window MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1721 of 1865

15 POWER WINDOW

OK Check power window switch

on

each door. Refer

to

page 15—67.

76G15X-059

INSPECTION

Power Window Driver's Side Switch

(For Sedan and Hatchback)

Check for continuity between terminals of the switch.

Main switch

—Terminal Position -——___ h i

Lock

Unlock

O o

O O:

Indicates continuity

76G15X-016

c f i i 0

b e h k n

a d R J m /

O O:

Indicates continuity

15-66

Page 1722 of 1865

REAR WINDOW 15

9 c a

CD [=• cm

•

h f d b

76G15X-017

g c a

I I I I

cm I I I I

h f d b

86U15X-11E

(For Coupe/MX-6)

Check for continuity between terminals of the switch.

Main switch

-—-—^^Terminal Position

——- ^

a c

Lock

Unlock 0 O

o

-O: Indicates continuity

Switch

'erminal

Position

UP

OFF

DOWN

Driver's side

O

O

o

o-

o

-o

-o

-o

=o

-o

Passenger's side

O

O

O-

O

O

-o

-o

-o

-o

-o

O O:

Indicates continuity

Switch on Each Side

(For Sedan And Hatchback)

Check for continuity between terminals of the switch.

Position Terminal

UP

OFF

DOWN

O-

O-

O-

-0

O-

O-

-o

-o -o

-o

O O:

Indicates continuity

(For Coupe/MX-6)

Check for continuity between terminals of the switch.

Position

~———^

a b d f h

UP O—

O— —0

—o

OFF o—

O—

—o —O

DOWN O—

o—

—0 —o

O

O:

Indicates continuity

76G15X-019

15-67

Page 1723 of 1865

15 POWER WINDOW

15-68

Power Window Motor

1. Connect 12V to the "a" terminal and ground the

"b" terminal of the motor connector, and check

that the motor operates.

2. Reverse the above connections and check for re-

verse operation of the motor.

Page 1726 of 1865

REAR WINDOW WIPER 15

REAR WINDOW WIPER

STRUCTURAL VIEW

1. Wiper arm and blade

2. Seal cap

86U15X-126

3. Wiper motor

4. Washer tank and motor

5. Hose

6. Washer nozzle

15—71

Page 1727 of 1865

![MAZDA 626 1987 Repair Manual

15 REAR WINDOW WIPER

CIRCUIT DIAGRAM

BATTERY MAIN FUSE X-01

X-01

REAR WIPER

&

WASHER SW GW [!]>• Control (Sectin Eb)

To Instrument Panel Light

D-01 Combination Sw [D]

LO

L B ±±±

LW MAZDA 626 1987 Repair Manual

15 REAR WINDOW WIPER

CIRCUIT DIAGRAM

BATTERY MAIN FUSE X-01

X-01

REAR WIPER

&

WASHER SW GW [!]>• Control (Sectin Eb)

To Instrument Panel Light

D-01 Combination Sw [D]

LO

L B ±±±

LW](/img/28/57059/w960_57059-1726.png)

15 REAR WINDOW WIPER

CIRCUIT DIAGRAM

BATTERY MAIN FUSE X-01

X-01

REAR WIPER

&

WASHER SW GW [!]>• Control (Sectin Eb)

To Instrument Panel Light

D-01 Combination Sw [D]

LO

L B ±±±

LW

LB LR

D-02 Front Wiper Motor [F]

B

LR

LW

±±±

L LB L

D-03 Rear Wiper Sw [I] x

x GW

\±U±±

TTTT

(5 Door)

B

L BL

D-04 Rear Wiper Motor [R3]

^bGL (5Door)

D-05 Rear Washer Motor 1 D-06 Headlight Cleaner Sw

[

LY

RB

(5 Door)

LW GW

C-05 Washer Motor Assembly |Fj

LW

LY L

©I®T

T

LO

15-72

86U15X-127

Page 1728 of 1865

REAR WINDOW WIPER

15

TROUBLESHOOTING

76G15X060

76G15X-061

15—73

Page 1729 of 1865

15 REAR WINDOW WIPER

76G15X-062

76G15X063

15-74

Page 1730 of 1865

REAR WINDOW WIPER 1 5

86U15X-132

INSPECTION

Operation Check of Rear Wiper Motor

1. Check that the motor operates continuously when

12V is connected to the (a) terminal and ground

is connected to the (b) terminal of the motor.

2. Start the motor again.

Disconnect the ground from the (b) terminal, and

then connect the ground to the motor body im-

mediately. Check that the motor shaft reaches the

auto-stop position, and that there is conductivity

through the grounding of the motor body.

Note:

Be sure to re-install the rubber seal correctly.

Operation Check of Rear Washer Motor

1. Using a voltmeter, measure the voltage between

the (b) terminal and a body ground with the igni-

tion switch ON.

2. If no voltage, check the fuse or repair the harness.

3. If the (b) terminal voltage is 12 V, connect the (a)

terminal to a body ground.

4. If the washer motor does not operate, replace the

washer motor.

76G15X-094

15-75

Page 1795 of 1865

16 OUTLINE

Thermometer (Dry)

Thermometer

(Dry & Wet)

76G16X-633

69G16X-024

DETERMINING THE RELATIVE HUMI-DITY: Read the temperatures of the dry- and v^et-bulb thermometers at the air inlet (evapo-rator inlet). Then bring them into mutual relation on the chart and determine the intersection, which is the relative humidity^ For exampie, if the dry-bulb temperature^ is 90° F. and the wet-bulb temper- ^ ature is 78° F, the relative humidity is ^ 60%.

DRV BUL8 TEMPERATURE

Performance Test

After finishing repairs, be sure to conduct a perfor-

mance test of the air conditioning system as follows.

Procedure

1. Connect the manifold gauge set. (Refer to page

16-8)

2. Run the engine and keep the engine speed at

1750 rpm.

3. Operate the air conditioner at MAX COOLING.

4. Open all windows and doors.

5. Insert a dry-bulb thermometer in the center of the

ventilator outlet.

6. Place a dry and wet thermometer close to the in-

let of the blower inlet.

7. The high pressure should be within 1374—1569

kPa (14.0—16.0 kg/cm2, 200—227 psi).

Note:

If the pressure is too high, pour water on the

condenser; if it is too low, cover the front sur-

face of the condenser.

8. The dry-bulb thermometer at the inlet should be

within 25—35°C (77—95°F).

Operate the air conditioning system in this condi-

tion until the conditions of the high and low pres-

sure gauges and thermometers are stabilized.

Reading the standard performance curve

1. Read the inlet temperature an get the relative hu-

midity from the psychrometric chart.

2. Read the cool air temperature at the air outlet.

3. Determine the difference between the inlet and out-

let dry-bulb temperature.

4. For example, when the difference is 17°C (30.6°F)

and the relative humidity is 60%:

If

the closing point is the upper part of the line, cool-

ing performance is satisfactory.

76G16X-634

READING THE GRAPH: After reading the temperatures of the wet-and dry-bulb thermometers at the evapo-rator air inlet, the relative humidity (%} can be determined Example: If the dry- and wet-bulb temperatures at the evaporator air inlet are 25°

C

and 19 5°C respectively, find the point of intersection of the dotted lines in the graph, which is

• i

•.p-I--!1. fi -GL^TIULB ': "'.L .T.L CL

16—12

Page 1864 of 1865

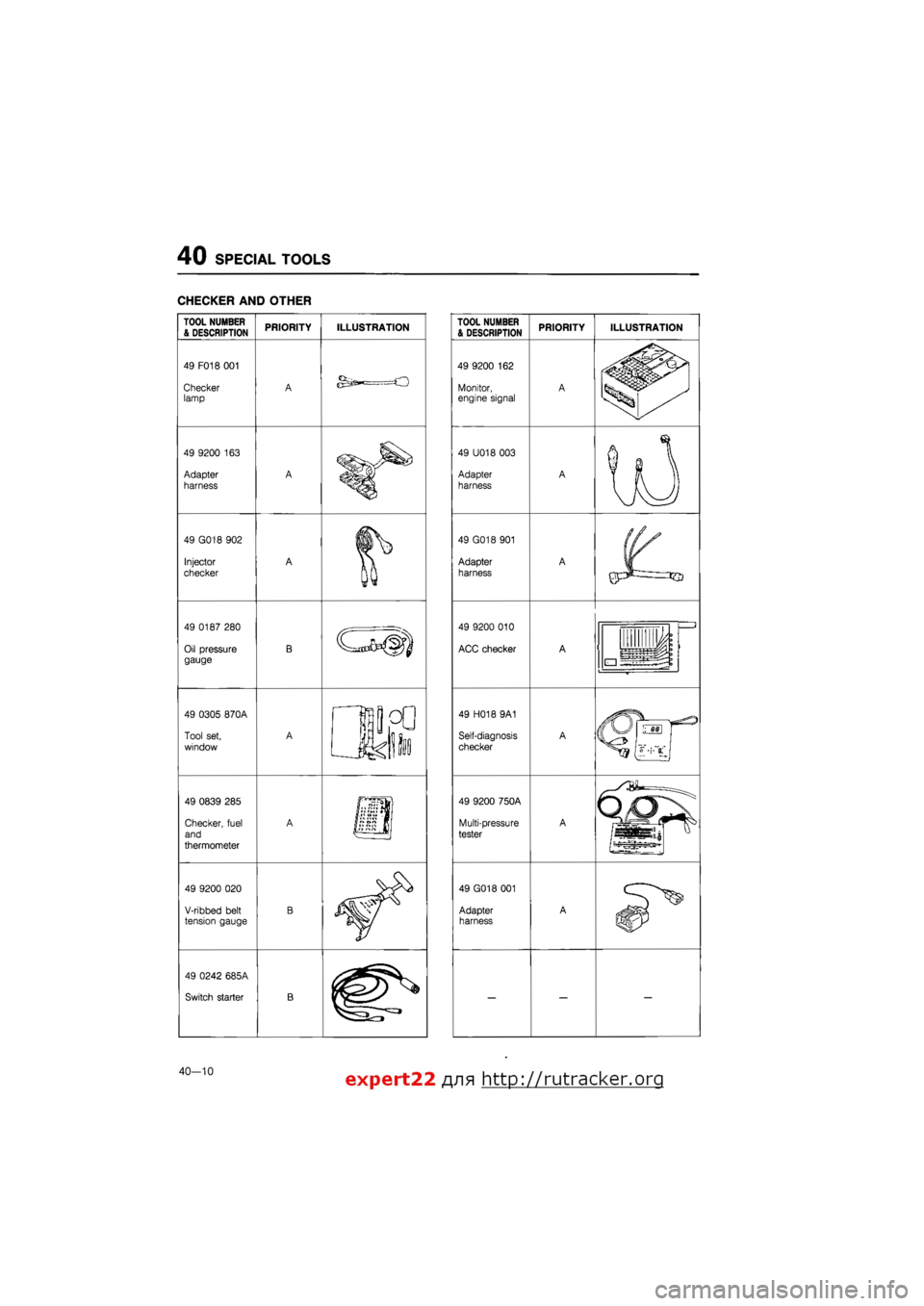

40 SPECIAL TOOLS

CHECKER AND OTHER

TOOL NUMBER & DESCRIPTION

49 F018 001

Checker lamp

49 9200

163

Adapter

harness

49 G018 902

Injector

checker

49 0187 280

Oil pressure gauge

49 0305 870A

Tool set,

window

49 0839 285

Checker, fuel

and

thermometer

49 9200

020

V-ribbed belt tension gauge

49 0242 685A

Switch starter

PRIORITY ILLUSTRATION TOOL NUMBER & DESCRIPTION

49 9200

162

Monitor, engine signal

49 U018 003

Adapter harness

49 G018 901

Adapter

harness

49 9200 010

ACC checker

49 H018 9A1

Self-diagnosis

checker

49 9200 750A

Multi-pressure

tester

49 G018 001

Adapter harness

PRIORITY ILLUSTRATION

40—10 expert22 /yia http://rutracker.org