ECU MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1361 of 1865

ENGINE SPEED SENSING POWER STEERING 1 0

3. Tap in a new roll pin.

86U10X-175

i V

vlM^lPl'' \f ) j//

/f

Boot

1. Apply grease to the inner surface of the small end

of the boot.

2. Install the boot. Wrap a new wire around the large

end of the boot two times and then twist it 4 to 4.5

times. Bend the twisted part toward the mounting

bracket.

Note

Be careful not to break the boot wire.

3. Install the spring clip on the small end of the boot.

86U10X-176

Tie-rod end

Align with the mark made before disassembly, and

then tighten the nut.

86U10X-177

Oil pipe

Secure the mounting bracket in a vise so that the oil

pipe connections face upward.

86U10X-178

10-73

Page 1364 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

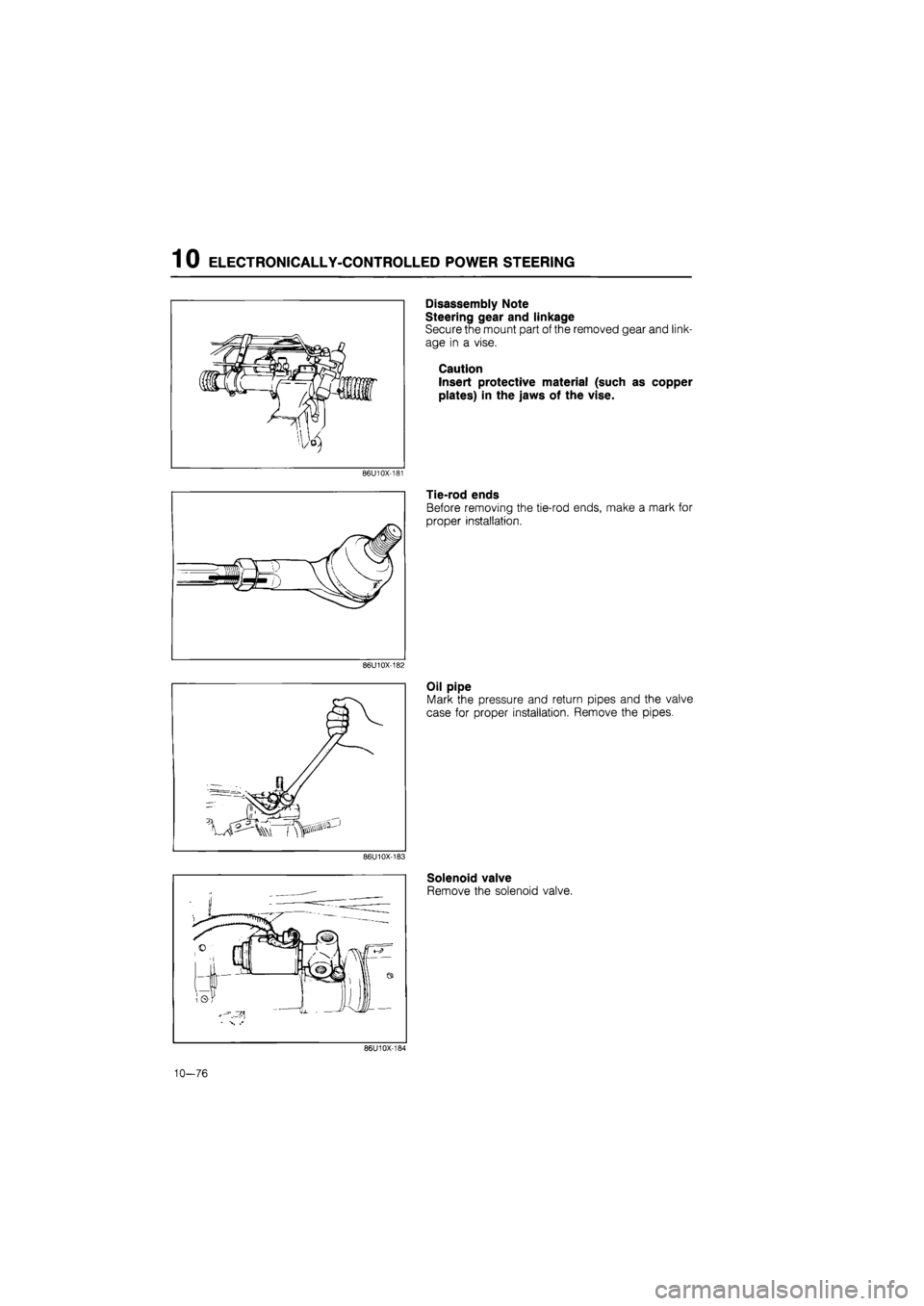

Disassembly Note

Steering gear and linkage

Secure the mount part of the removed gear and link-

age in a vise.

Caution

Insert protective material (such as copper

plates) in the jaws of the vise.

86U10X-181

Tie-rod ends

Before removing the tie-rod ends, make a mark for

proper installation.

86U10X-182

Oil pipe

Mark the pressure and return pipes and the valve

case for proper installation. Remove the pipes.

86U10X-183

Solenoid valve

Remove the solenoid valve.

86U10X-184

10—76

Page 1376 of 1865

1 0 ELECTRICAL COMPONENTS OF ELECTRONICALLY-CONTROLLED POWER STEERING (ECPS)

76G10X-020

76G10X-021

Checking Condition

Condition A

1. Turn the ignition switch OFF.

2. Start the engine and let it idle.

3. Turn the steering wheel to the straight-ahead po-

sition, and check the output pattern.

Refer to page 10—89 for other patterns and indi-

cated failure points.

Condition B

1. Turn the ignition switch OFF.

2. Start the engine and let it idle.

3. Turn the steering wheel 45° left and right from the

center, and check the output pattern.

Refer to page 10—89 for other patterns and indi-

cated failure points.

Condition C

1. Turn the ignition switch OFF.

2. Place the vehicle on a chassis roller tester. Block

the rear wheels, and secure it with chains.

3. Start the engine. Put the transmission in gear and

operate the vehicle at more than 10 km/h (6.2

mph).

4.Check the output pattern.

76G10X-022

Normal pattern

4 4V

Normal pattern Normal pattern

uV

Refer to page 10—90 for other patterns and indi-

cated failure points.

Note

For vehicles equipped with ABS, the ABS

warning light may come on. This is not a fail-

ure. The light will go off when turning the ig-

nition switch OFF and back ON.

86U10X-213

10—88

Page 1384 of 1865

1 0 ELECTRICAL COMPONENTS OF 4-WHEEL STEERING

Condition B

1. Place the vehicle on a chassis roller tester. Block

the rear wheels, and secure it with chains.

2. Turn the ignition switch OFF.

3. Start the engine after the ignition switch has been

OFF for at least 10 seconds. Put the transmission

in gear and operate the vehicle at more than 40

km/h (25 mph).

4. Check if the 4WS warning light flashes or il-

luminates within 60 seconds.

5.

If

flashing or illumination occurs, inspect the circuit

by referring to the table below.

76G10X045

Diagnosis Output Pattern

Warning light output pattern

0.5 sec —i 2.5 sec

Malfunction

Normal operation, control unit or wir-ing harness

Speed sensors or

wiring harness

Flow chart

No.

4WS—0

4WS—1

Rear steering gear

assembly

Solenoid valve or wiring harness

Stepper motor or wiring harness

Rear-to-front steer-ing ratio sensor or wiring harness

4WS—2

4WS—3

4WS—4

4WS—5

86U10X-225

10-96

Page 1423 of 1865

POWER BRAKE UNIT 1 1

76G11X-071

Disassembly Note

Front and rear shells

1. Secure the front shell studs in a vise after attach-

ing suitable nuts to them to prevent damage to the

studs.

2. Before separating the front and rear shell assem-

blies, make matching marks to be used in reas-

sembly.

3. Fit a wrench onto the rear shell studs; then fasten

two of them with suitable nuts.

4. Rotate the rear shell counterclockwise to unlock.

Caution

The rear shell is spring loaded; loosen it

carefully.

Retainer key

Depress the plunger rod fully; then remove the re-

tainer key.

86U11X-049

86U11X-050

Assembly Note

Application of Grease

Before assembly, coat the parts shown in the figure

with silicon grease.

(1) Entire surface of reaction disc

(2) Dust seal lip

(3) Push rod

(4) Diaphragm-to-shell contacting surfaces

(5) Power piston

(6) Valve plunger oil seal

Retainer key

1. Push down the plunger rod.

2. Align the groove of the valve plunger with the slot

of the power piston.

3. Insert the retainer key.

86U11X-051

11—31

Page 1443 of 1865

REAR DISC BRAKE 1 1

86U11X-093

86U11X-094

86U11X-095

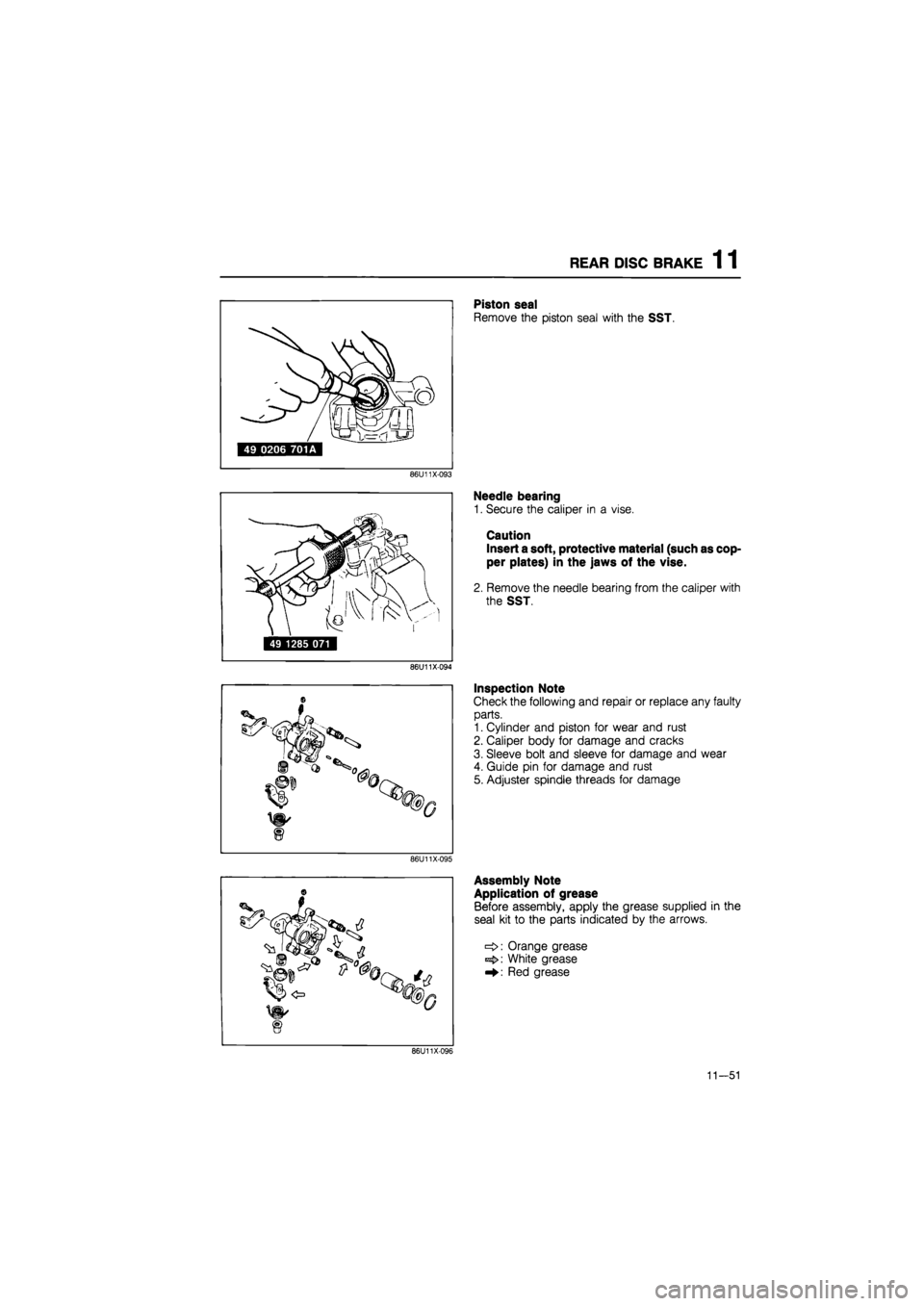

Piston seal

Remove the piston seal with the SST.

Needle bearing

1. Secure the caliper in a vise.

Caution

Insert a soft, protective material (such as cop-

per plates) in the jaws of the vise.

2. Remove the needle bearing from the caliper with

the SST.

Inspection Note

Check the following and repair or replace any faulty

parts.

1. Cylinder and piston for wear and rust

2. Caliper body for damage and cracks

3. Sleeve bolt and sleeve for damage and wear

4. Guide pin for damage and rust

5. Adjuster spindle threads for damage

Assembly Note

Application of grease

Before assembly, apply the grease supplied in the

seal kit to the parts indicated by the arrows.

Orange grease

White grease

Red grease

86U11X096

11-51

Page 1456 of 1865

1 1 REAR DRUM BRAKE

Brake drum

1. Move the quadrant against the backing plate with

a screwdriver and increase the shoe clearance.

2. Install the brake drum.

Note

The shoe clearance will be automatically ad-

justed by applying the parking brakes.

76G11X089

Locknut

Tighten the new locknut to the specified torque and

securely stake it to the spindle groove.

Tightening torque:

98—177

N

m (10—18 m-kg, 72—130 ft-lb)

Caution

Do not use a pointed tool for staking.

86U11X-129

11-64

Page 1480 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

86U11X-170

86U11X-171

Removal of Front Wheel Speed Sensor

1. Remove the wheel and tire.

2. Remove the parts shown in the figure, and remove

the sensor from the knuckle.

Installation of Front Wheel Speed Sensor

1. Install the sensor to the knuckle.

Tightening torque:

16—23 N m (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

The left and right sensors are not interchange-

able. L or R is indicated on the bracket.

2. Install the sensor harness bracket onto the knuckle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

3. Push the sensor harness through the splash shield

and secure it with the clip.

4. Install the sensor harness bracket to the body.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

Caution

Verify that the harness is not twisted and does

not contact the shock absorber or body when

the steering wheel is turned.

5. Connect the sensor connector.

6. Install the wheel and tire.

86U11X-172

11-88

Page 1485 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Installation of Rear Sensor Rotor

Install in the reverse order of removal, referring to installation note for the specially marked parts.

Torque specifications

86U11X-184

Installation

Sensor rotor

Press the sensor rotor onto the hub with the SST.

86U11X-185

Locknut

1. Install and tighten the locknut.

2. Stake a new locknut securely in the driveshaft

groove.

Caution

Do not use a pointed tool for staking.

3. Check that the hub rotates freely by hand.

86U11X-186

11—93

Page 1513 of 1865

![MAZDA 626 1987 Repair Manual

1 3 FRONT SHOCK ABSORBER AND SPRING

76G13X-015

I N

49 G034 102 1

| 49 G034 103 | iBHssfllil 49 G034 101 |

mmy

LojaiiaiciS]

86U13X-018

76G13X-016

Disassembly Note

1. Loosen the piston rod up MAZDA 626 1987 Repair Manual

1 3 FRONT SHOCK ABSORBER AND SPRING

76G13X-015

I N

49 G034 102 1

| 49 G034 103 | iBHssfllil 49 G034 101 |

mmy

LojaiiaiciS]

86U13X-018

76G13X-016

Disassembly Note

1. Loosen the piston rod up](/img/28/57059/w960_57059-1512.png)

1 3 FRONT SHOCK ABSORBER AND SPRING

76G13X-015

I N

49 G034 102 1

| 49 G034 103 | iBHssfllil 49 G034 101 |

mmy

LojaiiaiciS]

86U13X-018

76G13X-016

Disassembly Note

1. Loosen the piston rod upper nut several turns, bu

do not remove.

Caution

a) Do not remove the nut.

b) Use copper or aluminum plates in the jawj

of a vice.

2. Set the SST in a vise.

3. Secure the shock absorber in the SST.

4. Compress the coil spring with the SST, then re

move the upper nut.

5. Remove the coil spring.

Inspection Note

Check the following and repair or replace any fault}

parts.

1. Oil leakage or abnormal noise from shock ab

sorbers

2. Deterioration or damage of mounting block anc

bearing

3. Wear or damage of bound stopper

4. Smooth rotation of control rod (AAS)

86U13X-020

13—16