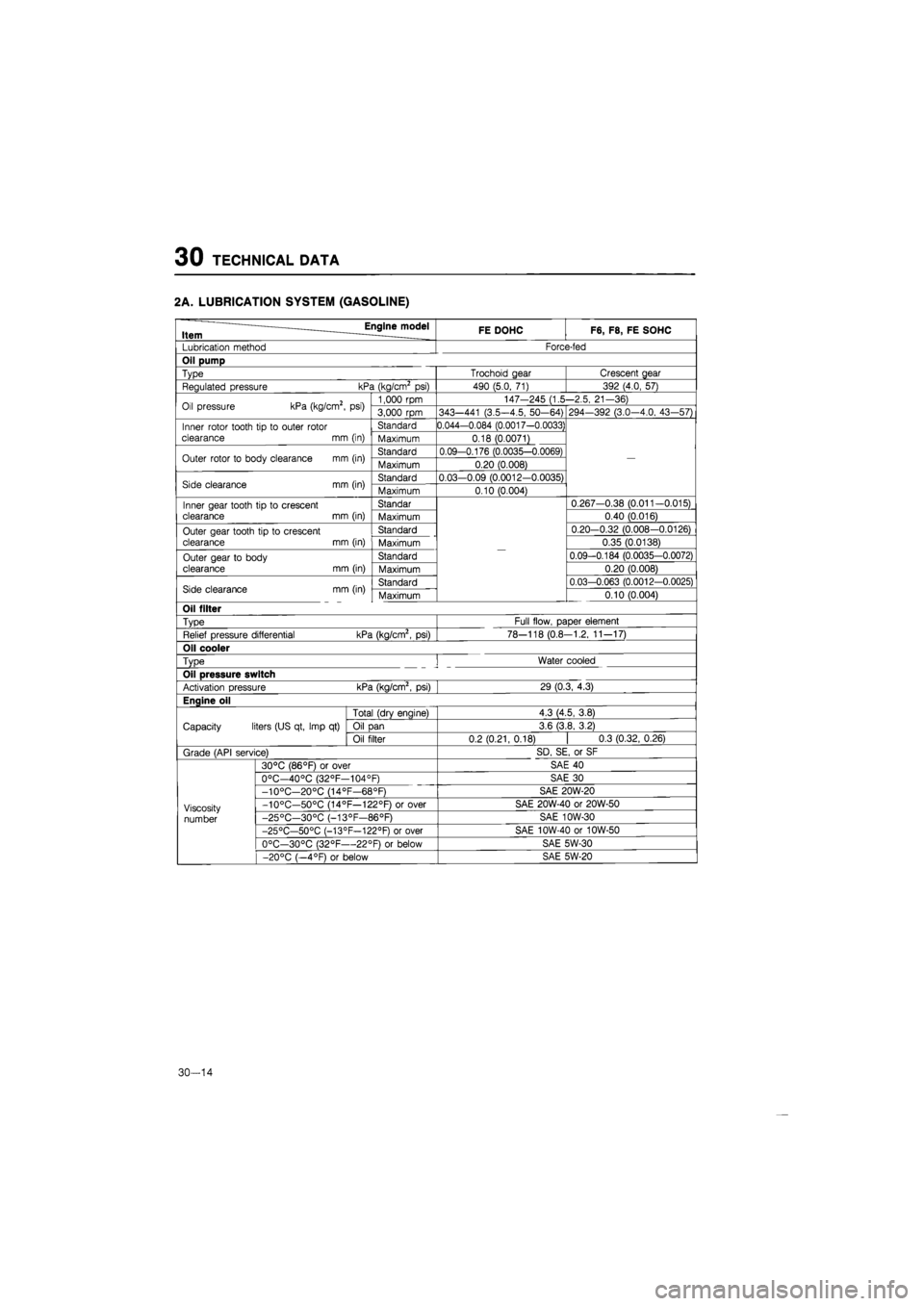

2A. LUBRICATION SYSTEM (GASOLINE)

Engine model Item ____ FE DOHC F6, F8, FE SOHC

Lubrication method Force-fed

Oil pump

Type Trochoid gear Crescent gear

Regulated pressure kPa (kg/cm2

psi)

490 (5.0,

71)

392 (4.0, 57)

Oil pressure kPa (kg/cm2,

psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pressure kPa (kg/cm2,

psi)

3,000

rpm

343—441 (3.5-4.5, 50-64) 294—392 (3.0—4.0, 43-57)

Inner rotor tooth

tip to

outer rotor

clearance

mm

(in)

Standard 0.044-0.084 (0.0017-0.0033)

—

Inner rotor tooth

tip to

outer rotor

clearance

mm

(in) Maximum 0.18 (0.0071)

—

Outer rotor

to

body clearance

mm

(in) Standard 0.09-0.176 (0.0035-0.0069)

—

Outer rotor

to

body clearance

mm

(in) Maximum 0.20 (0.008)

—

Side clearance

mm

(in) Standard 0.03-0.09 (0.0012-0.0035)

—

Side clearance

mm

(in) Maximum 0.10 (0.004)

—

Inner gear tooth tip

to

crescent clearance

mm

(in)

Standar

—

0.267-0.38 (0.011-0.015) Inner gear tooth tip

to

crescent clearance

mm

(in) Maximum

—

0.40 (0.016)

Outer gear tooth tip

to

crescent clearance

mm

(in)

Standard

—

0.20-0.32 (0.008-0.0126) Outer gear tooth tip

to

crescent clearance

mm

(in) Maximum

—

0.35 (0.0138)

Outer gear

to

body

clearance

mm

(in)

Standard

—

0.09-0.184 (0.0035-0.0072) Outer gear

to

body

clearance

mm

(in) Maximum

—

0.20 (0.008)

Side clearance mm (in) Standard

—

0.03-0.063 (0.0012-0.0025) Side clearance mm (in) Maximum

—

0.10 (0.004)

Oil filter

Type Full flow, paper element

Relief pressure differential kPa (kg/cm2,

psi)

78-118 (0.8-1.2, 11-17)

Oil cooler

Type

!

Water cooled

Oil pressure switch

Activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Enaine oil

Capacity liters (US qt, Imp

qt)

Total (drv enaine) 4.3 (4.5, 3.8)

Capacity liters (US qt, Imp

qt)

Oil

Dan

3.6 (3.8, 3.2) Capacity liters (US qt, Imp

qt)

Oil filter 0.2(0.21,0.18)

|

0.3 (0.32,0.26)

Grade (API service) SD, SE,

or

SF

Viscosity

number

30°C (86°F)

or

over SAE

40

Viscosity

number

0°C—40°C (32°F—104°F) SAE

30

Viscosity

number

-10°C—20°C (14°F—68°F) SAE 20W-20

Viscosity

number

-10°C—50°C (14°F—122°F)

or

over SAE 20W-40

or

20W-50 Viscosity

number -25°C—30°C (-13°F—86°F) SAE 10W-30 Viscosity

number

-25°C—50°C (-13°F—122°F)

or

over SAE 10W-40

or

10W-50

Viscosity

number

0°C—30°C (32°F—22°F)

or

below SAE 5W-30

Viscosity

number

-20°C (—4°F)

or

below SAE 5W-20

30-14